Patents

Literature

82results about How to "Will not affect the sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

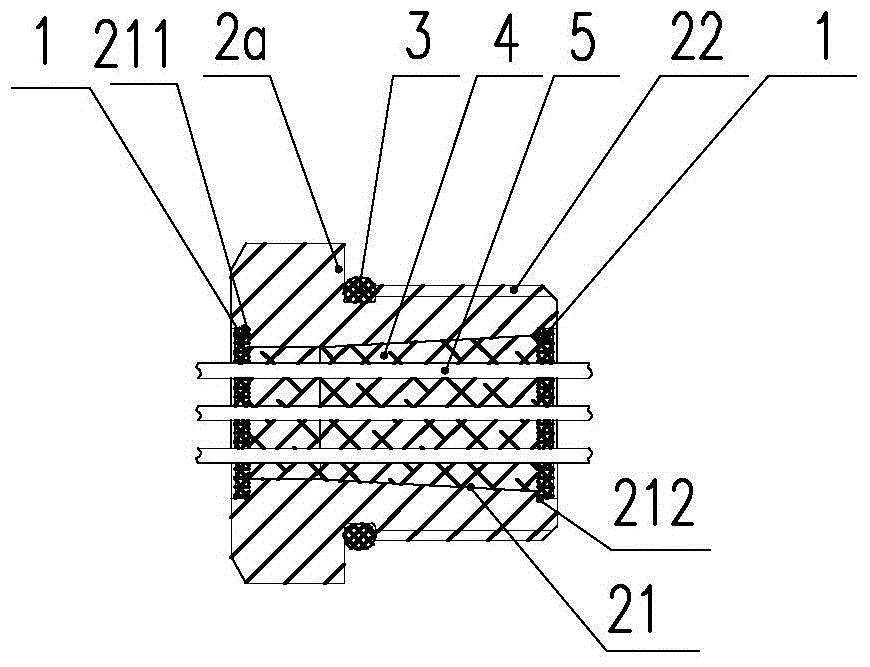

Electronic equipment

PendingCN109862161AAchieve airtight installationWill not affect the sealing effectTelevision system detailsColor television detailsComputer scienceElectric equipment

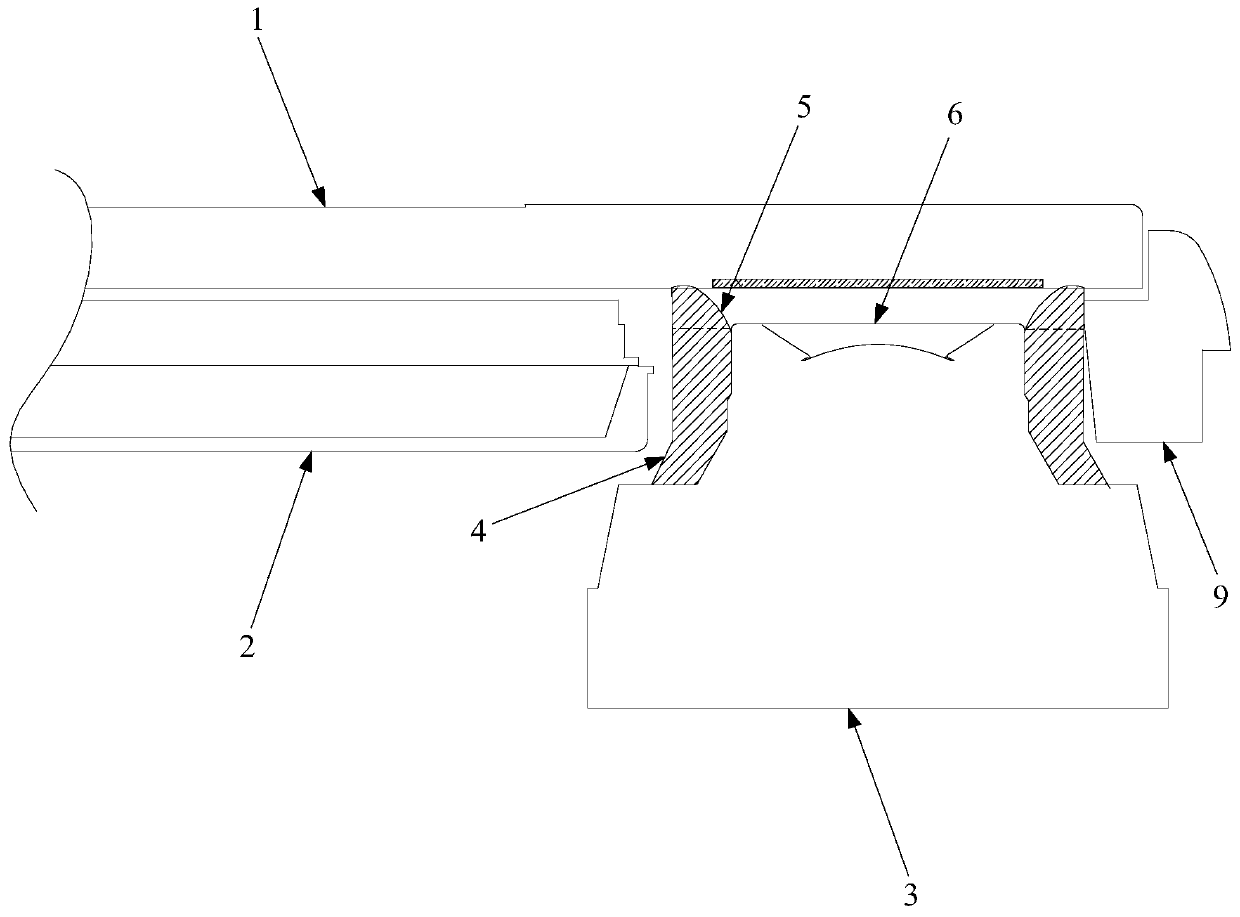

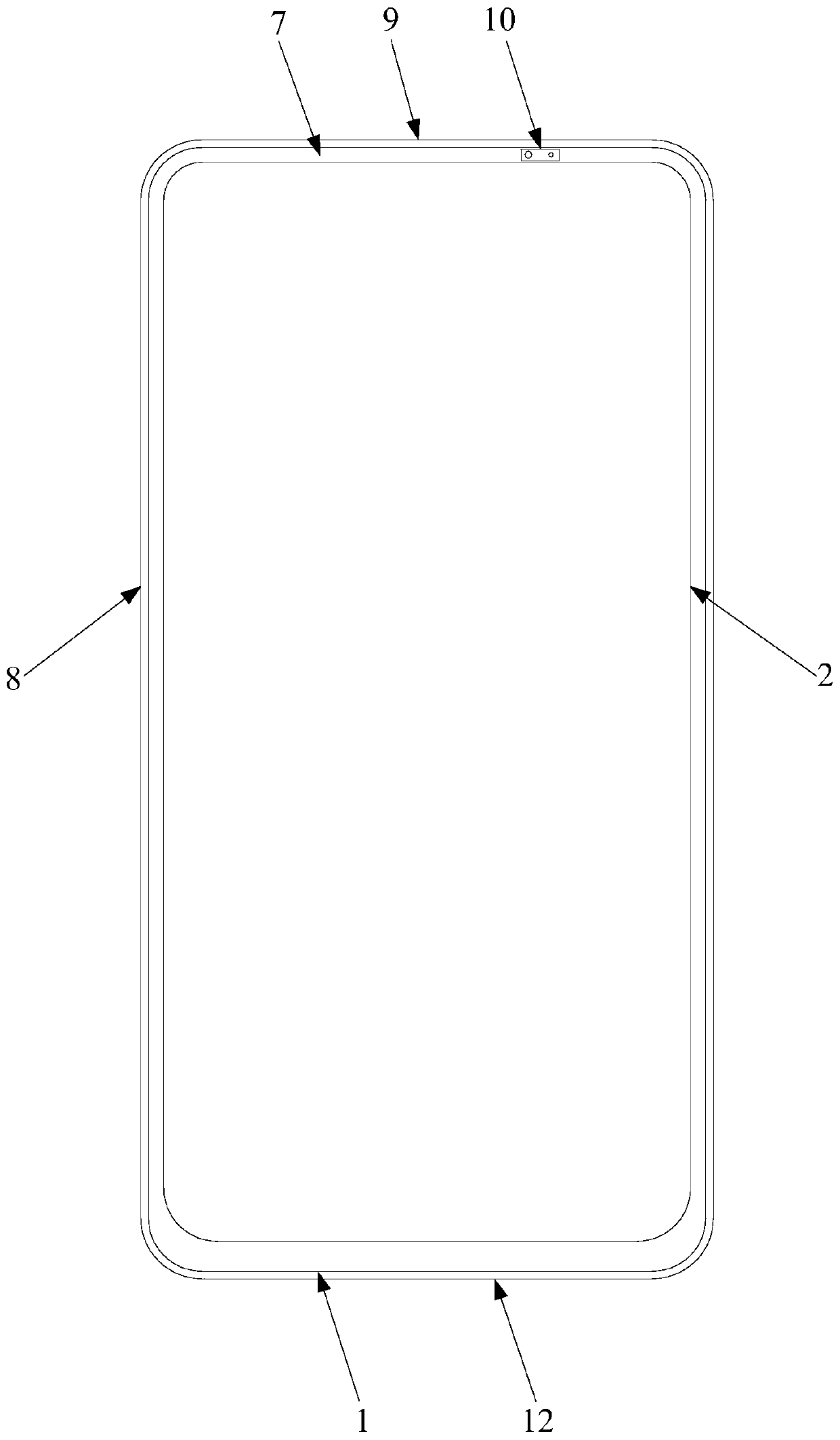

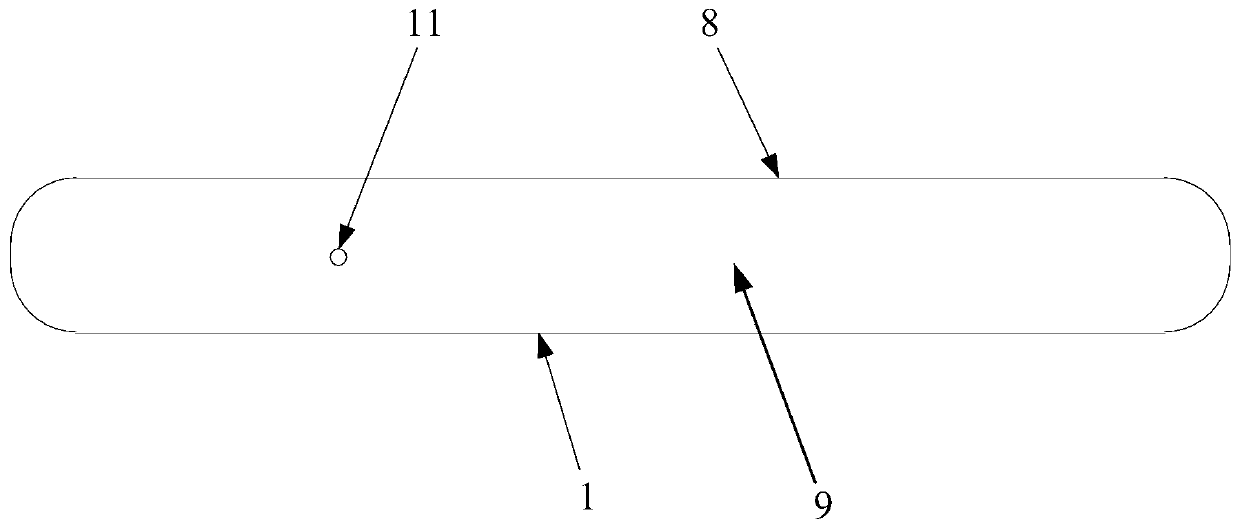

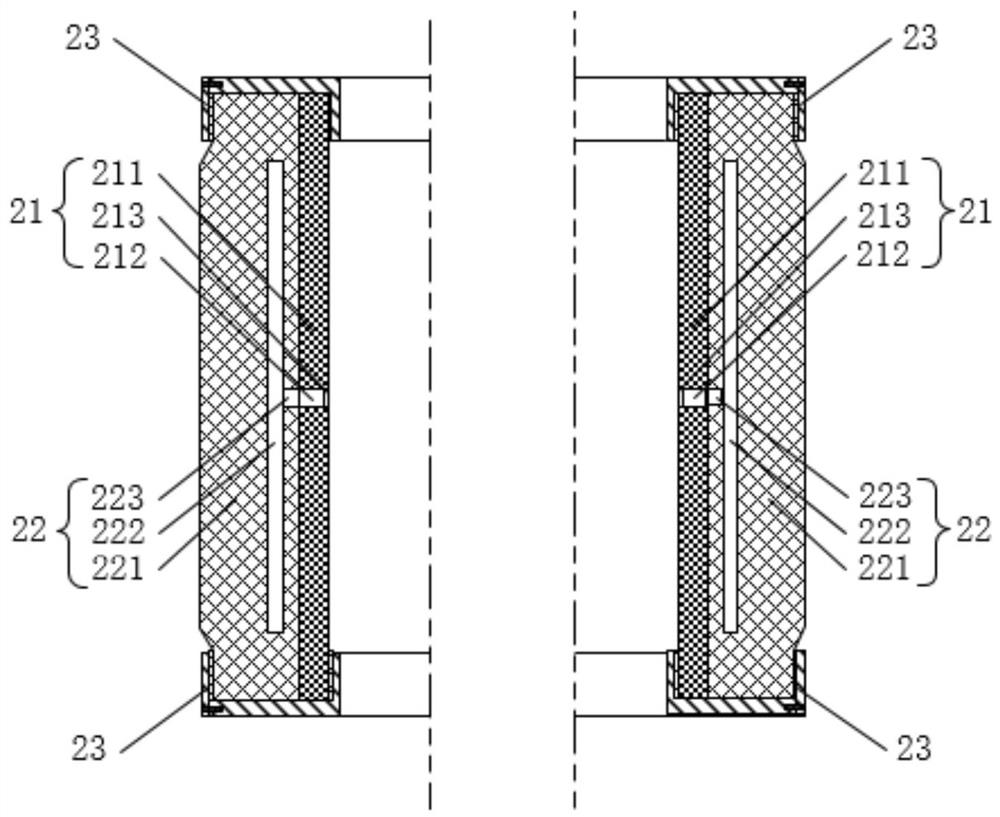

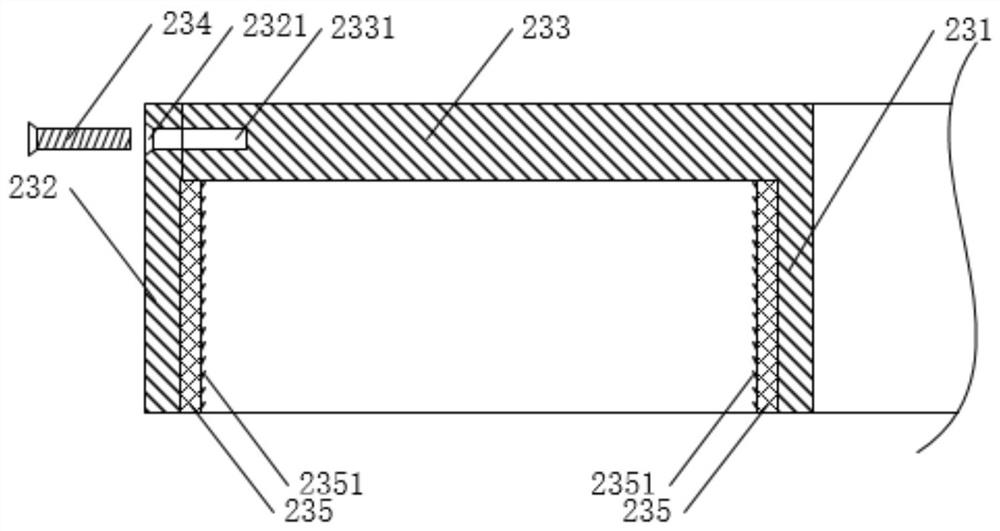

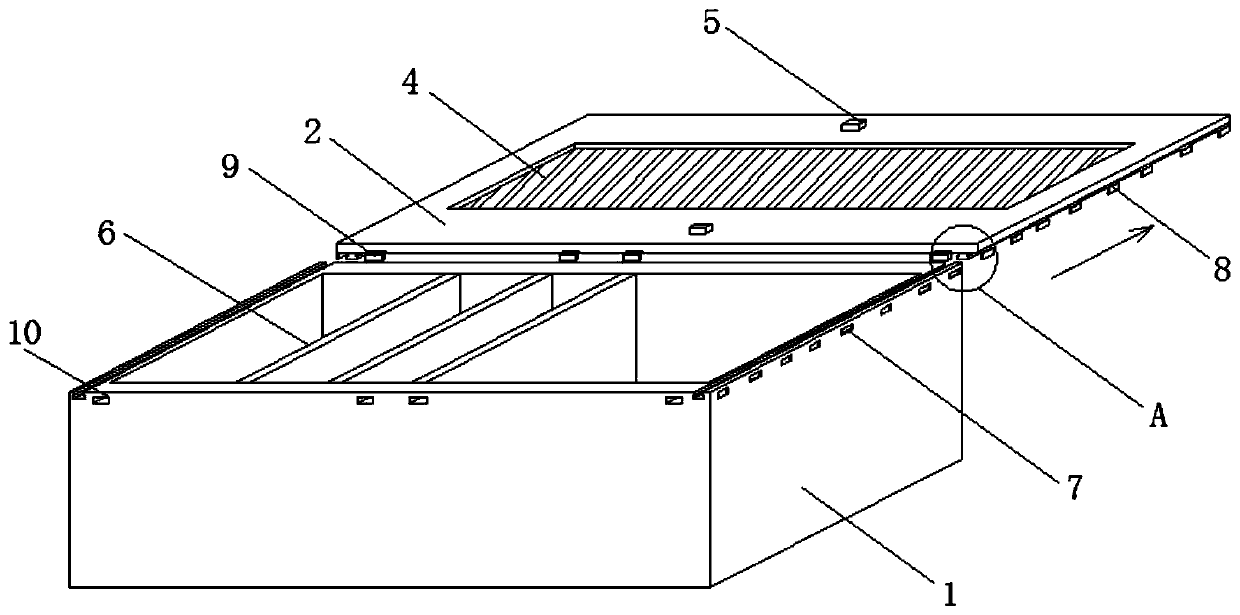

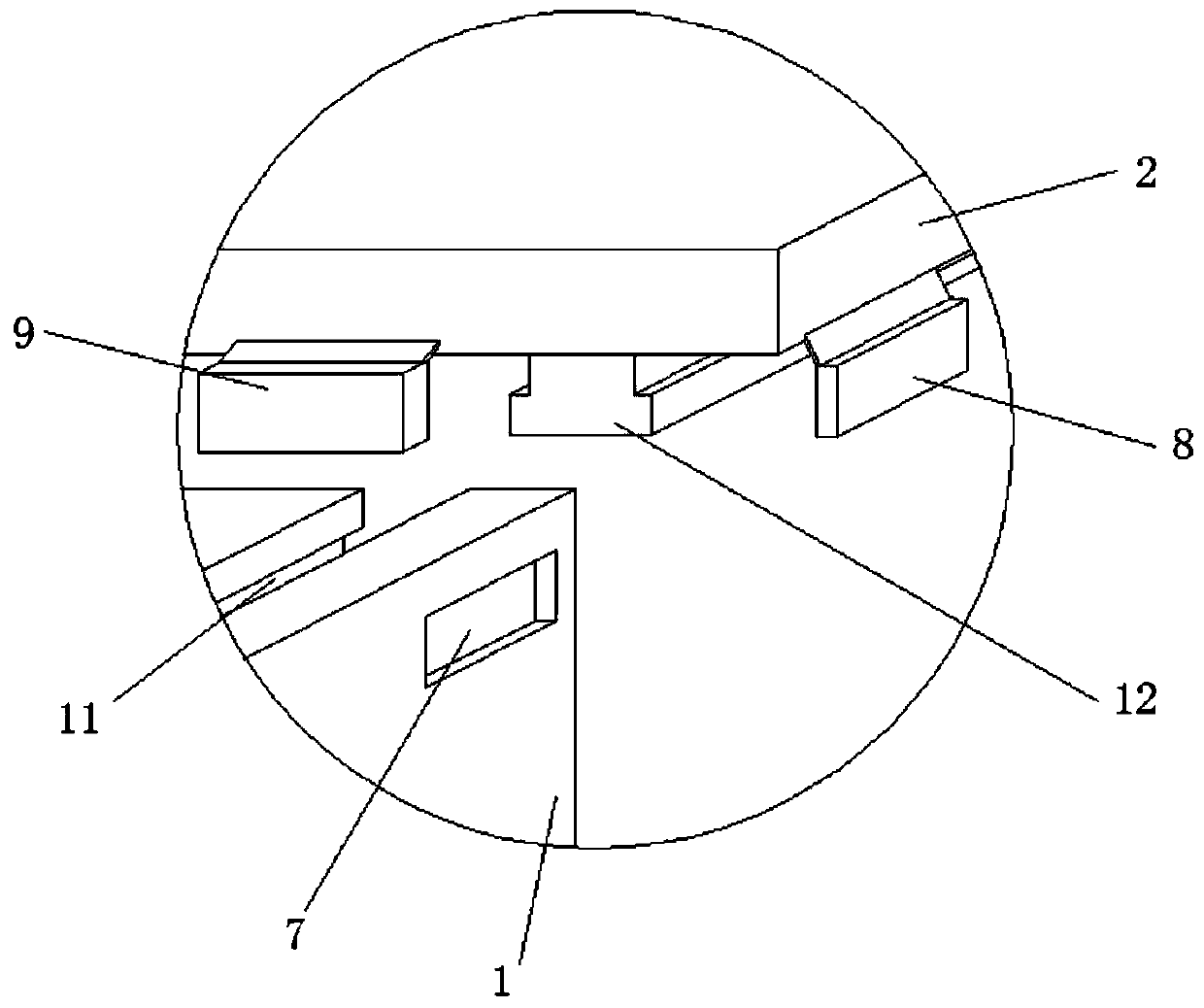

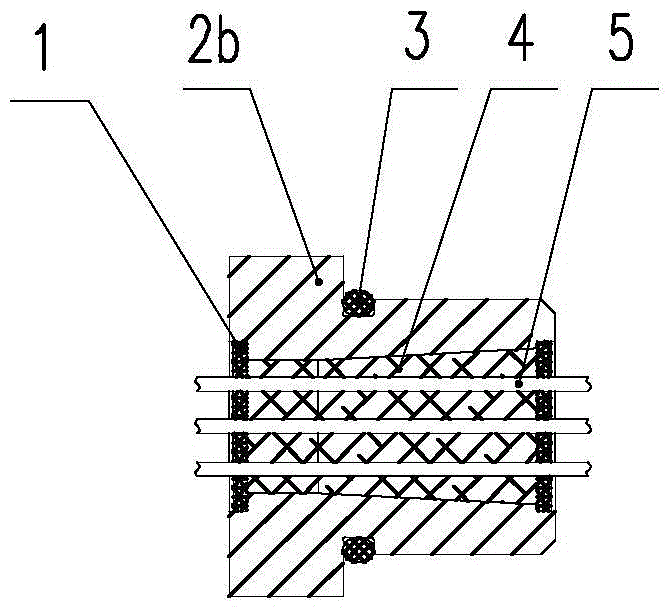

The invention discloses electronic equipment. The electronic equipment comprises: a cover plate, wherein The cover plate is provided with a transparent area, a shielding area and an image acquisitionarea; a display screen, wherein The display screen is provided with a display output area, and the display output area corresponds to the transparent area; a camera, wherein The lens of the camera corresponds to the image acquisition area; And a sealing sleeve, wherein the sealing sleeve at least sleeves the outer side of the lens barrel of the lens of the camera, the sealing sleeve is provided with a protruding end part, and the protruding end part protrudes out of the lens barrel of the lens of the camera and is in sealing connection with the cover plate, so that sealing of the lens barrel is realized. A sealing mode that the lens cone is sealed in an inner cavity of the sealing sleeve is adopted, so that the sealing contact surface is moved from the top surface of the lens cone to the outer side of the lens cone, and the sealing contact surface is not positioned on the top surface of the lens cone, so that the sealing effect on the camera is not influenced even if the size of the camera and the size of a shielding area where the camera is positioned are small, and the sealing effect of the camera is improved.

