Cashmere roving dual-region drafting and spun milk sliminess drafting siro-spinning device and method

A technology of siro spinning and roving, applied in spinning machine, drafting equipment, yarn and other directions, can solve the problem of low cost of transformation, and achieve the effect of clear texture, high strength and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

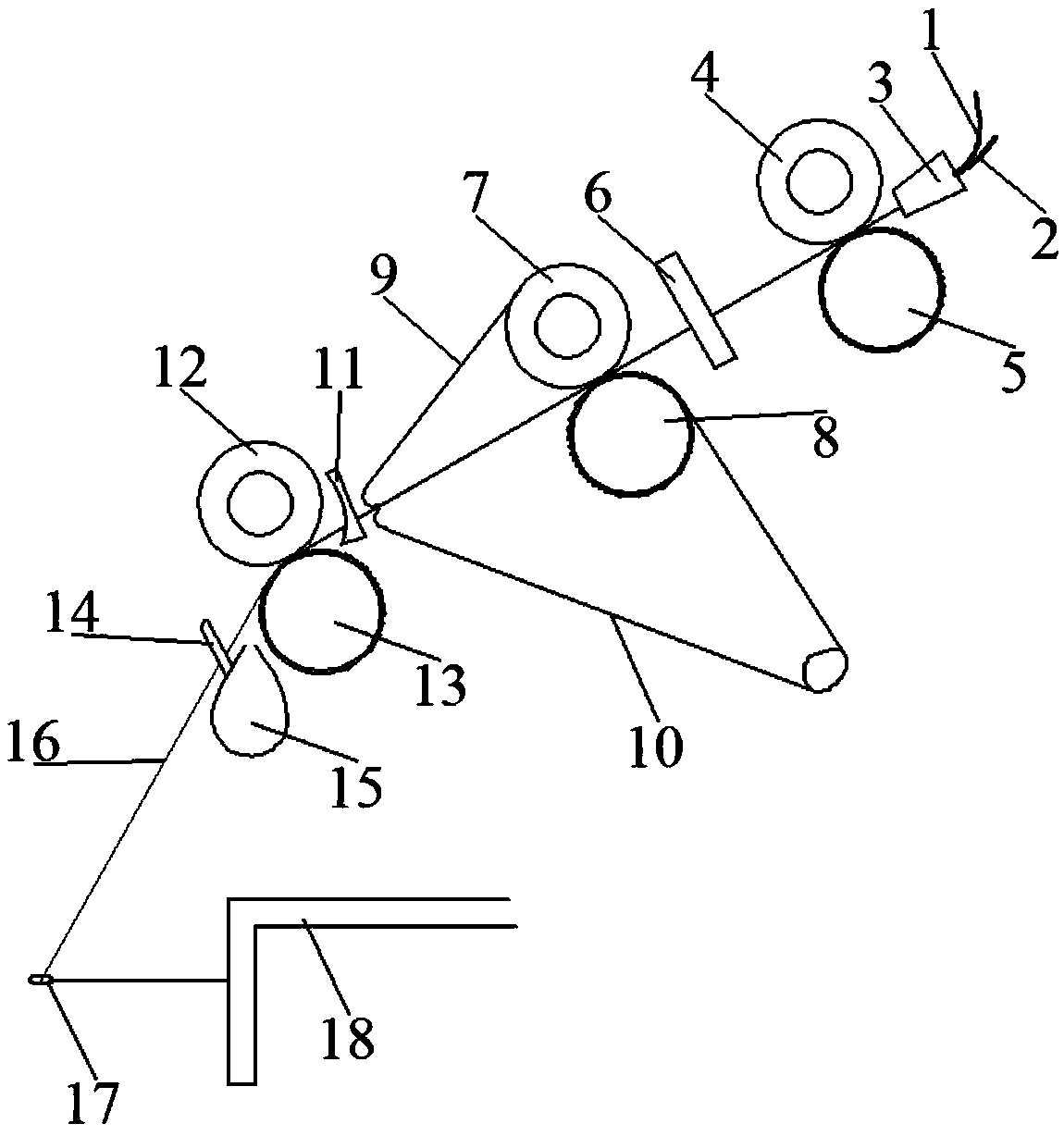

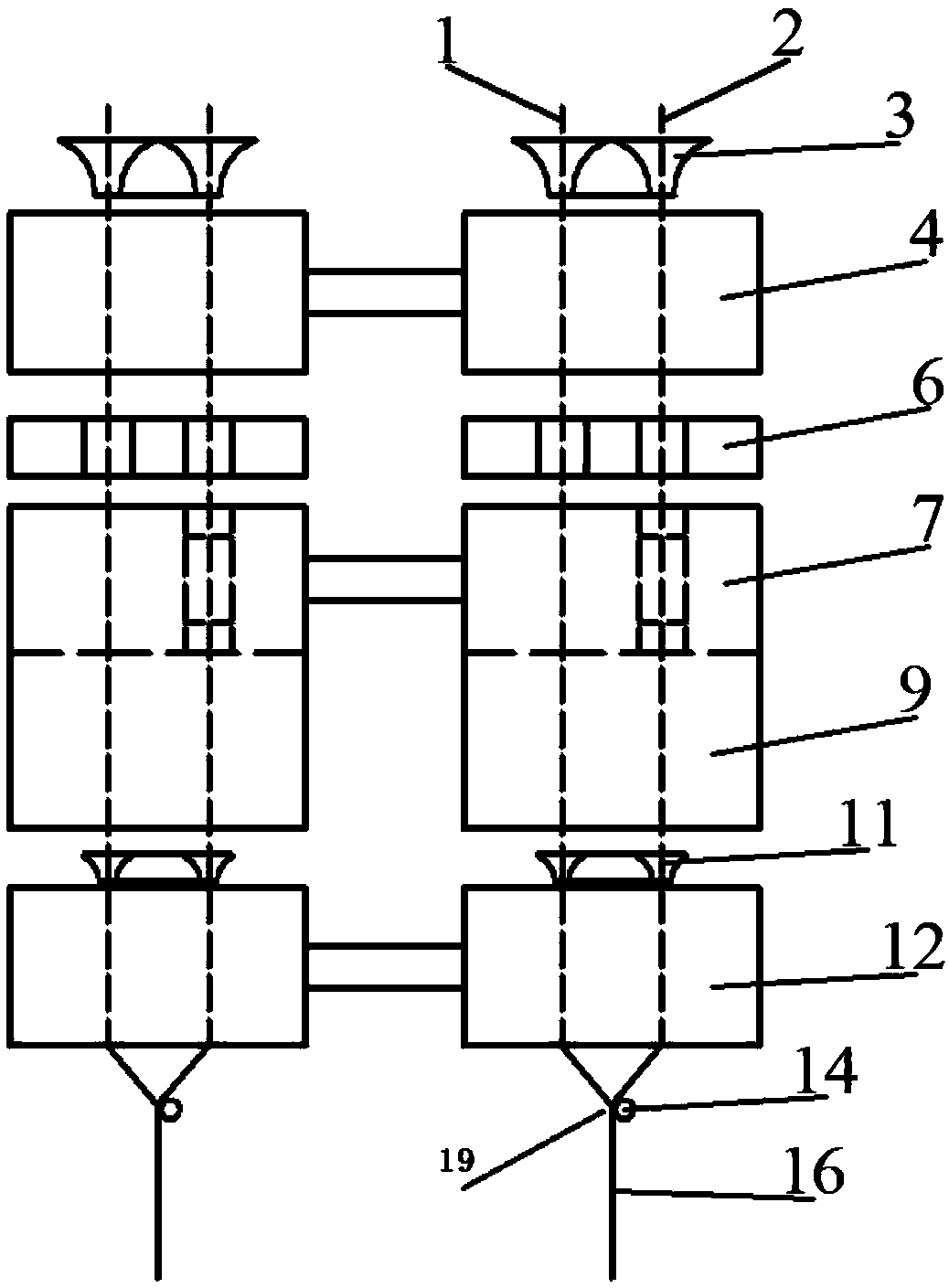

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

[0034] A cashmere roving dual-zone drafting and spun silk smooth drafting siro spinning method, in which two rovings are fed into a semi-worsted spinning frame in the form of siro spinning, and one