Hot-blast air flow automatic control mechanism for hot-blast air baking oven

A technology of hot air flow and interlocking mechanism, which is applied in the direction of engine components, valve housing structure, mechanical equipment, etc., can solve the problems of damage to the damper 3 deformation, leakage, and the stability of the heating chamber temperature of the hot air oven, etc., to achieve good The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

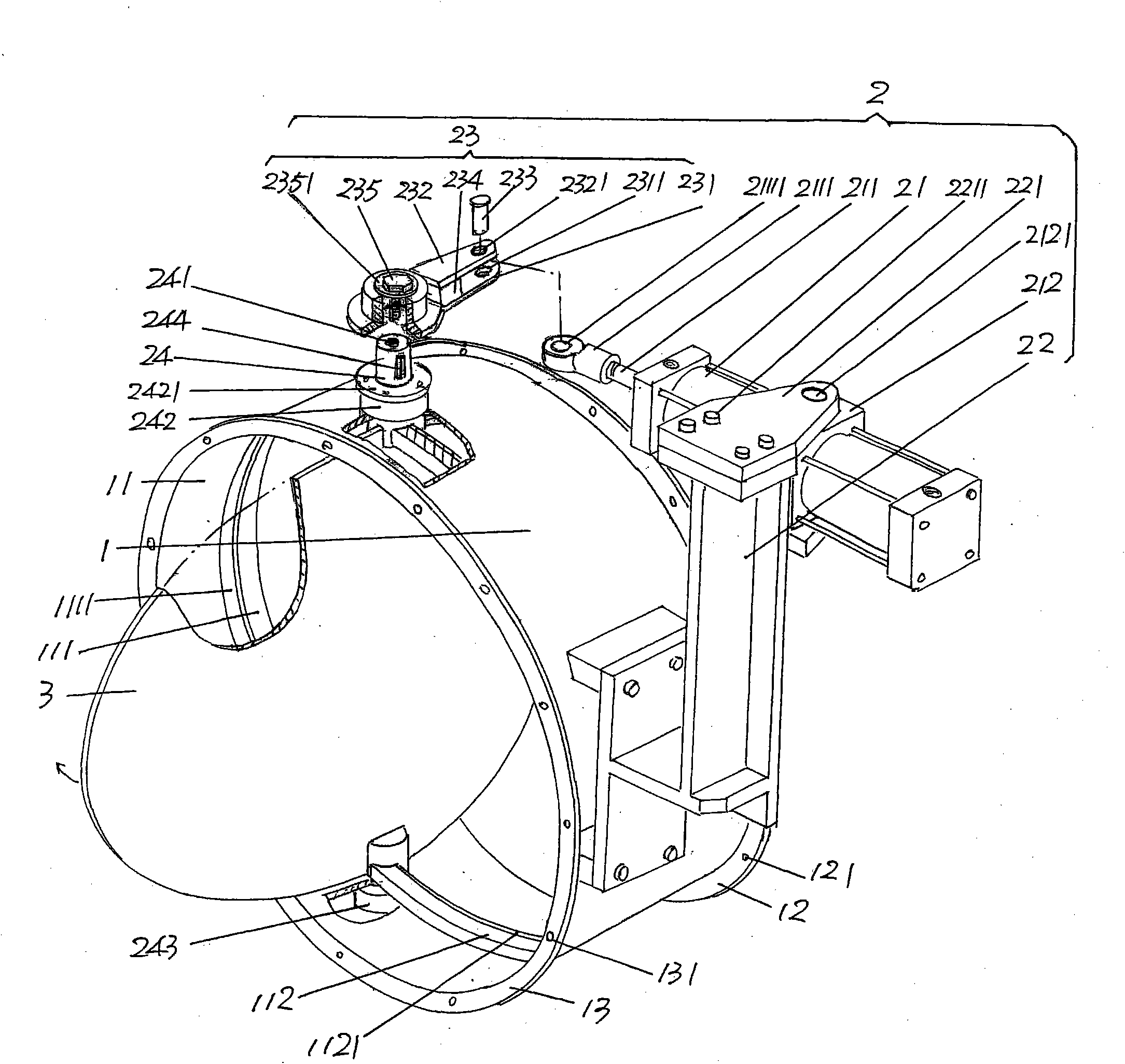

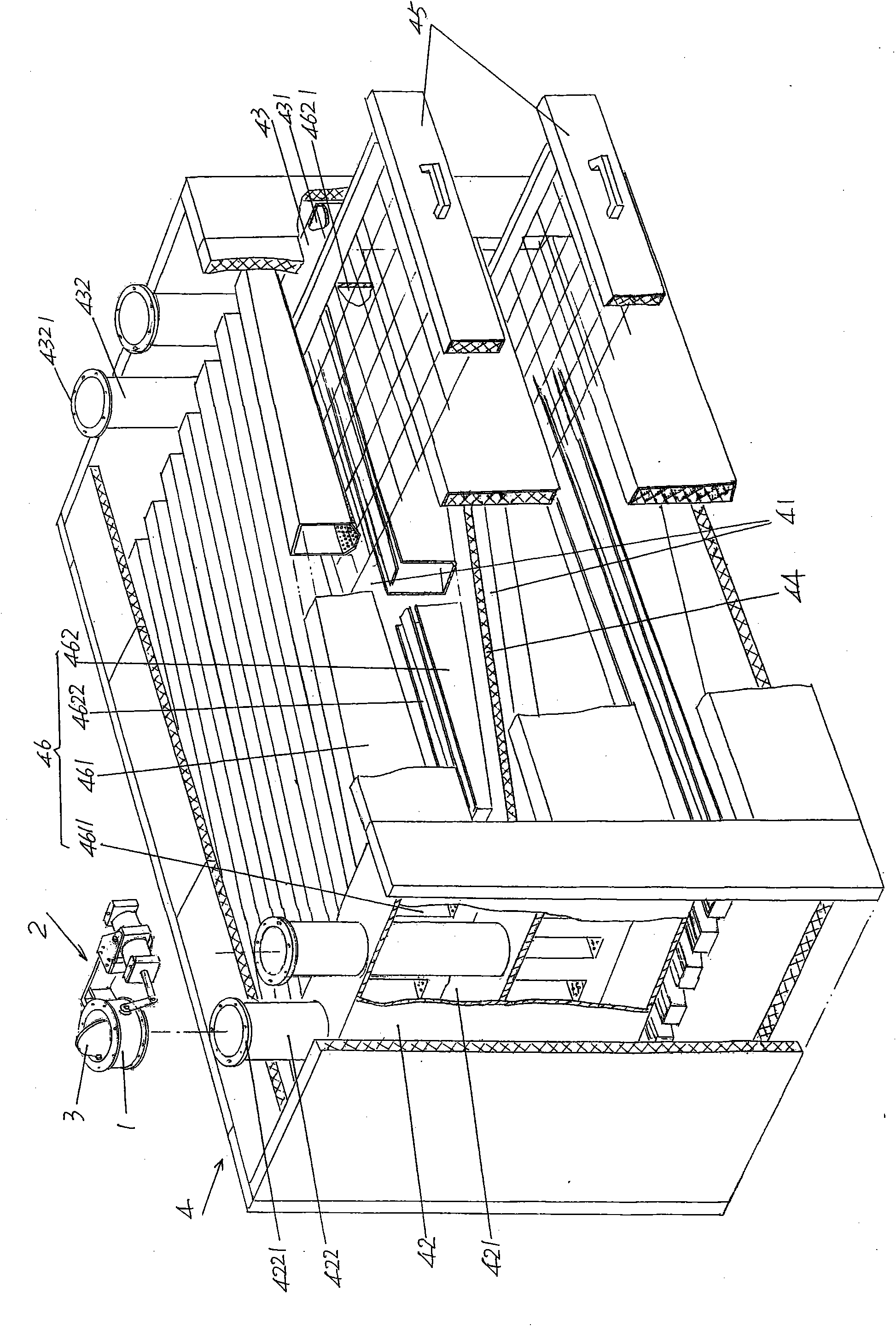