Owner:LENOVO (BEIJING) LTD

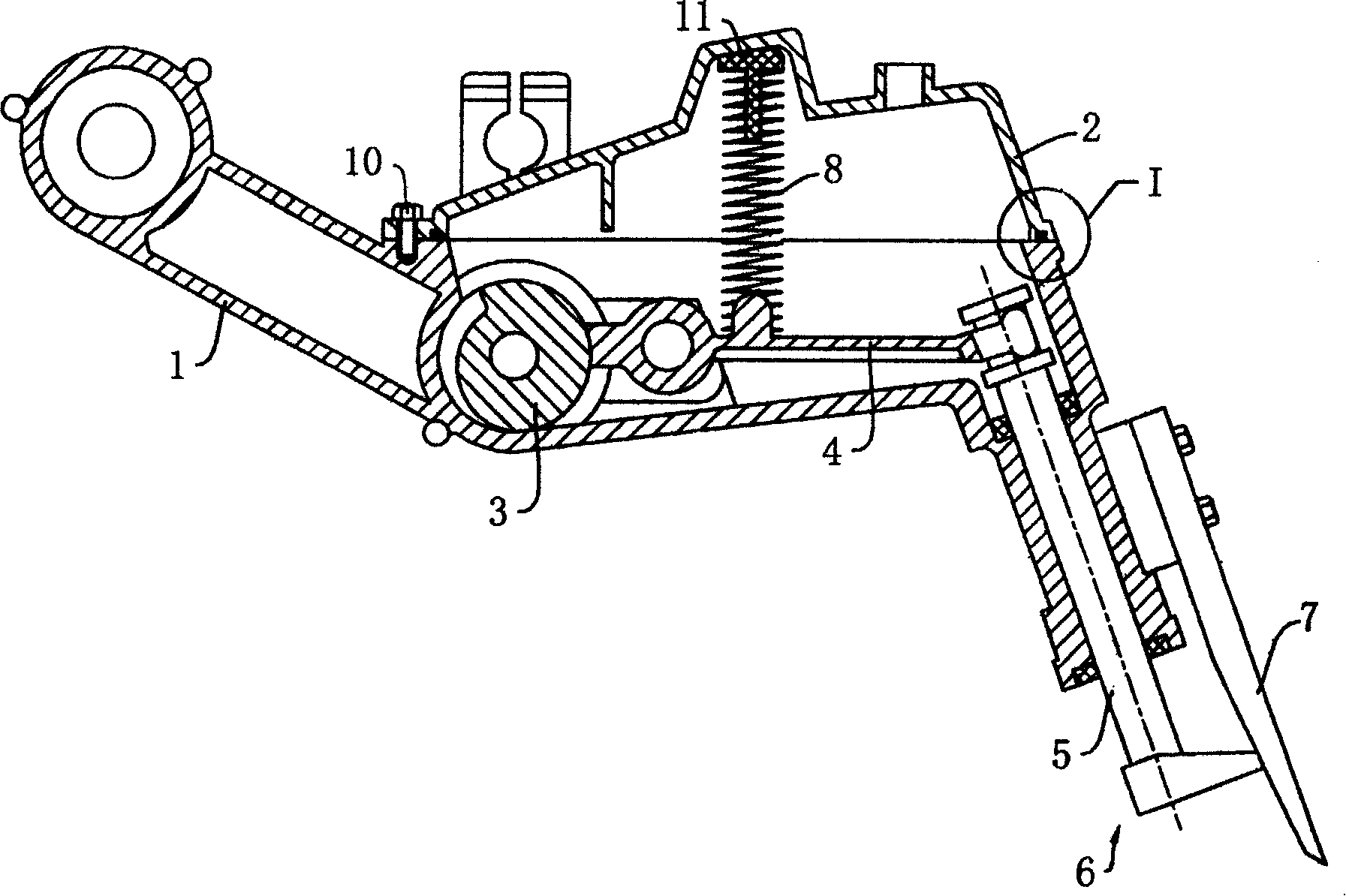

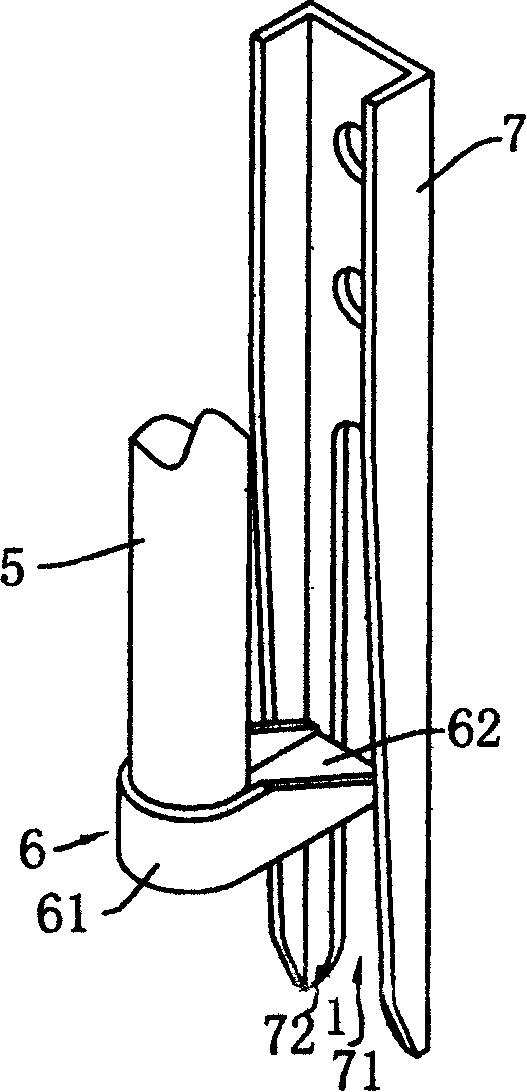

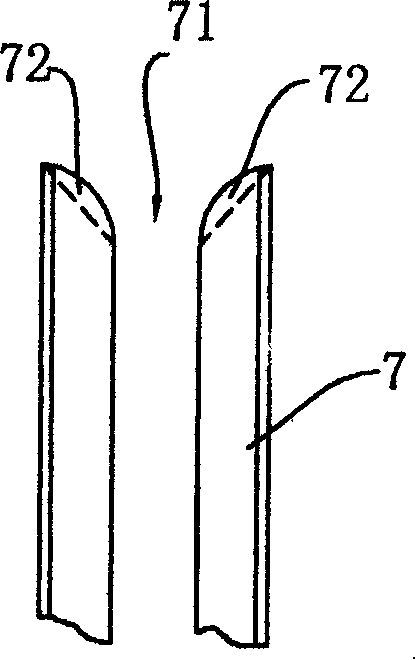

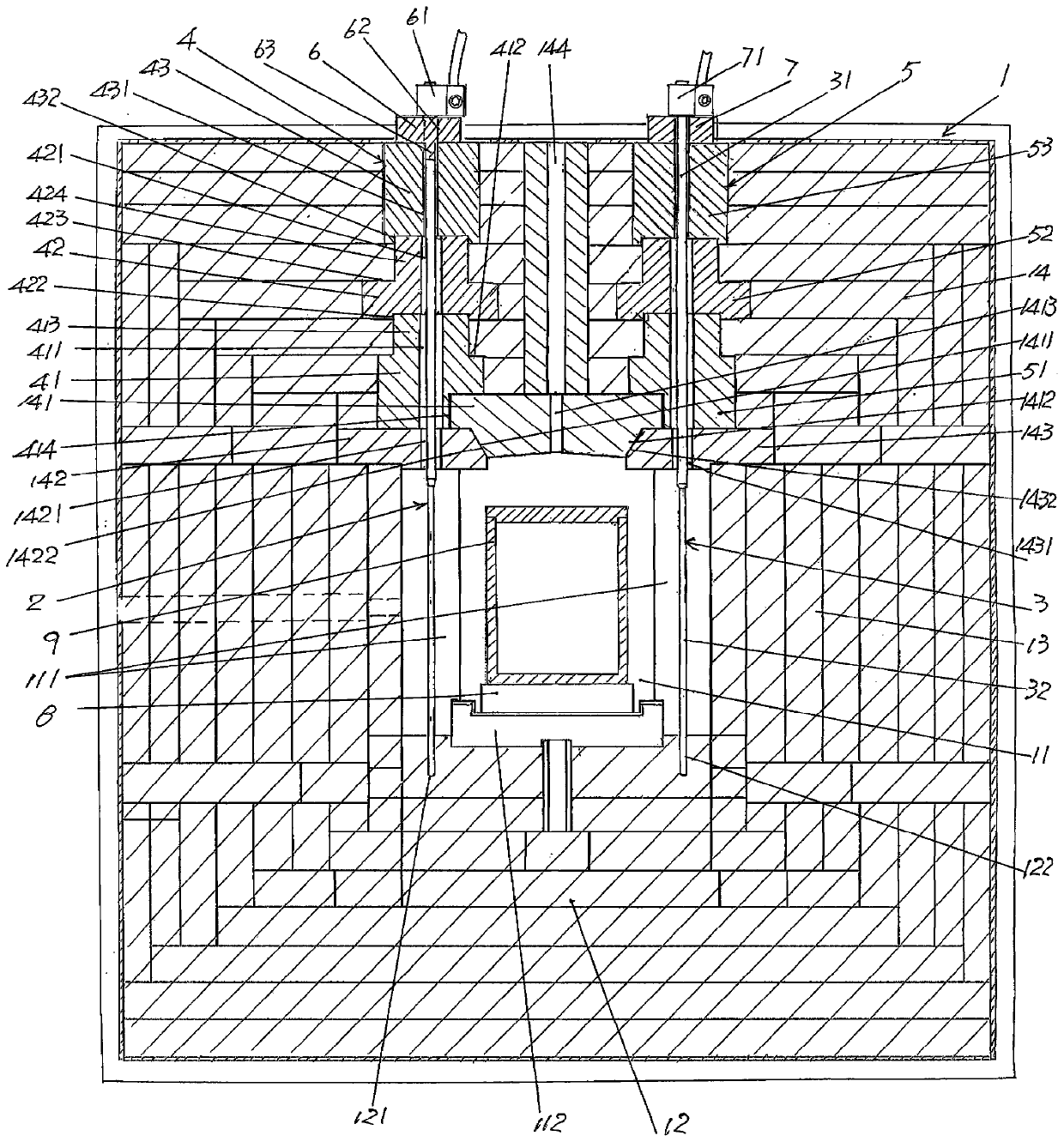

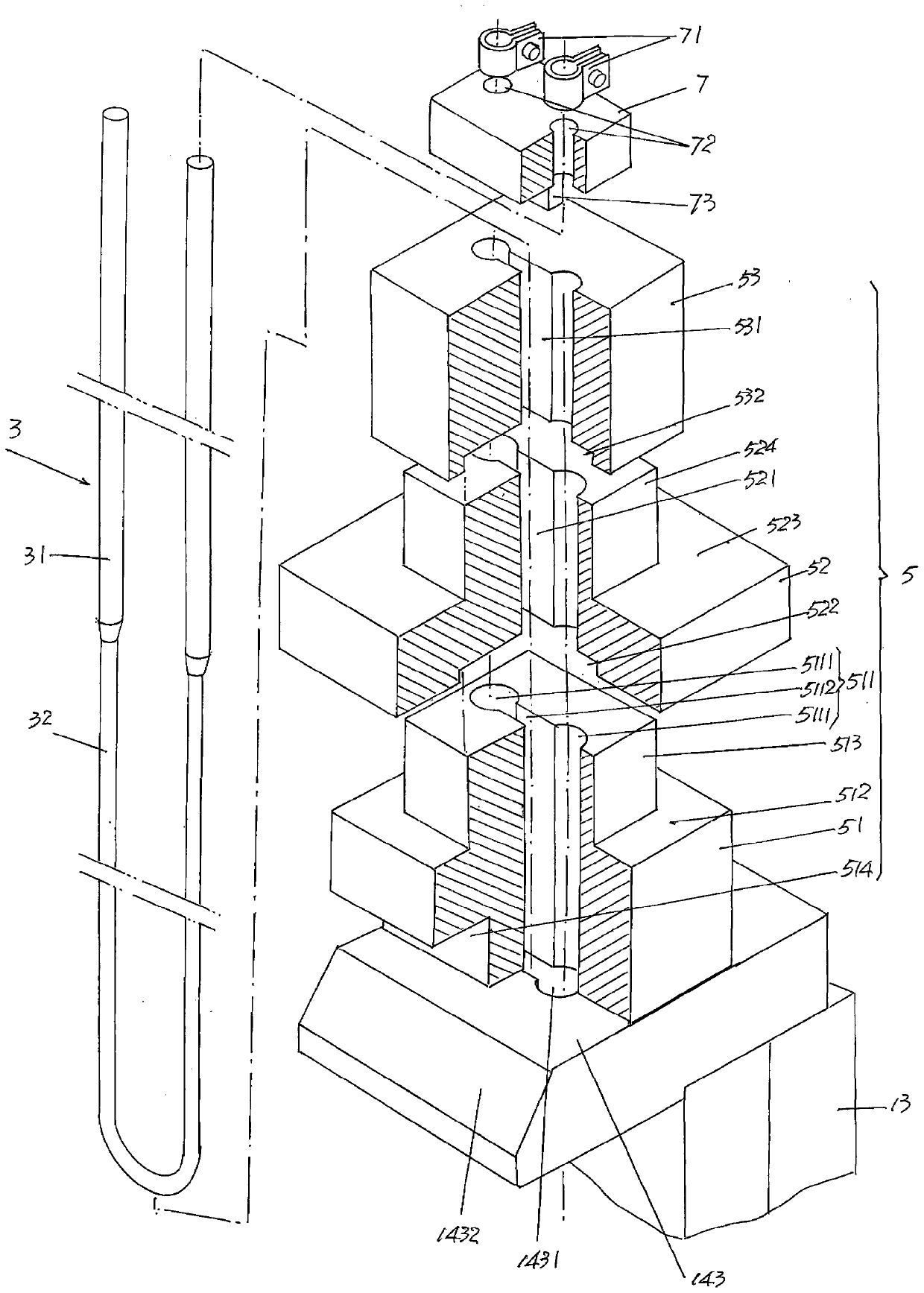

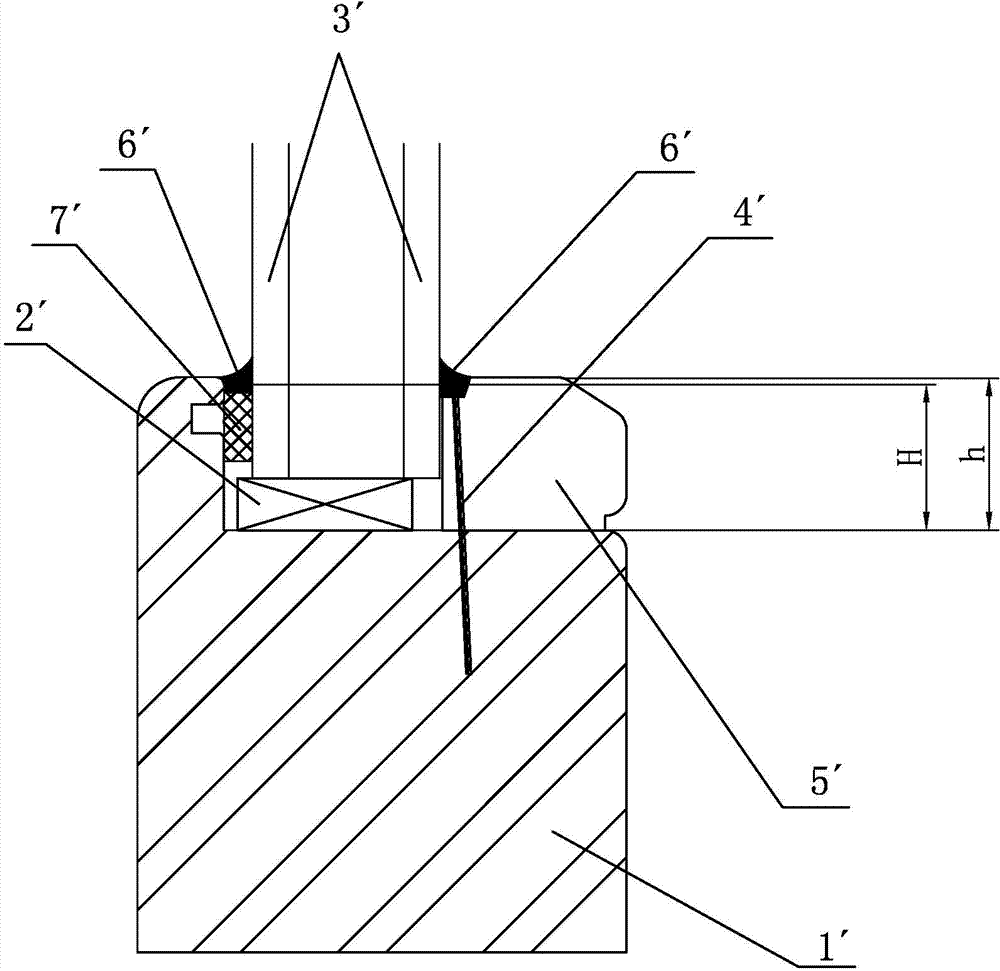

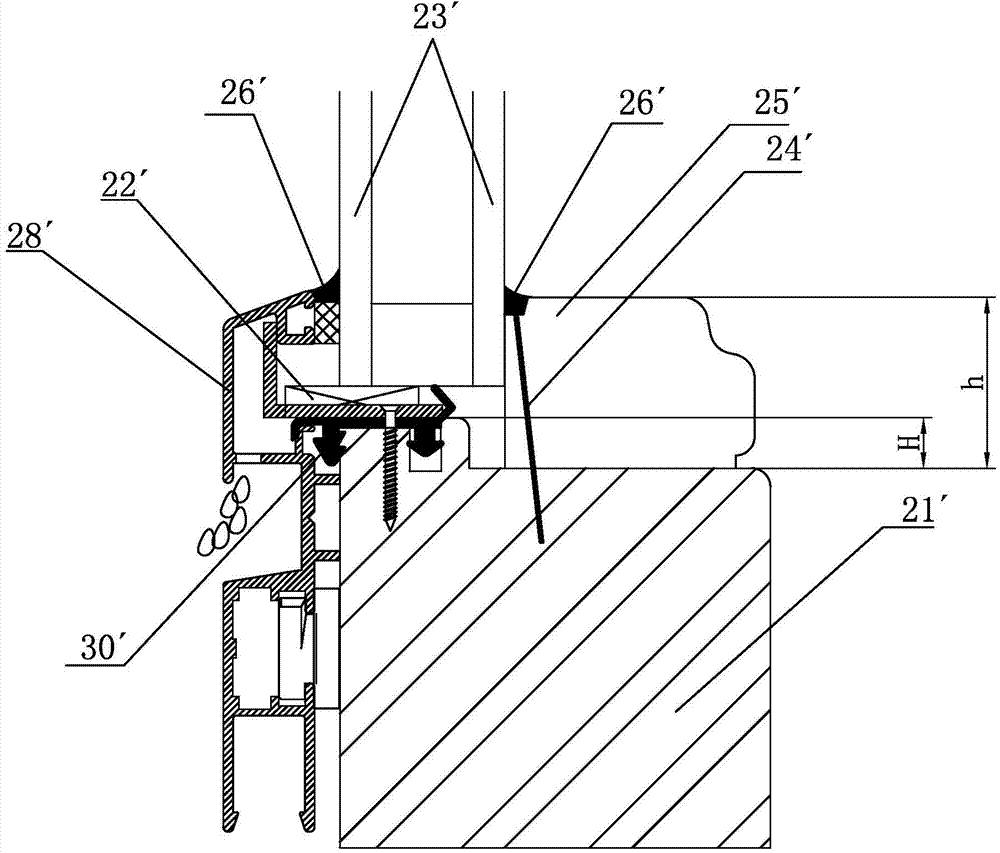

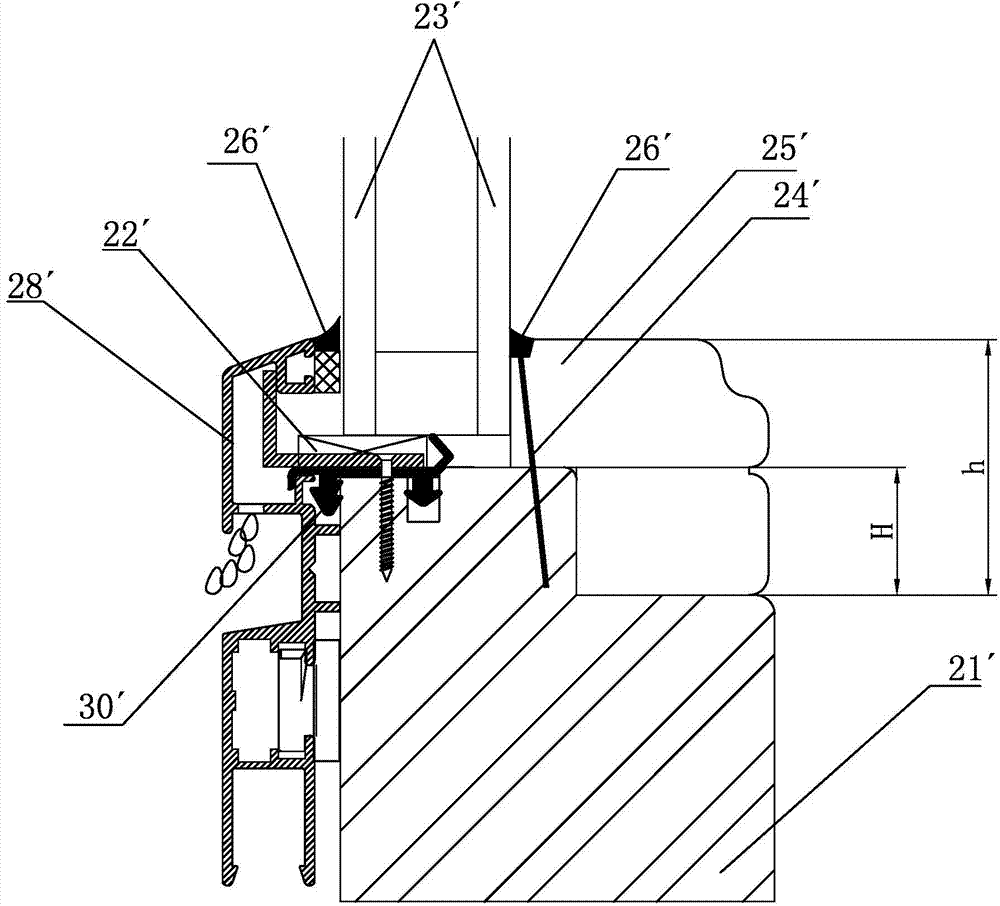

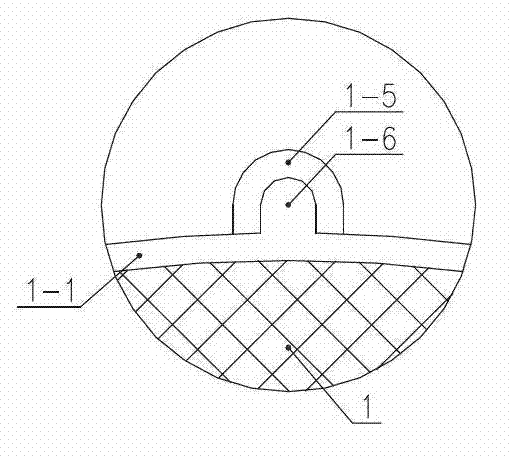

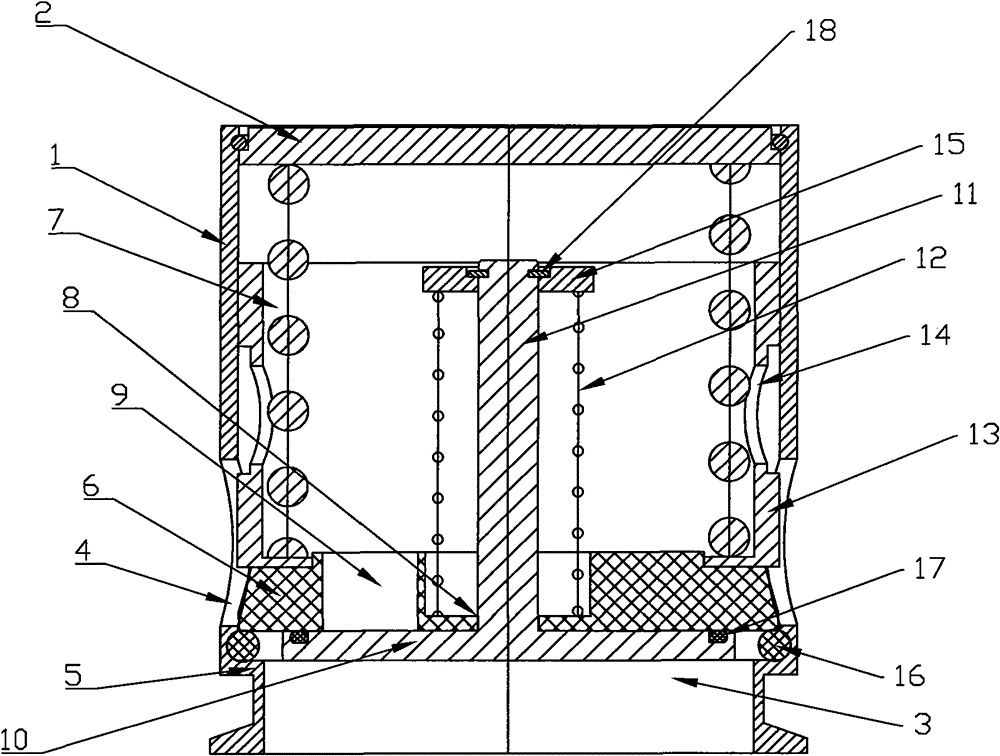

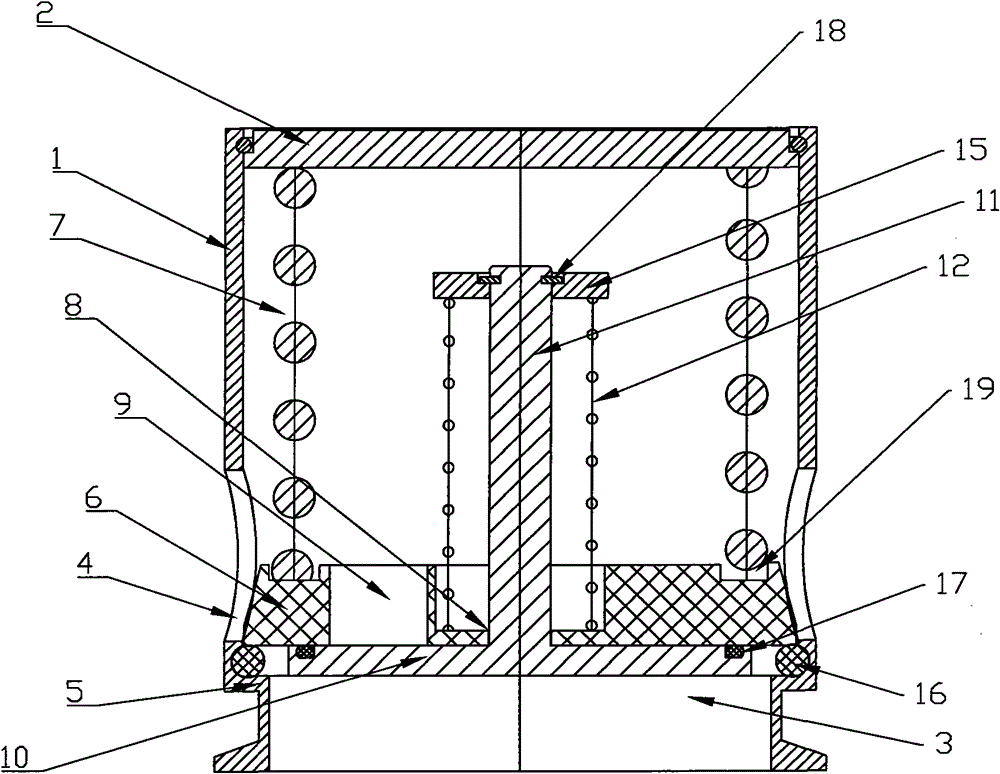

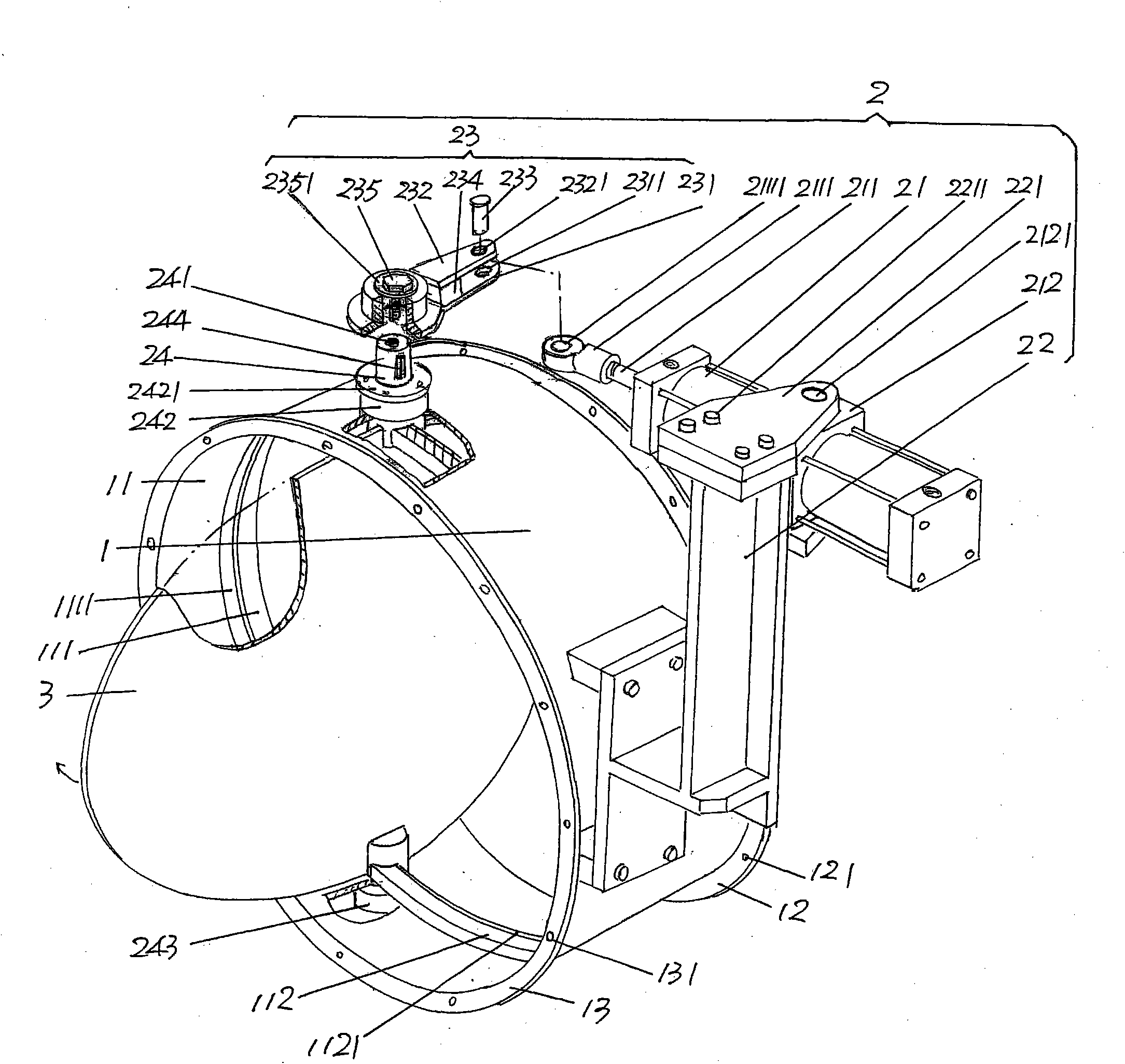

Transplanting machine cultivating arm

The present invention discloses a transplating arm of transplanting machine. Its main technical key point is that an elastic supporting component is set between the contact positions of spring and transplanting arm cover; the seedling needle is equipped with a guideway, the extension direction of said guideway is identical to the movement direction of seedling-pushing bar, the seedling-pushing end portion of seedling-pushing jaw is extended into the guideway interior. Said seedling needle is made up by using metal sheet bent component; the transplanting arm shell or transplanting arm cover is equipped with a recessed groove around its connection end face, in the recessed groove interior an elastic sealing ring is set, the height of cross-section of the described sealing ring is greater than the depth of the described recessed groove, and the seal between the connecting end faces of transplanting arm shell and transplanting arm cover is reliable.

Owner:郭保可

Leakless wear pump sealer

Owner:江雪忠

Cut-off valve structure for fast opening or closing

InactiveCN1343846ALarge circulationAchieve leak-proof and durable effectOperating means/releasing devices for valvesLift valveConvex sideEngineering

A cut-off valve structure operated fastly is composed of valve core and valve seat. The part of valve core opposite to the valve seat appears as almost conic shape, on which there is a lining sleeve.The said lining sleeve has concave surfaces and on the opposite surface of valve seat there are convex surfaces. They are matched for sealing. Its advantages are high flow and good sealing. Lifting up valve core by a small distance can fully open the valve.