roving is a semi-worsted cashmere roving less than 30mm , the other roving is worsted spun silk roving less than 80mm, in which the cashmere roving is drafted in two stages through the rear drafting zone and the front drafting zone, and the spun silk roving is drafted slippery, with two strands in the front Roller nips converge into yarn. The specific steps are:

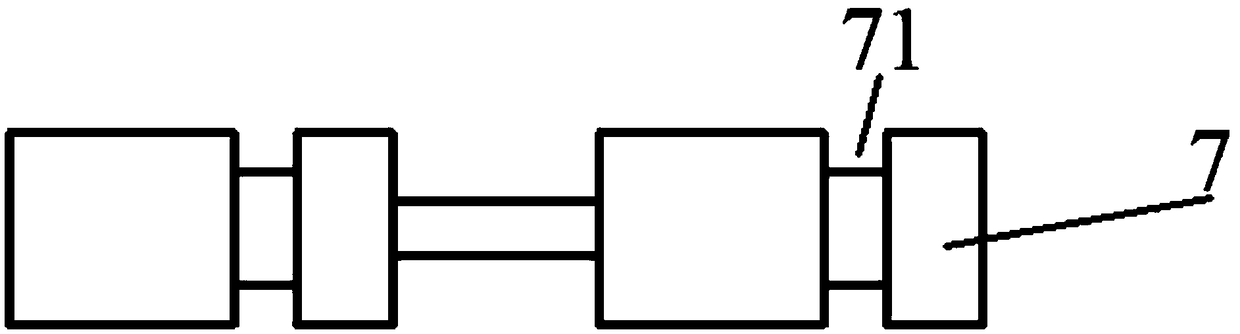

[0035]Cashmere roving 1 and spun silk roving 2 are respectively fed into the left hole and right hole of the double-hole bell mouth 3, pass through the back top roller 4 and back roller 5 and enter the rear drafting zone, and enter through the yarn guide 6 in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com