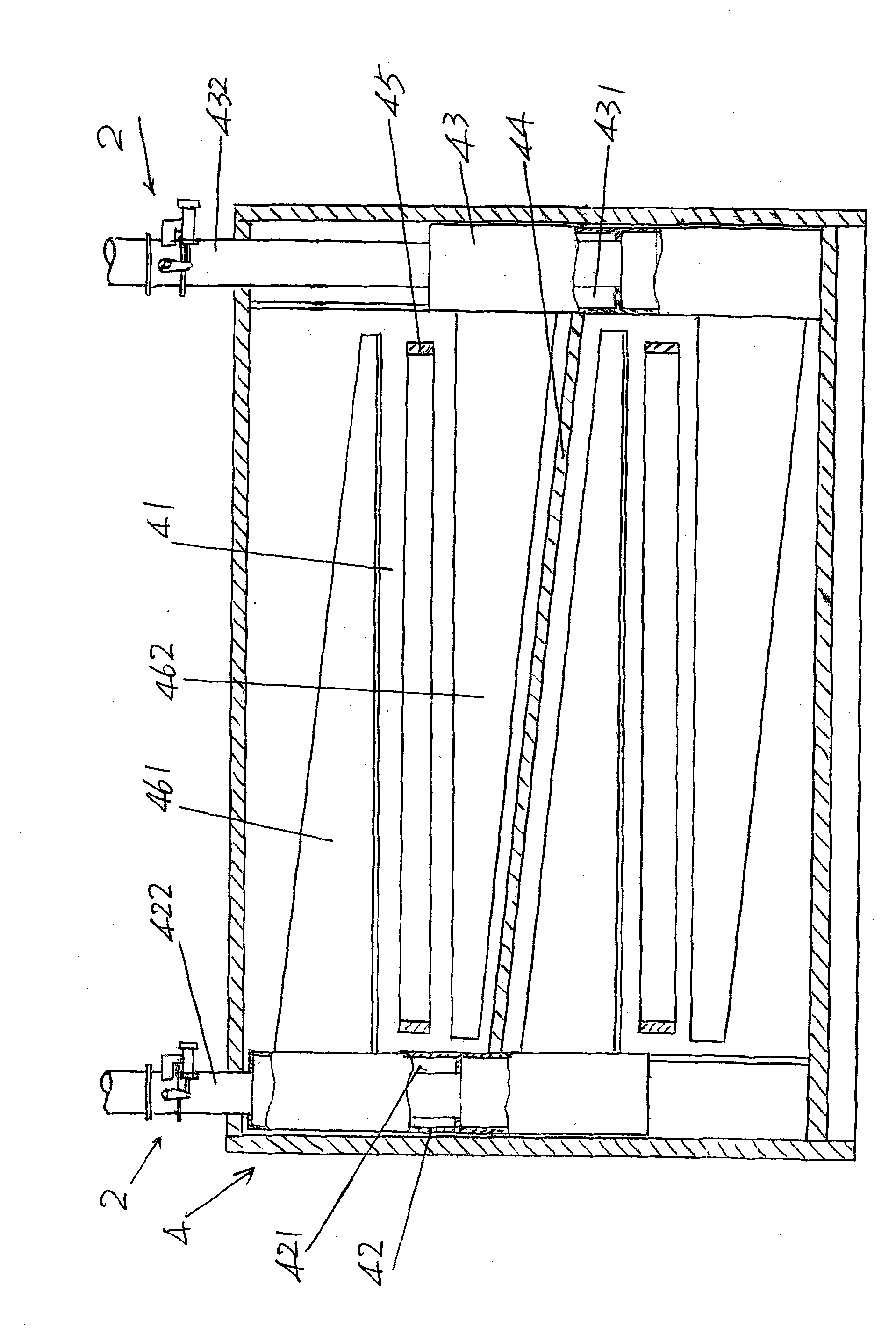

[0024] Please see figure 1 , the geometric shape of the given valve body 1 is a cylinder, and at one end of the valve body 1, that is, the right end shown in the figure, there is a first mating flange 12 that is turned outwards, and on the first mating flange 12 There are first matching holes 121 interspersed therebetween, and the first matching flange 12 is used for matching with the high-temperature hot air source pipeline, that is, the gas source pipeline. The other end of the valve body 1, that is, the left end shown in the figure, has a second mating flange 13 that is turned outwards, and a second mating hole 121 is arranged at intervals on the second mating flange 13. The second mating method Lan 13 is used for connecting with the interface flange 4221 of the high-temperature air introduction interface 422 of the hot air oven ( figure 2 Show). On the inner wall 11 of the valve chamber of the valve body 1, the first and second half-ring sealing seats 111, 112 are corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com