Owner:陈西火

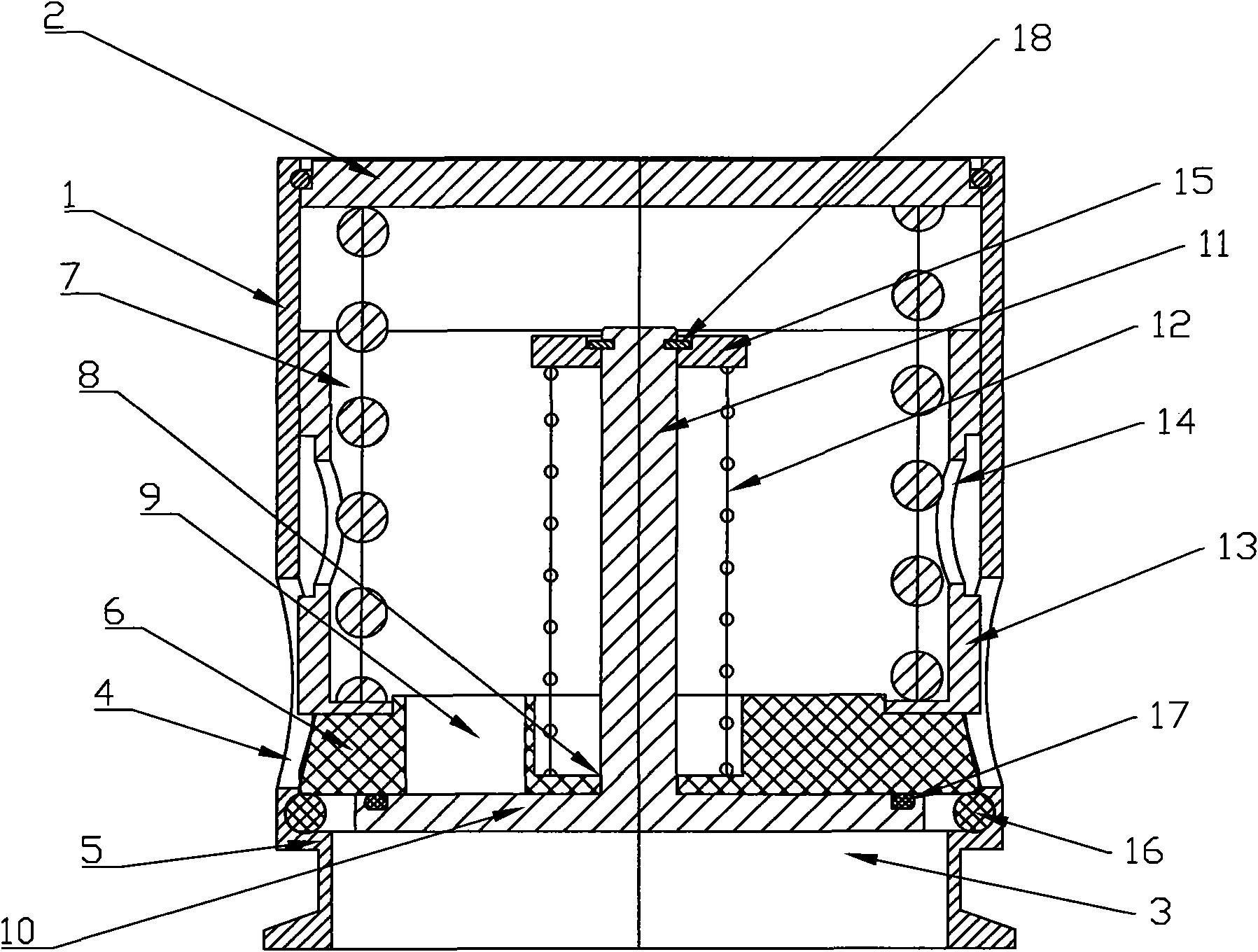

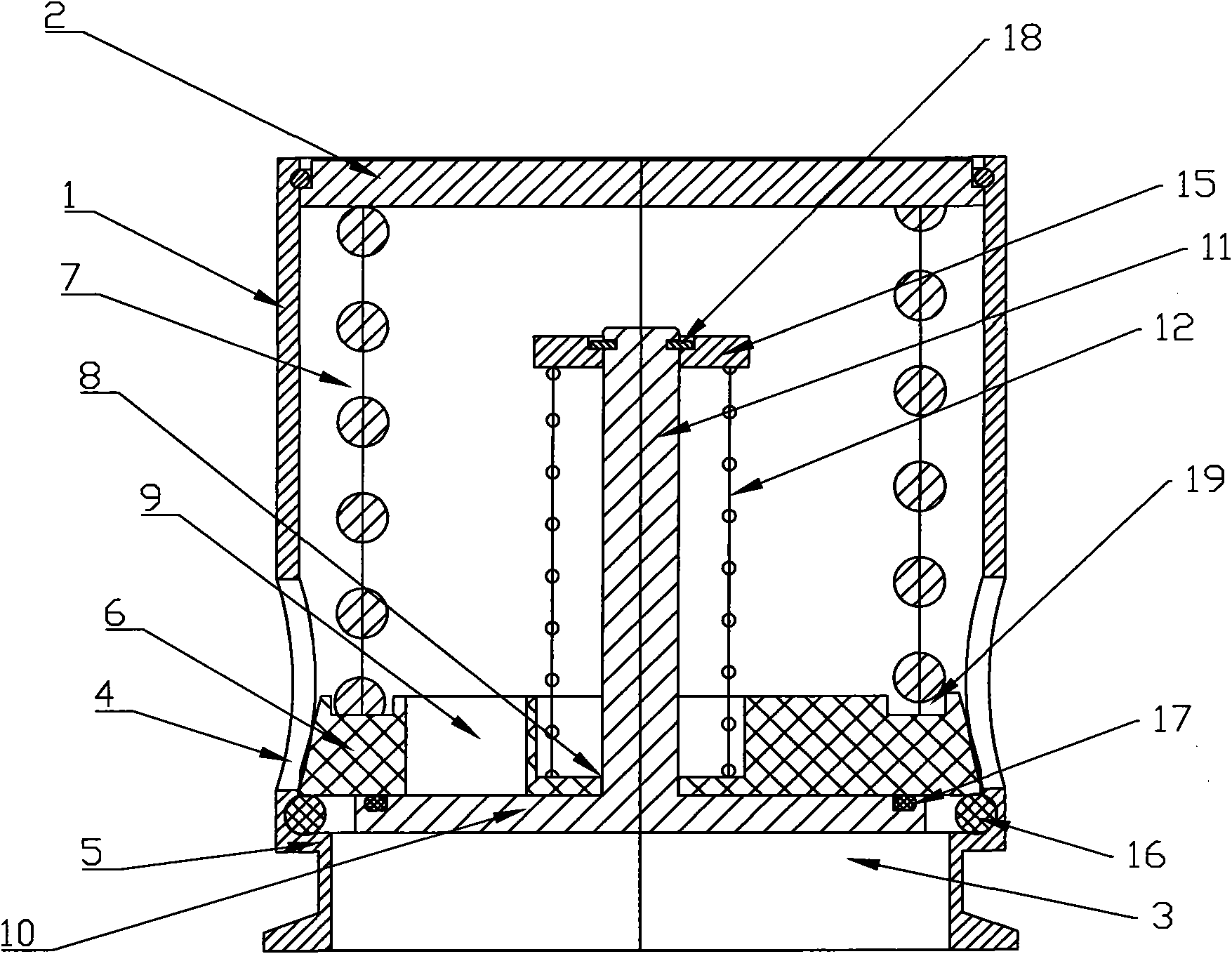

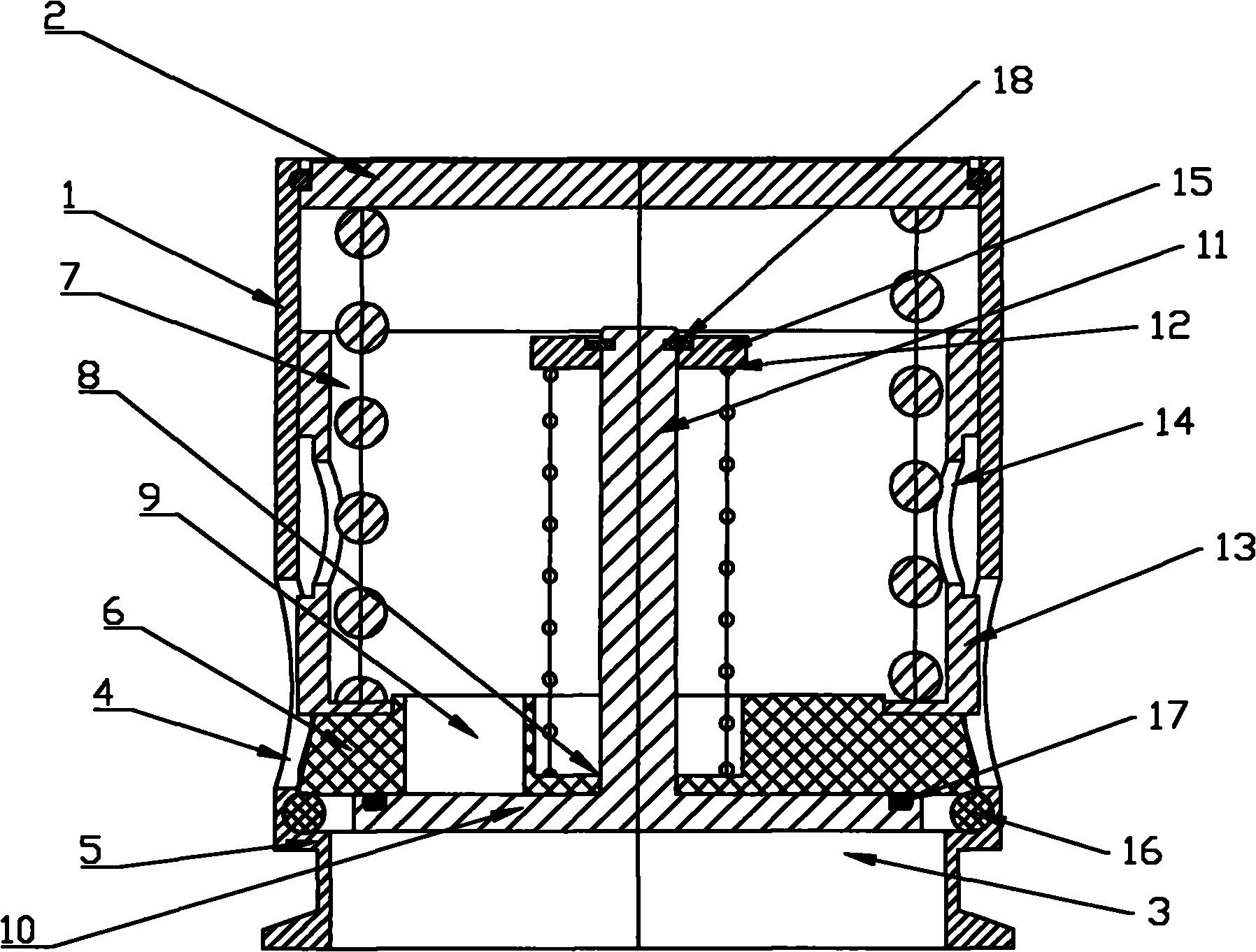

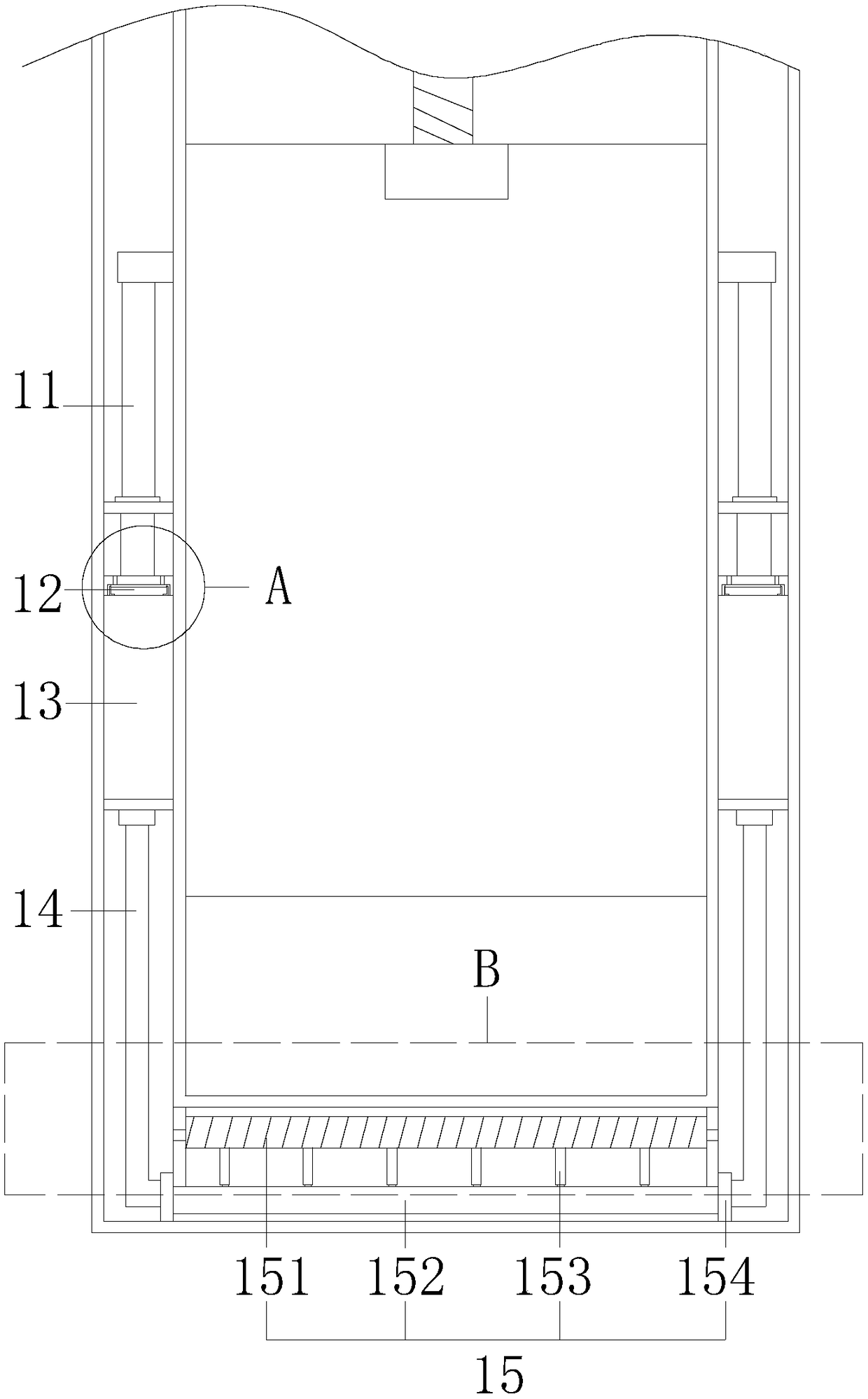

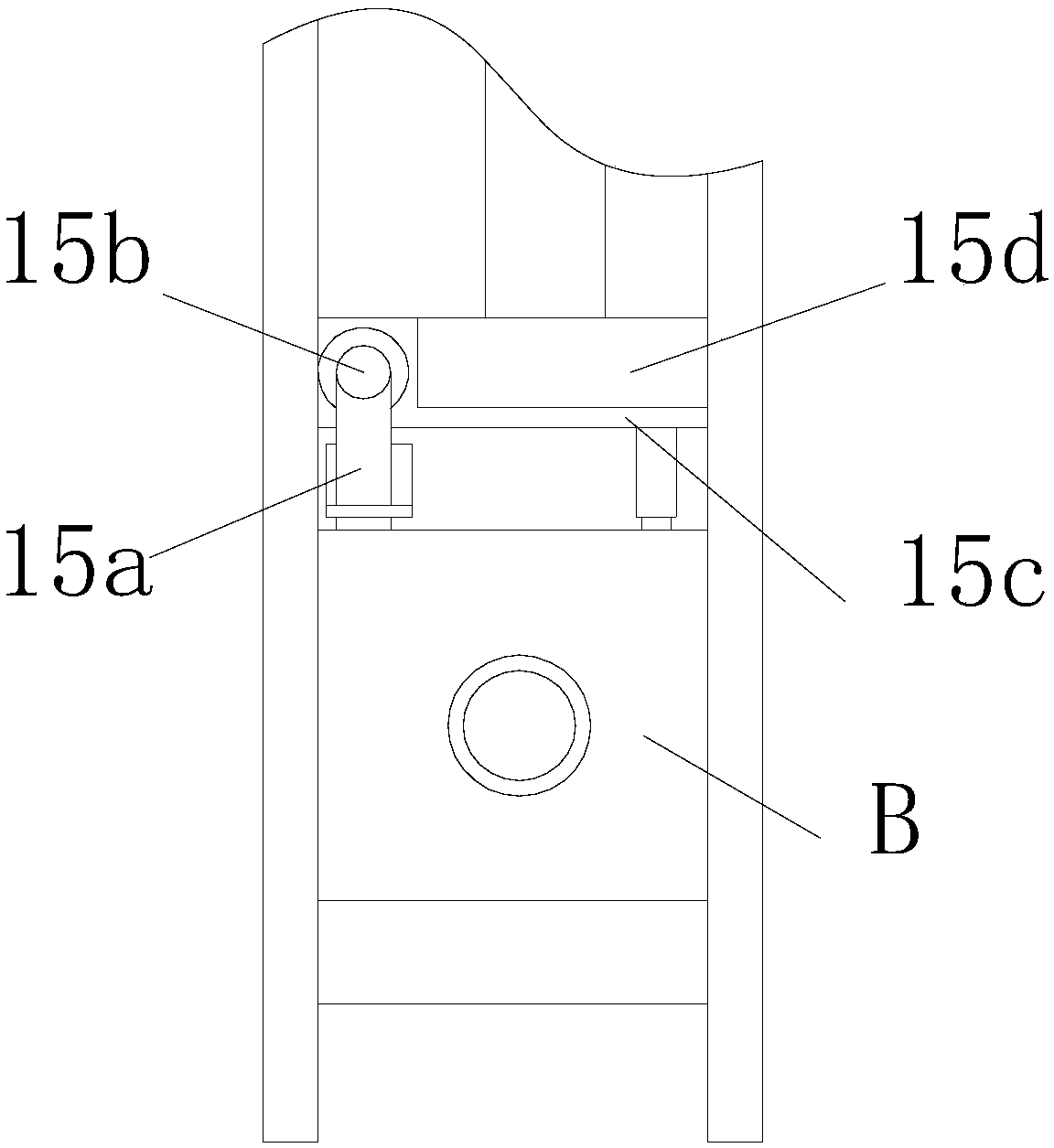

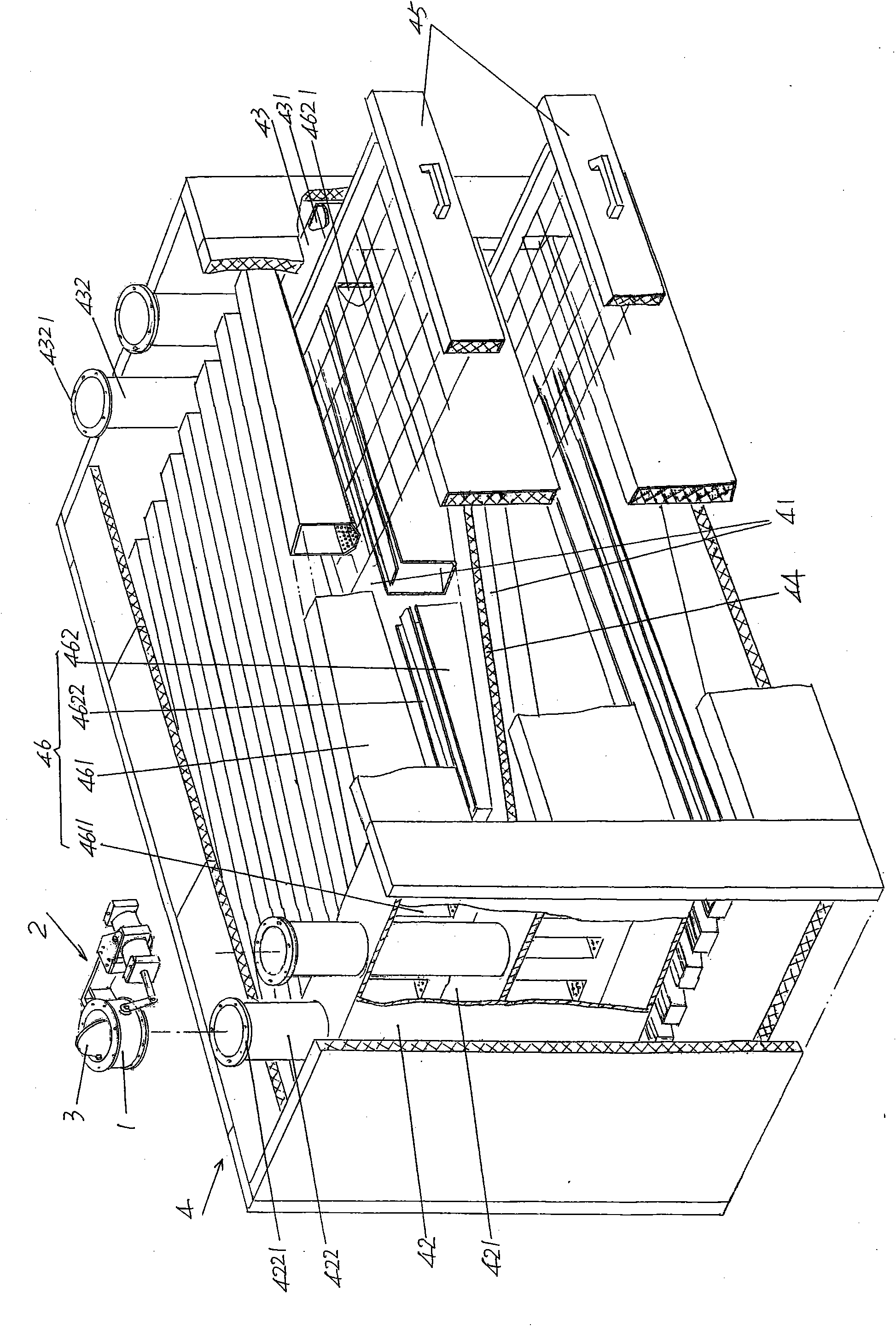

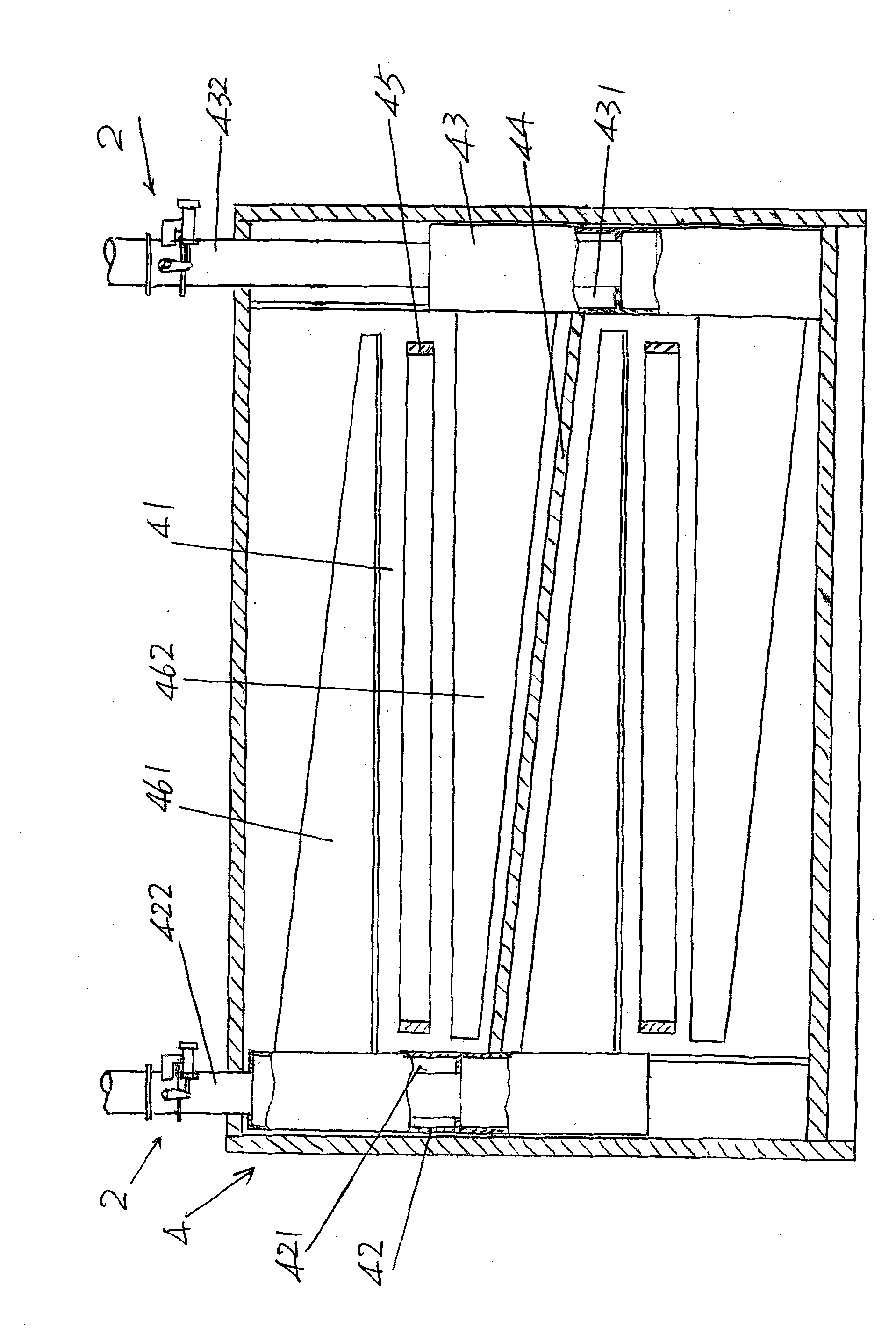

Electronic product high-temperature sintering furnace

InactiveCN110425886AShorten the timeImprove efficiencyElectric heating for furnacesFurnace crowns/roofsBrickSilicon

The invention provides an electronic product high-temperature sintering furnace and belongs to the technical field of electronic kiln furnace facilities. The electronic product high-temperature sintering furnace comprises a furnace body, the center of the furnace body is provided with a furnace cavity, silicon molybdenum bar left heating units and silicon molybdenum bar right heating units are distributed to the rear end of the furnace cavity from the front end of the furnace cavity at the positions corresponding to the left side and the right side of the furnace cavity, the electronic producthigh-temperature sintering furnace is characterized by further comprising left plug brick mechanisms, right plug brick mechanisms, left extraction release bricks and right extraction release bricks,the left plug brick mechanisms and the right plug brick mechanisms are built inside furnace top bricks at the positions corresponding to the silicon molybdenum bar left heating units and the silicon molybdenum bar right heating units, the left extraction release bricks and the right extraction release bricks are located at the top of the furnace body, the lower ends of the silicon molybdenum bar left heating units penetrate through the left plug brick mechanisms and stretch to the bottom of the furnace cavity, the upper ends of the silicon molybdenum bar left heating units penetrate through the left extraction release bricks from bottom to top and poke out of the upper surfaces of the left extraction release bricks, the lower ends of the silicon molybdenum bar right heating units penetratethrough the right plug brick mechanisms and stretch to the bottom of the furnace cavity, and the upper ends of the silicon molybdenum bar right heating units penetrate through the right extraction release bricks from bottom to top and poke out of the upper surfaces of the right extraction release bricks. By means of the electronic product high-temperature sintering furnace, the engineering cost of silicon molybdenum bar replacement is reduced, and the sintering efficiency is improved.

