Blowout preventer unit for workover rig

A blowout preventer and workover rig technology, used in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of limited use times, long-term shut-in use is not allowed, and achieve good sealing effect , to ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

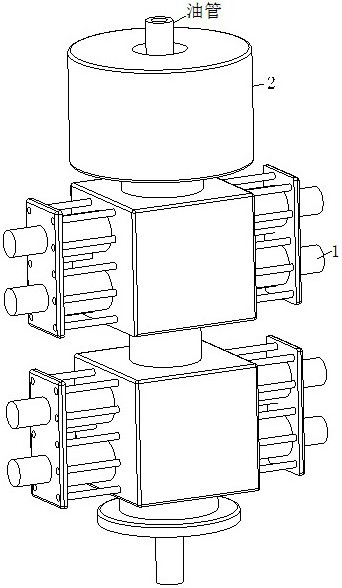

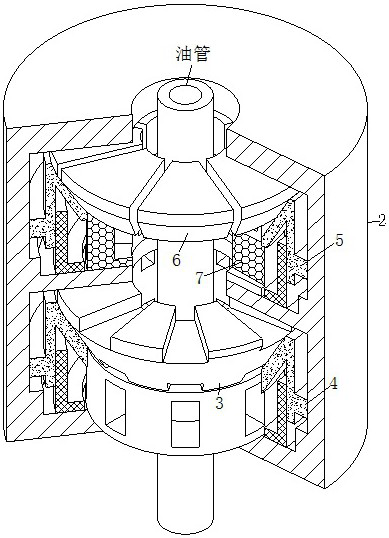

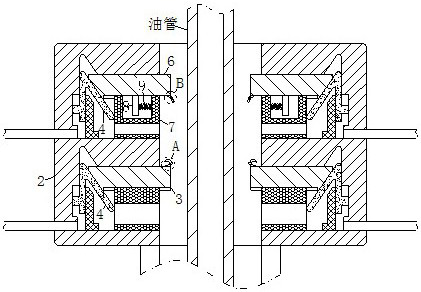

[0032] Such as Figure 1 to Figure 3 As shown, a blowout preventer group for a workover rig according to an embodiment of the present invention includes a ram blowout preventer body 1, an annular blowout preventer housing 2 and an annular rubber core 3; the ram blowout preventer The top of the body 1 is fixedly connected with an annular blowout preventer casing 2, and the annular blowout preventer casing 2 is designed in a ring structure; the inside of the annular blowout preventer casing 2 is provided with a first sealing groove; the first The inside of the sealing groove is slidingly connected with the first piston 4; the top position of the first piston 4 is provided with an annular rubber core 3; Two sealing grooves; the inside of the second sealing groove is slidably connected with the second piston 5; the inside of the second sealing groove is slidably connected with the sealing block 6 at the top position of the second piston 5, and the sealing block 6 is uniform along ...

Embodiment 2

[0040] Such as Figure 8 As shown in Comparative Example 1, another embodiment of the present invention is: one of the gaskets 16 has a connection groove on its surface, and the cross section of the connection groove is designed as a spherical structure; The surface of the sealing gasket 16 is fixedly connected with the connecting plate 21 relative to the position of the connecting groove, and the volume of the connecting groove is greater than the volume of the connecting plate 21; during work, by setting the connecting plate 21, when the two sealing gaskets 16 move relatively, a The connection plate 21 on the surface of the gasket 16 on one side will be inserted into the connection groove on the surface of the gasket 16 on the other side. Since the gasket 16 is designed with elastic material, the mouth of the connection groove is in a sealed state in the initial state. The elastic deformation automatically opens, ensuring that a large amount of foreign matter will not be int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com