Air-overturning and conveying device for autoclaved aerated cellular concrete moulding frames

A technology of autoclaved gas filling and conveying equipment, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., which can solve the problems of laborious operation, low safety, and injury of mold frames falling, and achieve stable and reliable movements , Hanging firmly, locking operation is convenient and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

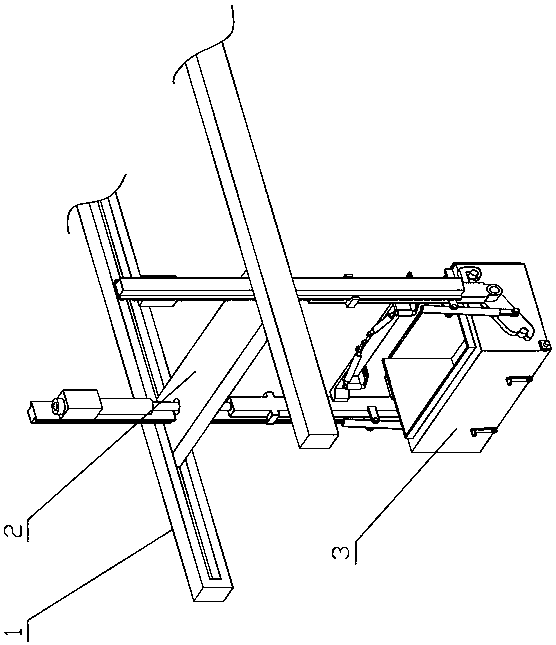

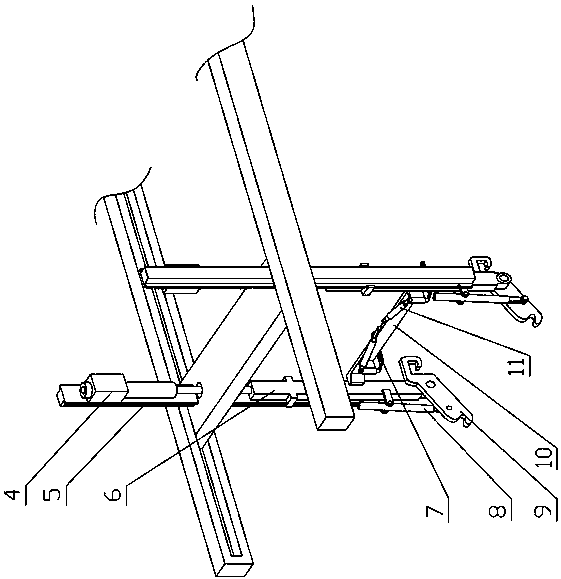

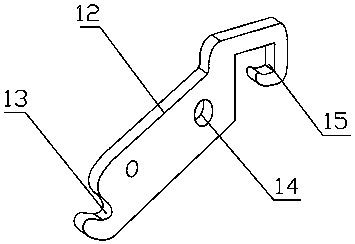

[0021] see Figure 1-Figure 7 , the present invention is an autoclaved aerated block mold frame flipping conveying device in the air. The lower part of the frame turning device is hoisted with an autoclaved aerated block mold frame 3. The autoclaved aerated block mold frame is composed of a mold frame body 17 provided with a side opening and a mold frame side plate 16. The mold frame overturning device has guide rods 5 arranged vertically side by side at both ends of the walking support plate, and a lift cylinder 4 is fixed on the inner symmetrical position of the two guide rods. The piston rods of the lift cylinders are arranged vertically downward and each piston The lower end of the rod is connected with a lifting arm 6, and the lifting arms on both sides are connected by a cross arm 10. The lower end of each lifting arm is hinged with a mold frame turning hook 9, and the middle part of the mold frame turning hook is hinged with the lifting arm. The two mold frame overturn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com