Owner:SUZHOU HUIKE EQUIP CO LTD

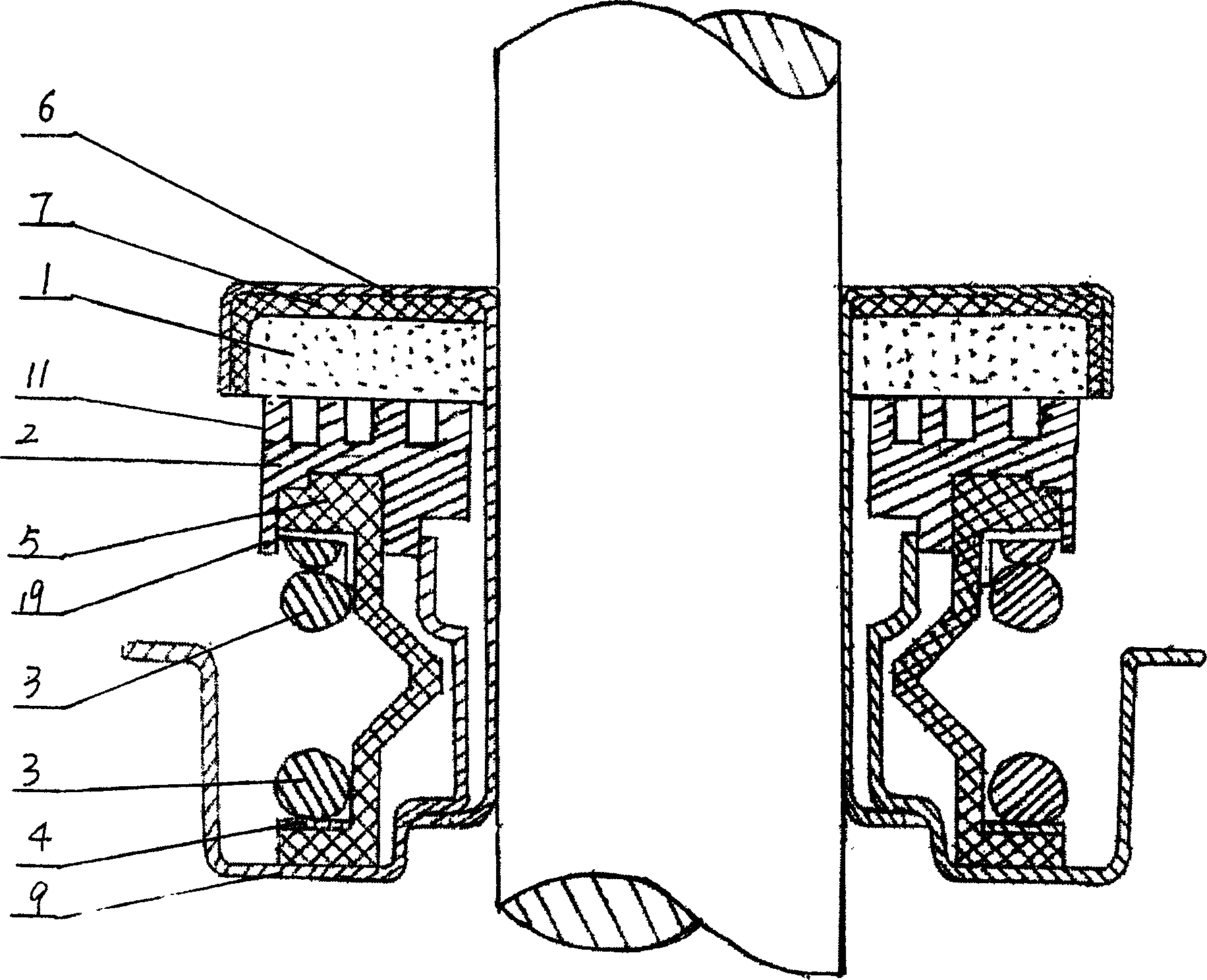

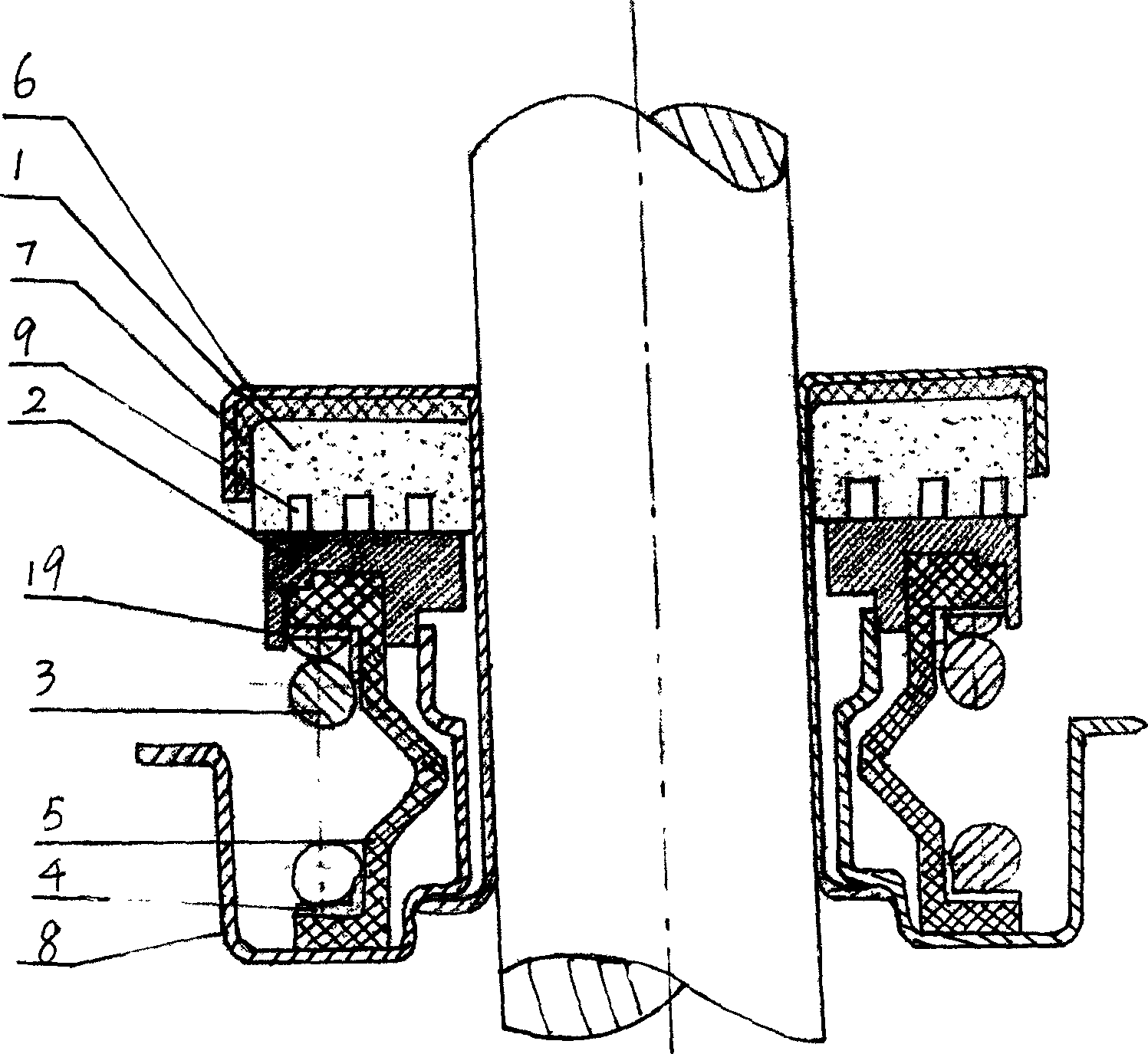

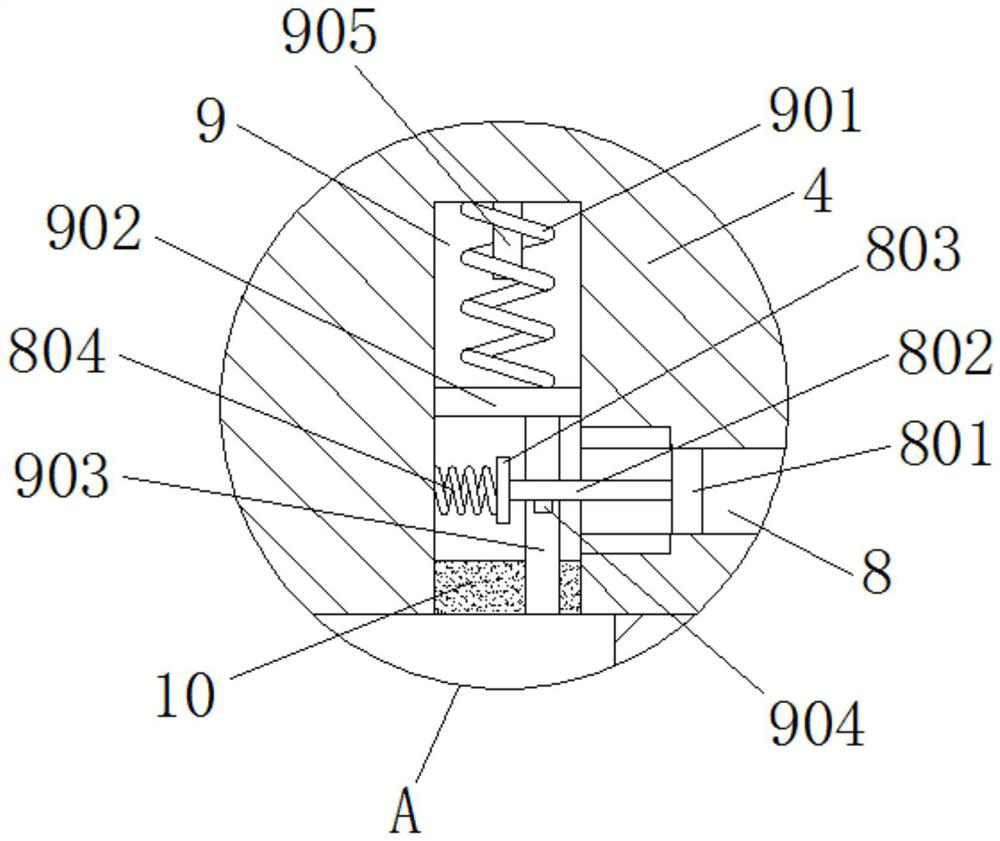

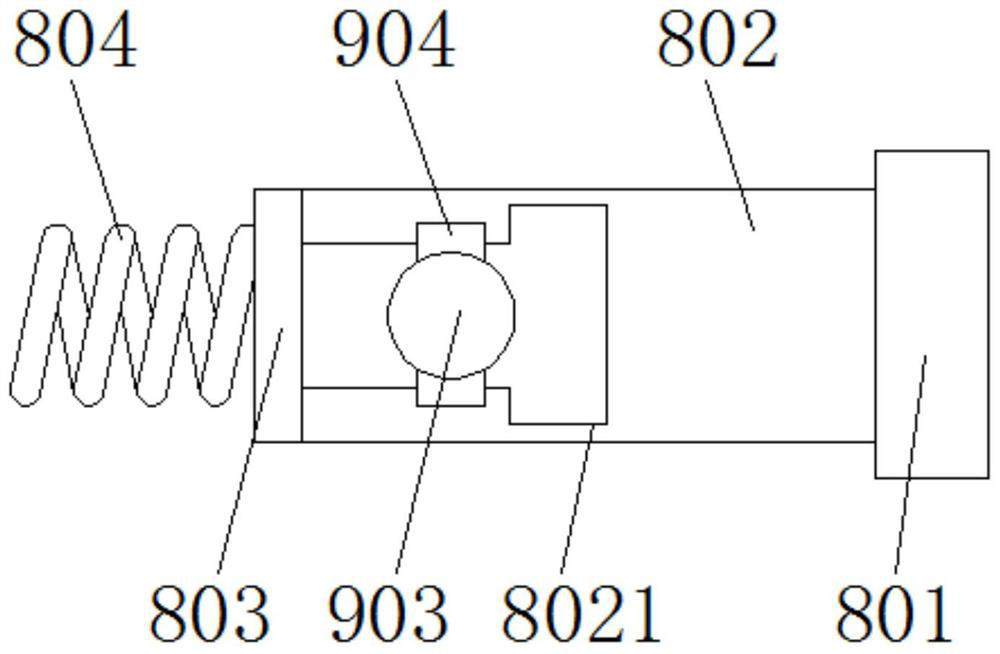

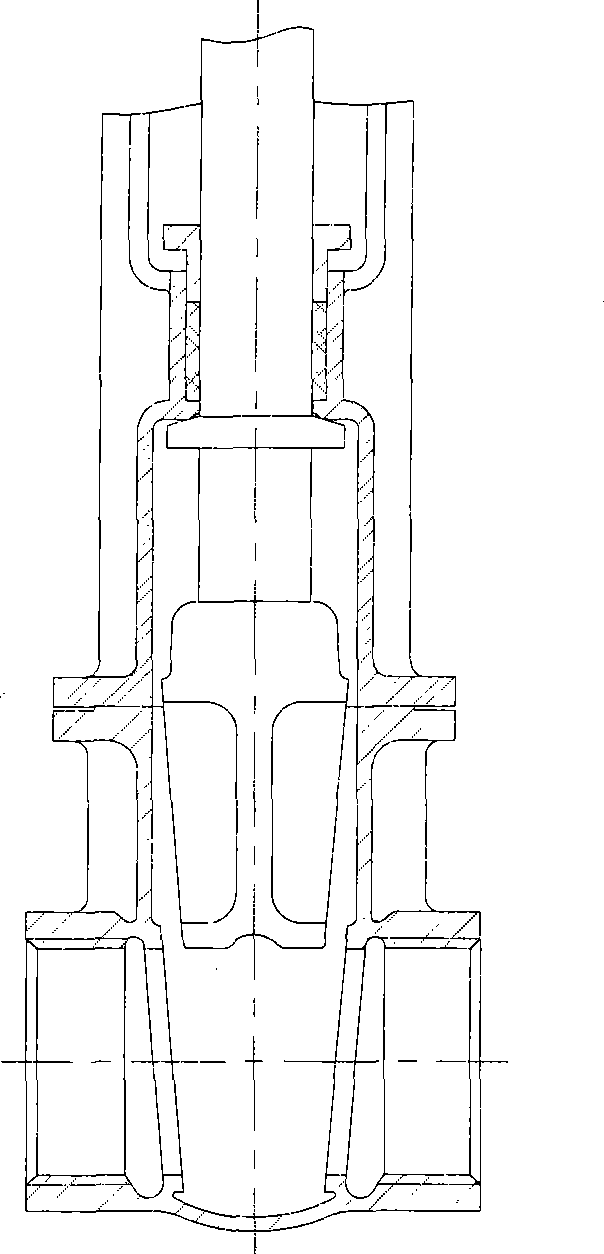

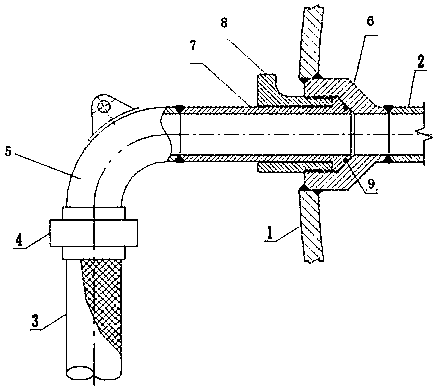

Dual-use vacuum relief valve

ActiveCN101943283AWill not affect the sealing effectExtended service lifeEqualizing valvesSafety valvesEngineeringRelief valve

A dual-use vacuum relief valve comprises a valve body and a spool, wherein the valve body is provided with a cylindrical shell and a sealing cover plate; a first gas port is formed on the other end of the cylindrical shell, a second gas port is formed on the side wall of the cylindrical shell, a sealing boss is formed on the inner wall of the cylindrical shell and between the two gas ports; the spool comprises a first valve plate component and a second valve plate component; the first valve plate component contains a first valve plate and a first bias spring; a guide hole and a vent hole are formed on the first valve plate; the second valve plate component contains a second valve plate and a second bias spring, the center of the second valve plate is fixedly connected with a guide post; and the second gas port is near the edge of the first valve plate. The invention has the advantages of simple structure and convenient processing and assembling.

Owner:上海远安流体设备科技有限公司

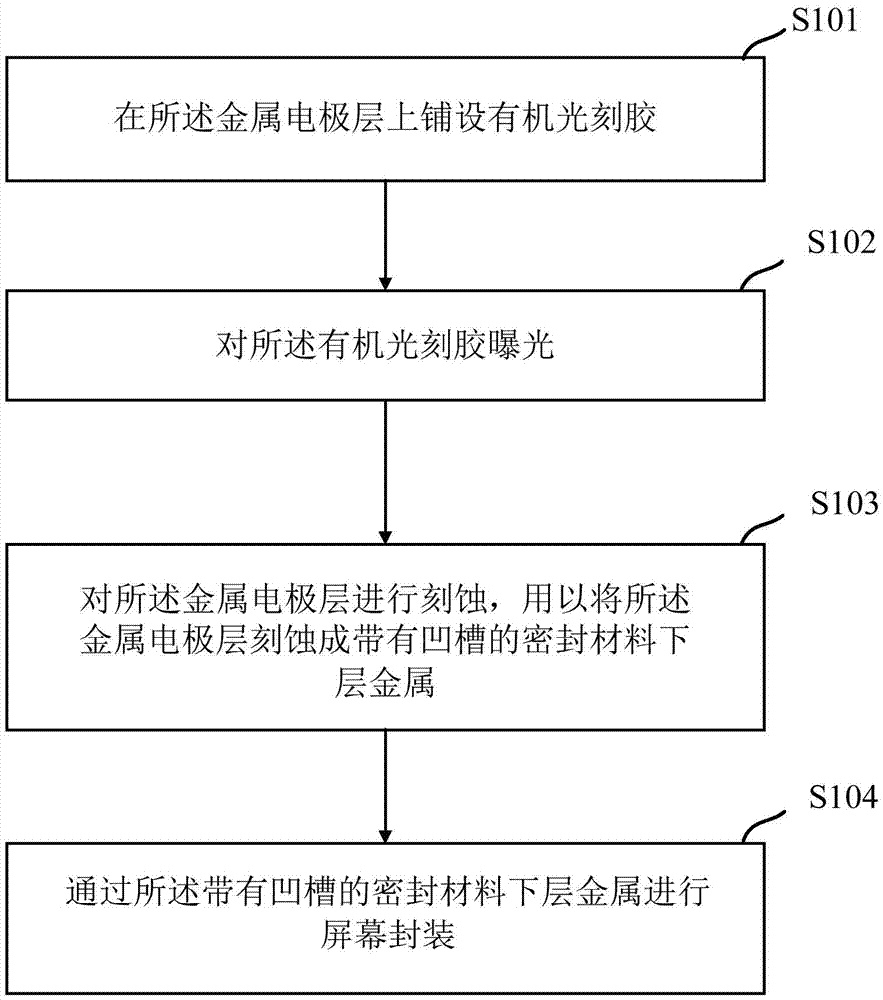

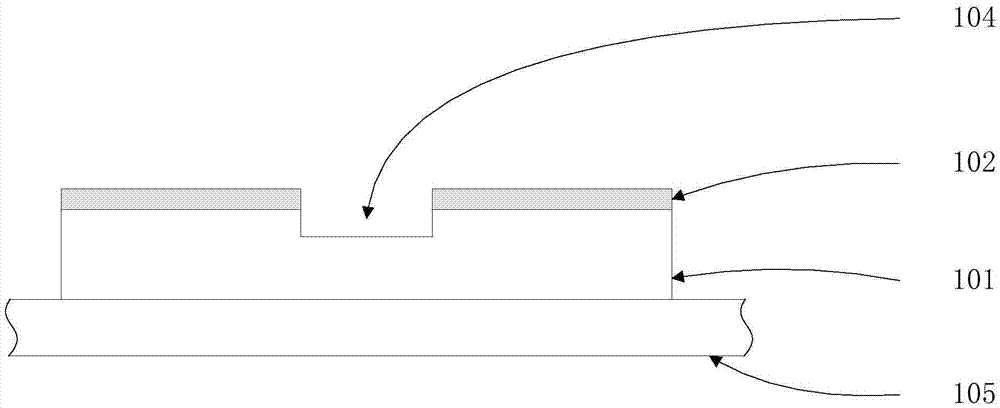

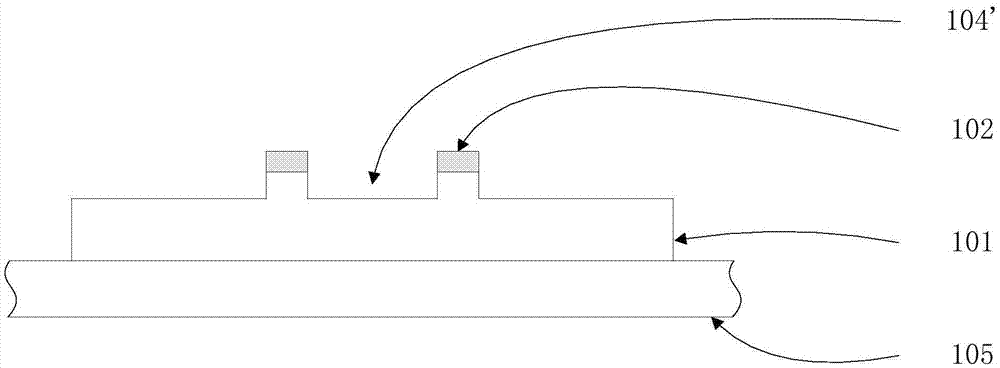

Screen package method

ActiveCN106920889AWill not affect the sealing effectImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringGlass cover

The embodiment of the invention provides a screen package method. During fabricating sealing material lower-layer metal by a photoetching method, a groove is formed in a surface of the sealing material lower-layer metal, so that the flowing of the sealing material can be limited due to the construction of the groove when a glass cover plate and a glass substrate are packaged by the sealing material lower-layer metal with the groove, the sealing effect of screen package cannot be affected even due to presence of defects or bubbles in the sealing material printed on the glass cover plate by a silk-screen printing mode, the yield of the produced screen is improved, and the service lifetime of the screen is enabled not to be affected by the package effect.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

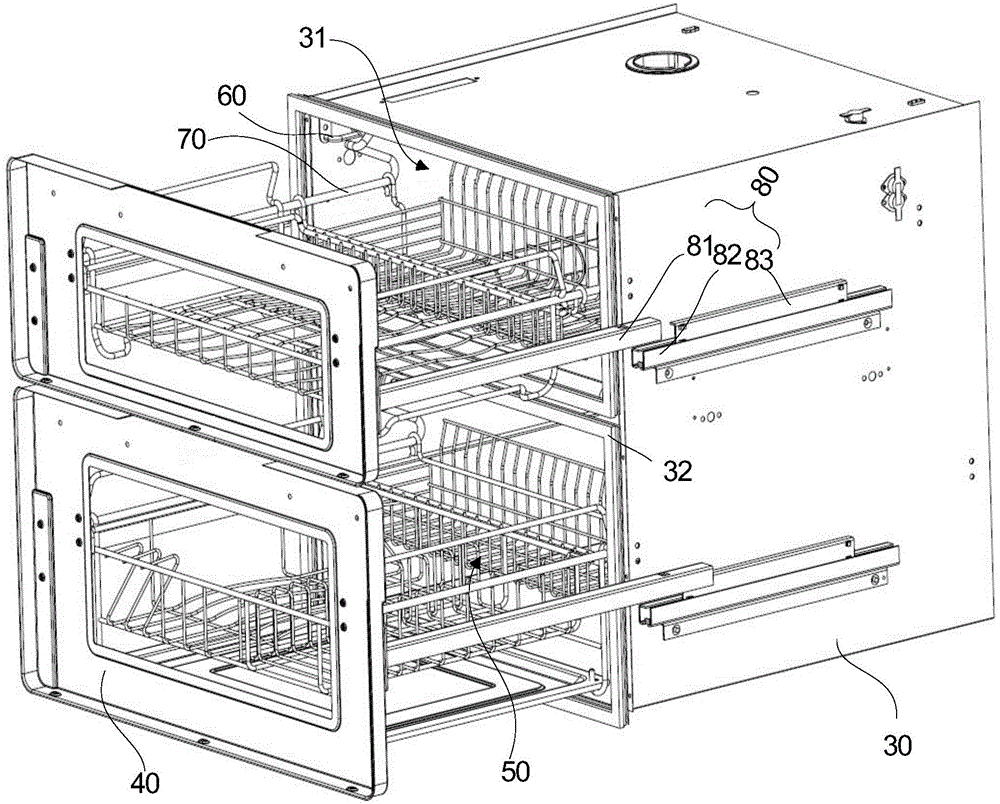

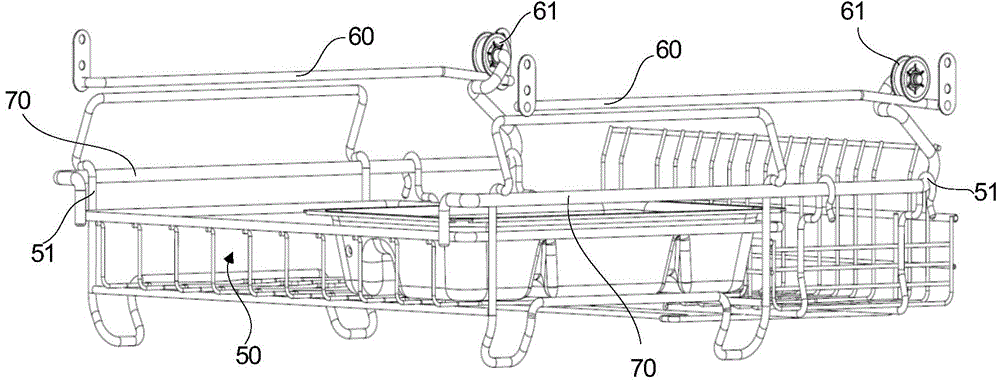

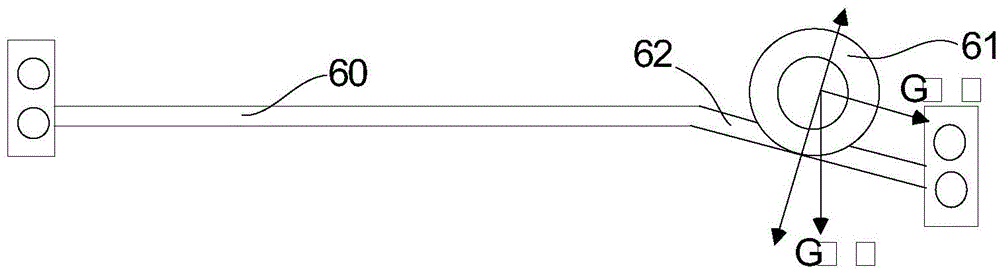

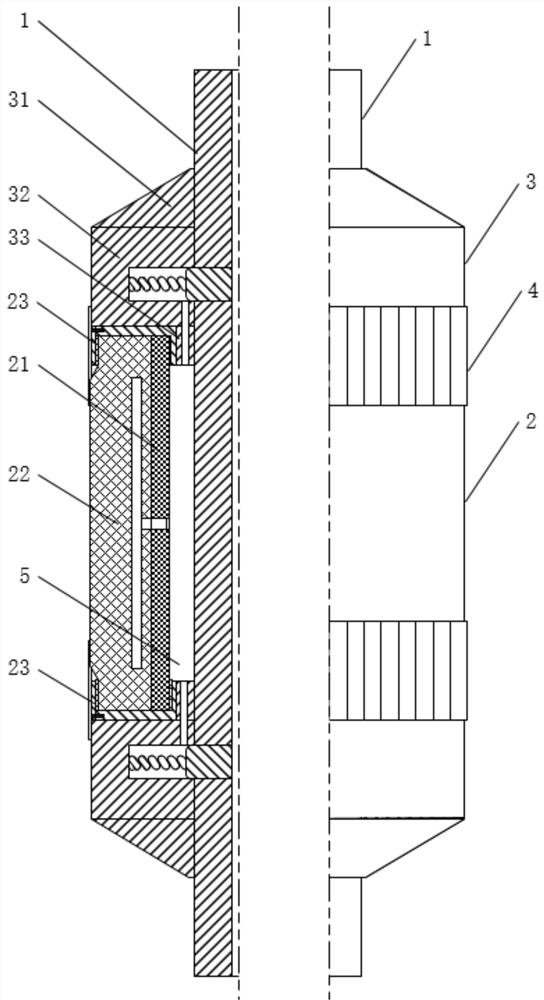

Household appliance

InactiveCN105770936AClose smoothlyImprove experienceLavatory sanitoryKitchen cabinetsEngineeringMechanical engineering

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

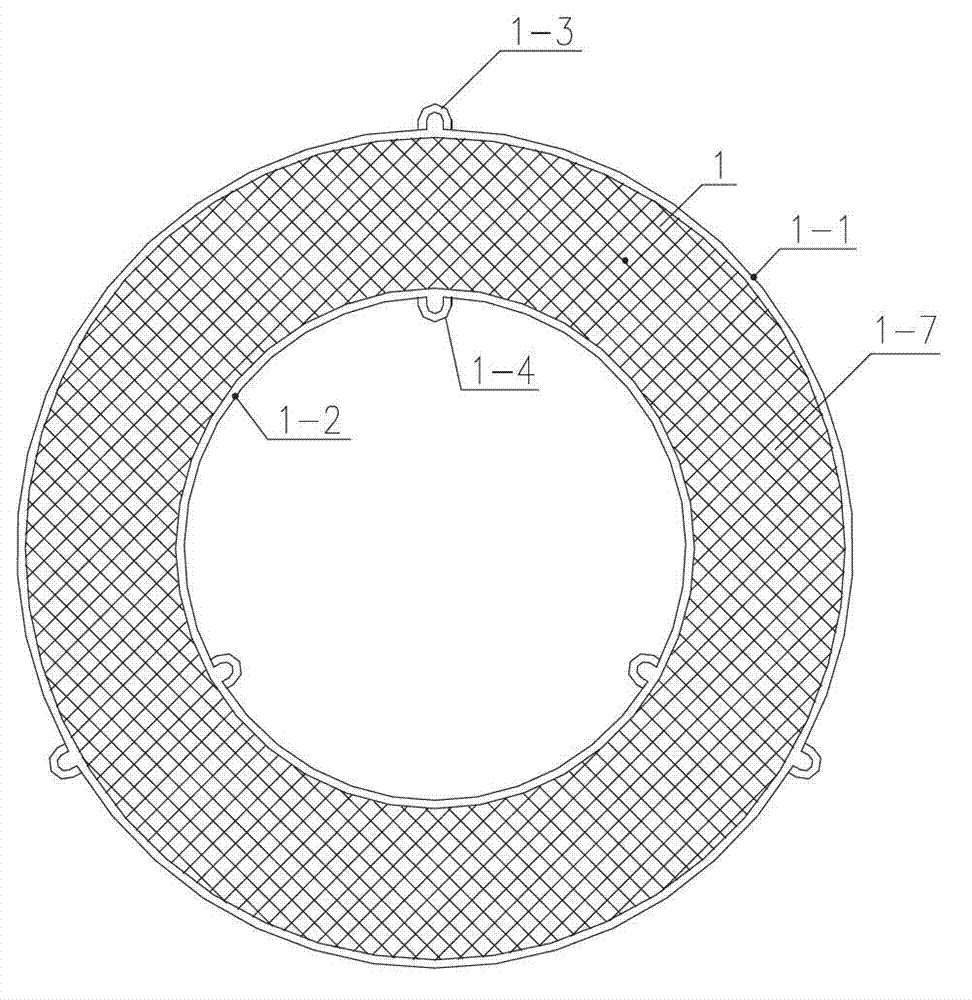

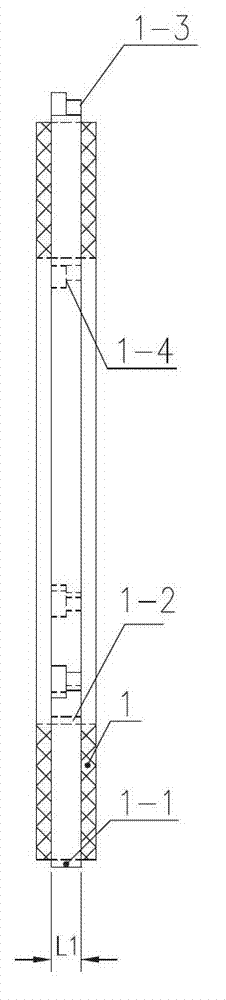

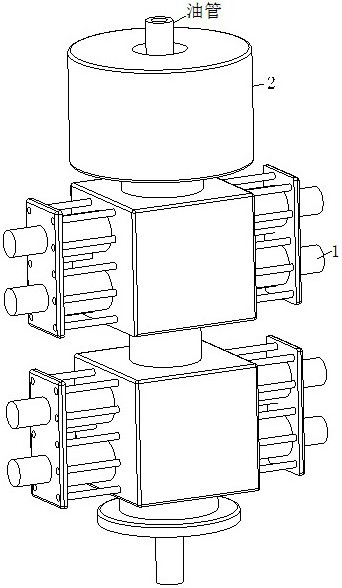

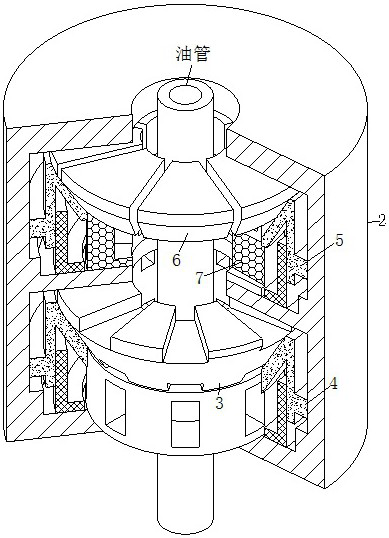

External casing packer

The invention relates to the technical field of oil and gas drilling, well completion, well cementation or well logging, in particular to an external casing packer. The external casing packer comprises a center pipe, a rubber sleeve and a rubber sleeve fixing ring, the rubber sleeve is arranged outside the center pipe in a sleeving mode, the rubber sleeve fixing ring is fixed to the center pipe and fixedly connected with the two ends of the rubber sleeve, and an annular space is reserved between the rubber sleeve and the center pipe. The rubber sleeve comprises an inner sleeve made of an elastic material which does not expand when encountering liquid and an outer sleeve made of an elastic material which expands when encountering oil, a first flow channel leading to the annular space is formed in the rubber sleeve fixing ring, and a sealing valve element is arranged at an inlet of the first flow channel; and the inner sleeve comprises an inner sleeve body, a radial through hole is formed in the axial center of the inner sleeve body, a fracturing sealing film is arranged at the end, facing the center pipe, of the through hole, and a finger-shaped reed is arranged at the joint of therubber sleeve and the rubber sleeve fixing ring in a surrounding mode. The external casing packer can prevent the rubber sleeve from bursting, tearing and extruding, and the packing effect is improved.

Owner:DONGYING XIN HUALIAN PETROLEUM MACHINERY

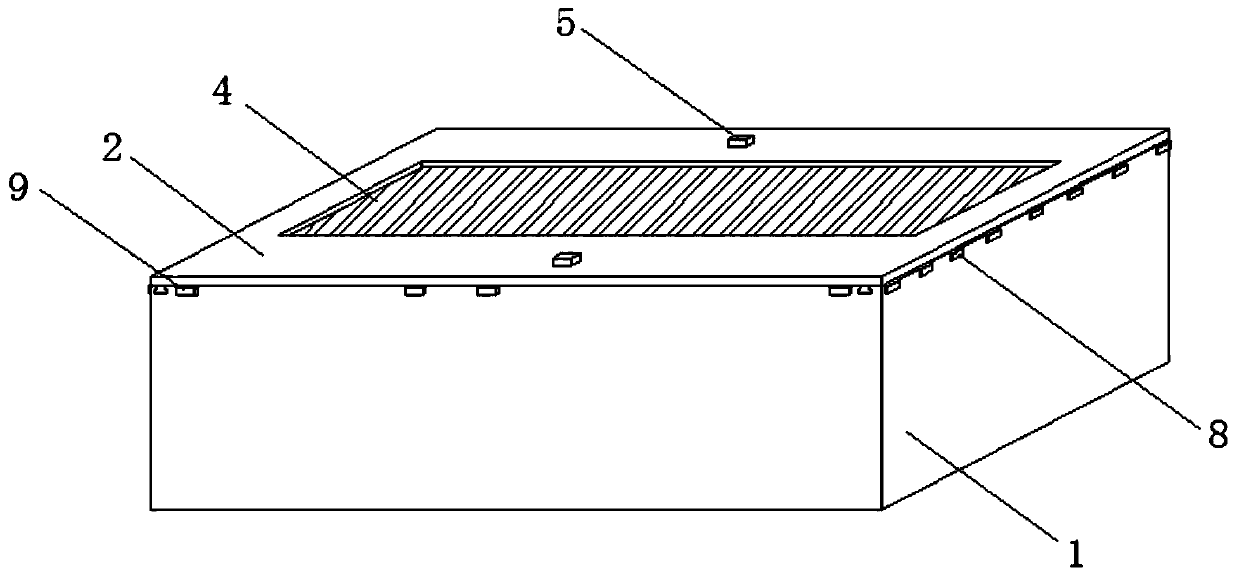

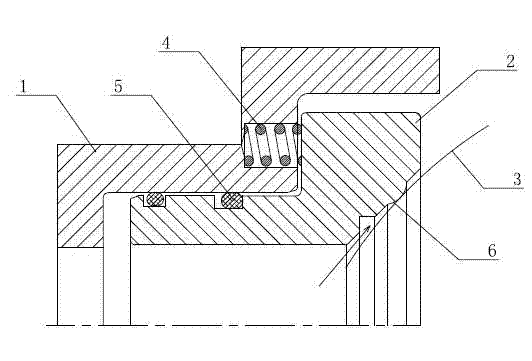

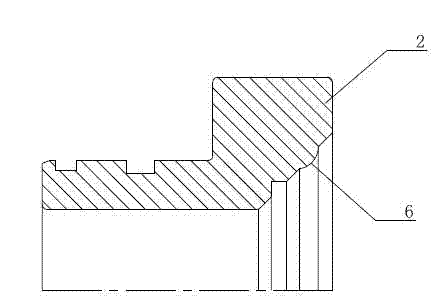

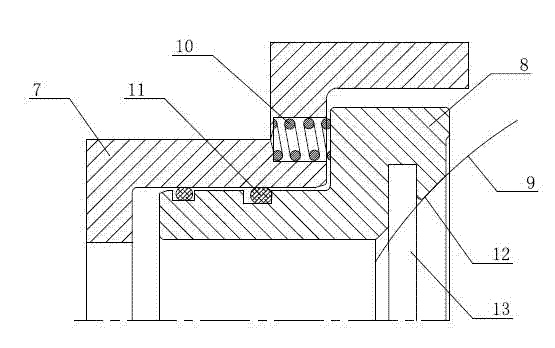

Environment-friendly packaging box

InactiveCN109911393AAvoid bringing out spillsAvoid Accidental SplashesRemovable lids/coversContainers for heating foodEngineeringRice grain

The invention discloses an environment-friendly packaging box, and belongs to the field of environment-friendly package. The environment-friendly packaging box is characterized in that through the design that an environment-friendly box cover can slide on the upper end of an environment-friendly box boxy, in the process of opening the environment-friendly box cover, rice grains bonded on the innerend of the environment-friendly box cover are blocked by the side wall of the environment-friendly box body, and therefore the rice grains and vegetable pieces are prevented from being scattered andleaked during bringing out, food contained in the environment-friendly box body can be effectively prevented from being accidently splashed, and the experience consumption of a consumer can be greatlyimproved. In addition, a self-heating structure is arranged at the inner bottom end of the environment-friendly box boxy, and is convenient to carry when a user goes out, food in the environment-friendly box body can be heated at any time, the sharp end on the lower end of a tip end screw plug is used for puncturing a liquid storage bag capable of being punctured, normal-temperature tap water inthe liquid storage bag capable of being punctured flows out to have a reaction with CaO powder to generate heat, generated heat can rapidly heat food above a heat insulation heat partition board, thefast food is achieved, the environment-friendly packaging box can be recycled and re-machined, and the environment-friendly energy-saving idea is achieved.

