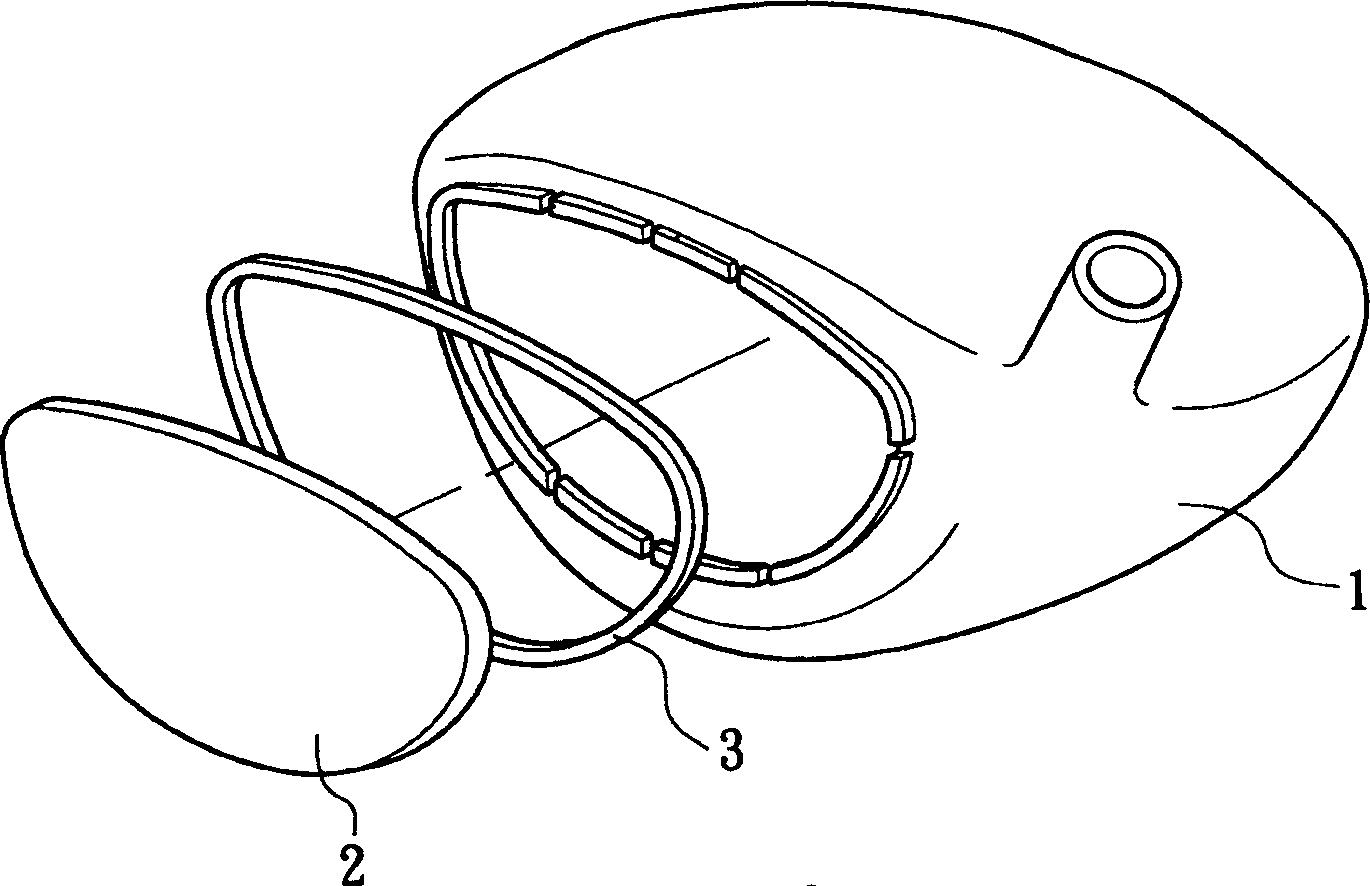

Fabricating method for combining head of golf ball rod by infrared ray heating

A golf club head and rapid heating technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of reduced mechanical strength of joints and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

