Al-mg-si alloy material, al-mg-si alloy sheet and method for producing al-mg-si alloy sheet

An al-mg-si, alloy material technology, applied in the field of manufacturing Al-Mg-Si alloy plates, can solve the problems of poor thermal conductivity and electrical conductivity, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

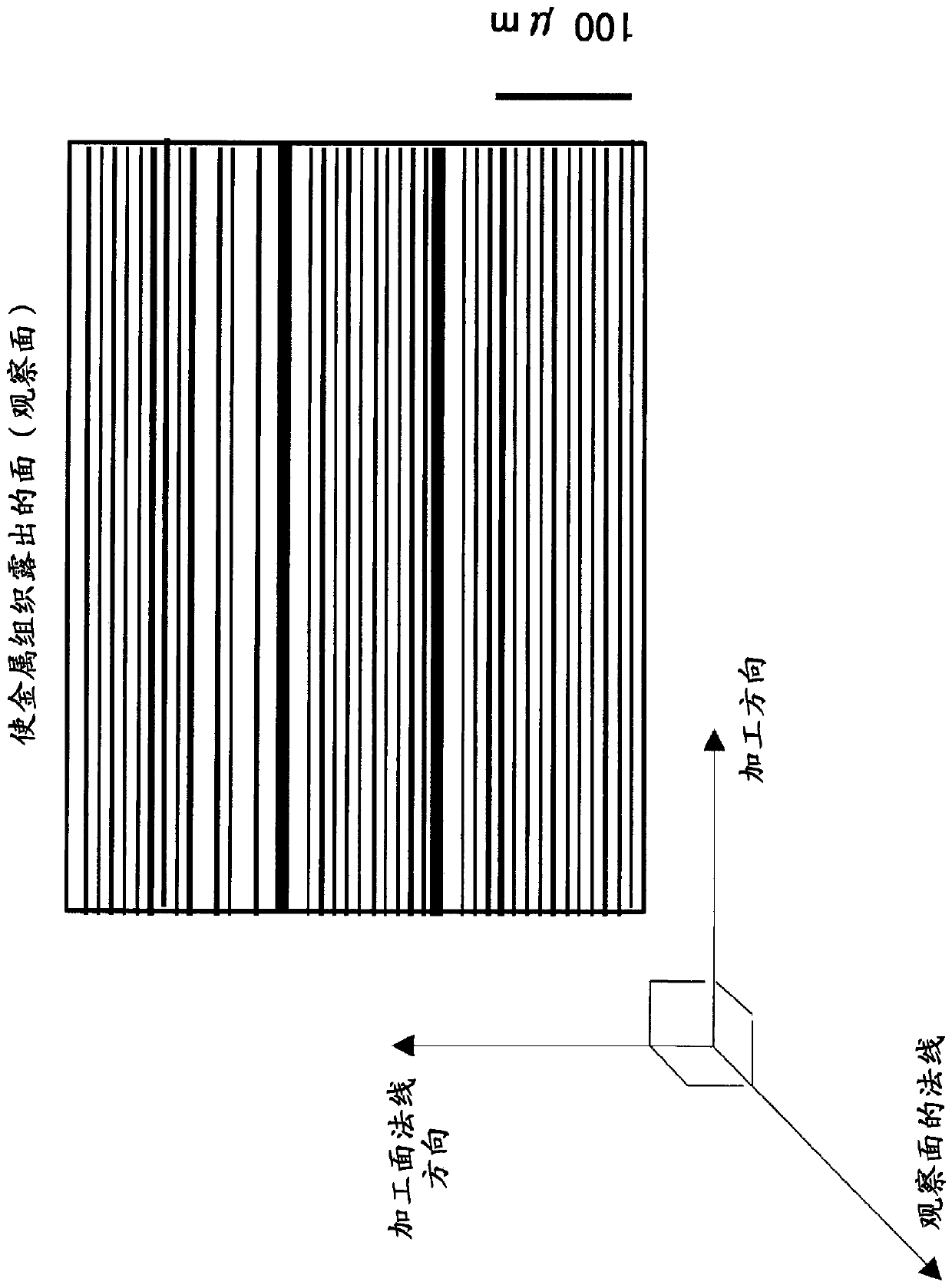

Image

Examples

Embodiment

[0154] Examples and comparative examples of the present invention are shown below.

no. 1 Embodiment

[0156] This example is an example for the invention according to claims 1 to 5 .