Owner:苏德祥

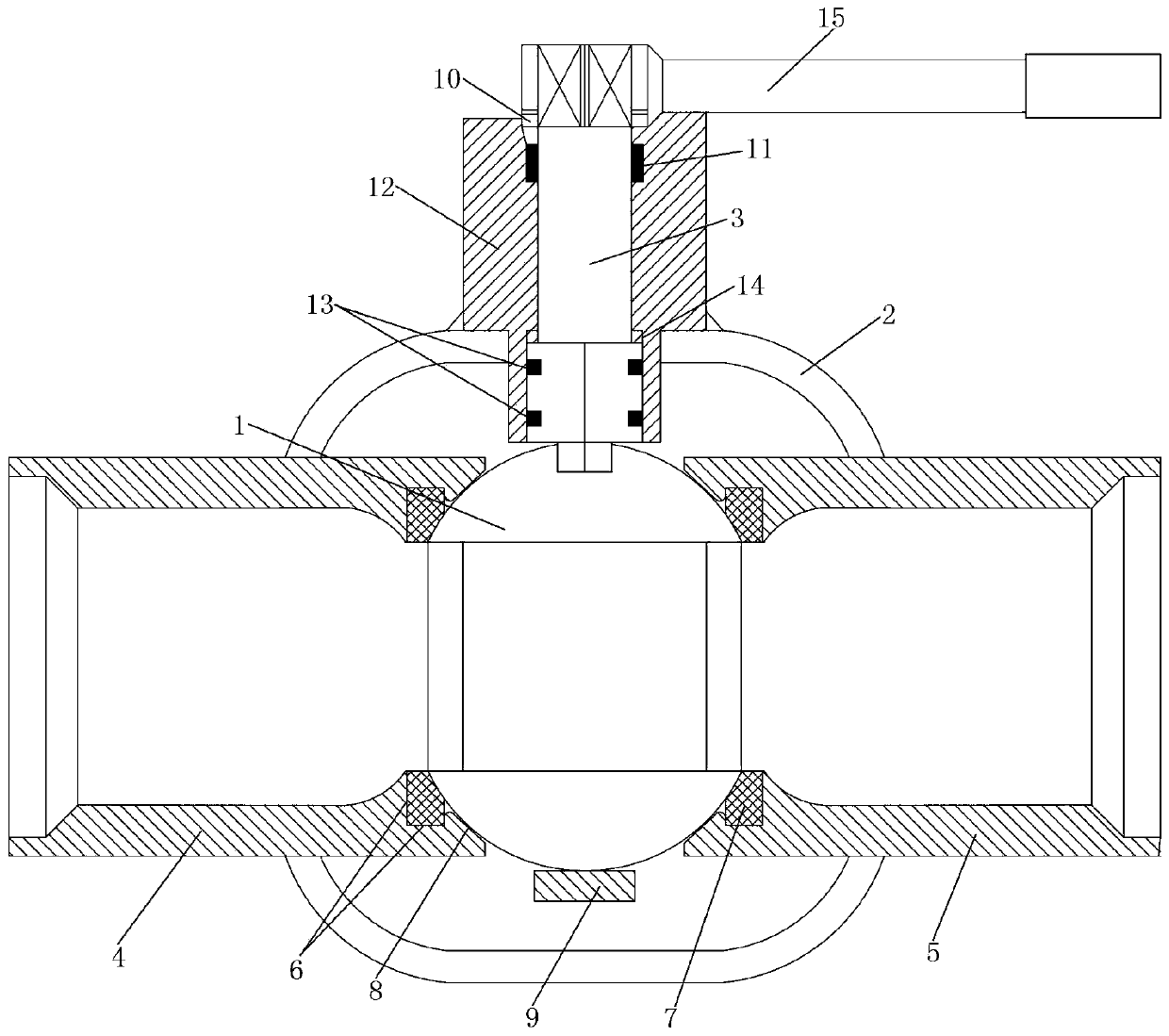

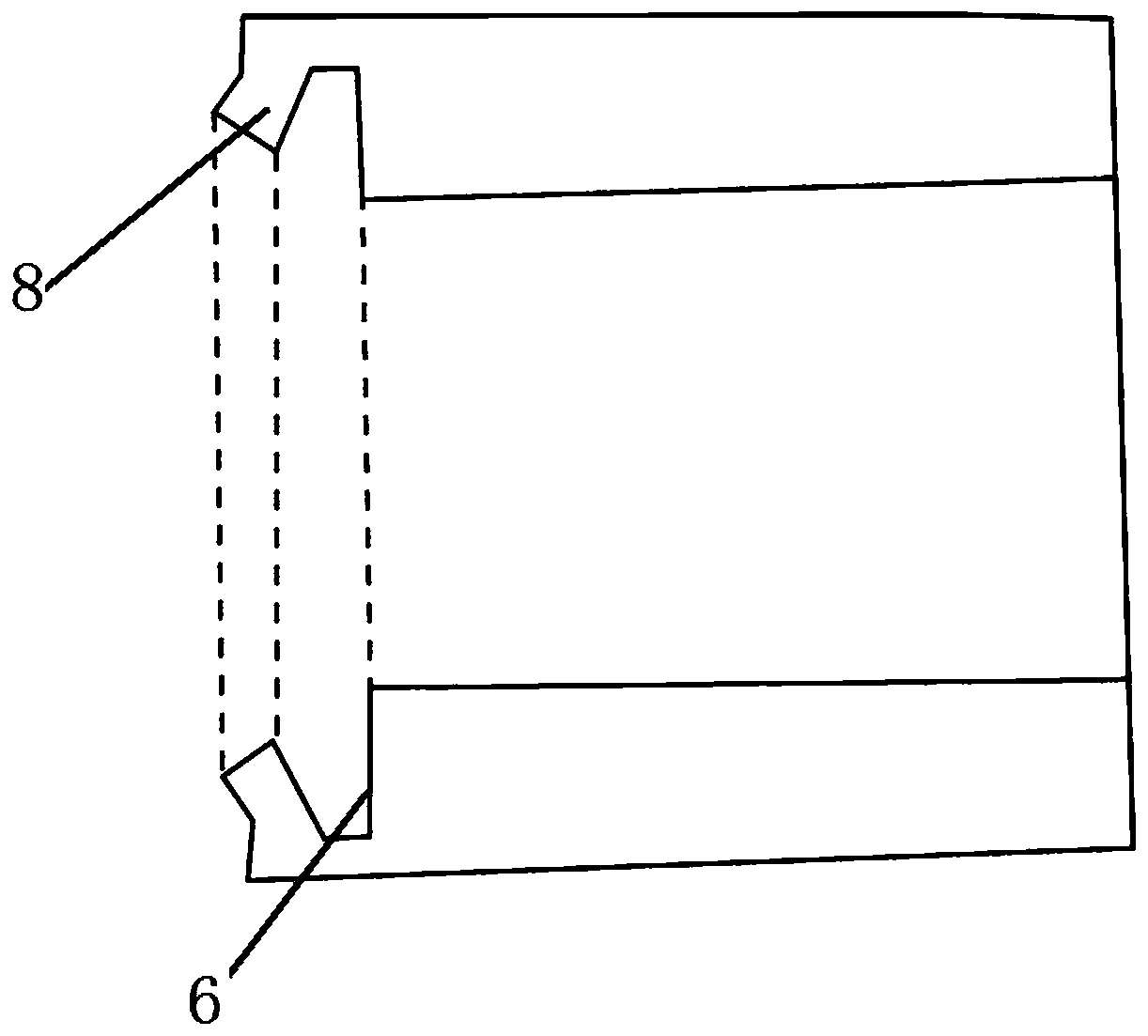

High-temperature-resistant ball valve

The invention discloses a ball valve which comprises a valve body, a valve seat and a ball body, wherein a spring is arranged between the valve body and the valve seat; an O-shaped seal ring is arranged between the valve body and the valve seat; an insertion slot is formed on the valve seat; a seal plug-in element is matched with the insertion slot; the valve seat is also provided with a seal protrusion; the end surface of the seal protrusion butts against the surface of the ball body so as to form a seal surface of the ball valve; and the front side of the seal surface is provided with an impurity containing groove. According to the invention, the impurity containing groove is formed on the valve seat, thus impurities can fall into the impurity containing groove, the seal effect can not be influenced, and because the impurity containing groove is formed, the seal protrusion has elasticity, and further the seal effect of the ball valve is improved.

Owner:GASKET SUZHOU VALVE COMPONENTS

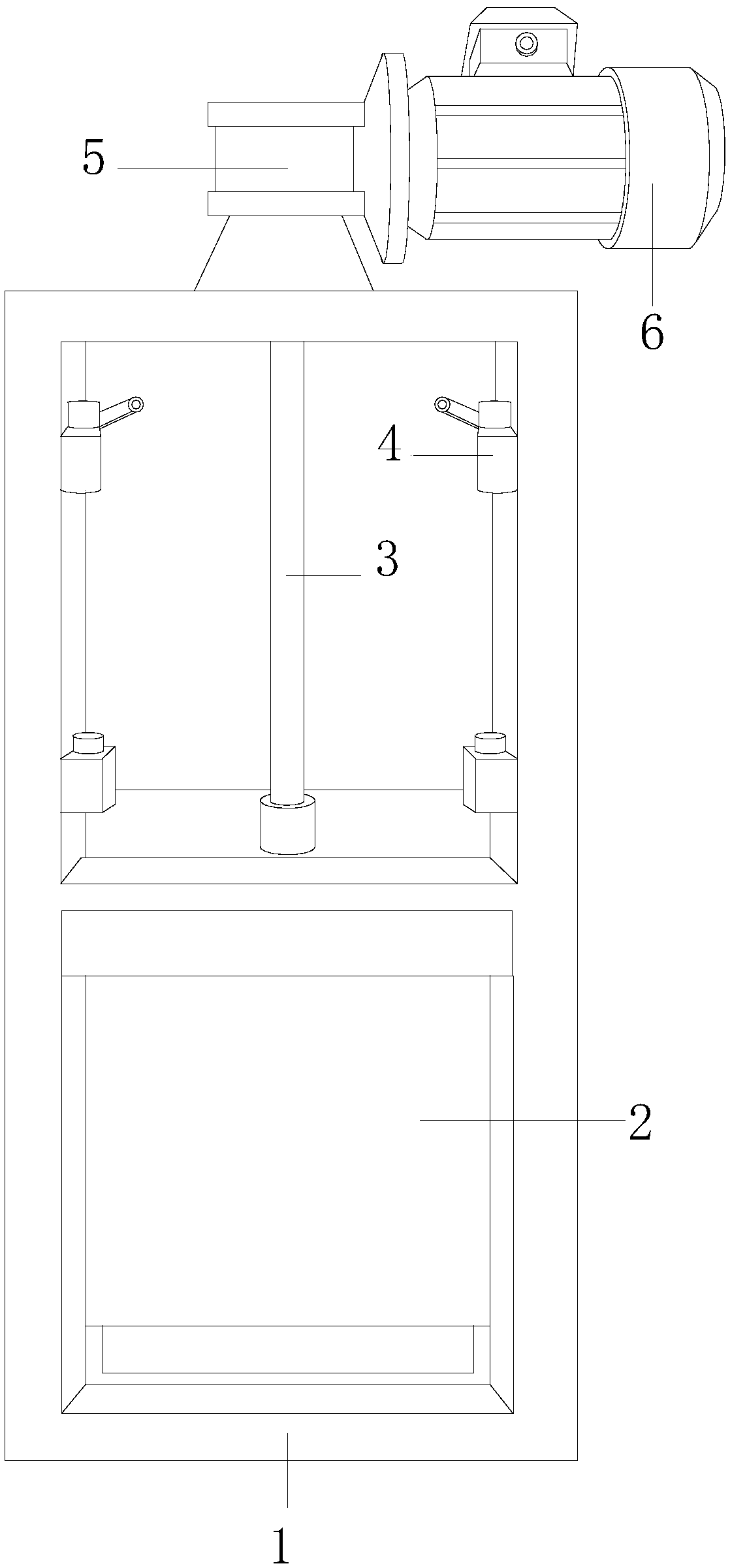

Irrigation gate of farmland canal for preventing cutting of water stop belt in internal groove

InactiveCN109083113ADoes not affect the effect of water insulationWill not affect the sealing effectConstructionsIrrigation ditchesFixed frameDrive shaft

The invention discloses an irrigation gate of a farmland canal for preventing cutting of a water stop belt in an internal groove. The irrigation gate of the farmland canal for preventing cutting of the water stop belt in the internal groove structurally comprises a fixed frame body, a water stop plate, a lifting screw, four limiting switches, a gear case and a driving motor. The water stop plate is vertically embedded into isolation grooves in the left and right sides of the fixed frame body, and a rotating block at the bottom end of the lifting screw is welded and fixed to the center of the top of the water stop plate. The limiting switches are arranged in pairs on the inner wall of the fixed frame body. A fixed flange on the left side of the driving motor is arranged on the right side ofa drive shaft of the gear case. In conclusion, after improvement is completed, gravel of the water stop belt is removed for cutting prevention protection, and meanwhile, the method of gradual meshingis adopted to ensure that no other impurities exist in a sealing contact clearance to affect the effect of water insulation.

Owner:李莲妹

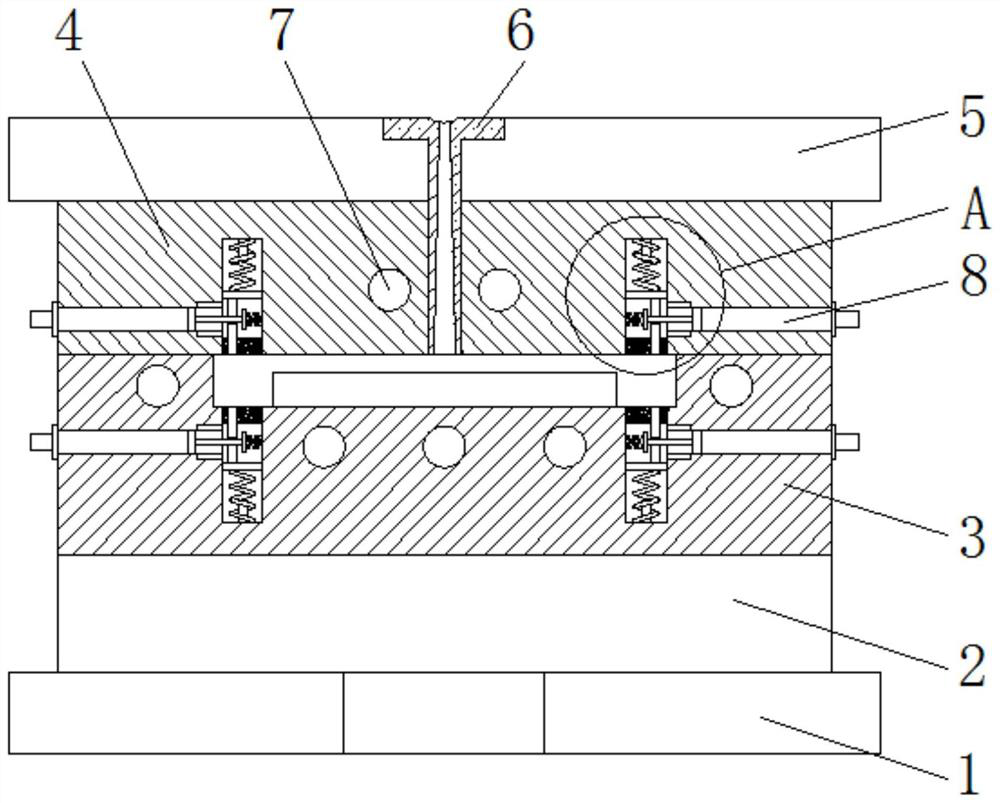

High-precision injection mold

The invention relates to the field of injection molding equipment, and discloses a high-precision injection mold. The high-precision injection mold comprises a lower die holder plate, an isolation plate, a lower die core fixing plate, an upper die core fixing plate and an upper die holder plate, wherein the isolation plate is fixedly mounted at the top of the lower die holder plate, the lower moldcore fixing plate is fixedly mounted at the top of the isolation plate, and the upper mold core fixing plate is fixedly mounted at the bottom of the upper die holder plate. According to the high-precision injection mold, through the structural design of a first sliding groove and a second sliding groove which communicate with each other in the lower die core fixing plate and the upper die core fixing plate, during demolding, water is injected into the first sliding groove for pressurization, so that a first piston plate reaches a through hole, the water pressure in the second sliding groove is increased, and a second piston plate drives an inserting rod to move upwards; and the injected water directly acts on the mold adhered to the upper die core fixing plate through a packing block, sothat the mold is separated from the upper die core fixing plate, and the problem that the quality of the mold is influenced due to the fact that an ejector pin damages the surface of the mold is avoided.

Owner:东莞市勤博塑胶制品有限公司

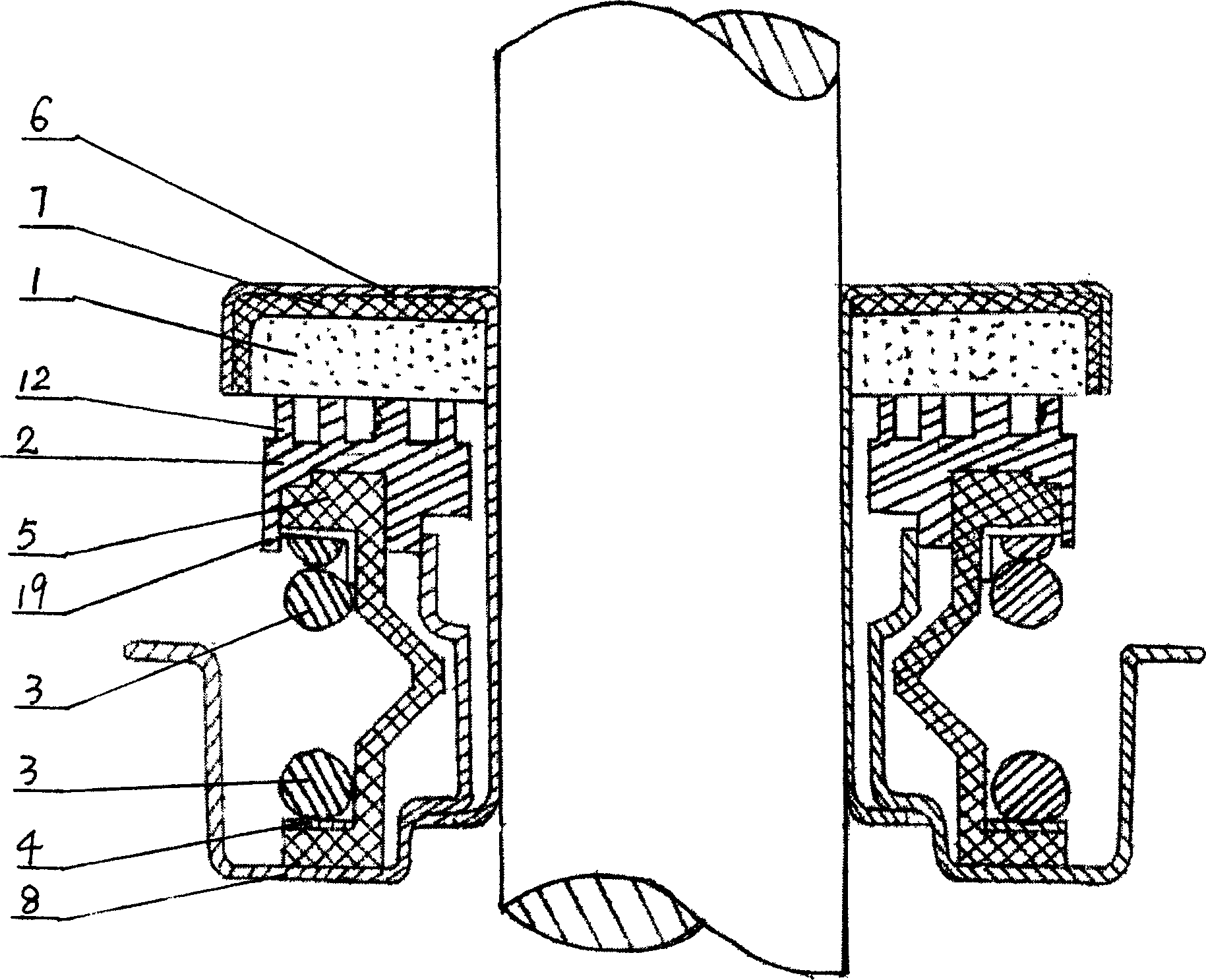

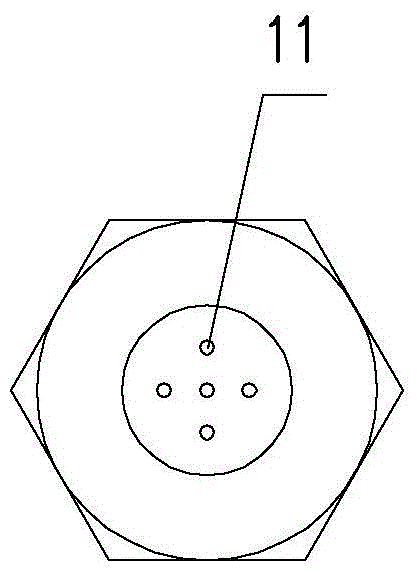

Pressure-tight wire connection device

InactiveCN104577936AGood sealing performanceEasy to installCable junctionsCable inlet sealing meansEngineeringSmall hole

The invention discloses a pressure-tight wire connection device which comprises sub-wire support plates, a joint, a seal ring, a filling and sealing material and wires for communicating the inner part and the outer part of a tank, wherein the joint is an unequal-diameter cylinder in the outline, which has a through hole formed by combining a straight hole with a taper hole; a large end of the taper hole faces the pressure gas direction; both ends of the through hole are respectively provided with steps; the joint is a screwed joint which has external threads on the outer diameter of the small end, or a flange joint, the large end of which is a flange plate; n small holes for threading the wires are formed in the sub-wire support plates; in assembly state, two sub-wire support plates are respectively placed on the steps at both ends of the through hole in the joint; m wires penetrate through the hole in the joint and n small holes corresponding to the sub-wire support plates; the through hole in the joint is filled with the filling and sealing material to bond the sub-wire support plates, the joint and the wires into a whole; the seal ring is located at cable entrances of the joint and a sealed tank; and n is not less than m, and n is not less than 1 and not greater than 20. The pressure-tight wire connection device is reliable in sealing under a certain gas pressure, simple in structure, and convenient to install.

Owner:LIUZHOU OVM MASCH CO LTD

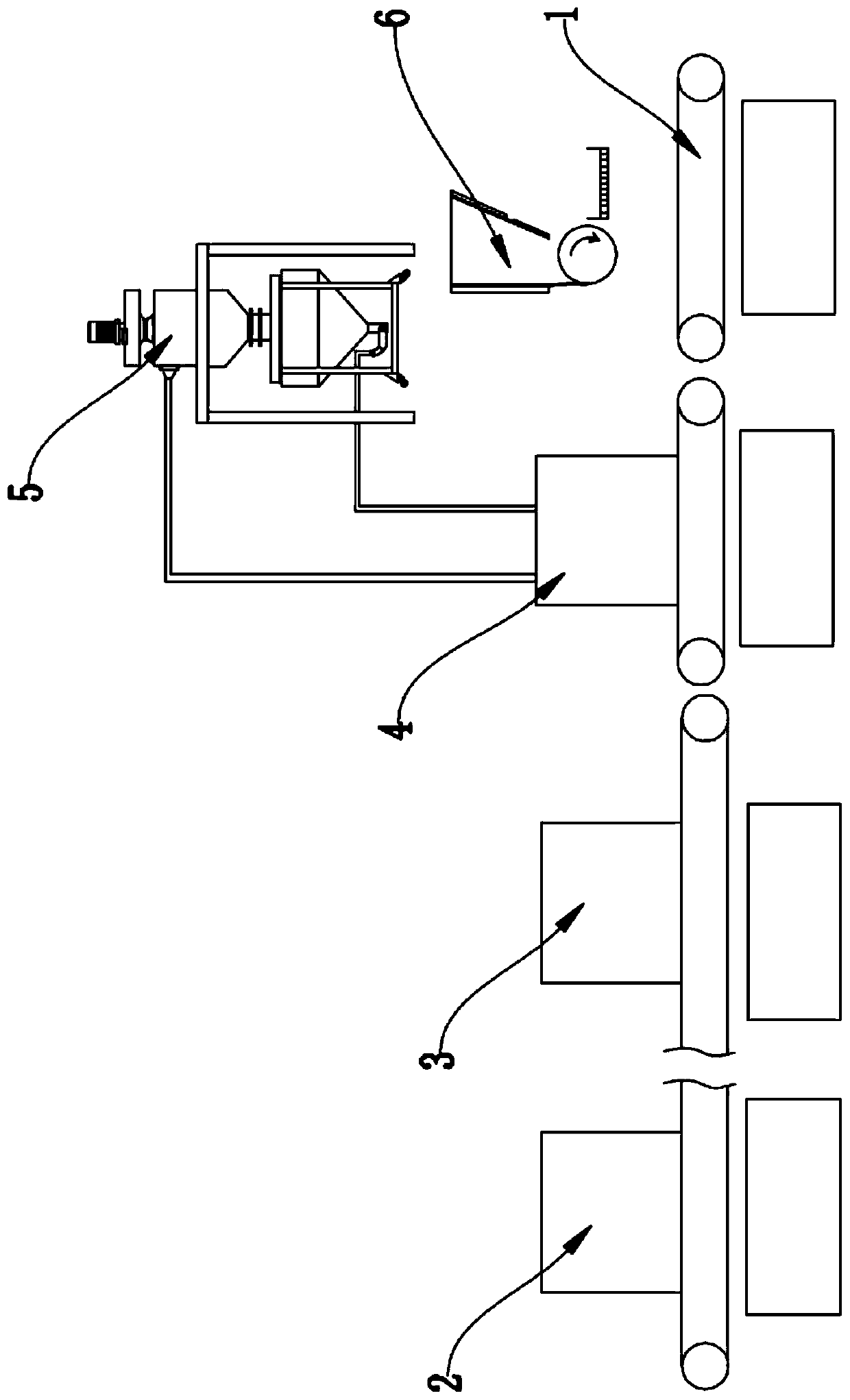

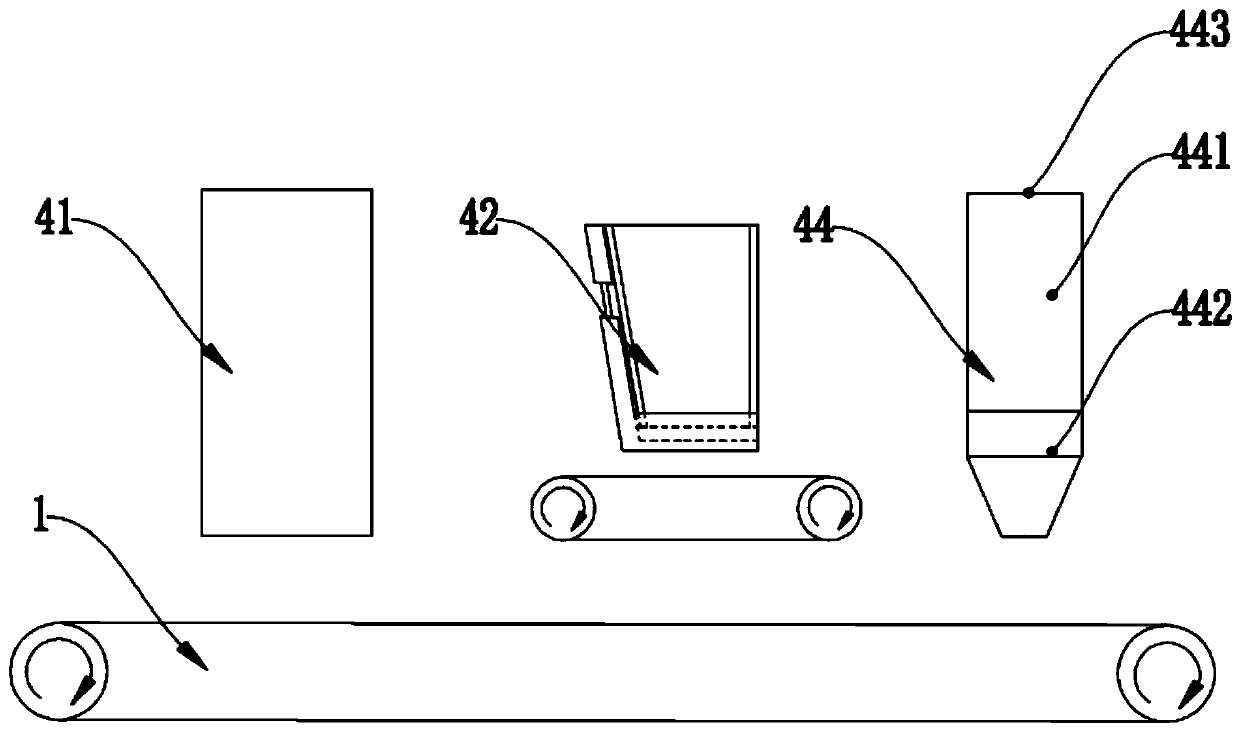

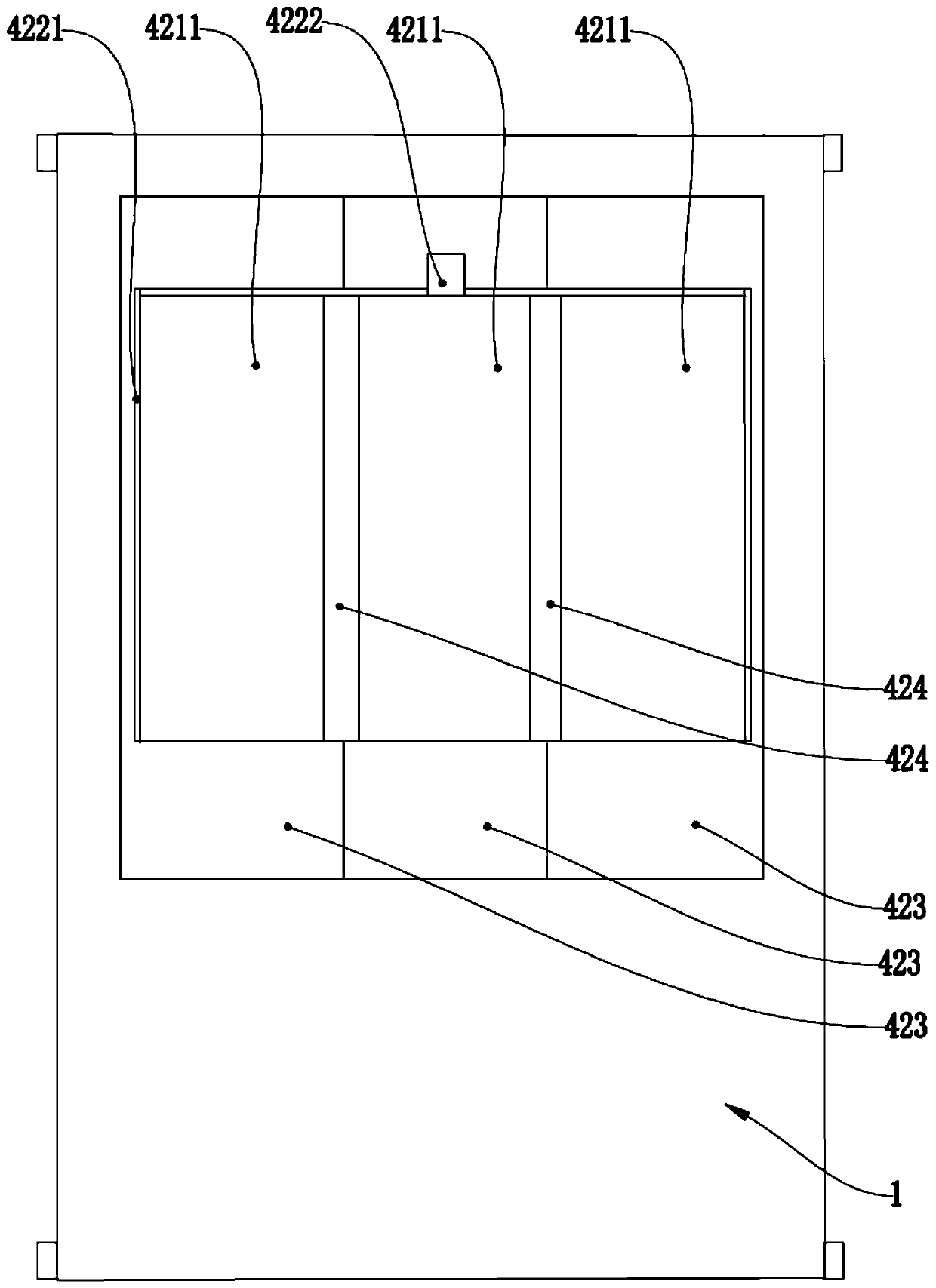

Ceramic tile decoration production system capable of distributing uniform ink-splashing patterns

PendingCN111558987AImprove the decorative effectStrong three-dimensional senseCeramic shaping plantsFeeding arrangmentsMetallurgyComputer printing

Owner:QINGYUAN NAFUNA CERAMICS

Glass fixing device

The invention provides a glass fixing device and relates to an installing device installing more than one piece of pane glass in a frame. The glass fixing device comprises a main frame material. The cross section of the main frame material is of a step shape high in exterior and low in interior. The main frame material is provided with a glass supporting block. The upper portion of the glass supporting block is provided with the hollow glass. An outer side sealing rubber strip is arranged between the main frame material and the outer side face of the hollow glass. The glass fixing device further comprises a fixing base. The fixing base is arranged on the inner side of the hollow glass and fixed to the main frame material. A pre-tightening filling block with the wedge-shaped bottom is wedged between the fixing base and the hollow glass in a bottom downward mode. The glass fixing device is simple in structure, low in cost and easy and convenient to operate; the glass fixing device can clamp the glass firmly, ensure the sealing waterproof effect, bring convenience to installation of the glass of doors and windows, lower the construction cost and ensure the construction safety.