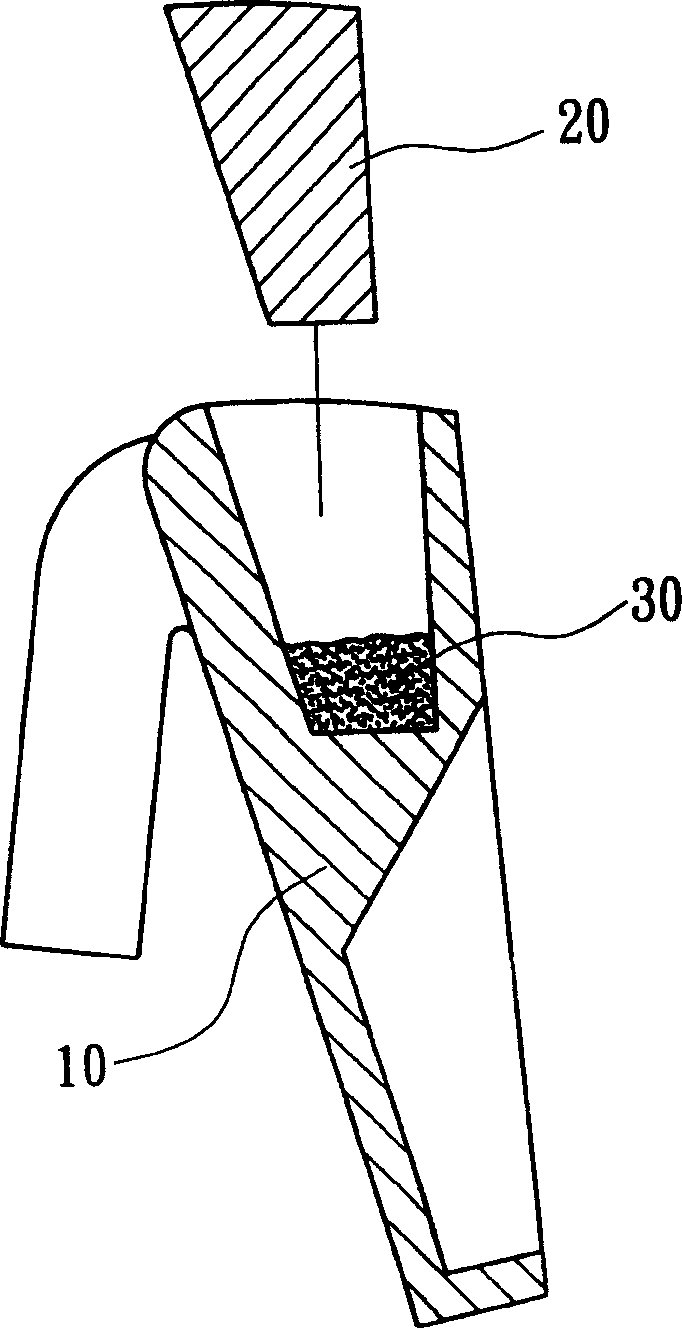

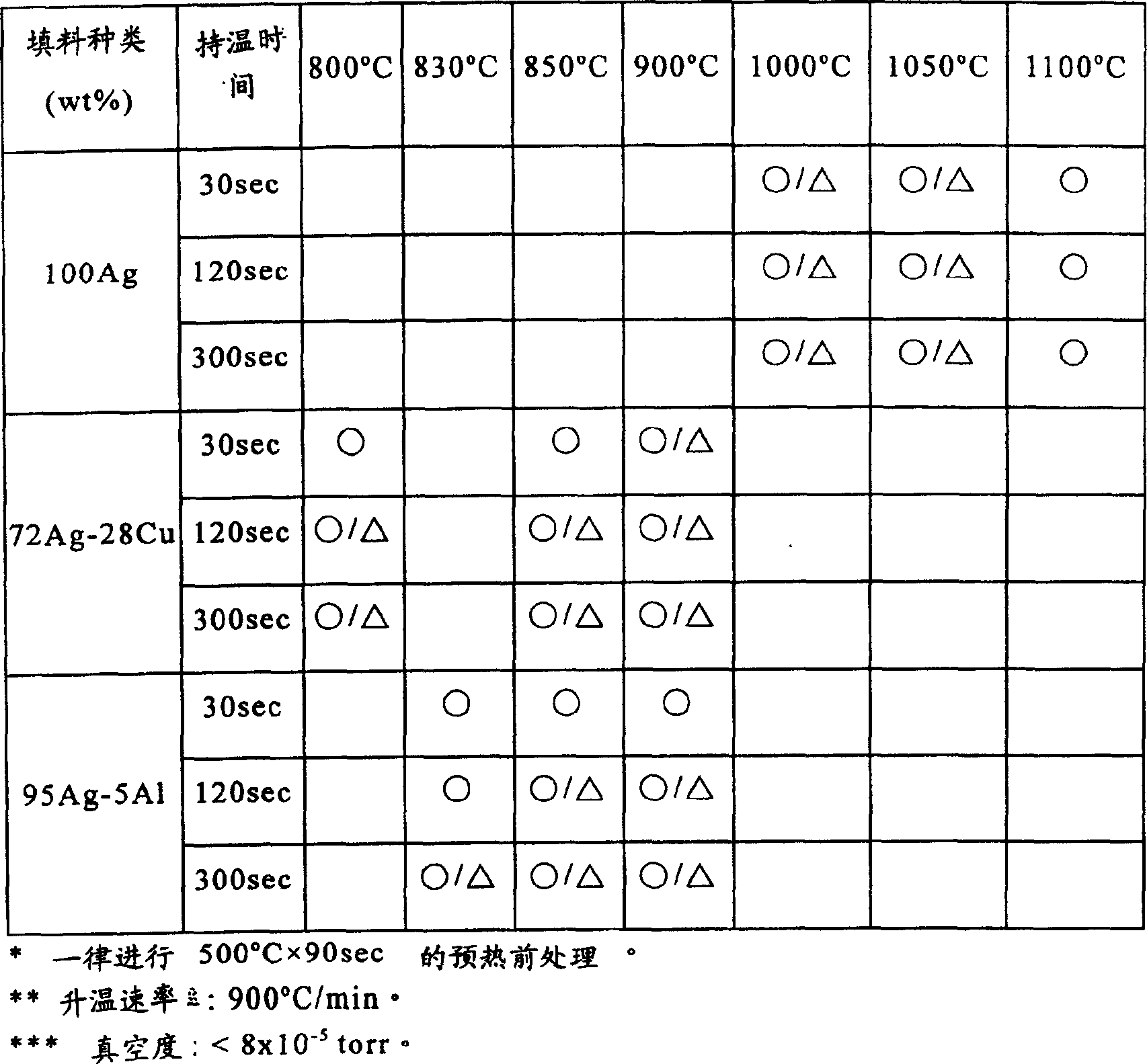

[0040] The infrared brazing bonding device used in the present invention is a Japanese-made ULVAC SINKO-RIKO RHL-P610C infrared heating furnace body, and the furnace is equipped with six sets of quartz lamp tubes with tungsten electric heating wires and six parabolic gold polymers. Light reflective curved surface, the maximum working temperature can reach about 1300℃, and the input power (Rating) is 12.0KW. The overall combination system is self-assembled in China. Equipped with a quartz protective tube with one end sealed and other auxiliary air intake and exhaust equipment. And this infrared rapid heating device can be used in flowing argon protective atmosphere or -5 Infrared rapid bonding process under mbar vacuum. Infrared wavelengths are approximately in the range of 0.76 to 1000 μm.

[0041]Infrared rays have the reflection characteristics of light waves, so geometric mirrors can be used to focus them to increase the energy density of infrared rays and increase the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com