Dual-use vacuum relief valve

A safety valve and vacuum technology, applied in the direction of safety valve, lift valve, balance valve, etc., can solve the problems of single safety valve function, high precision requirements, complicated assembly and processing technology of two-way safety valve, etc., and achieve the effect of long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

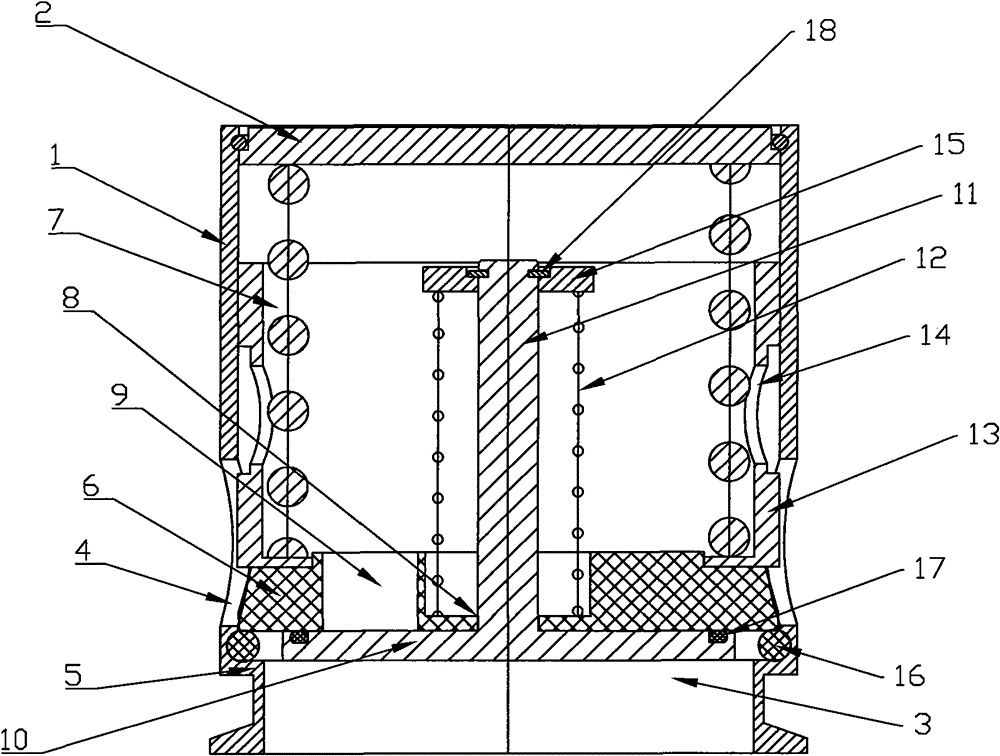

[0020] Dual-purpose vacuum safety valve of the present invention, as figure 1 Shown comprises a valve body, has a cylindrical housing 1 and a sealing cover plate 2 that seals one end of the cylindrical housing, a sealing ring is provided between the cylindrical housing 1 and the sealing cover plate 2, and the The other end of the cylindrical shell 1 forms a first air port 3, and a second air port 4 is formed on the side wall of the cylindrical shell 1, and the second air ports 4 are four, which are evenly distributed in the cylindrical shell 1, on the inner wall of the cylindrical shell 1 between the first gas port 3 and the second gas port 4, an inwardly protruding sealing boss 5 is formed, and the sealing boss 5 The sealing surface is facing the end provided with the sealing cover plate 2, the sealing surface of the sealing boss 5 here is a plane, in other embodiments it can be an upward slope or an arc, etc., as long as it can achieve the same The sealing of the first valv...

Embodiment 2

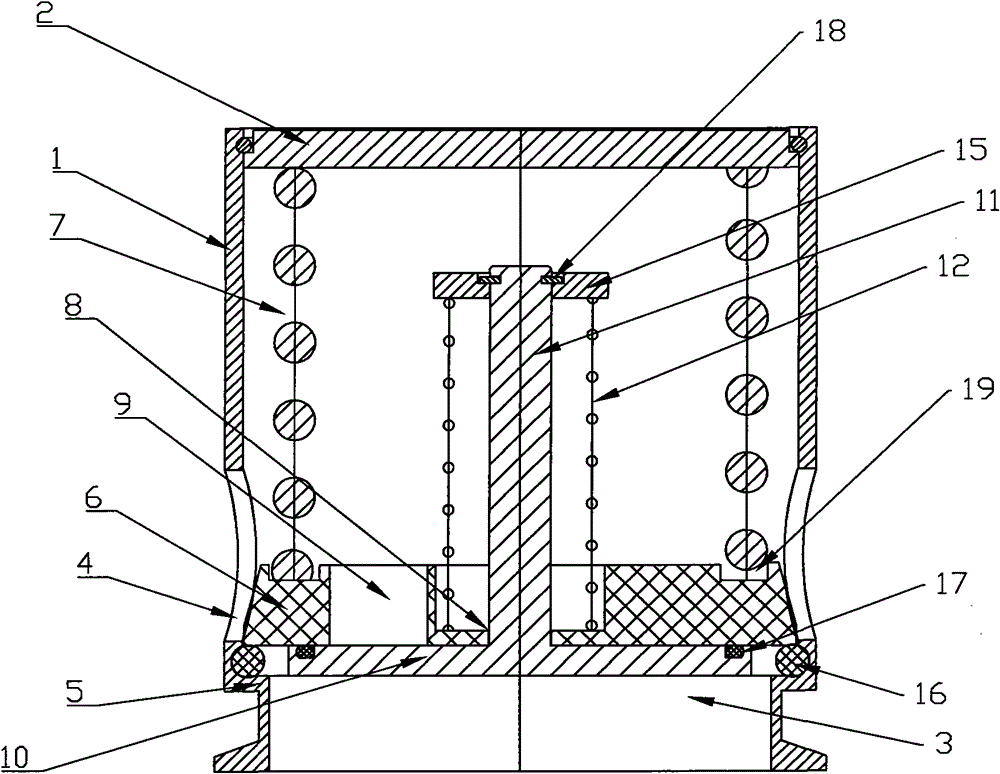

[0026] Dual-purpose vacuum safety valve of the present invention, as figure 2It includes a valve body and a valve core. The setting of the valve body is the same as in Embodiment 1. The valve core is also provided with a first valve plate assembly and a second valve plate assembly. The difference is that there is no cylindrical spring support on the top of the first valve plate. Instead, an annular groove 19 is provided on the upper surface of the first valve plate near the edge, and the first bias spring is installed on the sealing cover plate 2 and the annular groove 19 on the edge of the first valve plate 6 between. A sealing ring 16 is provided between the sealing boss 5 and the lower bottom surface of the first valve plate 6 . An annular groove is provided on the upper surface of the second valve plate 10 close to the outer edge, and a sealing ring 17 is arranged in the annular groove. The material of the first valve plate is polytetrafluoroethylene.

[0027] The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com