Owner:韩治国

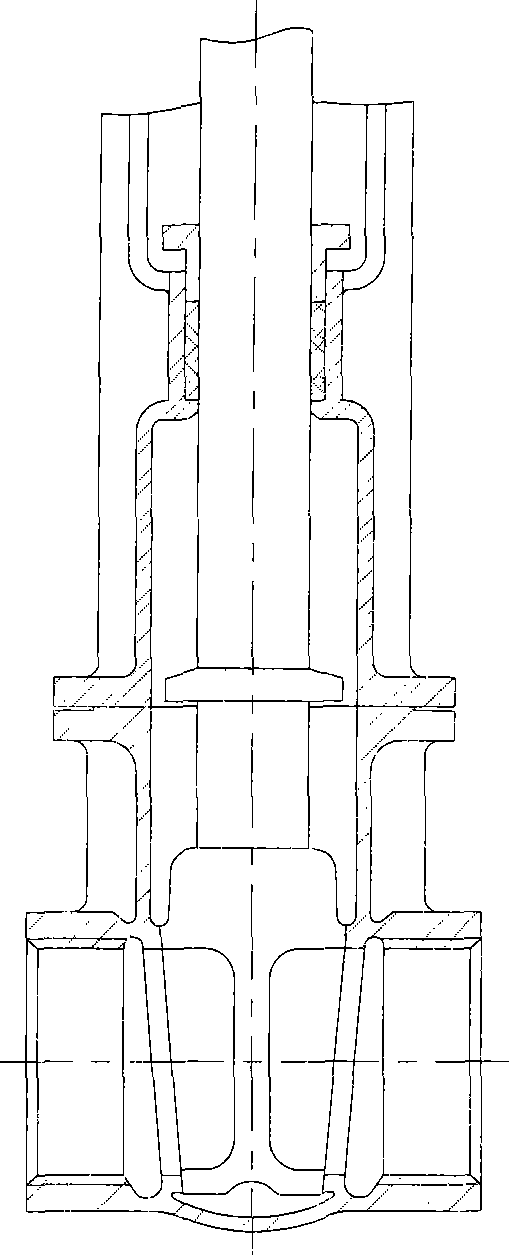

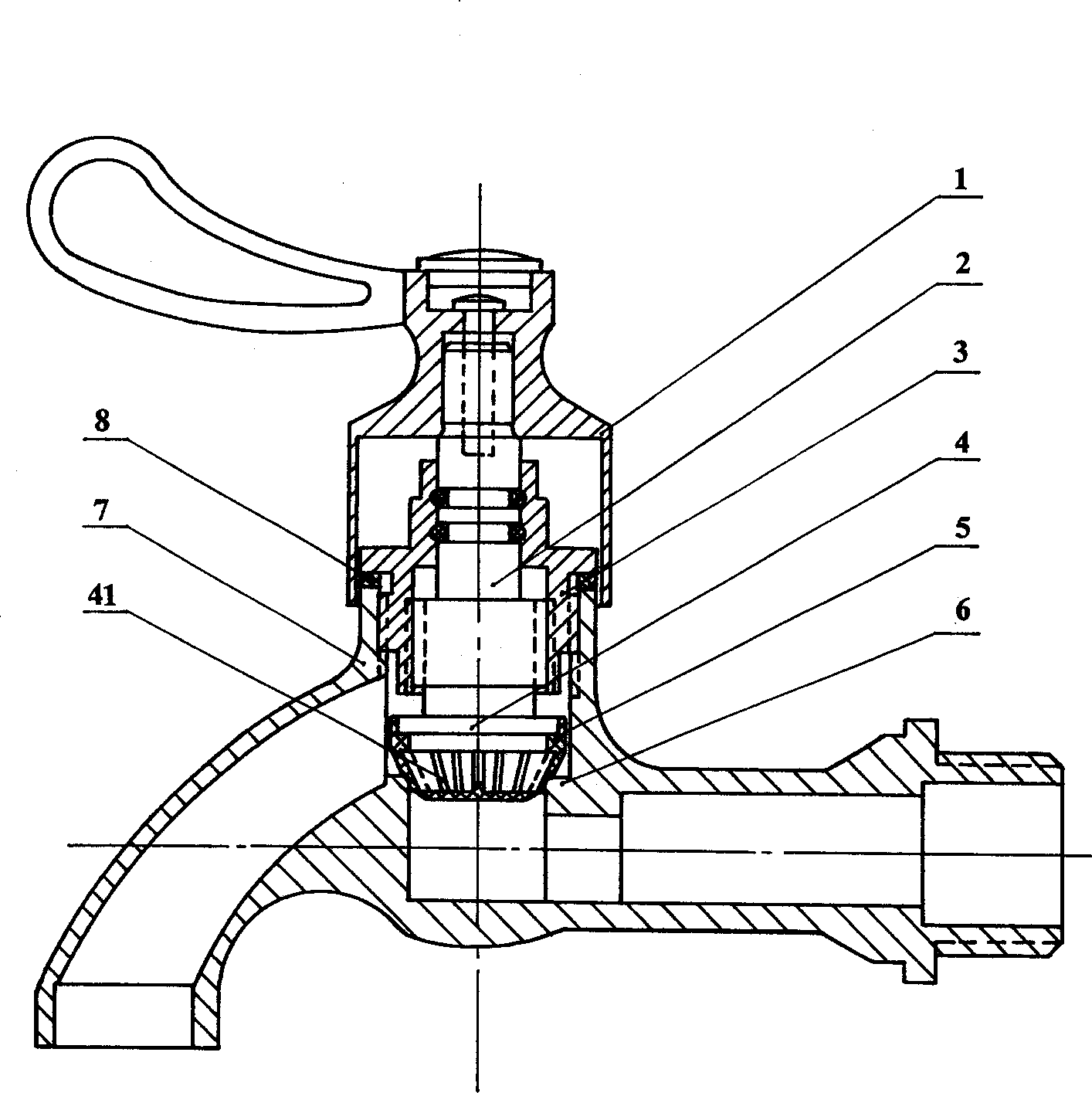

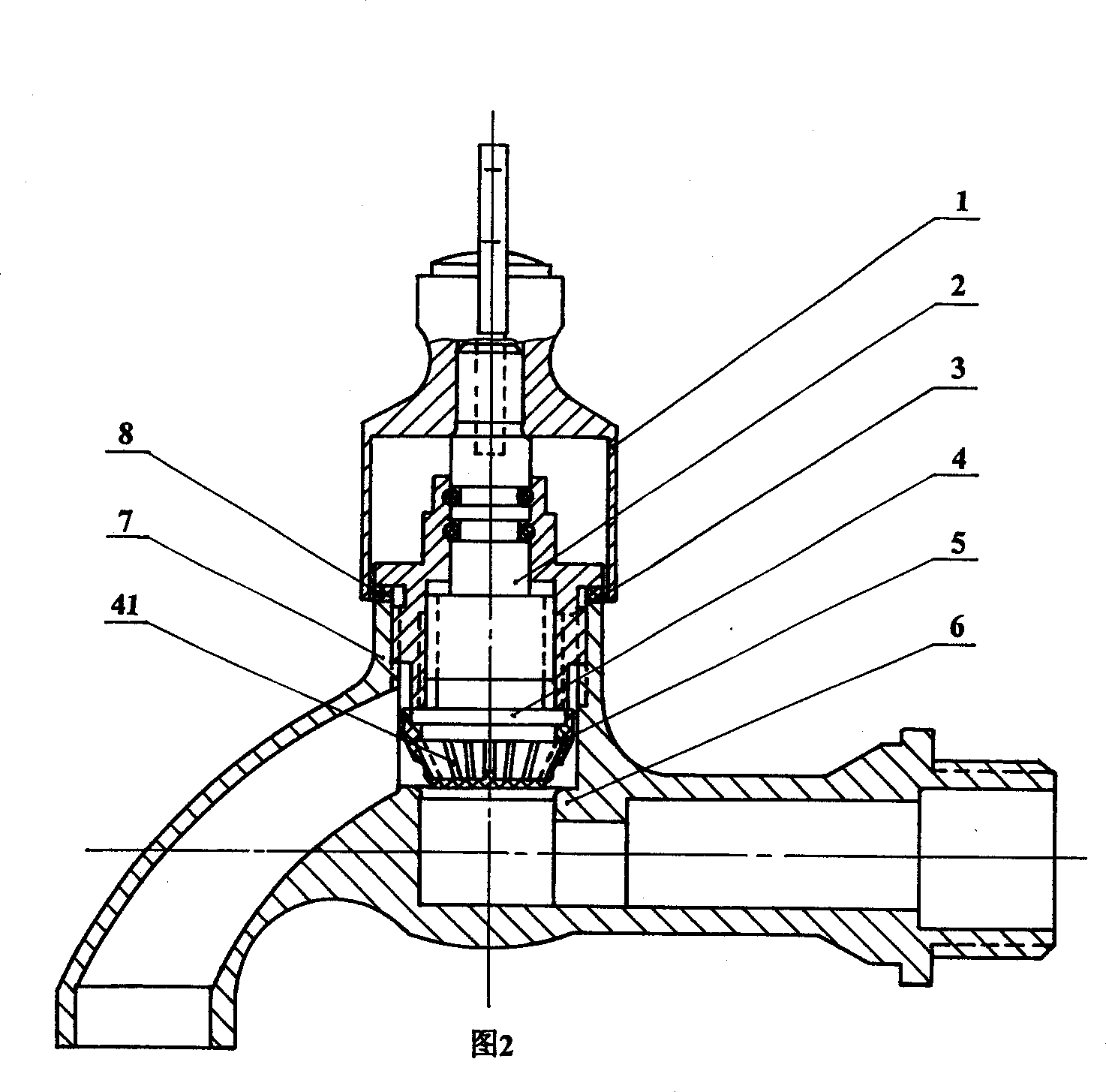

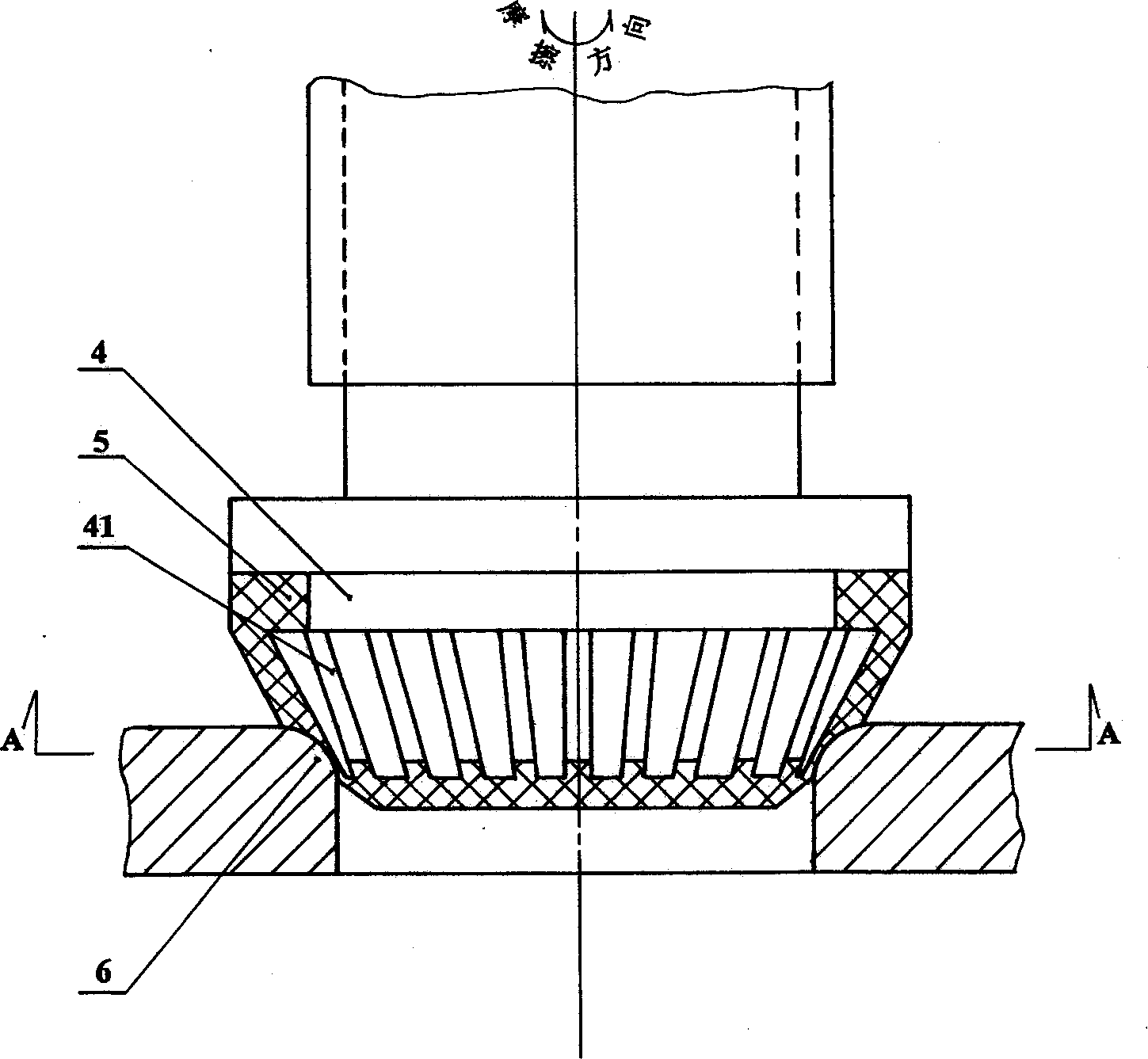

Double sealing valve structure

ActiveCN101451625AWill not affect the sealing effectGuaranteed tightnessSpindle sealingsEngineeringMechanical engineering

The invention discloses a double sealing valve structure, comprising a valve rod and a valve cover. The part between the valve rod and the valve cover is provided with a sealing stuffing as the first layer of a sealing structure, the lower end of which is provided with a second sealing structure, the second sealing structure is a self-pressure hard sealing structure, that is to say, a sealing structure of a metal sealing surface which is arranged between a sealing seat on the valve rod and the inner wall of the valve cover to a metal sealing surface, the second sealing structure is also provided with an accessory sealing structure which is a sealing ring sleeved with the valve rod, the bottom surface of the sealing ring is arranged on the sealing seat of the valve rod, and clearance whichcan ensure the sealing ring move on the sealing seat is kept between the sealing ring and the valve rod. The technical scheme provided by the invention protects the sealing stuffing effectively, has important positive role in energy saving and consumption reduction and greatly reduces the running cost of the pipeline system in the prior art.

Owner:广东联塑阀门有限公司

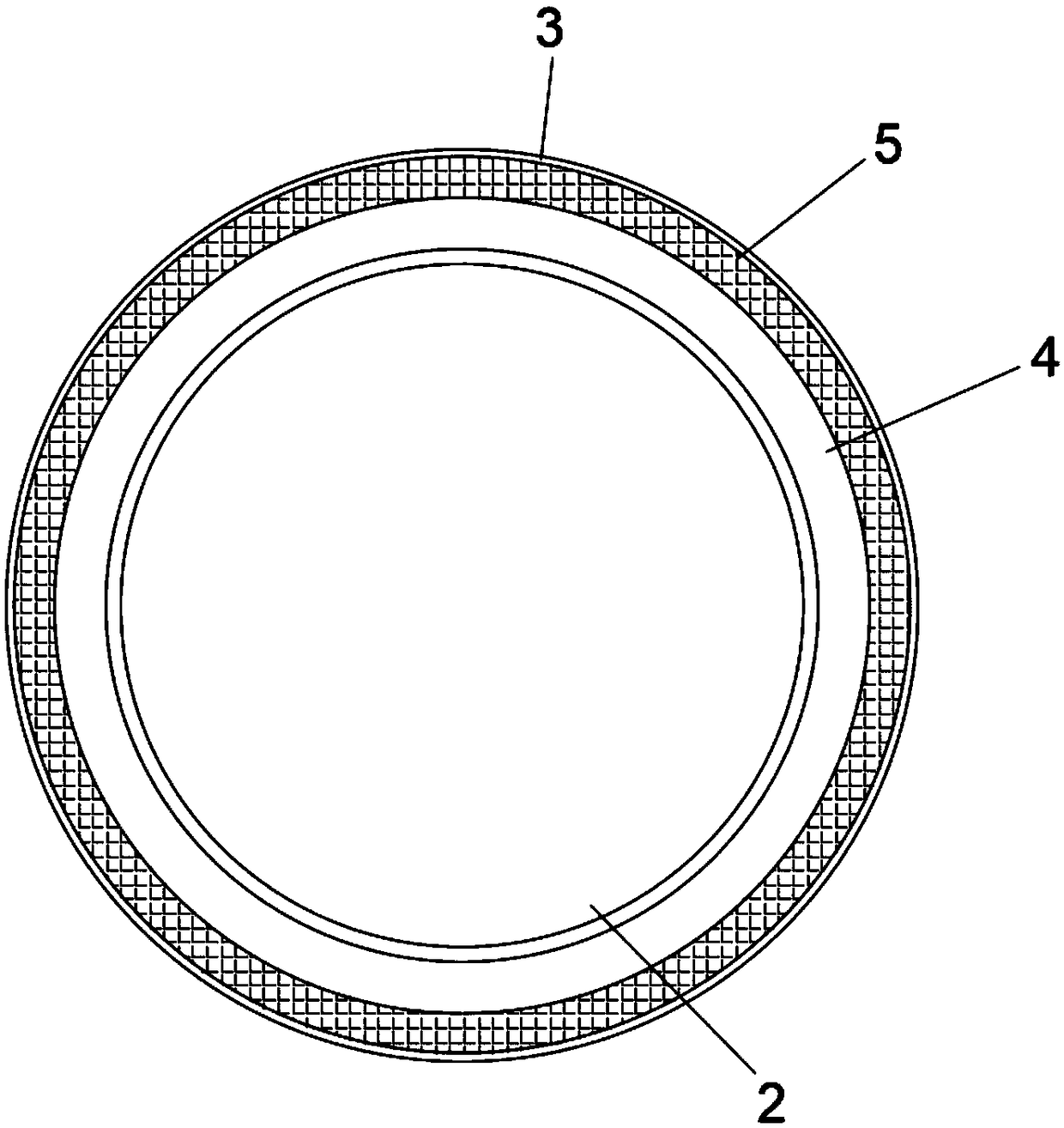

Metal winding type gasket, inner ring, centering ring and metal winding type gasket component

The invention discloses a metal winding type gasket, an inner ring, a centering ring and a metal winding type gasket component. The problem that the present metal winding type gasket component is completely discarded after being used is solved. According to the technical scheme, the metal winding type gasket component comprises the metal winding type gasket and the inner ring and / or the centering ring which is matched and sleeved with the metal winding type gasket, wherein a plurality of brackets are uniformly arranged on an inner supporting ring and / or an outer supporting ring of the metal winding type gasket, and a plurality of bracket clamping holes are correspondingly and uniformly arranged on the inner ring and / or the centering ring. The metal winding type gasket component has a simple structure, is flexible to mount and is excellent in reliability; after the metal winding type gasket component is used, the corresponding damaged component can be exchanged and the undamaged component is not exchanged; and the production and use costs are effectively lowered.

Owner:WUHUAN ENG

Cylindrical pile leg self-elevating platform jetted pile connector

InactiveCN108867603ASolve the problem of strength and inconvenient operationWill not affect the sealing effectArtificial islandsUnderwater structuresButt weldingEngineering

The invention discloses a cylindrical pile leg self-elevating platform jetted pile connector. One end of a hammering union joint serves as a butt welding end and is connected with a jetted pipe in a pile leg in a butt welding mode, and the other end of the hammering union joint serves as an internal thread female hammer union and is connected with a jetted pipe hose and welded to a hole formed inthe wall of the pile leg. The jetted pipe hose is connected with a pile leg jetted pipe connector through a male hammering union with a wing-shaped loose external thread sleeve. The external thread sleeve and the male union can be rotated mutually. It is ensured that the sealing surface cannot rotate relatively in the process of connecting and dismantling the hose. When not in use, the jetted pipeconnector needs to be blocked with a choke plug. The choke plug is composed of two parts, namely, the hex socket external thread head and the male hammering union choke plug which are connected through a screw. The thread head and the choke plug can rotate mutually. It is ensured that the sealing surface cannot rotate relatively in the process of connecting and dismantling the choke plug. A portable pneumatic outer hexagonal wrench can be used for dismounting and mounting the choke plug.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

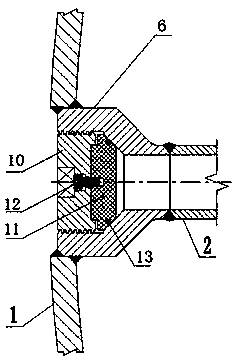

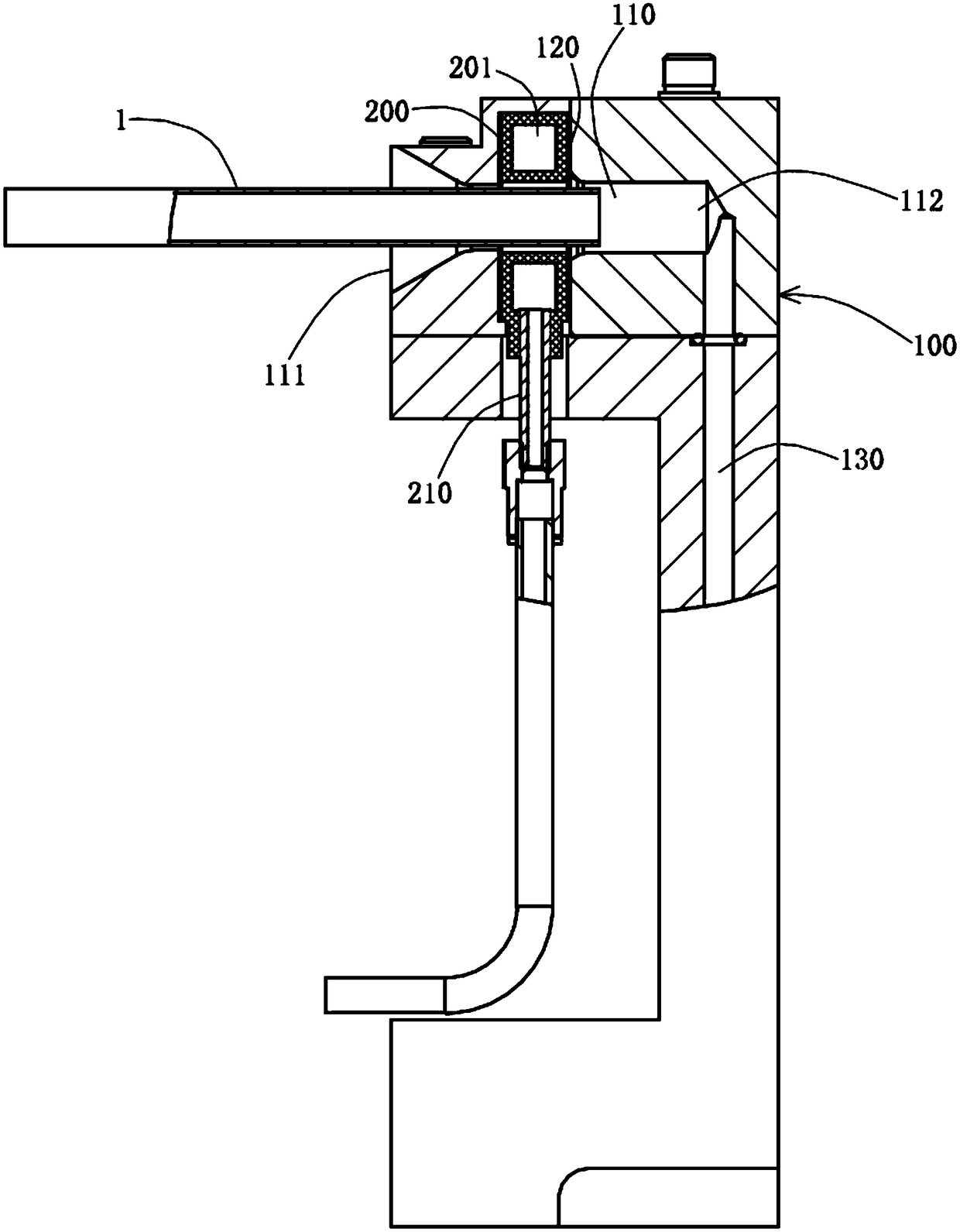

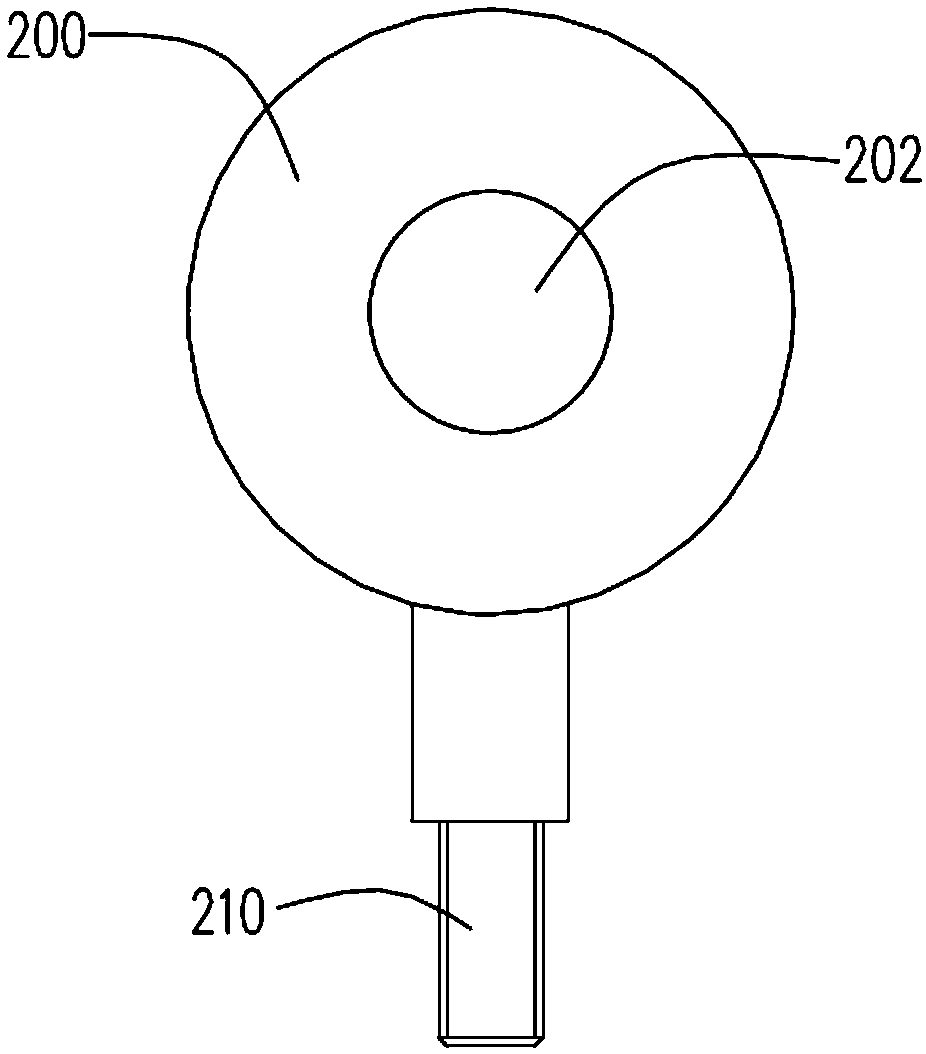

Connection structure of urea liquid level sensor and joint for vehicle

InactiveCN109029622AWill not affect the sealing effectImprove sealingExhaust apparatusSilencing apparatusLiquid level sensorMachining

The invention discloses a connection structure of a urea liquid level sensor and a joint for a vehicle. The connection structure comprises a liquid level sensor fixing seat; the side wall of the liquid level sensor fixing seat is fixedly connected with a hole opening; the hole opening is sleeved with the outer joint; one end of the outer joint is sleeved with an annular sealing ring; an annular inserting groove matched with the annular sealing ring to be used is formed in the side wall of the liquid level sensor fixing seat; the diameter of the annular inserting groove is equal to the sum of the diameter of the outer joint and the diameter of the annular sealing ring; two first grooves are symmetrically formed in the side wall of the annular inserting groove; a first clamping block is slidably connected into each first groove; first clamping grooves are formed in the positions, corresponding to the first clamping blocks, of the surface of the annular sealing ring correspondingly; and second clamping grooves are formed in the surfaces of the first clamping blocks correspondingly. The outer joint and the hole opening do not need to be subjected to threaded machining, mounting and connecting are convenient, the sealing effect of the sealing ring is not affected, and the sealing effect is good.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY +1

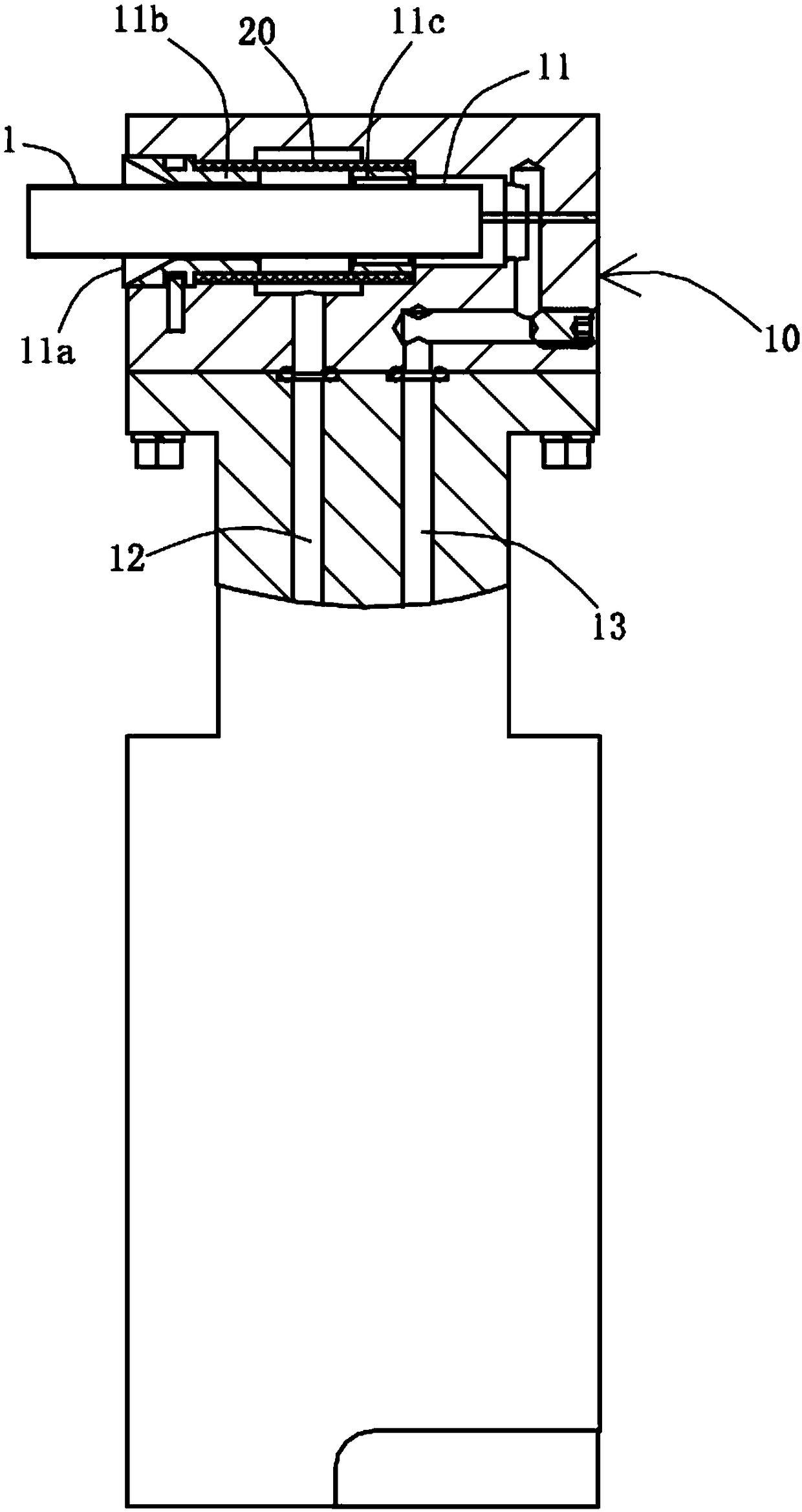

Blowout preventer unit for workover rig

InactiveCN113898311APlay a role of sealingGuaranteed StrengthSealing/packingForeign matterBlowout preventer

The invention belongs to the field of oil exploitation, and particularly relates to a blowout preventer unit for a workover rig. The blowout preventer unit comprises a ram preventer body, an annular blowout preventer shell and an annular rubber core. The annular blowout preventer shell is fixedly connected to the top of the ram preventer body. The annular rubber core and a sealing block are arranged in the annular blowout preventer shell, and the sealing block is located at the top of the annular rubber core. A first piston is arranged at the bottom of the annular rubber core. A second piston is arranged at the bottom of the sealing block. According to the blowout preventer unit, the annular rubber core is reserved and can achieve the sealing and shielding effects, and blowout objects are basically prevented from being continuously guided into the position of the sealing block; when the blowout state is stopped, the sealing block is controlled to conduct sealing, and the situation that a large number of foreign matter is clamped into the sealing face position of the sealing block, and the sealing effect is influenced is avoided; and sealing is conducted through the hard sealing block, the strength of a sealing structure is guaranteed, and therefore the continuous sealing effect can be achieved.

