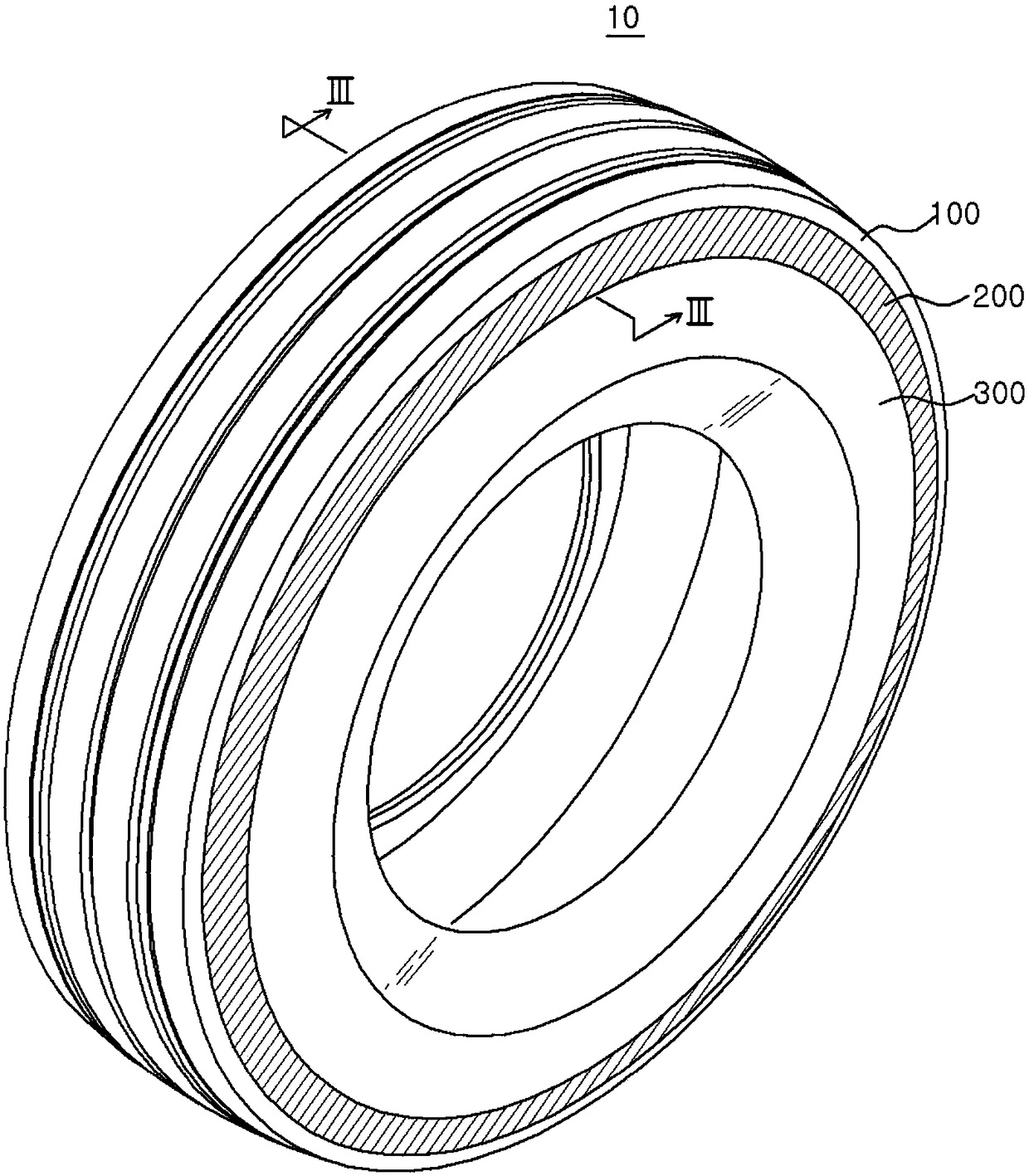

Semi-pneumatic tire and semi-pneumatic tire manufacturing method

A semi-pneumatic tire technology, applied to the reinforcement layer of pneumatic tires, pneumatic tires, non-pneumatic tires, etc., can solve the problems of non-pneumatic tires such as ride performance and prevent vibration performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

