Screen package method

A packaging method and screen technology, which is applied in the direction of instruments, semiconductor devices, electrical components, etc., can solve the problems of affecting the yield rate of the screen, affecting the service life of the screen, and poor packaging effect of the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

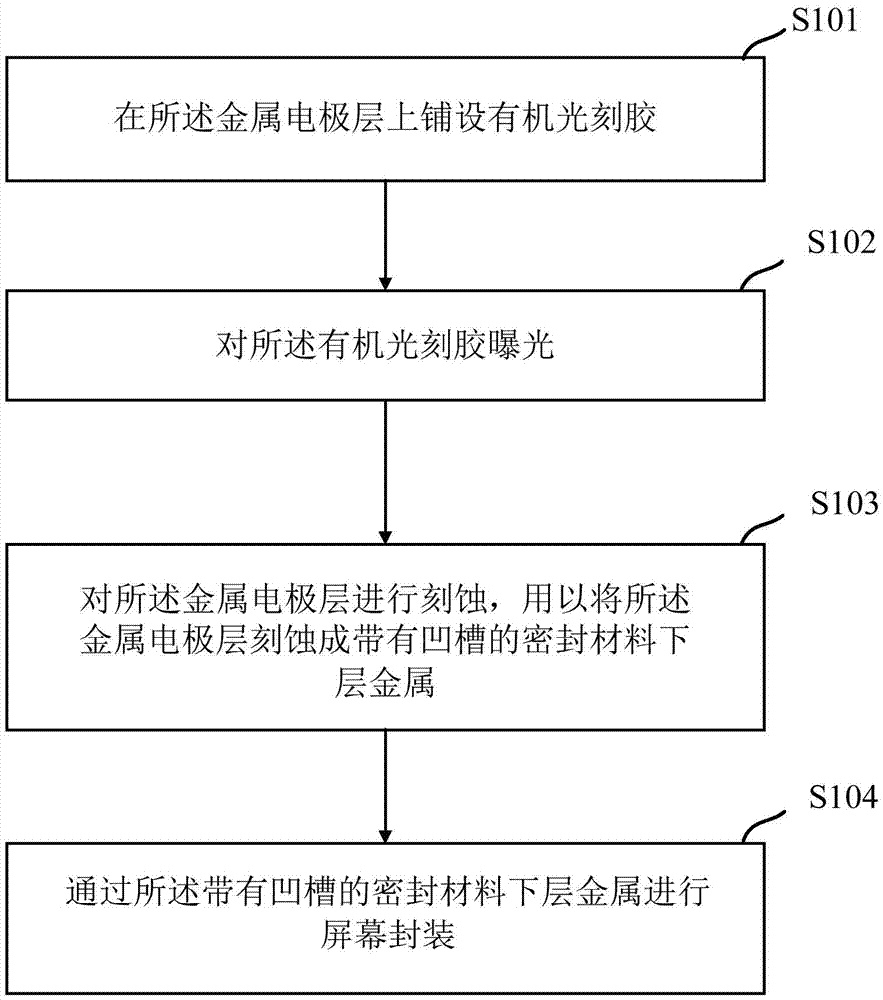

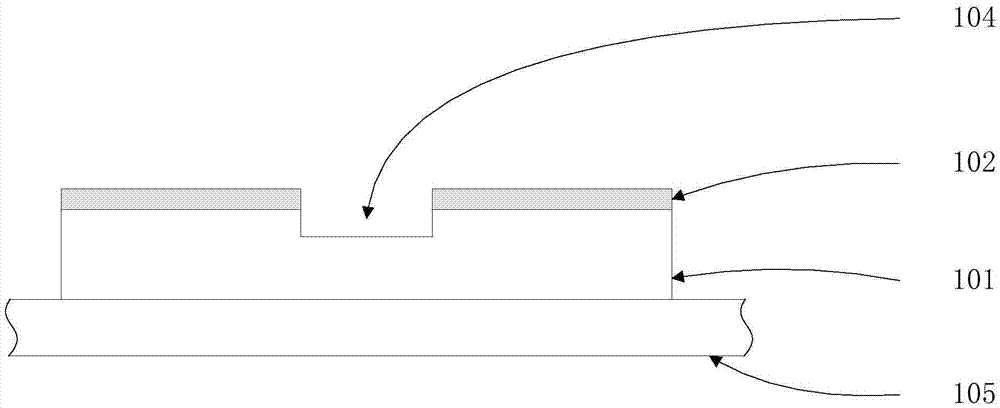

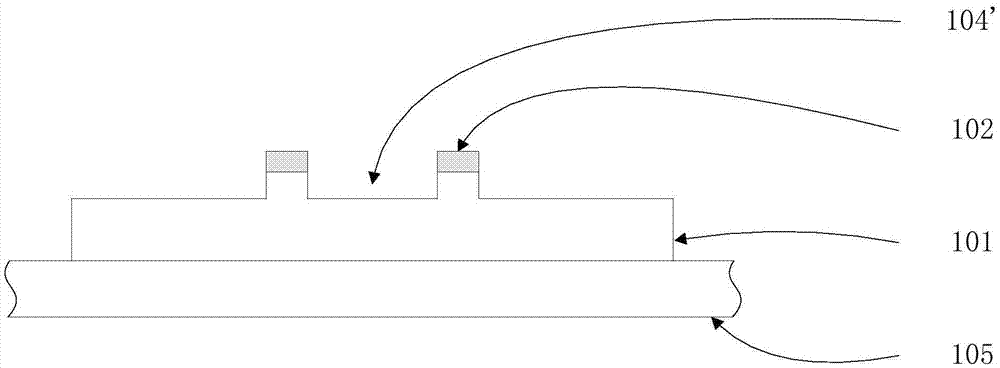

[0040] figure 1 The first screen encapsulation process provided by the embodiment of the present invention, wherein the pre-prepared metal electrode layer 101 is laid on the glass substrate 105, the method provided by the present invention specifically includes the following steps:

[0041] S101 : laying an organic photoresist 102 on the metal electrode layer 101 .

[0042] In the embodiment of the present invention, the metal electrode layer 101 can be etched using the photolithography method in the general screen production process, so the present invention can lay organic photolithography on the pre-prepared metal electrode layer 101. Glue 102.

[0043] For the convenience of subsequent description, in the present invention, the area of the metal electrode layer 101 that needs to be etched into the lower metal layer 103 of the sealing material is referred to as the encapsulation area, that is, the area where the structure used to encapsulate the screen is located during ...

Embodiment 2

[0069] based on figure 1 The same principle, the present invention also provides the second screen encapsulation process, such as Image 6 As shown, wherein the pre-prepared metal electrode layer 101 is laid on the glass substrate 105, the method provided by the present invention specifically includes the following steps:

[0070] S601: laying an inorganic material layer 109 on the metal electrode layer 101 .

[0071] In the embodiment of the present invention, different from figure 1 In the shown method, the groove is not directly etched on the metal electrode layer 101, but the inorganic material layer 109 is laid on the metal electrode layer 101, and the inorganic material layer 109 is etched, so that the inorganic material layer 109 and the metal The electrode layer 101 can be made into a sealing material lower layer metal 110 with grooves of inorganic material, so in the present invention, it is necessary to lay an inorganic material layer 109 on the electrical metal el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com