Owner:山东旭能石油装备有限责任公司

Dual-use vacuum relief valve

ActiveCN101943283BSimple processSimple structureEqualizing valvesSafety valvesEngineeringRelief valve

A dual-use vacuum relief valve comprises a valve body and a spool, wherein the valve body is provided with a cylindrical shell and a sealing cover plate; a first gas port is formed on the other end of the cylindrical shell, a second gas port is formed on the side wall of the cylindrical shell, a sealing boss is formed on the inner wall of the cylindrical shell and between the two gas ports; the spool comprises a first valve plate component and a second valve plate component; the first valve plate component contains a first valve plate and a first bias spring; a guide hole and a vent hole are formed on the first valve plate; the second valve plate component contains a second valve plate and a second bias spring, the center of the second valve plate is fixedly connected with a guide post; and the second gas port is near the edge of the first valve plate. The invention has the advantages of simple structure and convenient processing and assembling.

Owner:上海远安流体设备科技有限公司

Online automatic copper pipe purging device

PendingCN109454068ALarge amount of deformationPrevent leakageHollow article cleaningNitrogenEngineering

The invention discloses an online automatic copper pipe purging device which comprises a copper pipe purging sealing base and an air inflating sealing ring. A cylindrical sealing cavity for a copper pipe to be inserted is formed in the copper pipe purging sealing base. A ring-shaped sealing cavity is formed in the portion, located on the middle portion of the cylindrical sealing cavity, of the copper pipe purging sealing base. A nitrogen conveying channel is formed in the copper pipe purging sealing base. The air inflating sealing ring is installed in the ring-shaped sealing cavity. An air inflating short pipe is connected to the air inflating sealing ring. One end of the air inflating short pipe extends into the air inflating sealing ring and communicates with an air inflating cavity of the air inflating sealing ring, and the other end of the air inflating short pipe extends out of the copper pipe purging sealing base and is connected with the air supply end of an air compressor through a pipeline. According to the online automatic copper pipe purging device, nitrogen is effectively prevented from being leaked from the cylindrical sealing cavity to the outside, it is ensured thatthe nitrogen can only enter the inner cavity of a copper pipe to carry out purging, the inner wall purging quality of the copper pipe is ensured, and the inner wall cleanness degree of the copper pipeis improved.

Owner:SHANGHAI LONGYANG PRECISE COMPOUND COPPER TUBE CO LTD

XBL pipeline ball valve

PendingCN111577926AExtended service lifeGood elastic headwind performanceSpindle sealingsPlug valvesBall valveWasher

The invention discloses an XBL pipeline ball valve which is characterized by comprising a ball valve body. The ball valve body is mainly formed by a ball body, a middle valve body and a valve rod; a valve left body structure and a valve right body structure are respectively arranged on two sides of the ball body; an opening support seat is arranged on each of the valve left body structure and thevalve right body structure; a seal valve seat is arranged in each opening support seat; an opening press tongue is tightly pressed and fixed to the top end of each seal valve seat; a slope seal face is processed at the top end of each opening press tongue; a smooth support plate is arranged on the bottom part of the ball body; a pressing sleeve, an O-shaped filler, a neck filler tank and an O-shaped ring are sequentially arranged on the periphery of the valve rod from top to bottom; and a thrust washer is arranged between the neck filler tank and the valve rod. The XBL pipeline ball valve provided by the invention has the characteristics of simple structure, long service life, good sealing effect, difficulty in deformation and the like.

Owner:自贡新比隆阀门有限公司

Anti-leakage durable structure of cut-off valve

InactiveCN1338581AReduce frictionImproved leak-proof durabilityLift valveMaterials scienceValve seat

An antileakage high-durability cut-off valve is composed of metallic valve core and valve seat. A solid lubricating material layer is solidified on the sealing surface for one of them. The interface of said lubricating layer upon the valve seat or valve core is a rough plane formed by grooves or holes. The friction between said solid lubricating material layer and valve seat or valve core can transfer the molecular of lubricating material to the metallic surface of valve seat or valve core, improving the anti-leakage performance and durability.

Owner:陈西火

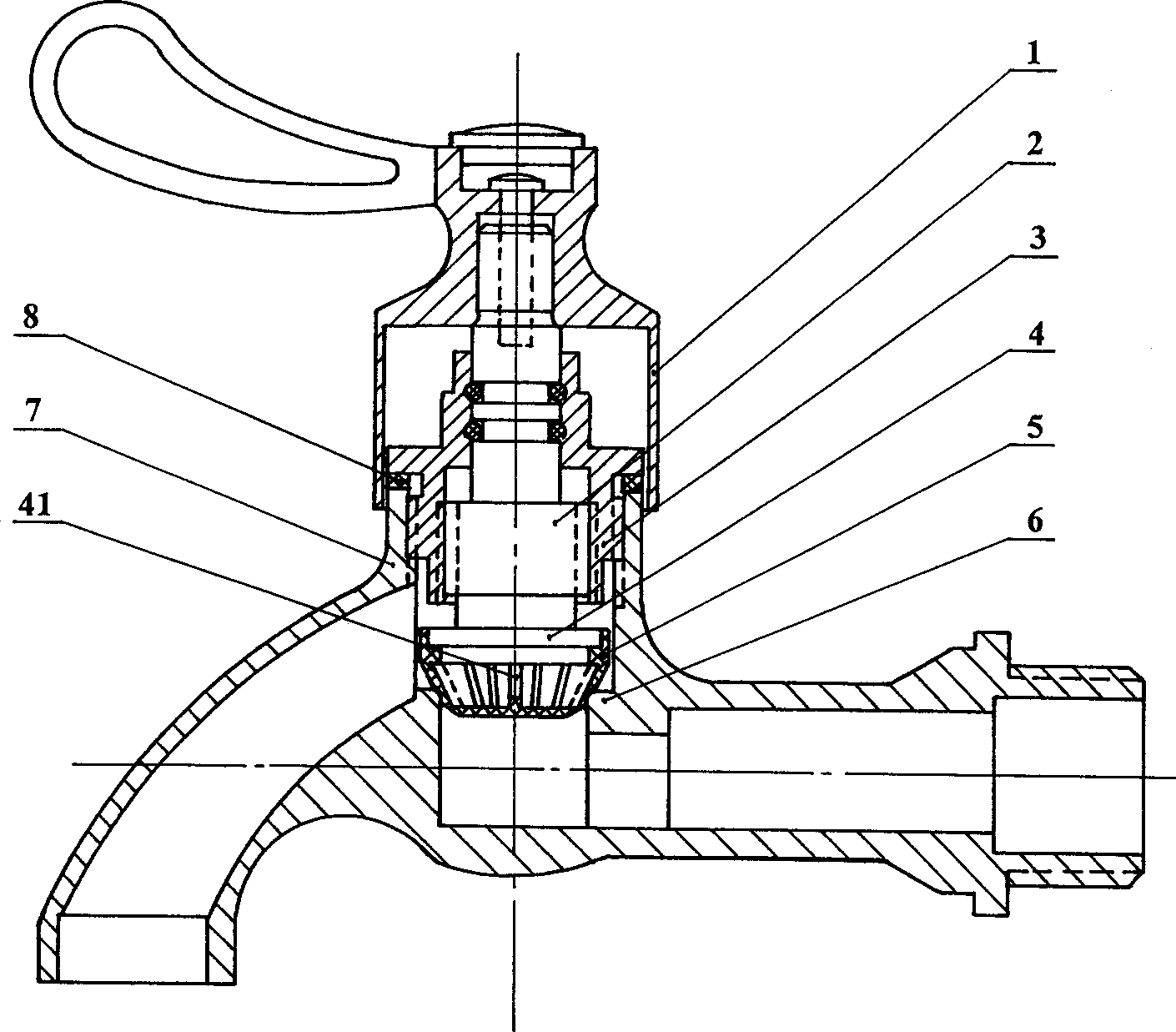

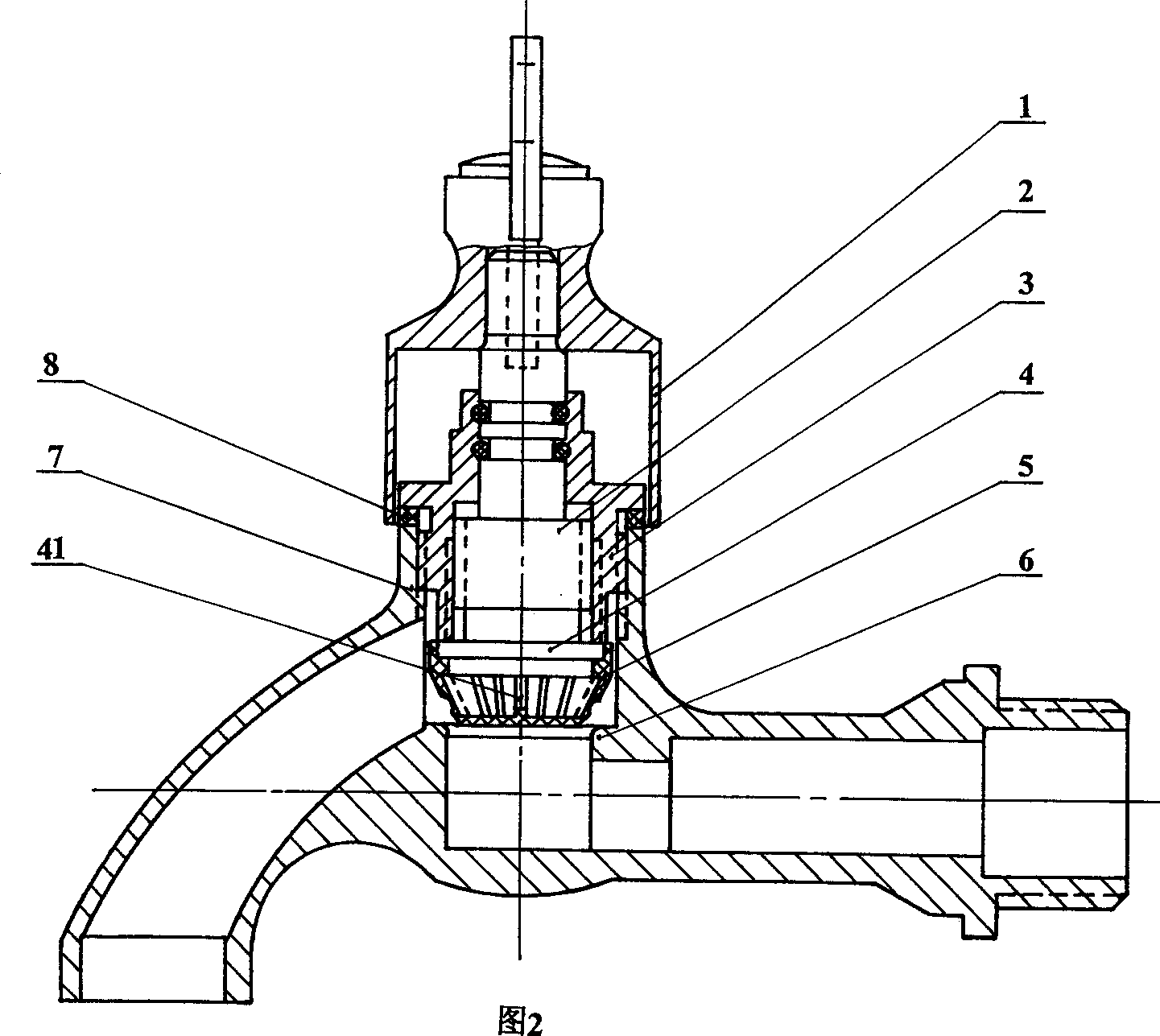

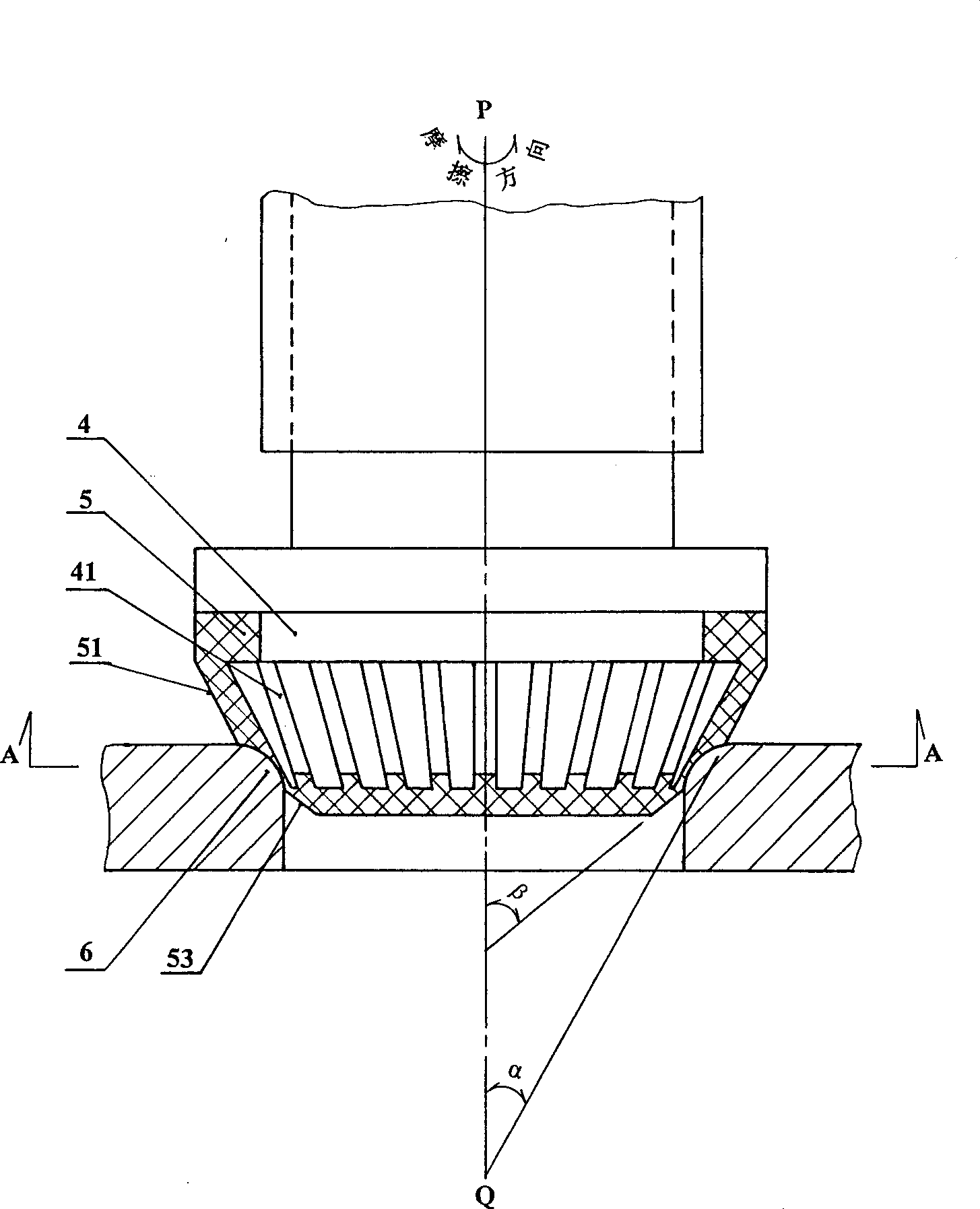

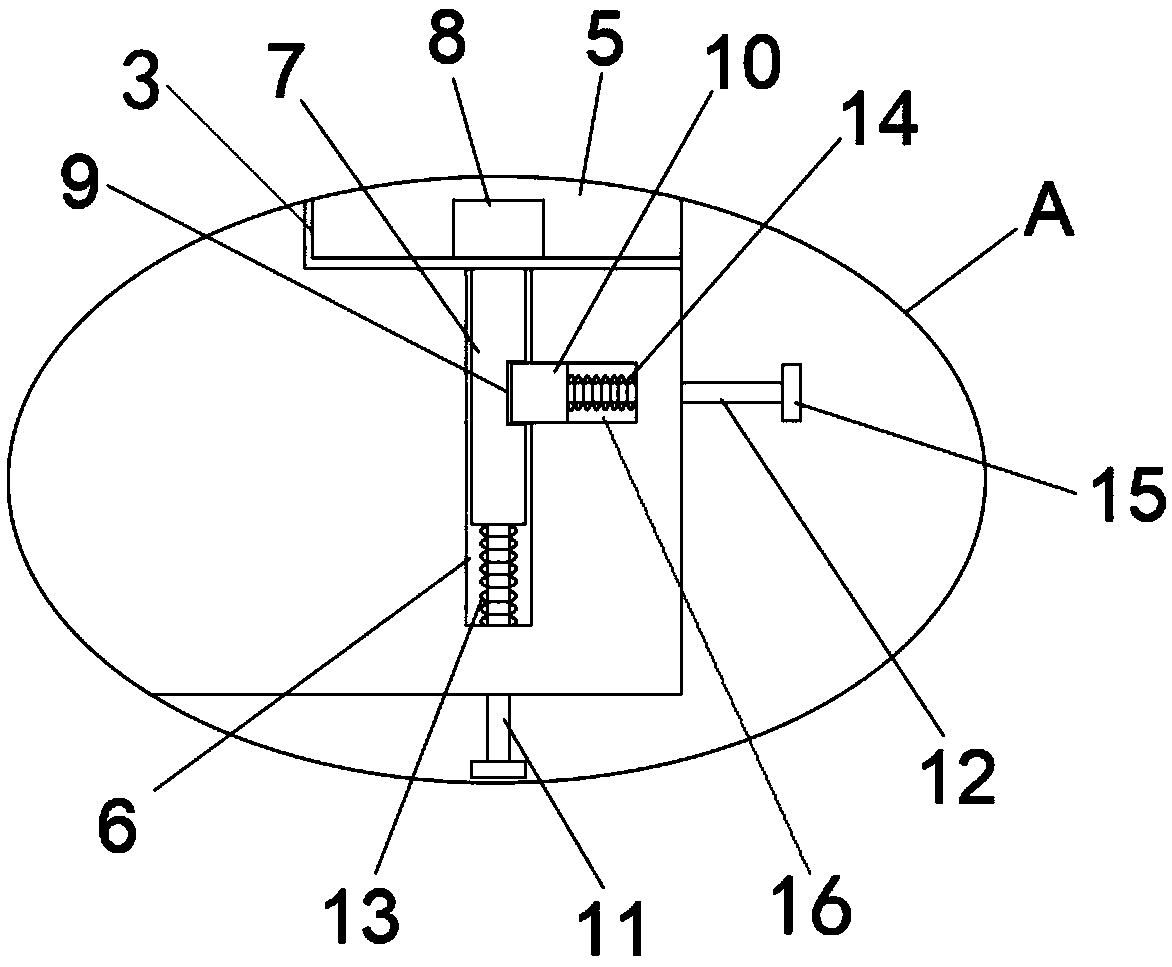

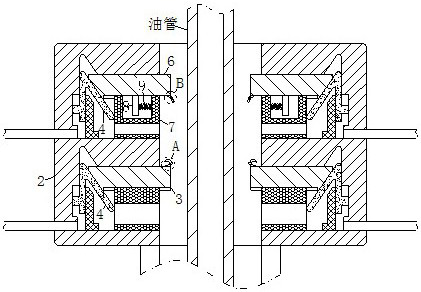

Hand-operated pilot valve

A hand-operated pilot valve comprises a handle, a valve body, an ejector rod, a first spring, a first spring seat, a valve seat, a valve rod, a second spring seat, a second spring and a plug, wherein one end of the handle is in rotational connection with a pin shaft in the valve body; the side surface at the bottom of the handle is propped against the ejector rod; the first spring is in sleeve joint with the ejector rod; one end of the first spring is propped against a lug boss on the ejector rod; the other end of the first spring is propped against the first spring seat; the ejector rod is in slide fit with the valve seat; an oil inlet, an oil outlet line and an oil return line are arranged on the valve seat; a blind hole and an oil return hole communicated with the blind hole are formed in the ejector rod; the valve rod is in slide fit with the valve seat; one end of the second spring is propped against the second spring seat; the other end of the second spring is propped against the plug; the second spring seat is in slide fit with the plug; one end of the plug is propped against the valve seat; the other end of the plug is in threaded connection with the valve body; and an oil chamber is communicated with the oil outlet line through a communication oil line. The hand-operated pilot valve is simple in structure, good in sealing performance and convenient to operate.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

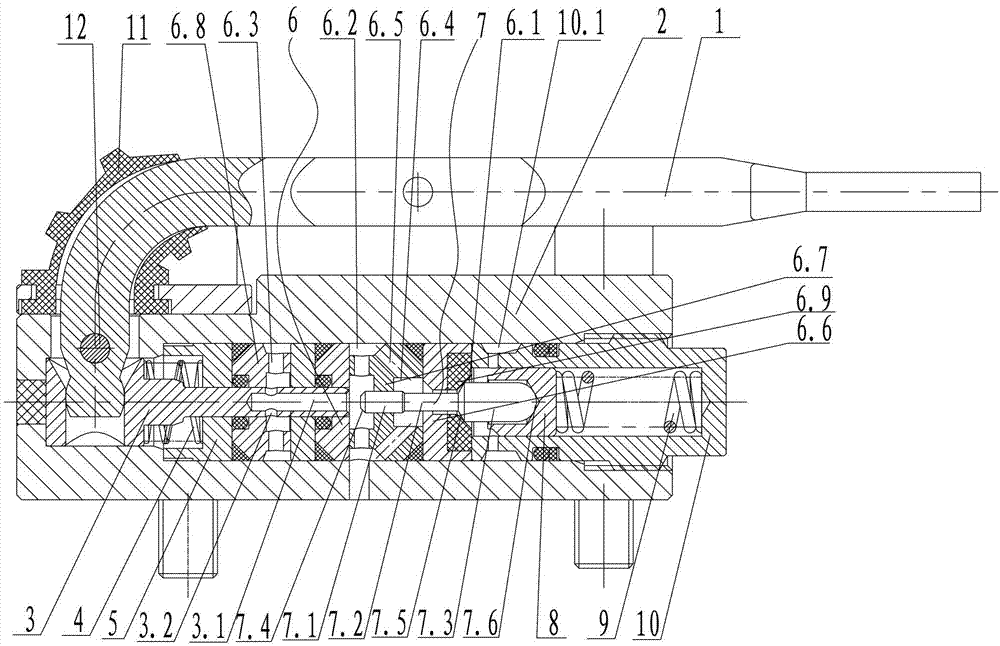

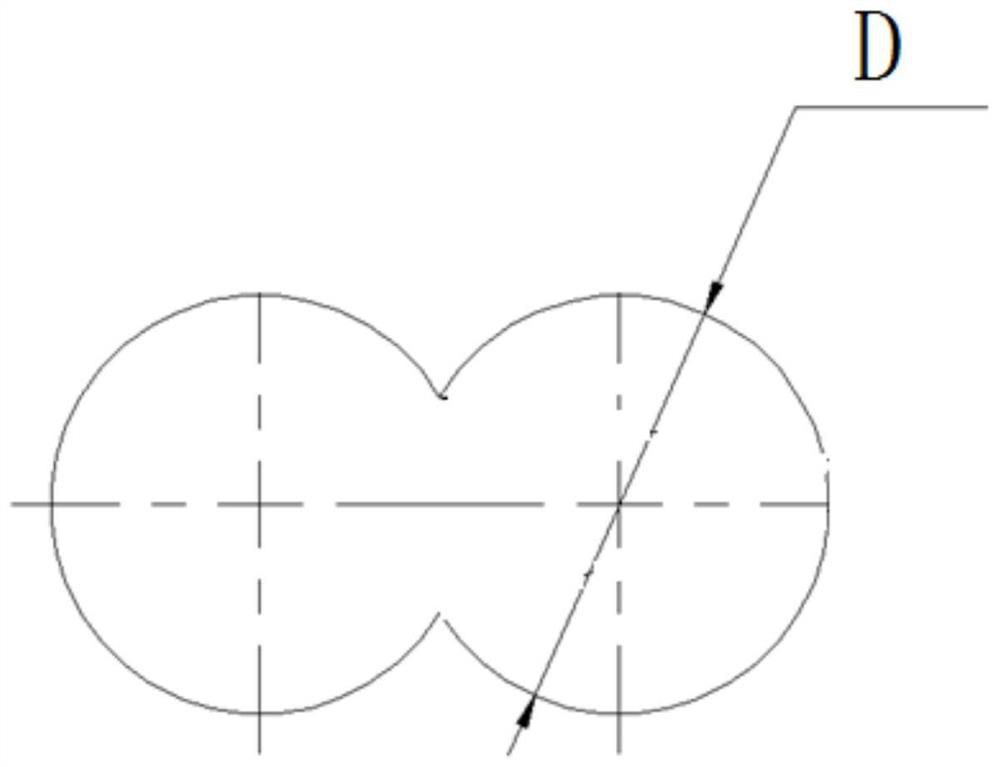

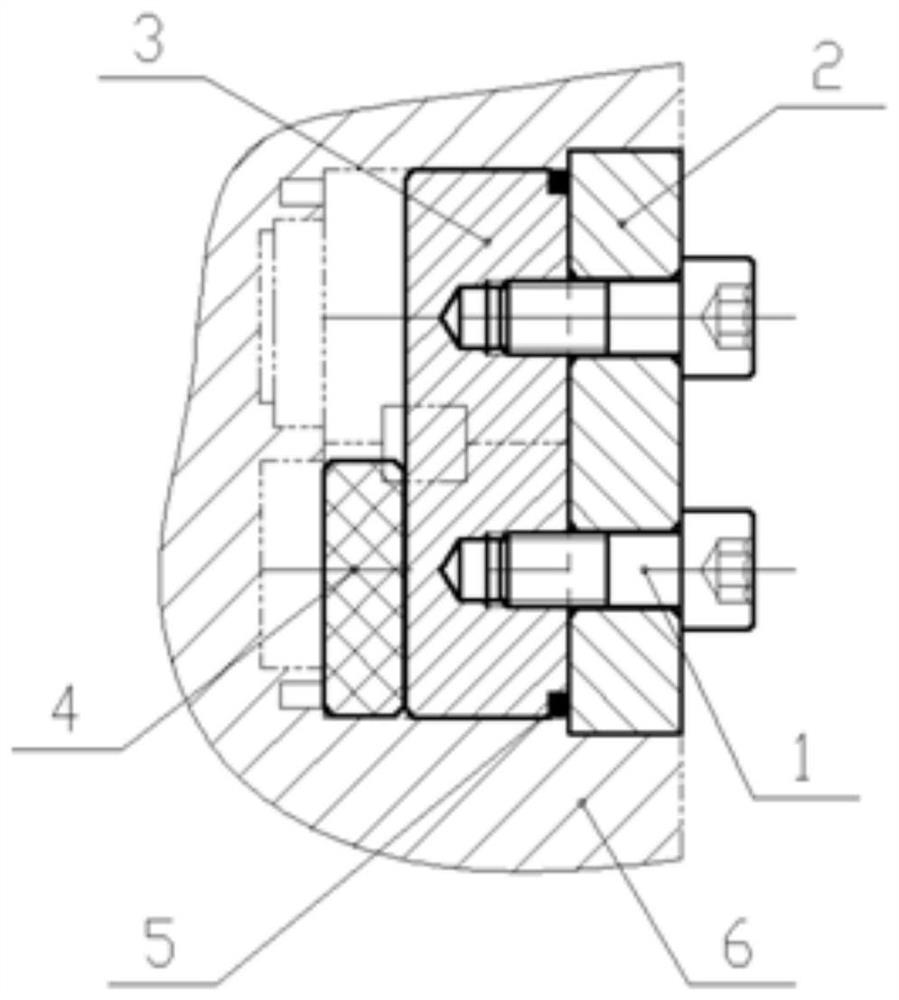

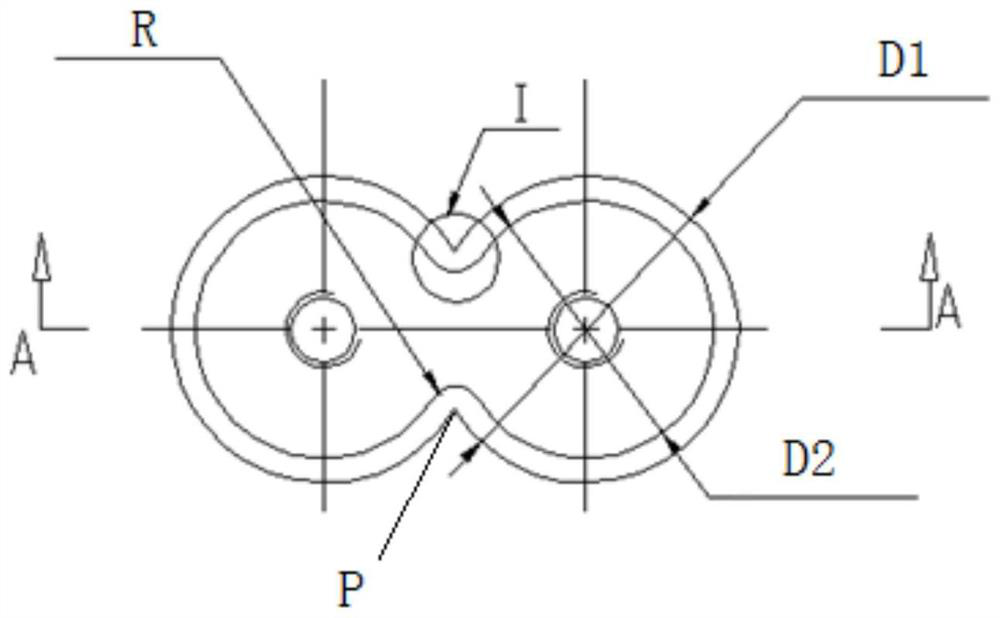

"8" hole sealing device and method for gear pump test

ActiveCN110630741BWill not affect the sealing effectImprove stabilityGeometric CADEngine sealsAviationGear pump

