Passive electric deviation rectifying device for belt conveyor

A technology of belt conveyor and deviation correction device, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient adjustment, belt deviation, low efficiency, etc., and achieves simple structure, reliable performance and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

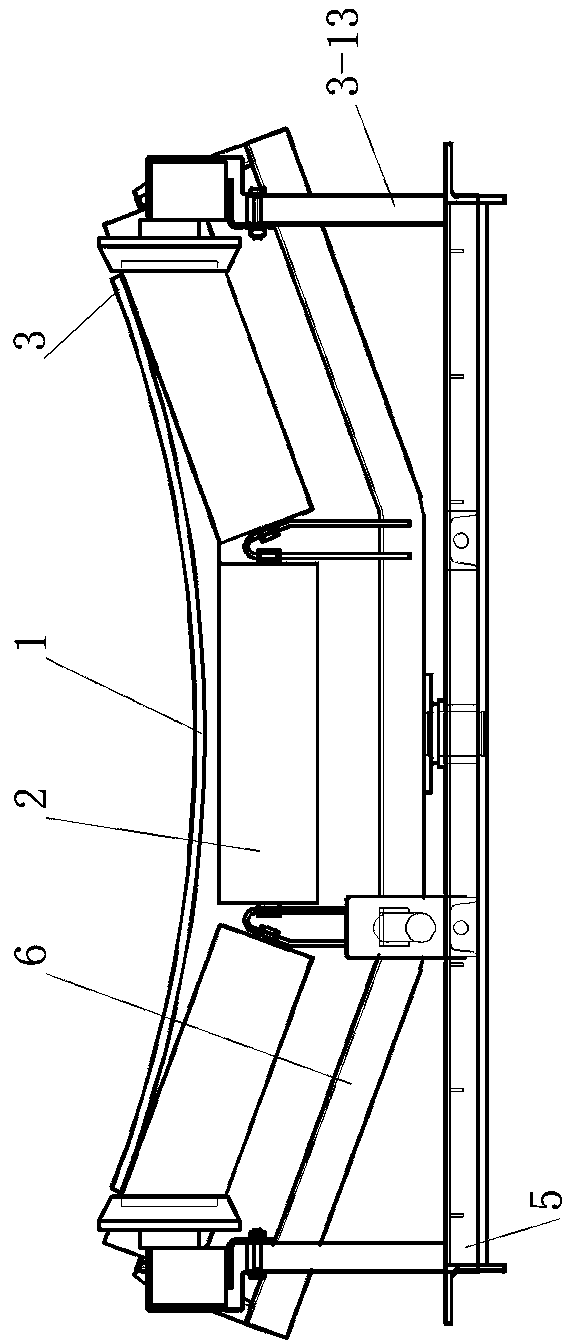

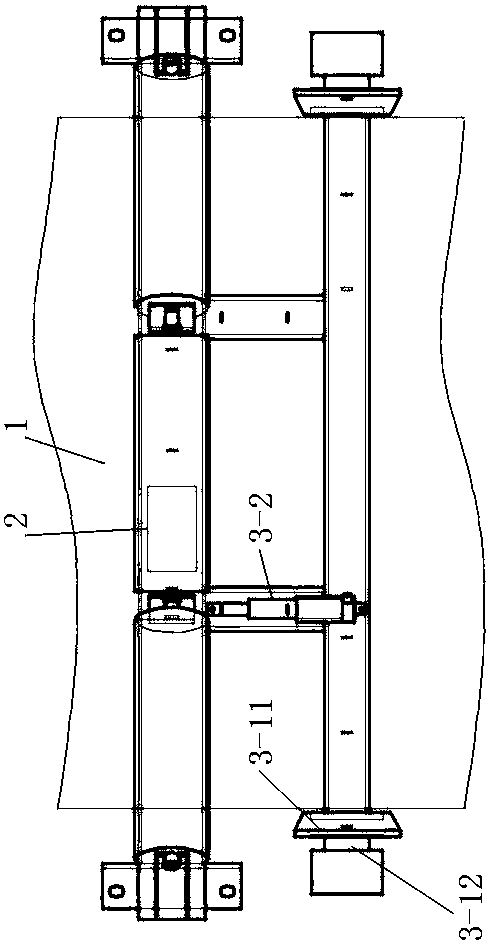

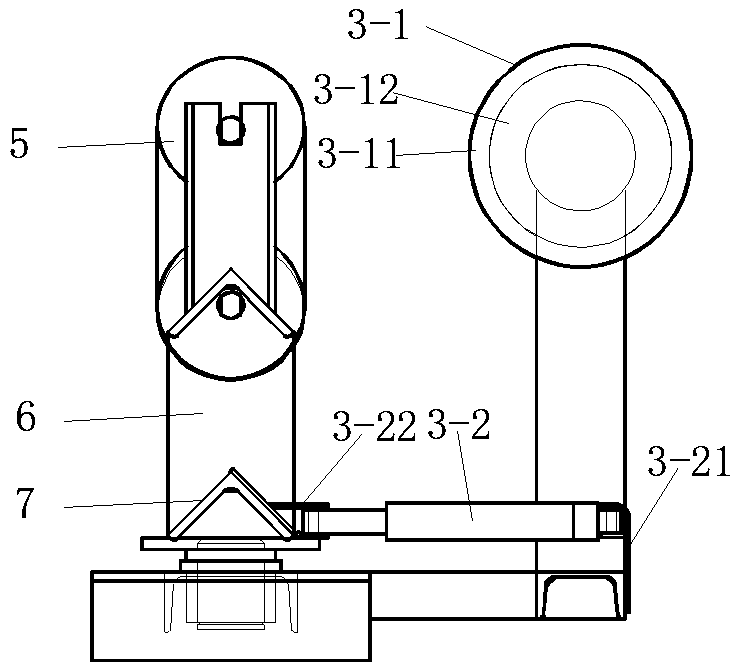

[0035] According to the running direction of the belt conveyor and the installation position of the self-aligning roller 2, the installation positions of the upper and lower deviation correction devices 3 and 4 are determined as follows: Figure 5 , 10 shown. Wrong installation will cause the deviation correcting machine to have the opposite effect, and may damage the oil pump, so attention should be paid to it during installation.

[0036] Set the power mechanisms 3-12 and 4-12 as electric push rods. When installing the electric push rods, select the appropriate position of the self-aligning roller 2 so that the deviation correction machine can exert its maximum performance. The self-aligning idler 2 must be more than 5m away from various redirecting rollers; and the self-aligning idler 2 should be about 10mm higher than the adjacent fixed idler.

[0037] When the electric push rod is fixed on the lower crossbeam of the idler frame of the upper adjustable idler roller by me...

Embodiment 2

[0046] Replace the electric push rod in Embodiment 1 with an oil cylinder, replace the generator with an oil pump and an oil tank, and the rest remain unchanged. The installation method of oil cylinder and power output device 3-1, 4-1 is the same as embodiment 1. After the oil cylinder and the power output device 3-1, 4-1 are installed, they need to be connected through the oil pipe, and the oil tank needs to be refueled, and the oil pipe is exhausted. The specific steps are as follows.

[0047] Oil pipe connection: Since the oil cylinder is placed on one side of the frame 1, and the oil pump assembly is placed on both sides of the frame 5, the oil pipe is divided into a long-side pipe and a short-side pipe. Two short-side pipes are used on the side near the oil cylinder, and two long-side pipes are used on the other side. Both ends of the oil pipe are flexible joints; the flexible joints are divided into straight joints and elbow joints. When installing the oil pipe, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com