Lubricant compositions for high efficiency engines

A lubricating composition and composition technology, applied in the direction of lubricating compositions, additives, base materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0189] The embodiments will be further illustrated by the following examples, which illustrate particularly advantageous embodiments. While examples are provided to illustrate certain embodiments, they are not intended to be limiting.

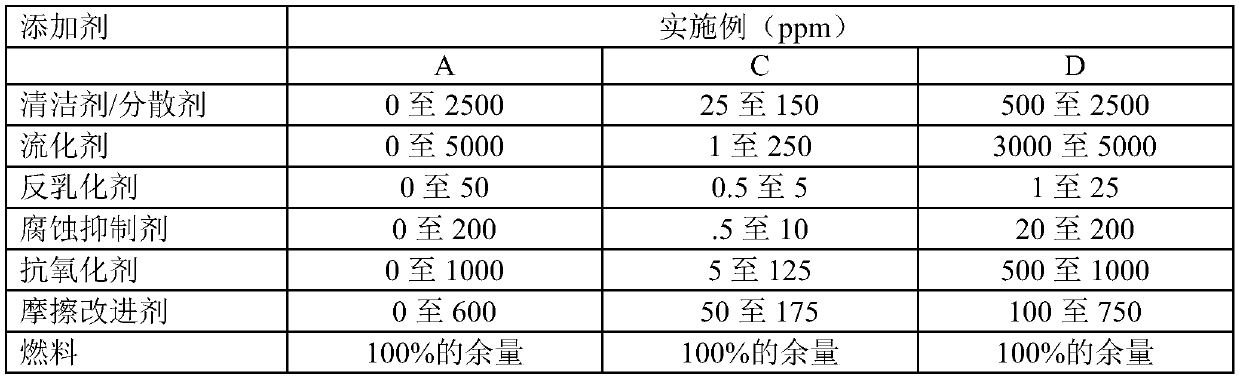

[0190] lubricating composition

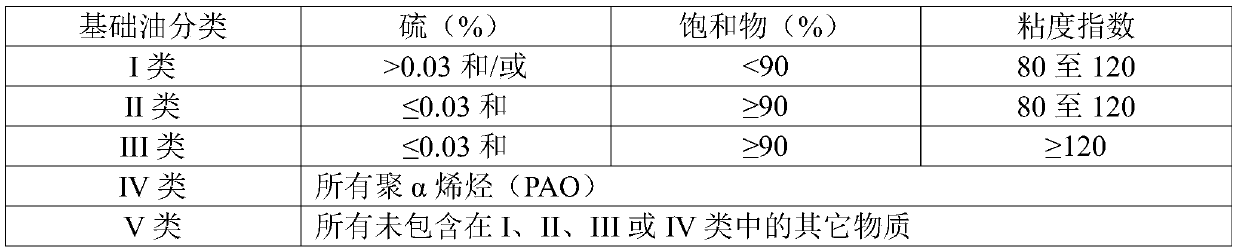

[0191] A series of 0W-20 engine lubricants in Group III base oils of lubricating viscosity were prepared containing the antiwear additives described above as well as conventional additives including polymeric viscosity modifiers, ashless succinimide dispersants, Overbased cleaners, antioxidants (a combination of phenolic esters and diarylamines), and other performance additives are as follows (Table 1). The phosphorous, zinc and ash content of each example is also partially listed in the table to show that each example has similar amounts of these materials so that a proper comparison can be made between comparative examples and examples according to embodiments of the invention.

[0192] Table 1 - Lubricat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com