A planetary transmission mechanism and method for shifting gears based on belt-type tooth brakes

A planetary transmission and brake technology, applied in the direction of brake actuators, mechanically driven drum brakes, components with teeth, etc., can solve the problem of high manufacturing requirements for brakes and brake pipelines, which affect vehicle power and economy , cost, and difficulty in structural design, etc., to achieve good cohesion performance, simple structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

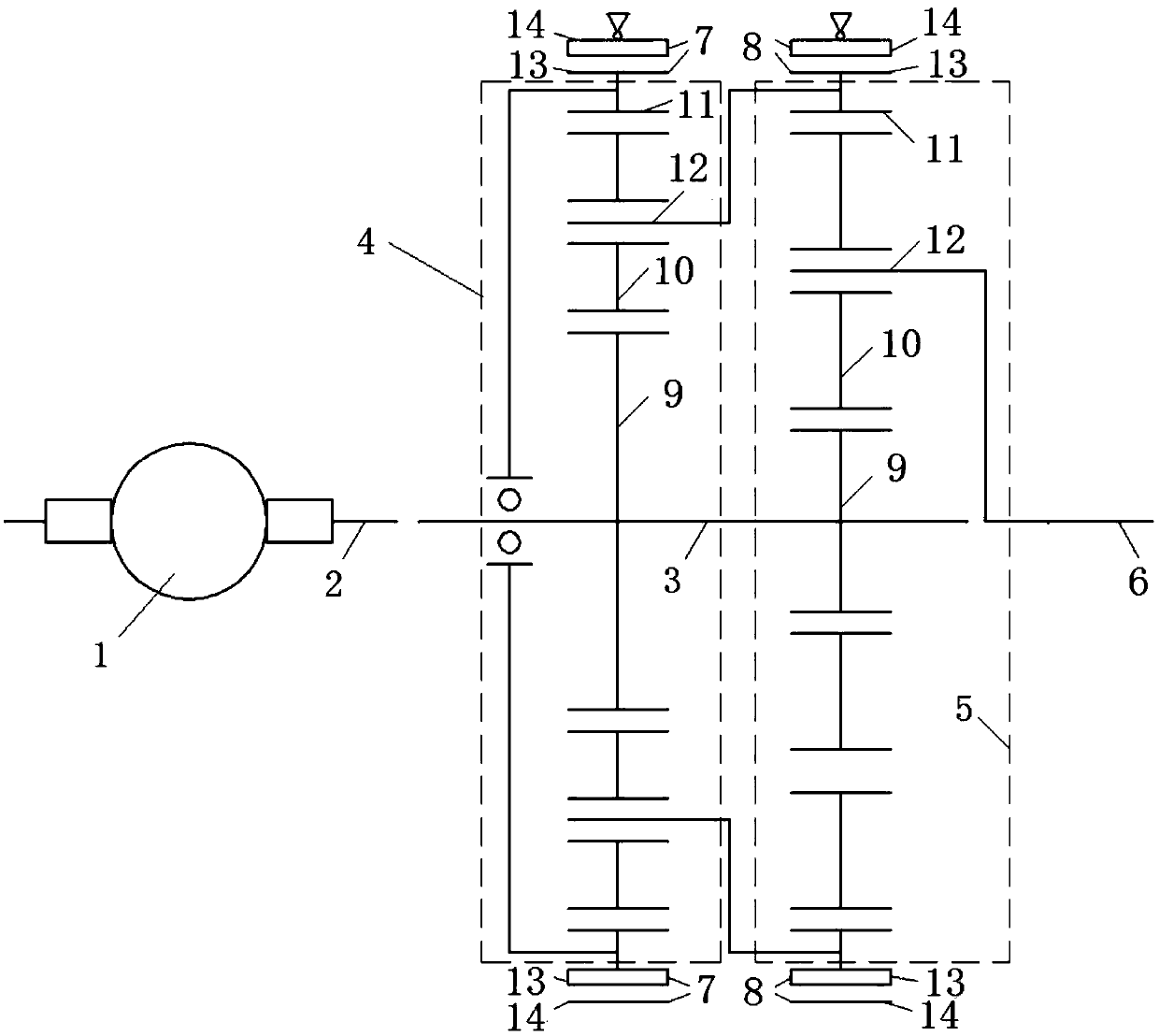

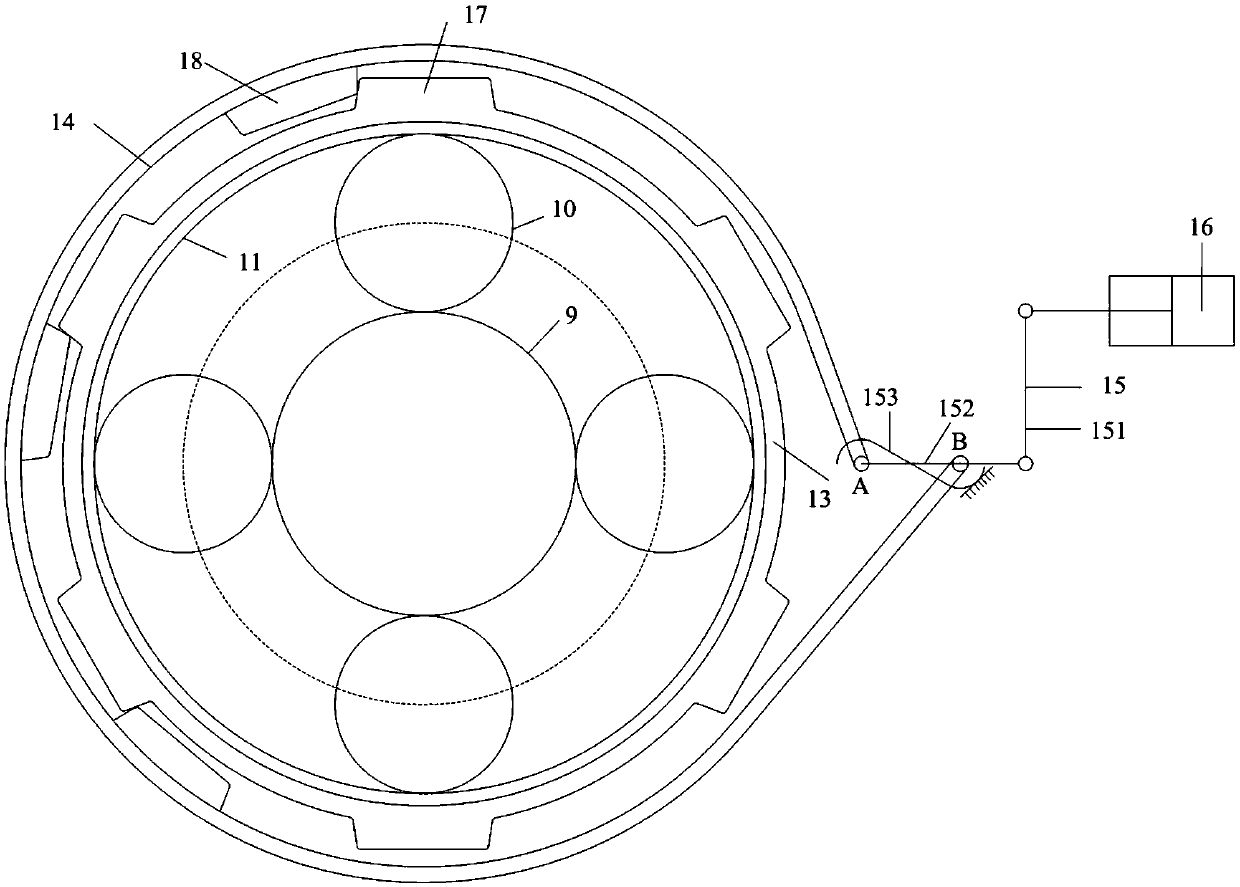

[0014] Such as figure 1 As shown, the present invention provides a planetary transmission mechanism based on belt-type tooth brake shifting, which includes a drive motor 1, a power input shaft 2, a transmission transmission shaft 3, a first planetary row 4, a second planetary row 5, a power Output shaft 6, first row of belt-type tooth brakes 7 and second row of belt-type tooth brakes 8. The output shaft of the driving motor 1 is connected to one end of the power input shaft 2 , and the other end of the power input shaft 2 is connected to the transmission shaft 3 , and then the torque of the driving motor 1 is transmitted from the power input shaft 2 to the transmission shaft 3 . Both the first planetary row 4 and the second planetary row 5 are connected to the transmission drive shaft 3, and the two planetary rows have the same input speed; the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com