Shaft seal

A shaft sealing and sealing lip technology, applied in the field of shaft sealing devices, can solve the problems of high power and loss, and achieve the effects of low friction power loss, small friction power loss, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

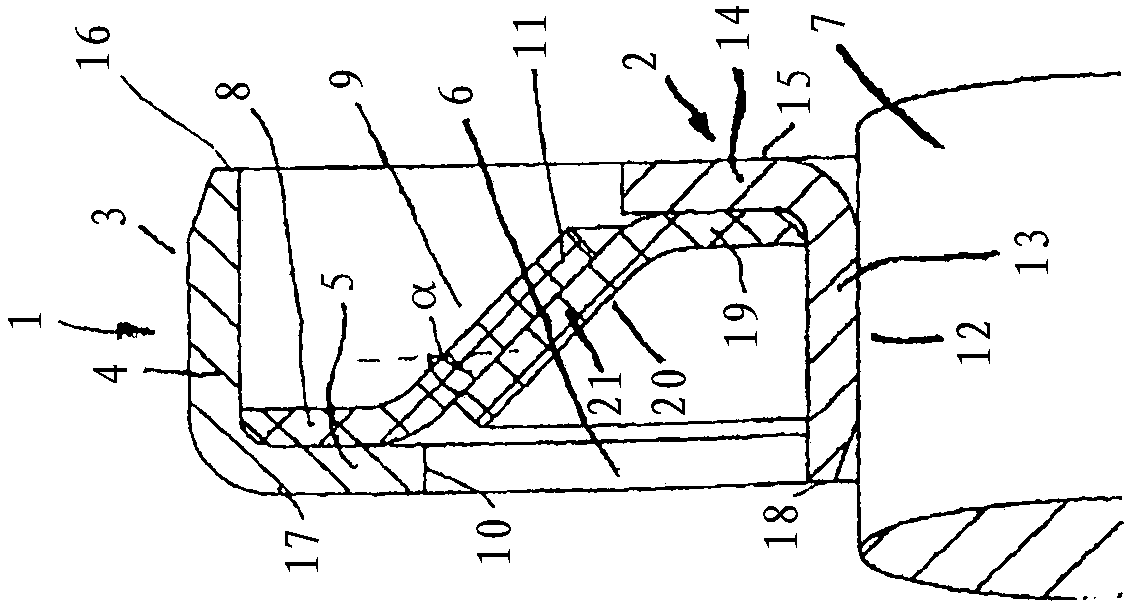

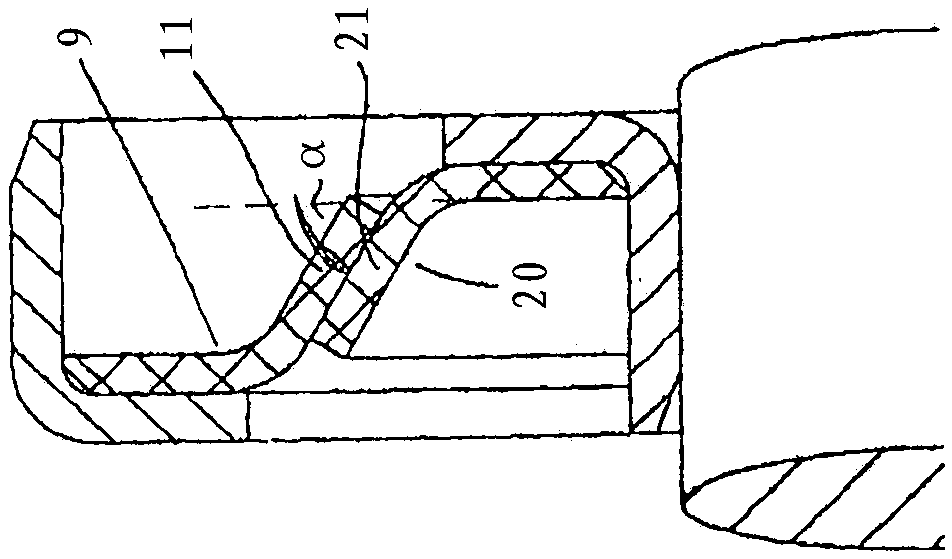

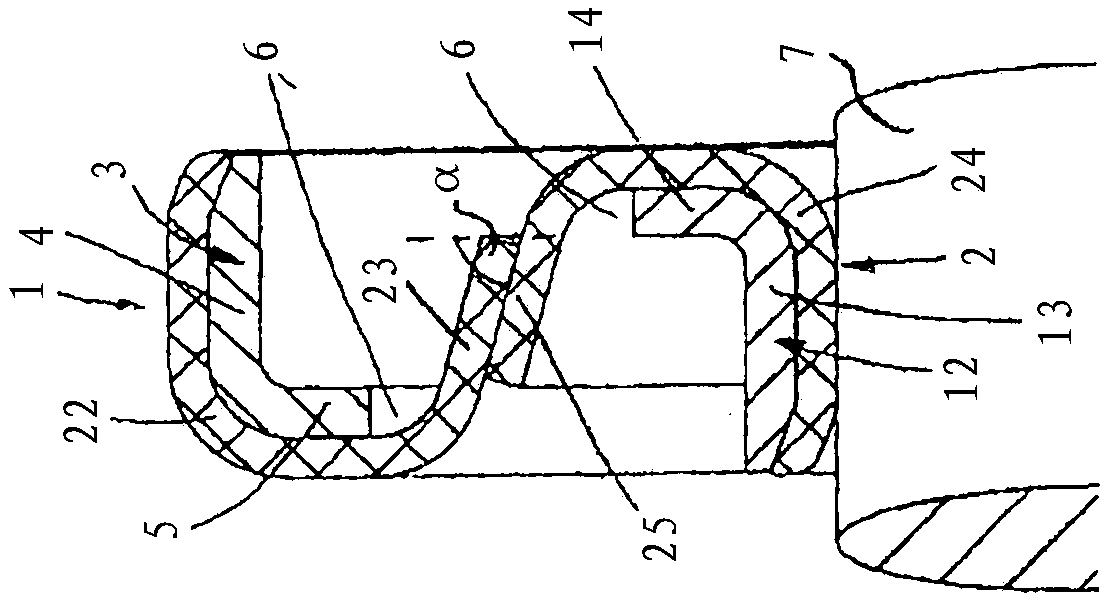

[0033] The outstanding feature of the shaft sealing device described below is that the shaft sealing device seals in contact in a dynamic state and has little friction on the sealing lip. The correspondingly designed shaft sealing device can be contactless when the rotation speed is high, and even at a very low rotation speed before lifting, the shaft sealing device has a very small frictional power loss. The shaft sealing device is constituted by two sealing units, which are arranged relative to each other such that the sealing parts of the sealing units are in contact with each other and in radial force and / or axial force. The sealing units are attached to each other. The dynamic sealing is no longer achieved by sealing the sealing element against the shaft, but by sealing the sealing element of one sealing unit against the sealing element of the other sealing unit.

[0034] figure 1 Shown is a shaft sealing device with two sealing units 1 and 2, which are each configured as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com