Composite heat insulation system that can be dismantled and method for the production and removal thereof

A composite system and thermal insulation material technology, applied in the field of manufacturing thermal insulation composite systems, can solve the problems of building materials that cannot be recycled, can no longer be separated, and hinder resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

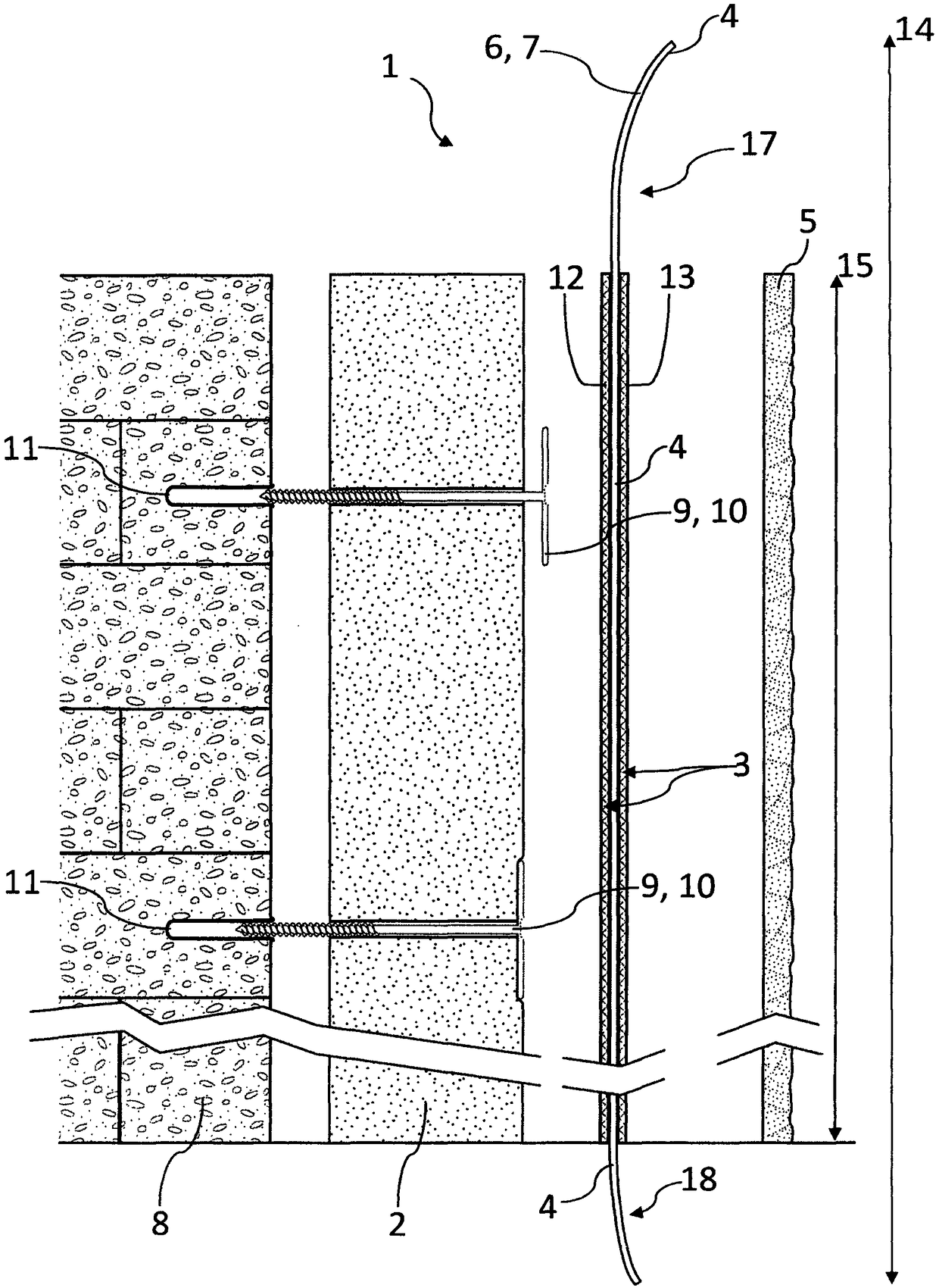

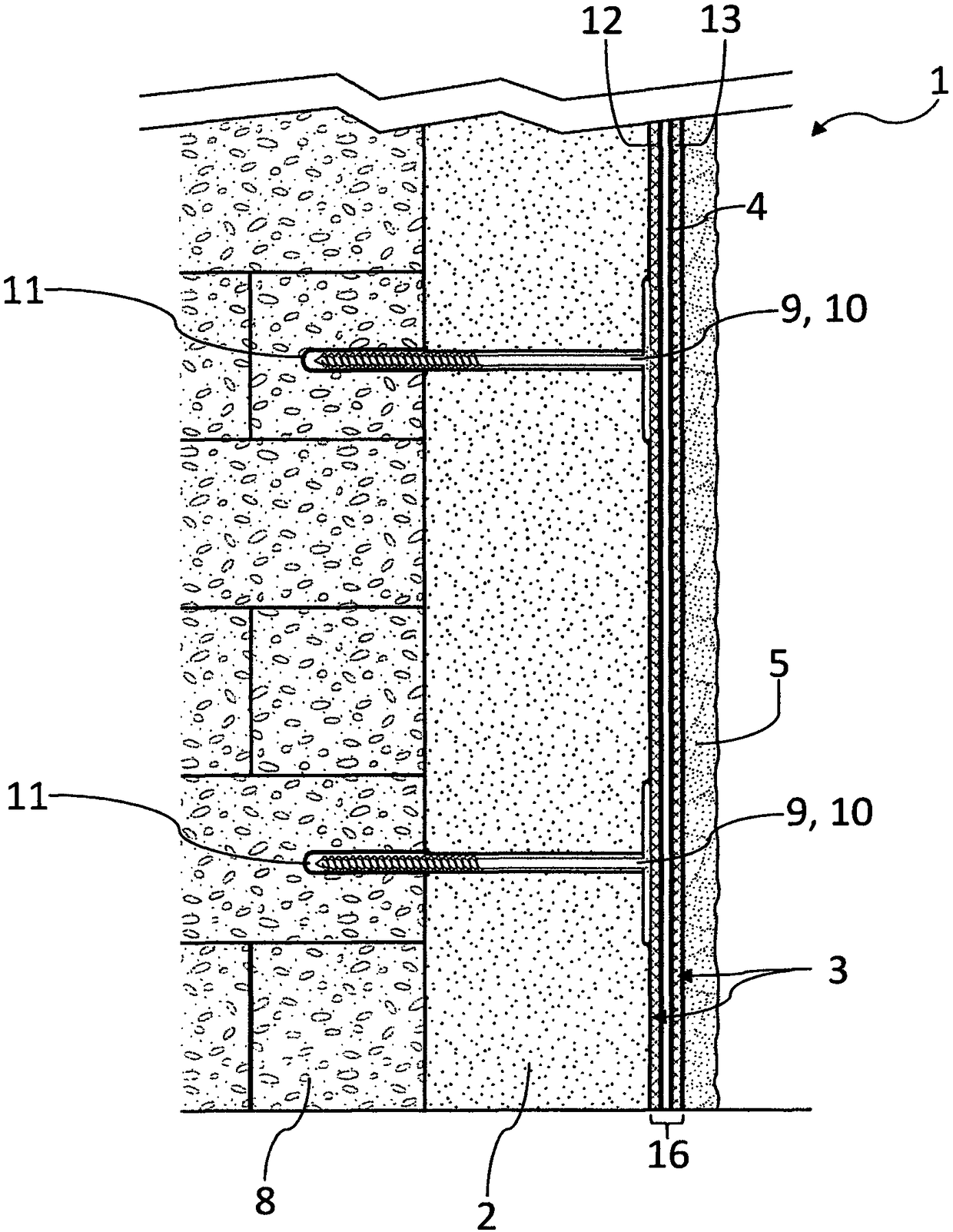

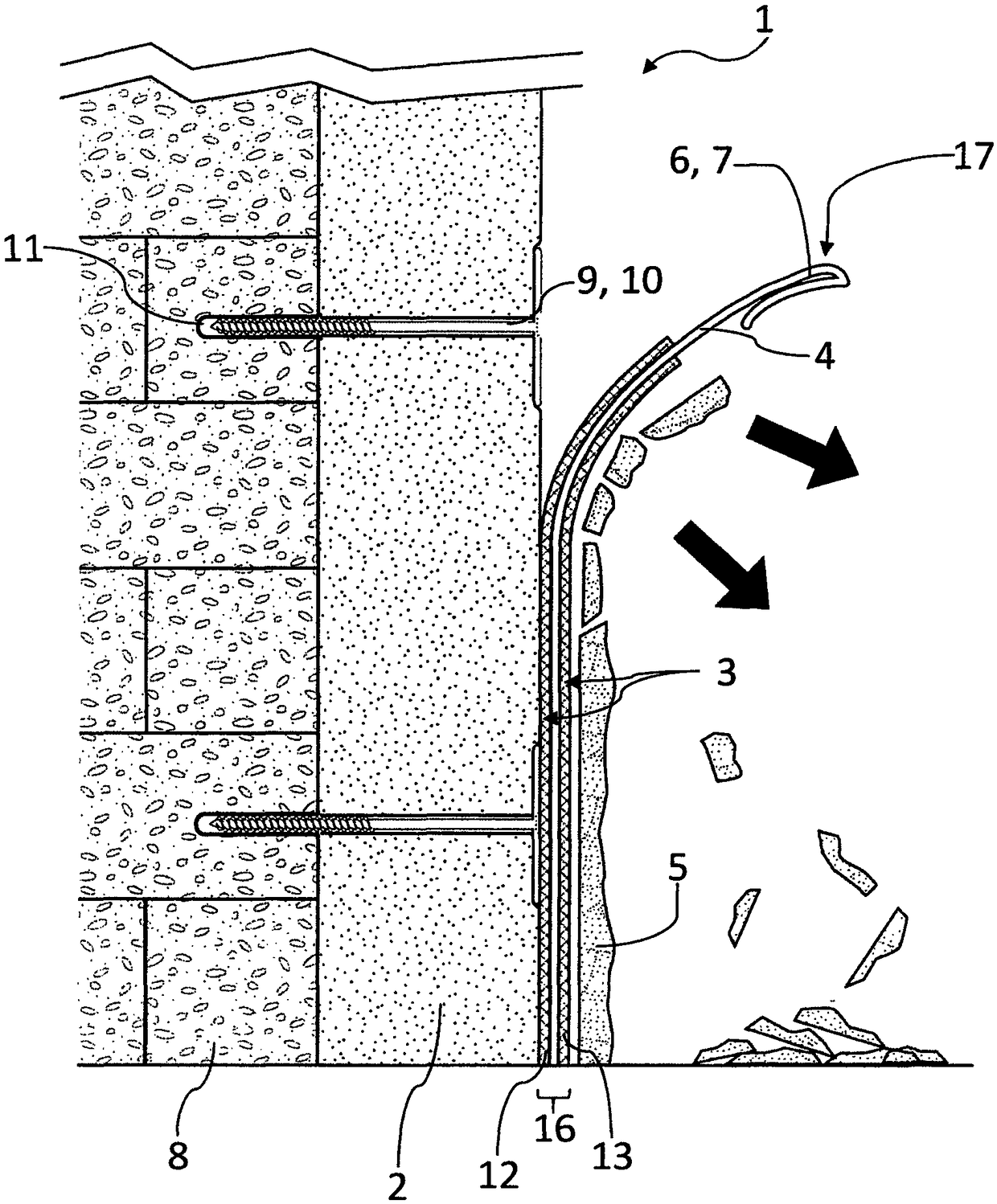

[0033] exist Figures 1 to 3 A particular embodiment of a thermal insulation composite system is shown in , which is designated as a whole by the reference number 1 .

[0034] exist figure 1 , the thermal insulation composite system 1 according to the invention is placed on a substrate. The base here is a building wall 8 made of brickwork.

[0035] The thermal insulation composite system 1 according to the invention has a layer 2 of thermal insulation material which is fastened or can be fastened to a building wall 8 by screw fastening means. The building wall is provided with boreholes for this purpose, into which expansion pins 11 are inserted or can be inserted. By screwing the screw 10 through the heat insulating material layer into the expansion pin 11 by means of a screw 10 that cannot conduct heat, the heat insulating material layer 2 is fastened or the heat insulating material layer can be fastened on the building wall 8 . A first layer 12 of the base plaster laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com