Full-automatic medical bed pipe heat-sealing machine

A heat sealing machine, fully automatic technology, applied in the direction of tubular objects, household components, applications, etc., can solve the problems of slow manual operation, uncontrollable product quality, machine mold pressing hands, etc., to achieve fast production speed and better product quality Stability and precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

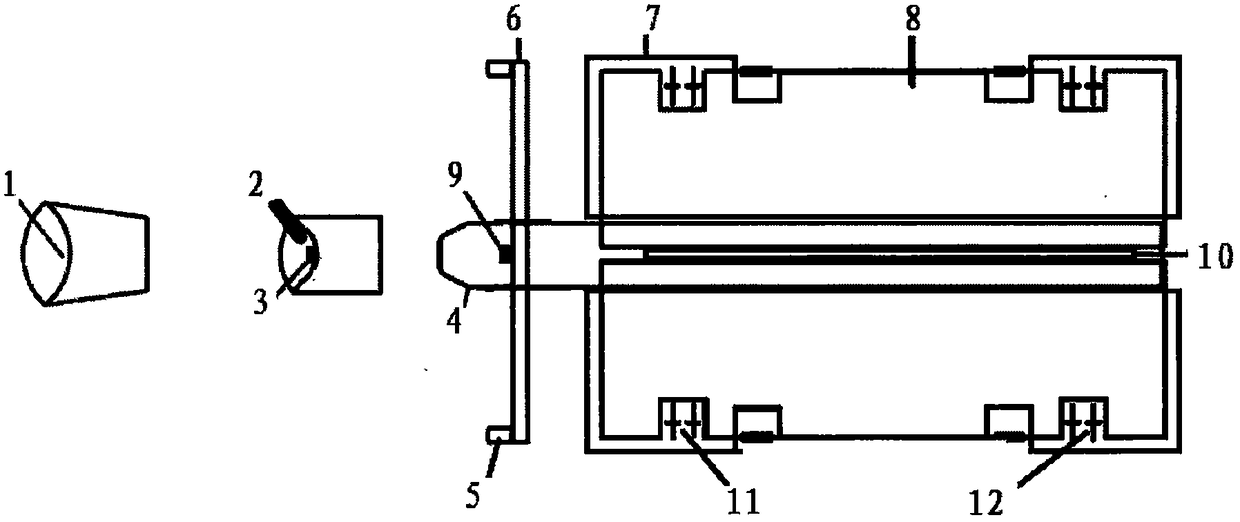

[0017] Such as figure 1 As shown, a fully automatic medical bed tube heat sealing machine includes a total feed port (1) and a material folding device (2); the total feed port (1) is a material delivery pipe whose width gradually decreases; the A special feed inlet (3) for PVC auxiliary materials is arranged above the material hemming device (2), and the special feed inlet (3) for PVC auxiliary materials is fixed on the horizontal side by a special feed inlet fixing device (9) for PVC auxiliary materials. On the brackets (6) on both sides of the material folding device (2); the insulating columns (5) are erected on both sides of the bracket (6); the copper plate (4) is fixed on the bracket (6), and is set on the PVC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com