The invention belongs to the field of testing of an aero-engine gear pump shell assembly, and particularly relates to an '8''-shaped hole sealing device and method for a gear pump test. At present, the '8'-shaped hole cannot be radially sealed and is often limited by a shell assembly structure, so that some other oil way holes can also be affected, the shell assembly can bear large end surface sealing compression force before pressing, damage to the shell deformation and the like is caused, the sealing effect is unstable, and even the shell is damaged. The invention provides an '8'-shaped holesealing device and method for a gear pump test, a cushion block and a '8'-shaped plug are sequentially put in the '8''-shaped hole, a sealing groove with a step structure is arranged on the edge of the outer end surface of the '8'-shaped plug in sequence, the sealing groove is in an arc transition in the transition area, the sealing groove is internally provided with a sealing ring matched with the shape, and the sealing groove is tightly pressed through a bottom plate, so that the problems that the shell assembly in the end surface seal is too large in compression force, unstable in sealingeffect and easy to cause deformation damage of the shell are solved.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

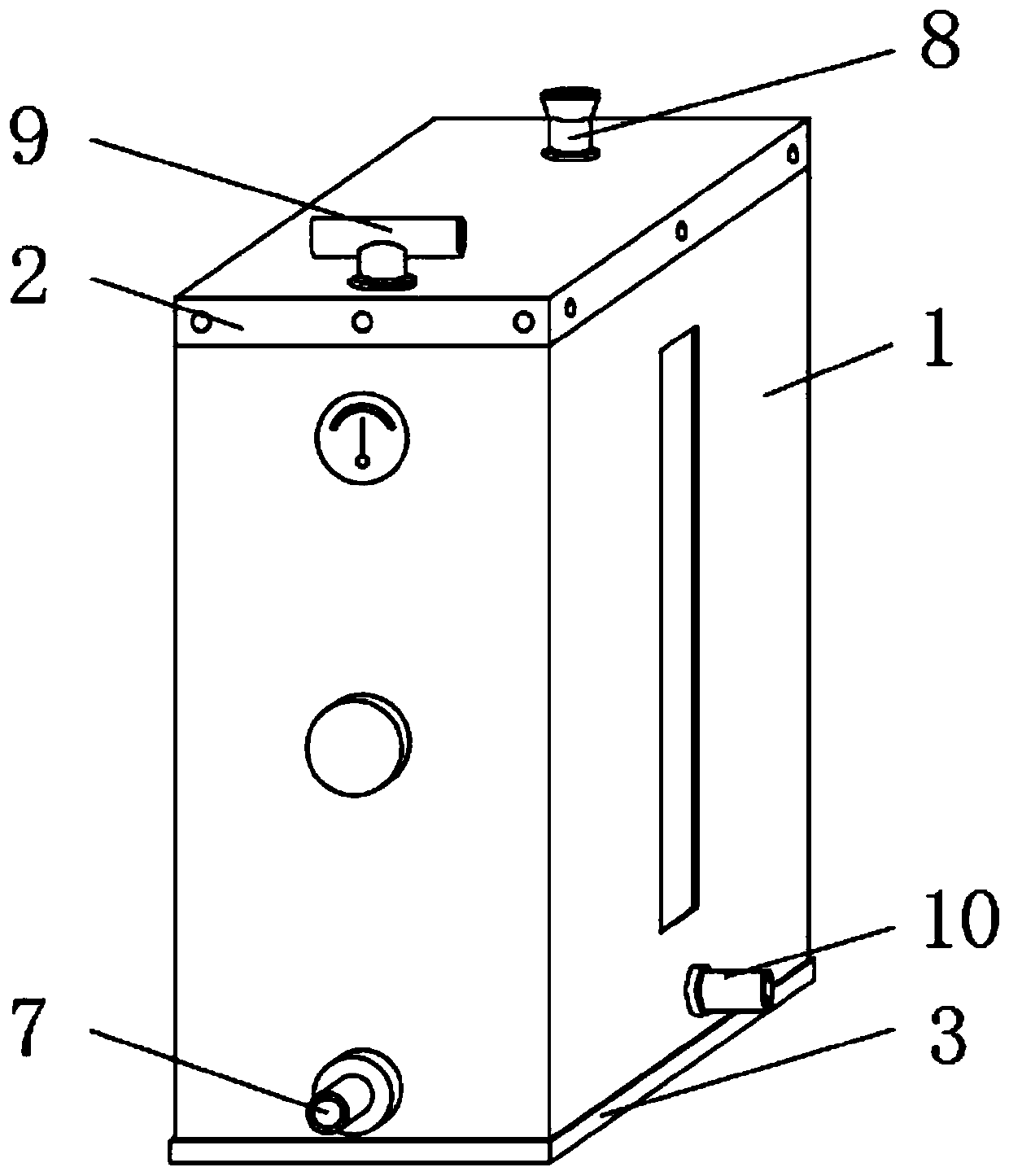

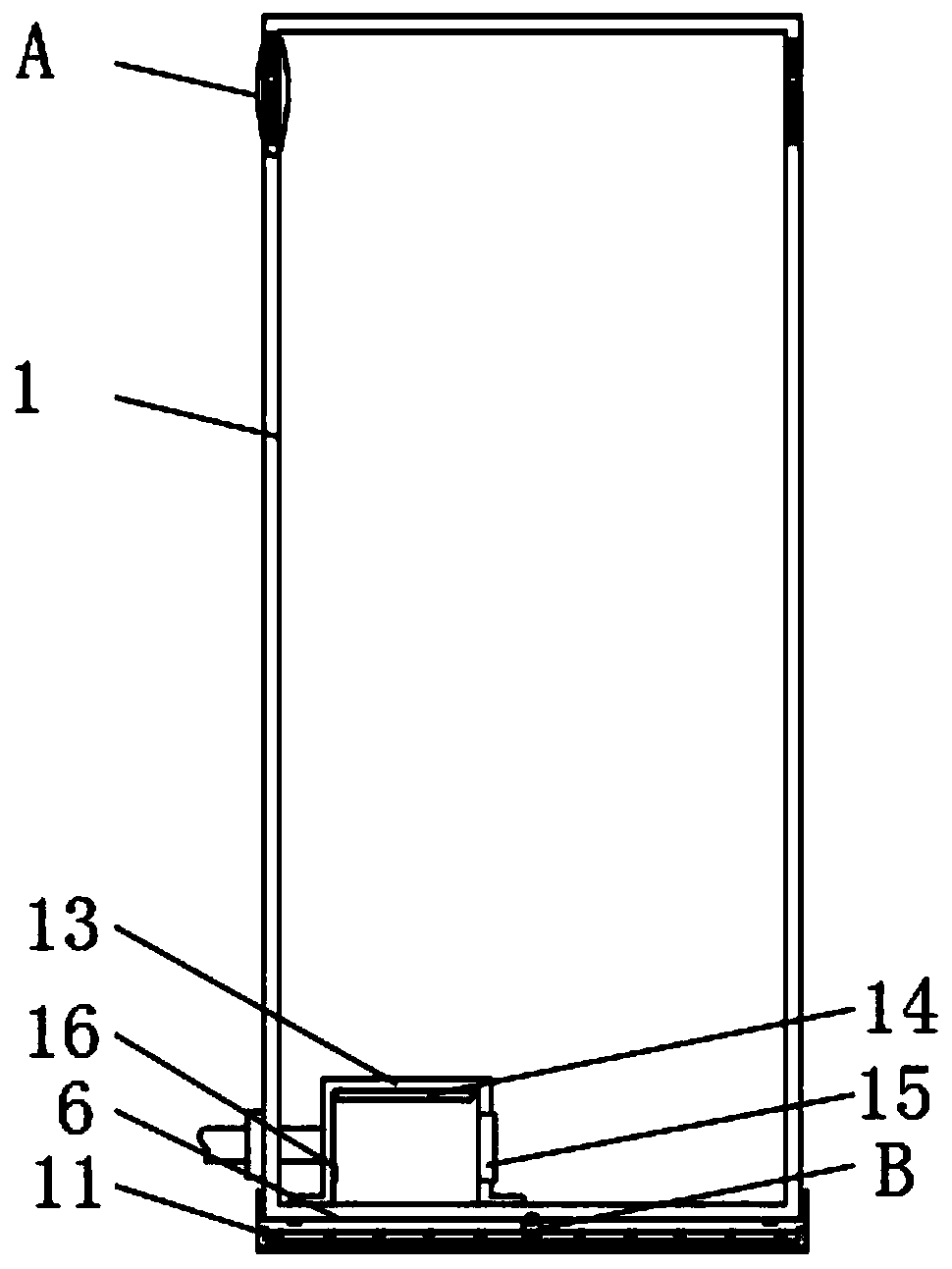

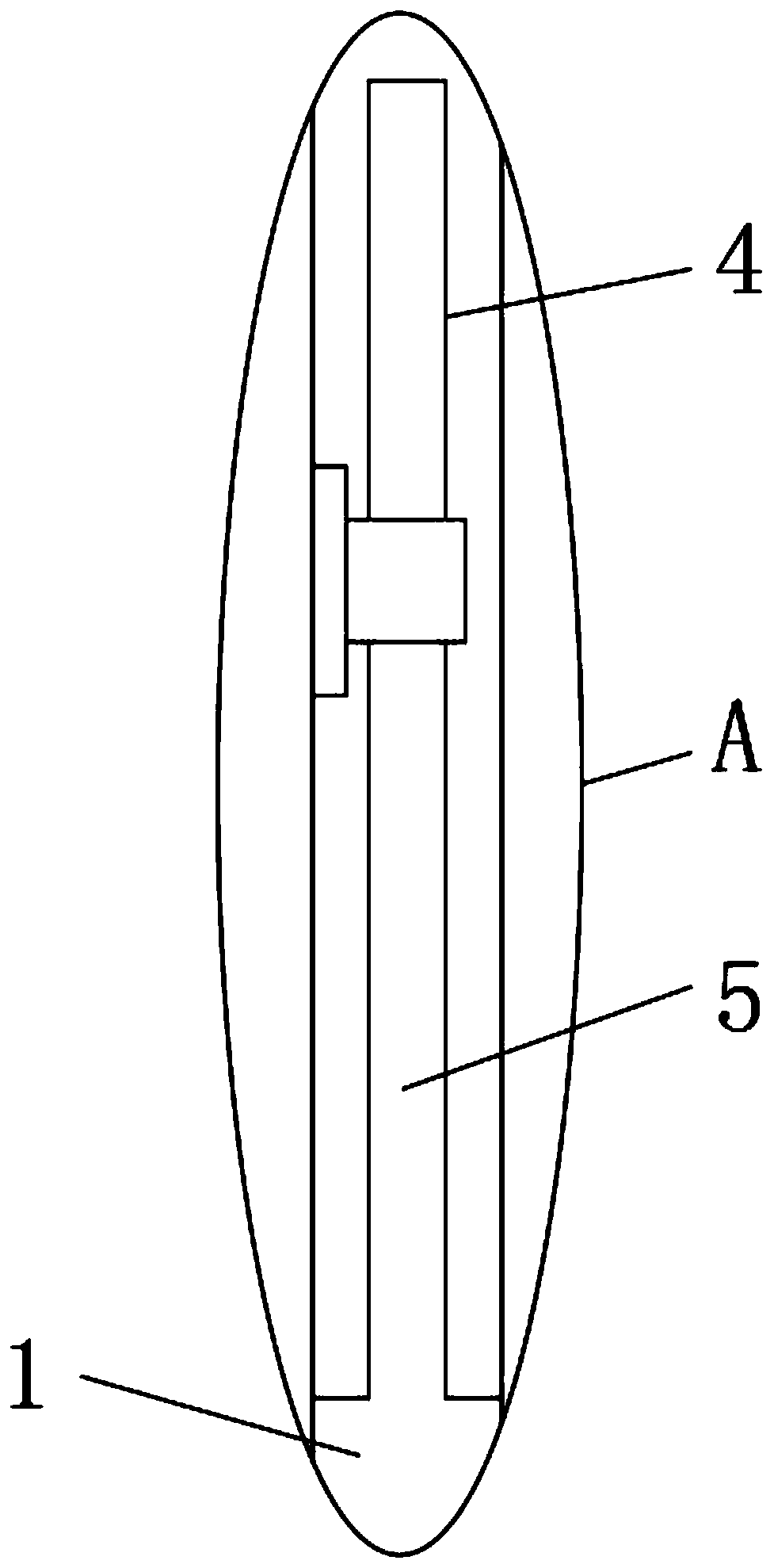

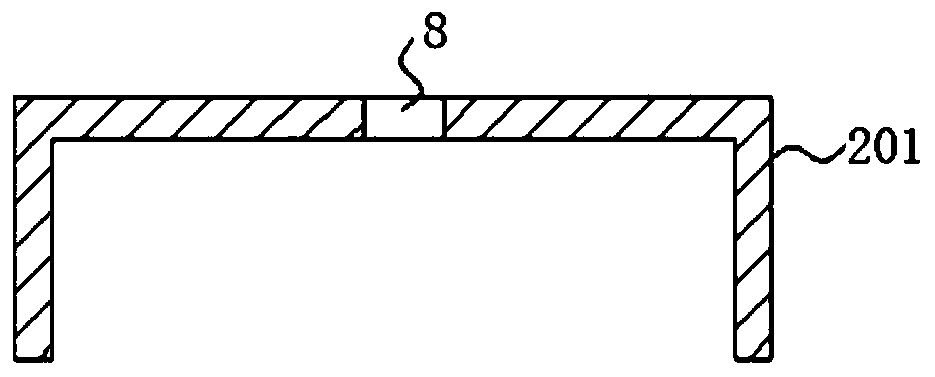

Pressure-bearing water tank structure and machining process

InactiveCN111089368AEasy to assembleHigh material utilizationLighting and heating apparatusAir conditioning systemsProcess engineeringMachining process

The invention discloses a pressure-bearing water tank structure and a machining process. The pressure-bearing water tank structure comprises a water tank main body, a water tank upper cover and a water tank base. The outer surface of the lower end of the water tank upper cover is provided with a clamping groove, a clamping strip is integrally formed in the outer surface of the upper end of the water tank main body, the clamping strip is positioned in the clamping groove, and the clamping strip and the clamping groove are fixedly connected through bolts. According to the pressure-bearing watertank structure and the machining process, the water tank upper cover and the water tank main body can be separated, internal devices of the pressure-bearing water tank can be conveniently repaired bypeople, the water tank upper cover and the water tank main body can be repeatedly utilized, the material utilization rate is higher, the vibration of the pressure-bearing water tank can be reduced, the connection effect of a pipeline on the vibration pressure-bearing water tank is reduced, the service life of the pipeline on the pressure-bearing water tank is prolonged, and finally the temperatureof cooling liquid can be increased to the optimal performance temperature, so that the use effect of the whole liquid cooling device is improved, and a better use prospect is brought.

Owner:合肥通用制冷设备有限公司

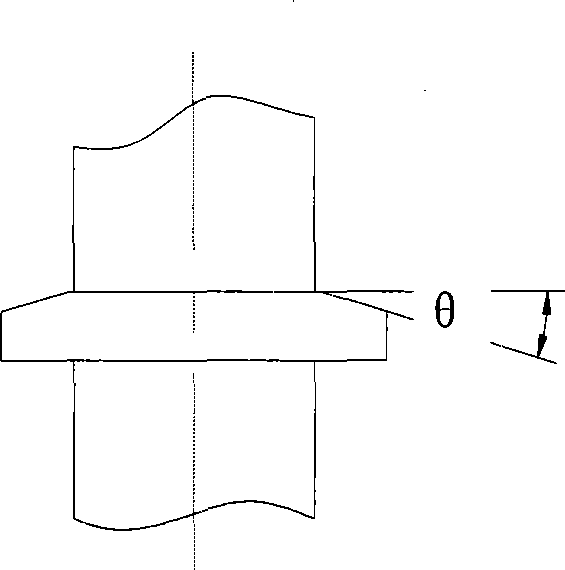

Hot-blast air flow automatic control mechanism for hot-blast air baking oven

InactiveCN101788060ANo frictionWon't wasteOperating means/releasing devices for valvesLift valveAutomatic controlThermal expansion

The invention relates to a hot-blast air flow automatic control mechanism for a hot-blast air baking oven, which belongs to the technical field of air flow control devices. The hot-blast air flow automatic control mechanism comprises a valve body, a throttle actuator and a throttle, and is characterized in that: a first semi-ring sealing socket and a second semi-ring sealing socket are fixedly arranged on the inner wall of a valve cavity of the valve body; the first semi-ring sealing socket corresponds to the second semi-ring sealing socket mutually to form an integral annular body; a plane at the edge position of the throttle is hermetically matched with the first semi-ring sealing socket and the second semi-ring sealing socket; the throttle actuator comprises an acting cylinder, a support, a rotating shaft linkage mechanism and a rotating shaft; the support is fixed on the valve body; an acting cylinder pivot is arranged on the support, and an acting cylinder column of the acting cylinder is connected with the rotating shaft linkage mechanism; the rotating shaft linkage mechanism is connected with the rotating shaft; and the rotating shaft is supported on the valve body and is connected with the throttle. The hot-blast air flow automatic control mechanism has the excellent sealing effect, does not cause energy waste with air leakage and ensures the heating effect of a heating cavity of the hot-blast air baking oven; the throttle does not influence the sealing effect with expansion caused by heat and contraction caused by cold; and the throttle avoids friction phenomenon and damages caused by friction.

Owner:常熟市双龙无纺设备有限公司

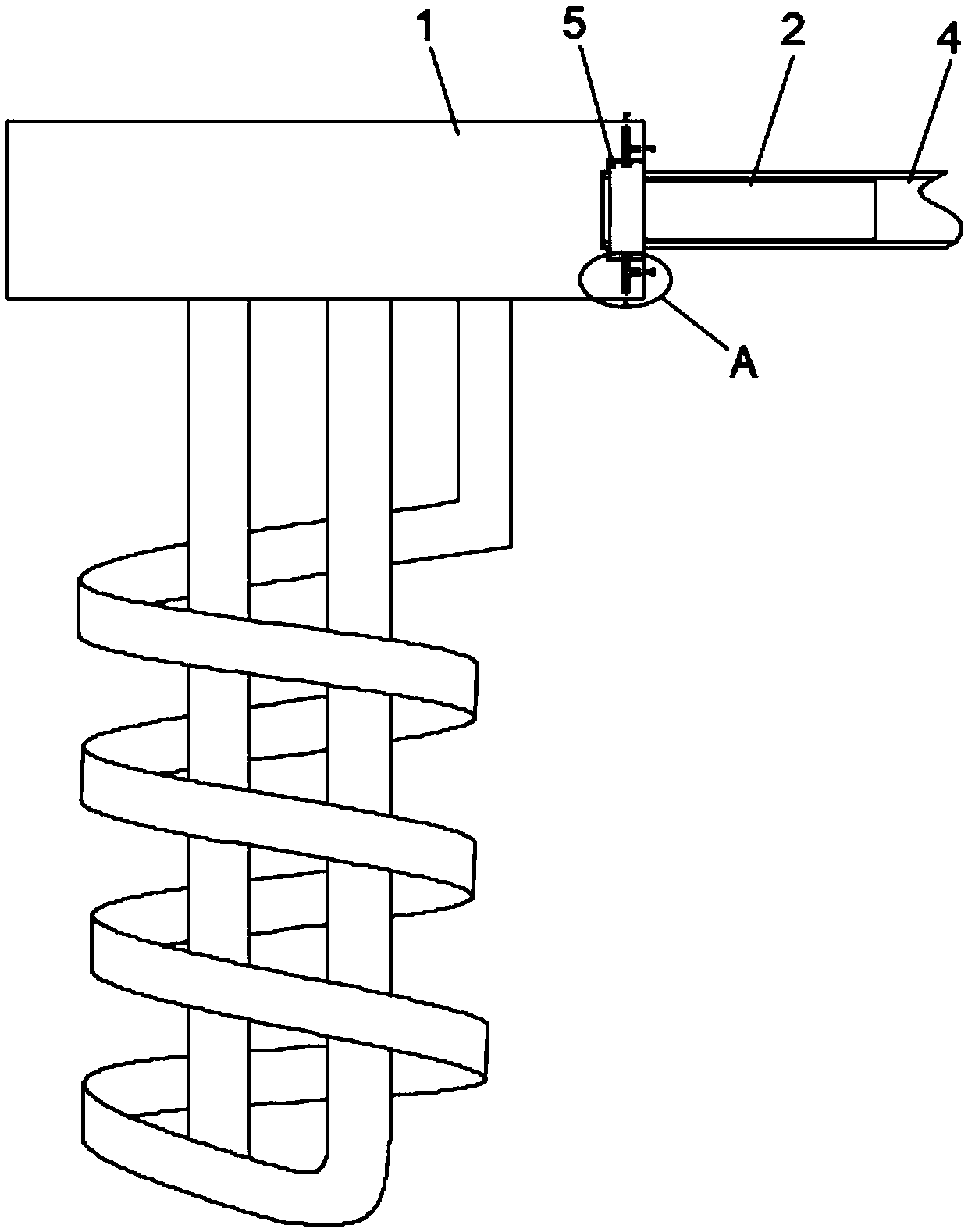

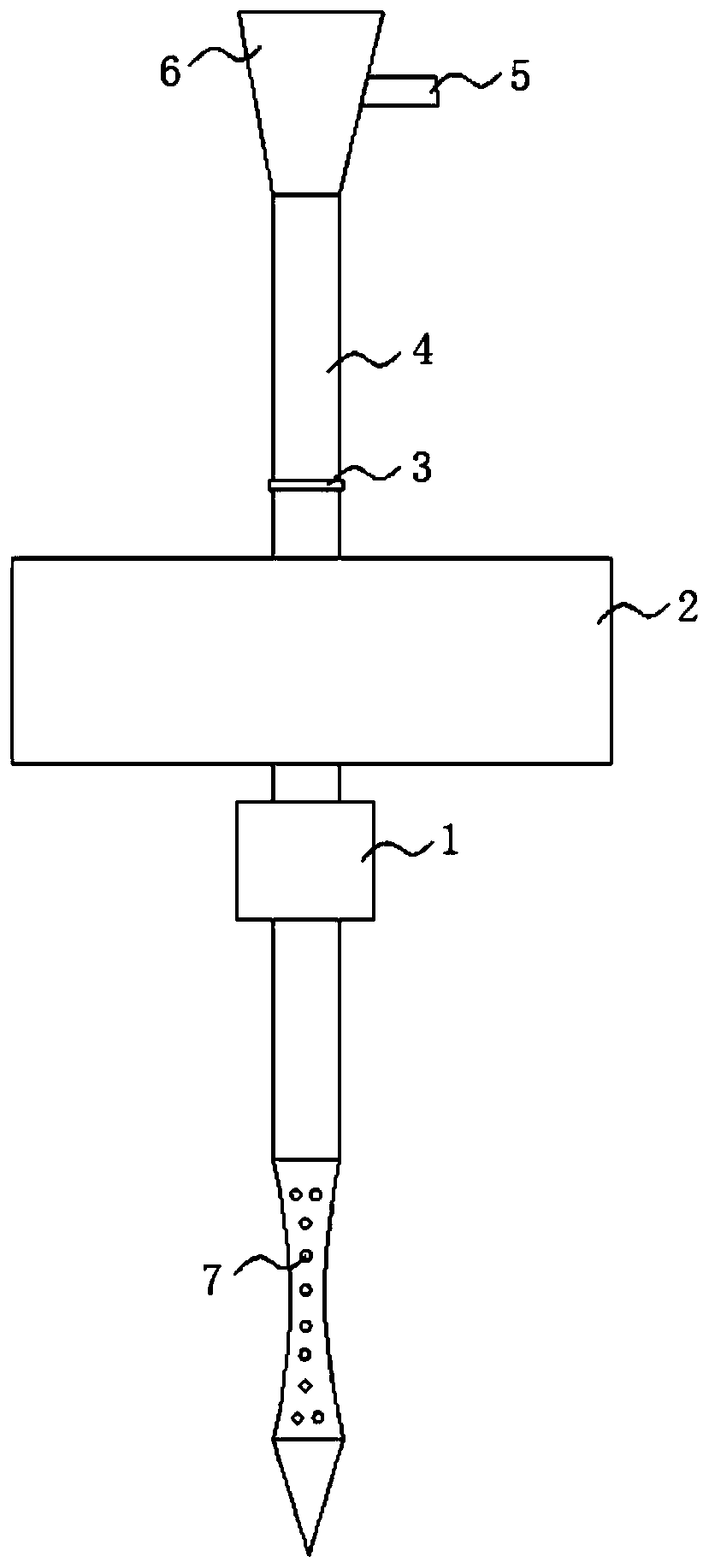

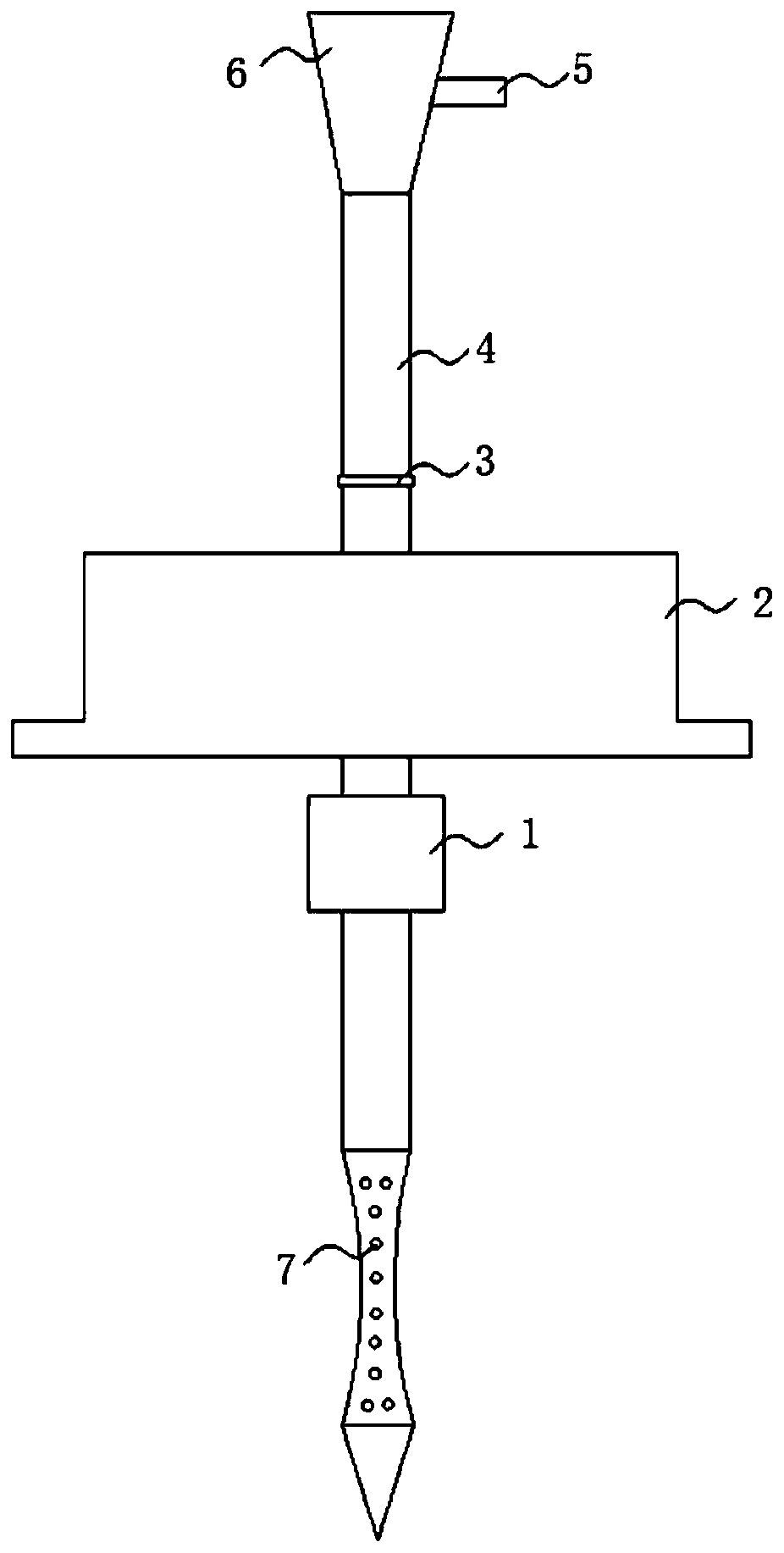

Sealing assembly, geogas prospecting sampler and application method of geogas prospecting sampler

The invention discloses a sealing assembly, a geogas prospecting sampler and an application method of the geogas prospecting sampler and belongs to the field of geogas prospecting equipment. The sealing assembly provided by the invention comprises a sealing plug, a sealing cover and a sealing ring which sleeve the sampler from bottom to top in sequence. The sealing plug is tightly attached to theouter wall surface of the sampler. A penetrating hole is formed in the middle of the sealing cover. The inner wall of the sealing ring is tightly attached to the outer wall surface of the sampler. Thesealing assembly provided by the invention is simple in structure, reasonable in design and easy to manufacture. The geogas prospecting sampler provided by the invention is formed by assembling the sealing assembly. When the sampler is used, part of the assembled sampler is inserted into an inspection hole, a gap between the sampler and the inspection hole is sealed by means of the sealing plug firstly, then the sealing cover is compacted to the ground where the inspection hole is formed, the sampler is downwards inserted into an inspection position of the inspection hole, and finally, a gapbetween the penetrating hole of the sealing cover and the sampler is sealed by means of the sealing ring. The application method steps are easy and convenient to implement, and the problem that an airinlet of an existing sampler is prone to being blocked is effectively solved.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com