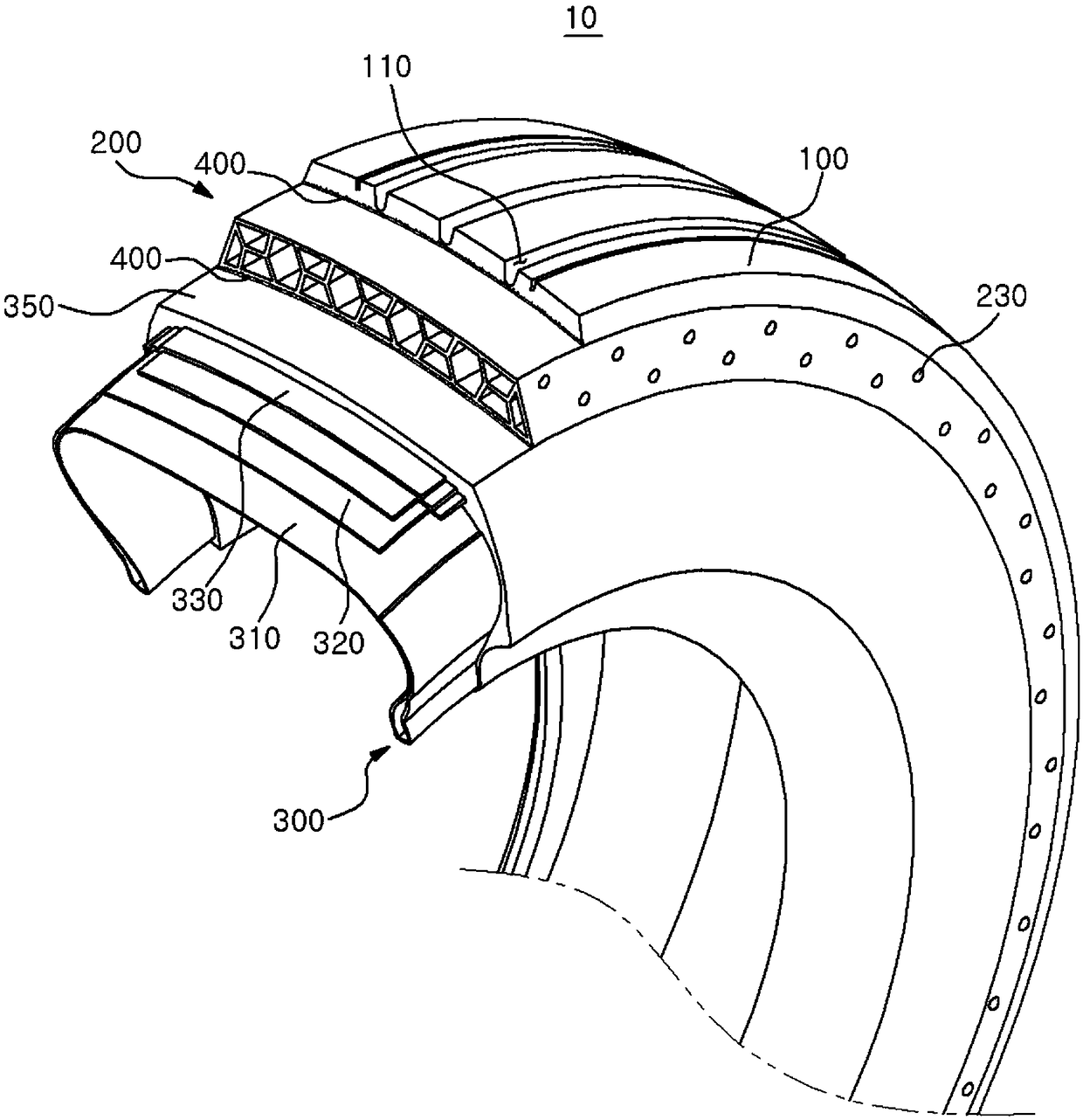

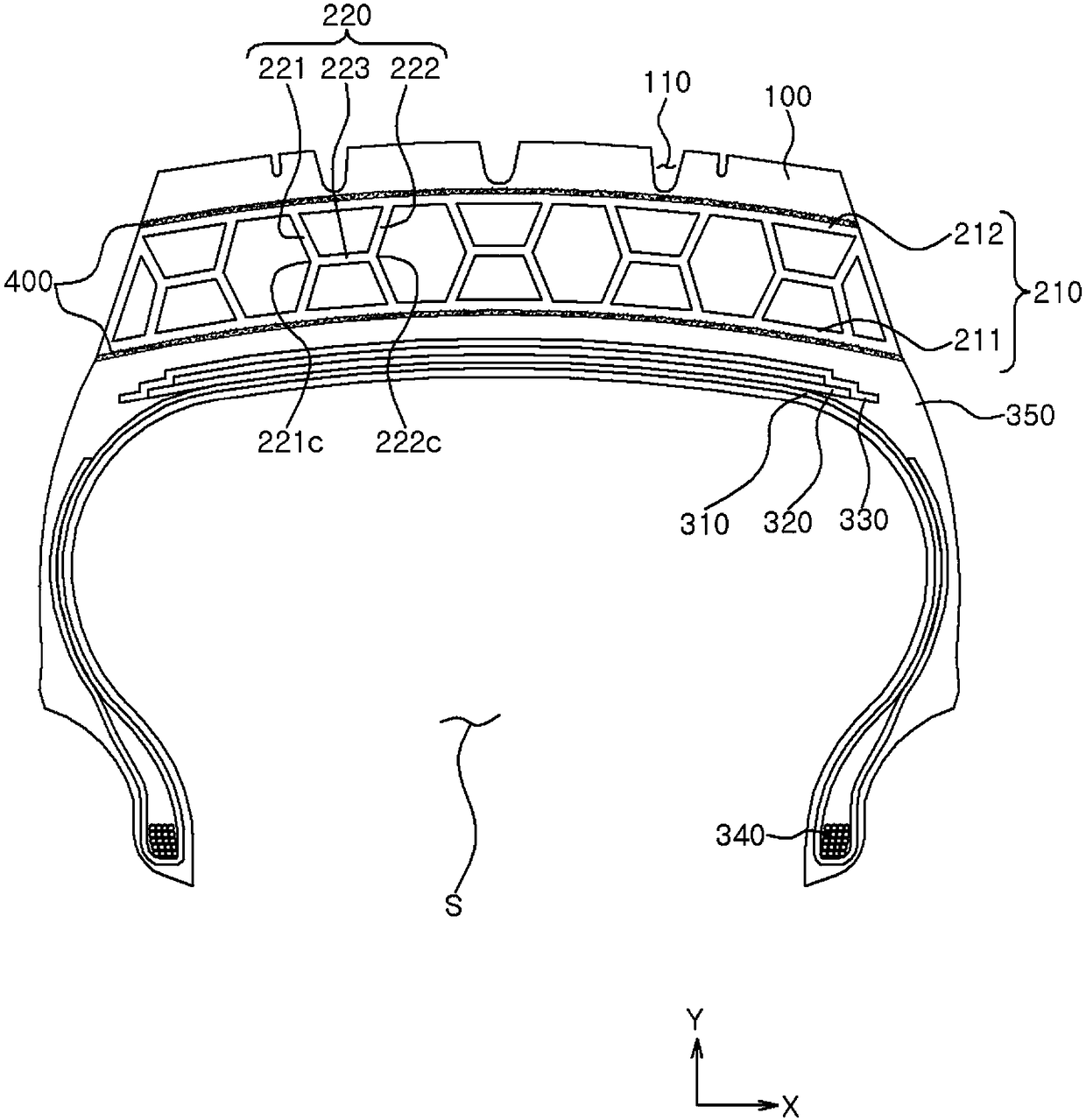

[0034] Before describing the present invention in detail, it should be pointed out that the terms and specific expressions used throughout the specification or claims should not be interpreted as ordinary or ordinary meanings, but can be based on the inventor's correct definition of the terms based on the most The best mode describes the principles of the present invention to be understood as meanings and concepts corresponding to the essence of the disclosed technology. Therefore, the embodiments and drawings of the present disclosure are illustrative only, and thus may represent all technical essences of the disclosure. Therefore, it can be understood that the scope of the present disclosure can also be defined by various equivalents and modifications.

[0035] Hereinafter, embodiments will be described in detail with reference to the accompanying drawings. Like reference numerals refer to like parts throughout the drawings. Also in the description of the present disclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com