High-temperature-resistant ball valve

A high-temperature, ball valve technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as poor sealing effect, affecting sealing performance, and failure of sealing inserts, achieving simple structure and improving sealing effect. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

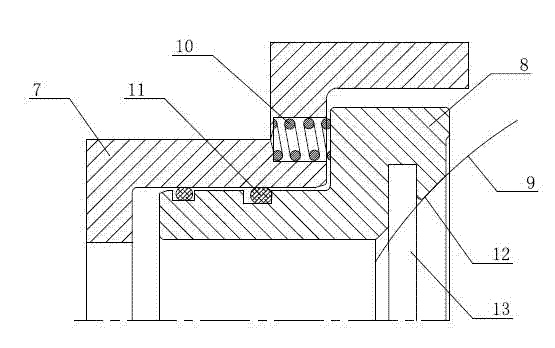

[0019] Embodiment one: see image 3 , 4 As shown, a high temperature resistant ball valve includes a valve body 7, a valve seat 8 and a ball 9, a spring 10 is provided between the valve body 7 and the valve seat 8, and a spring 10 is provided between the valve body 7 and the valve seat 8. O-shaped sealing ring 11, a slot is opened on the valve seat 8, and a sealing insert is provided in cooperation with the slot, and a sealing protrusion 12 is also provided on the valve seat 8, and the end surface of the sealing protrusion 12 Conflicting with the surface of the ball 9 constitutes the sealing surface of the ball valve, a foreign matter storage groove 13 is provided on the front side of the sealing surface, and the end surface of the sealing protrusion 12 is a slope structure.

[0020] When the ball valve is in use, when the fluid flows to the sealing surface in the ball valve, the impurities in the fluid will fall into the impurity storage tank on the side of the sealing surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com