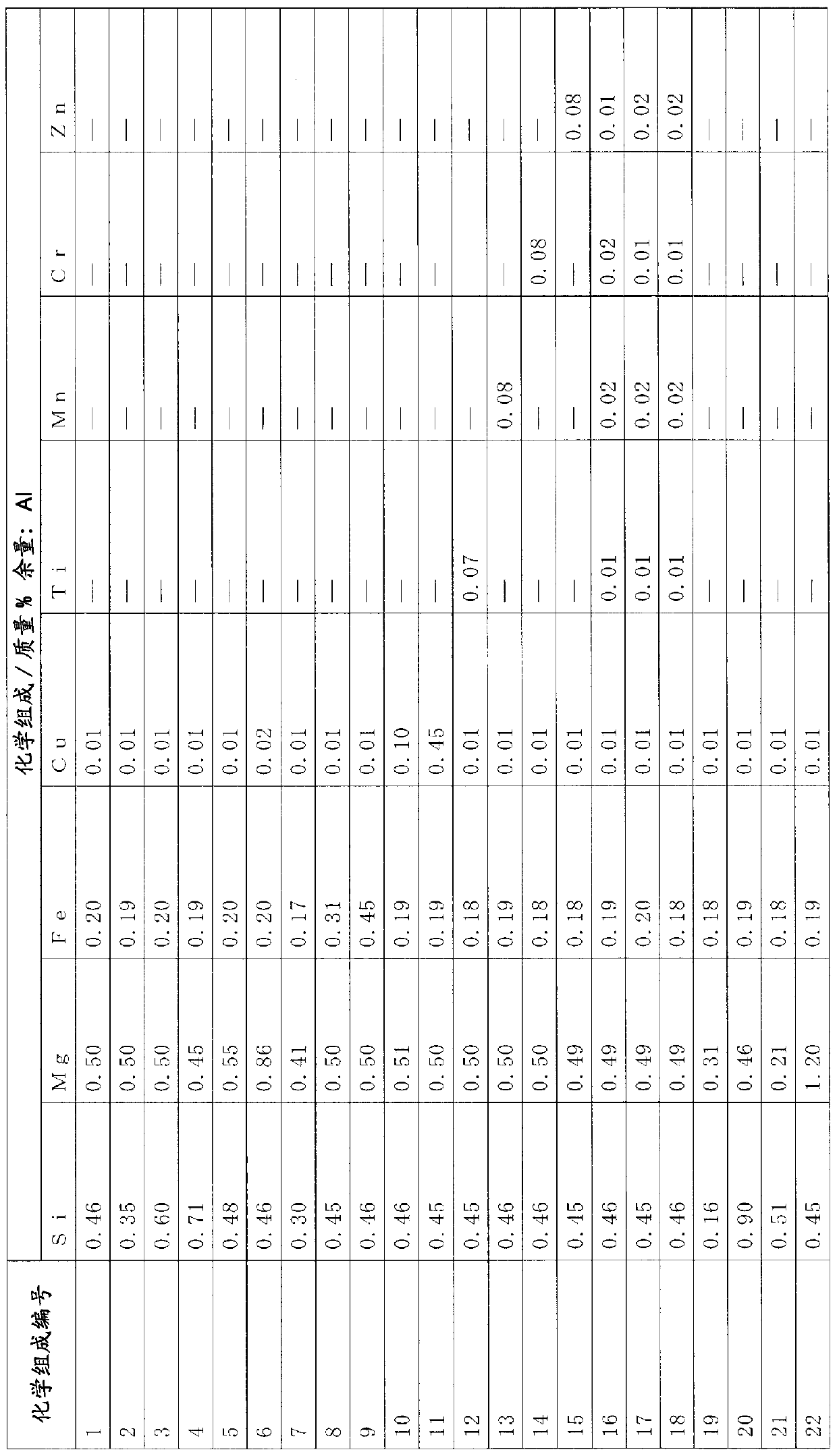

[0157] Aluminum alloy slabs having different chemical compositions shown in Table 1 were obtained by the DC casting method.

Embodiment 1

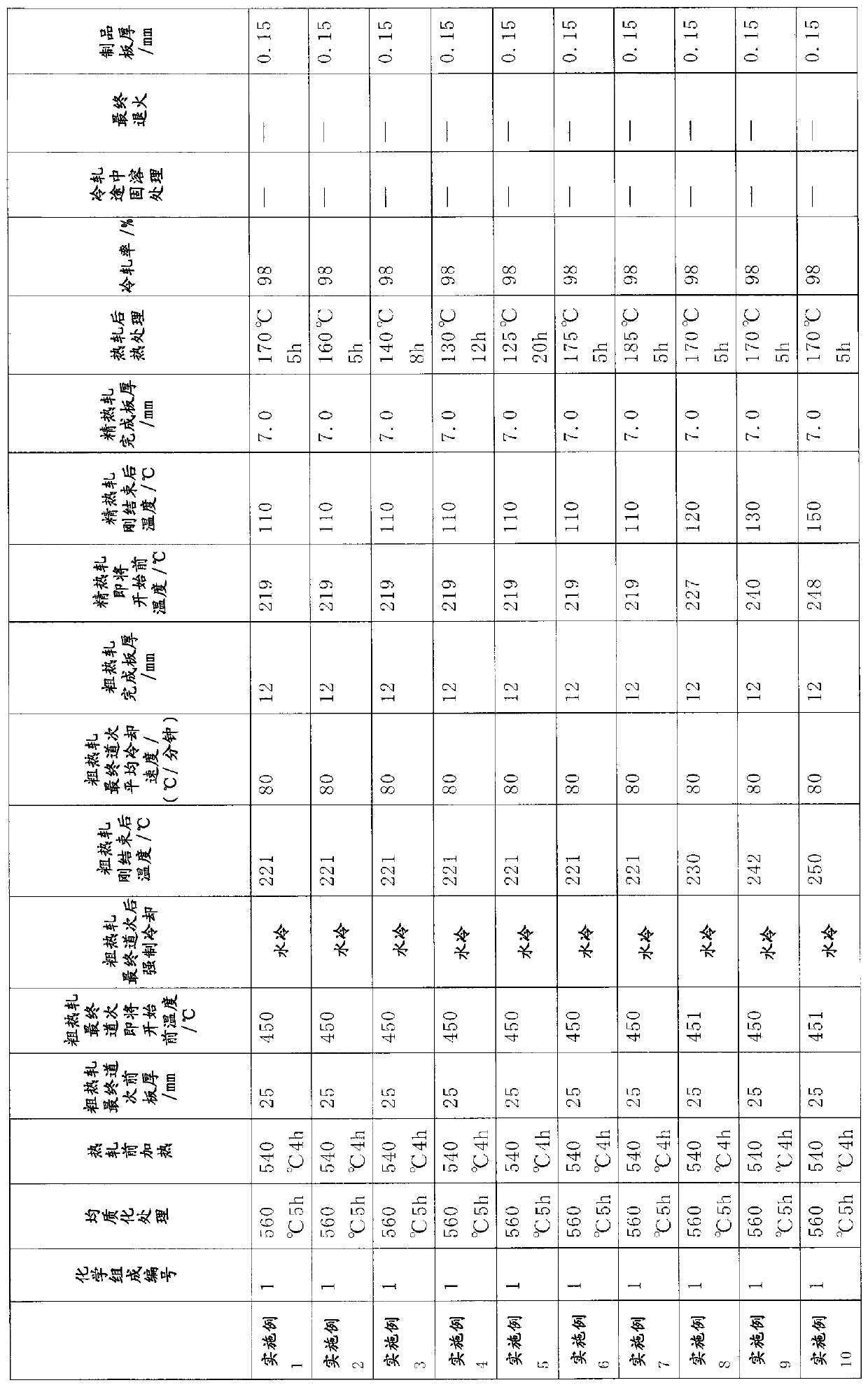

[0159] The aluminum alloy slab of chemical composition No. 1 in Table 1 was subjected to face cutting. Next, the alloy slab after face cutting was subjected to homogenization treatment at 560° C. for 5 hours in a heating furnace, and then heated before hot rolling at 540° C. for 4 hours while changing the temperature in the same furnace. After heating before hot rolling, the slab at 540° C. was taken out from the heating furnace, and rough hot rolling was started. After the thickness of the alloy plate in rough hot rolling reaches 25mm, the final pass of rough hot rolling is carried out at an average cooling rate of 80°C / min from the alloy plate temperature 450°C immediately before the pass, and the finish temperature of rough hot rolling is An alloy plate at 221° C. and a thickness of 12 mm. In addition, in the final pass of the rough hot rolling, forced cooling is performed, the alloy sheet is moved while rolling, and the rolled alloy sheet is subjected to water cooling by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com