Cut-off valve structure for fast opening or closing

A shut-off valve and switch technology, which is applied in the field of fast-switching shut-off valve structure, can solve the problems of leakage, ceramic valve core is brittle and fragile, and high manufacturing cost, and achieves the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

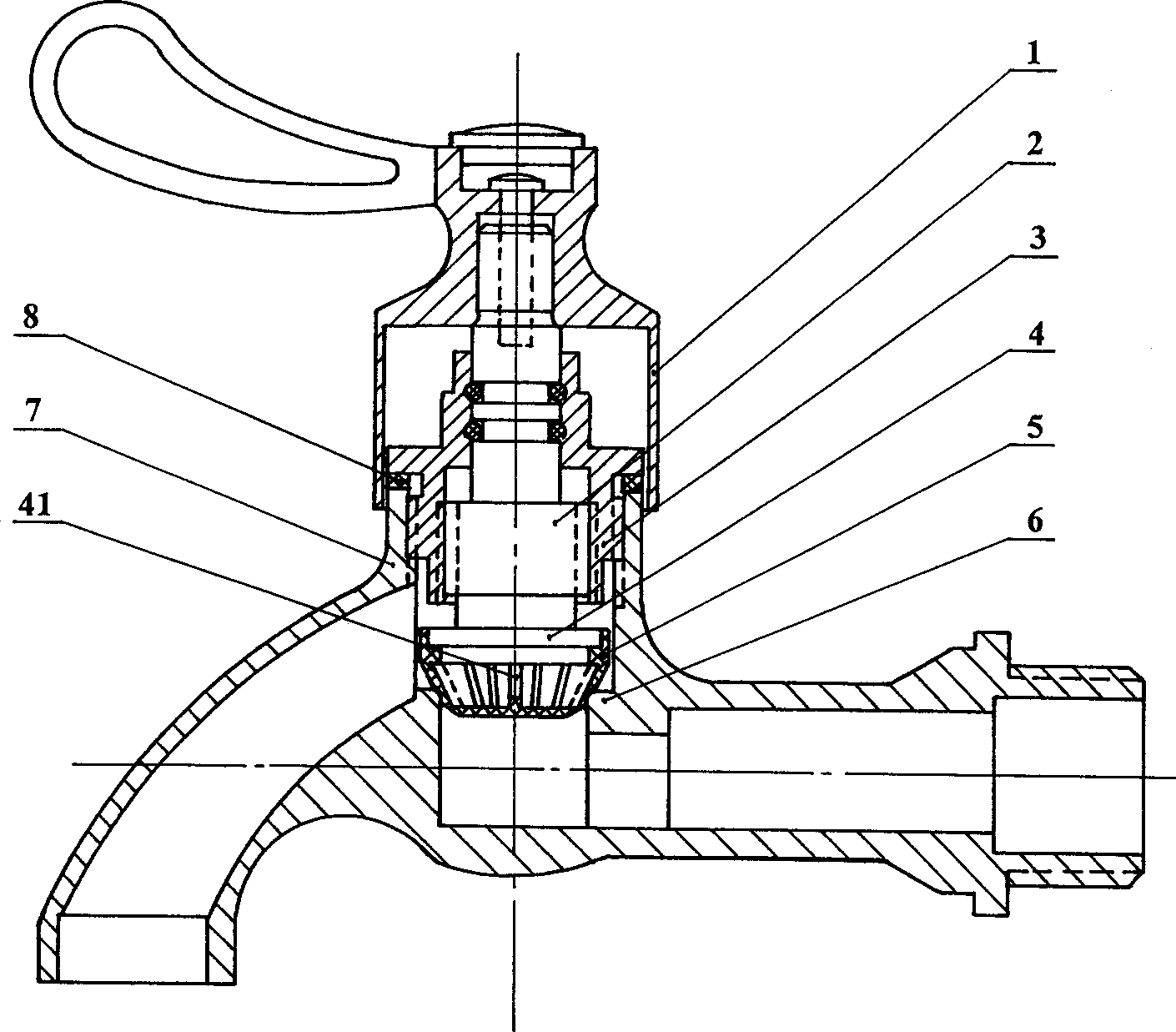

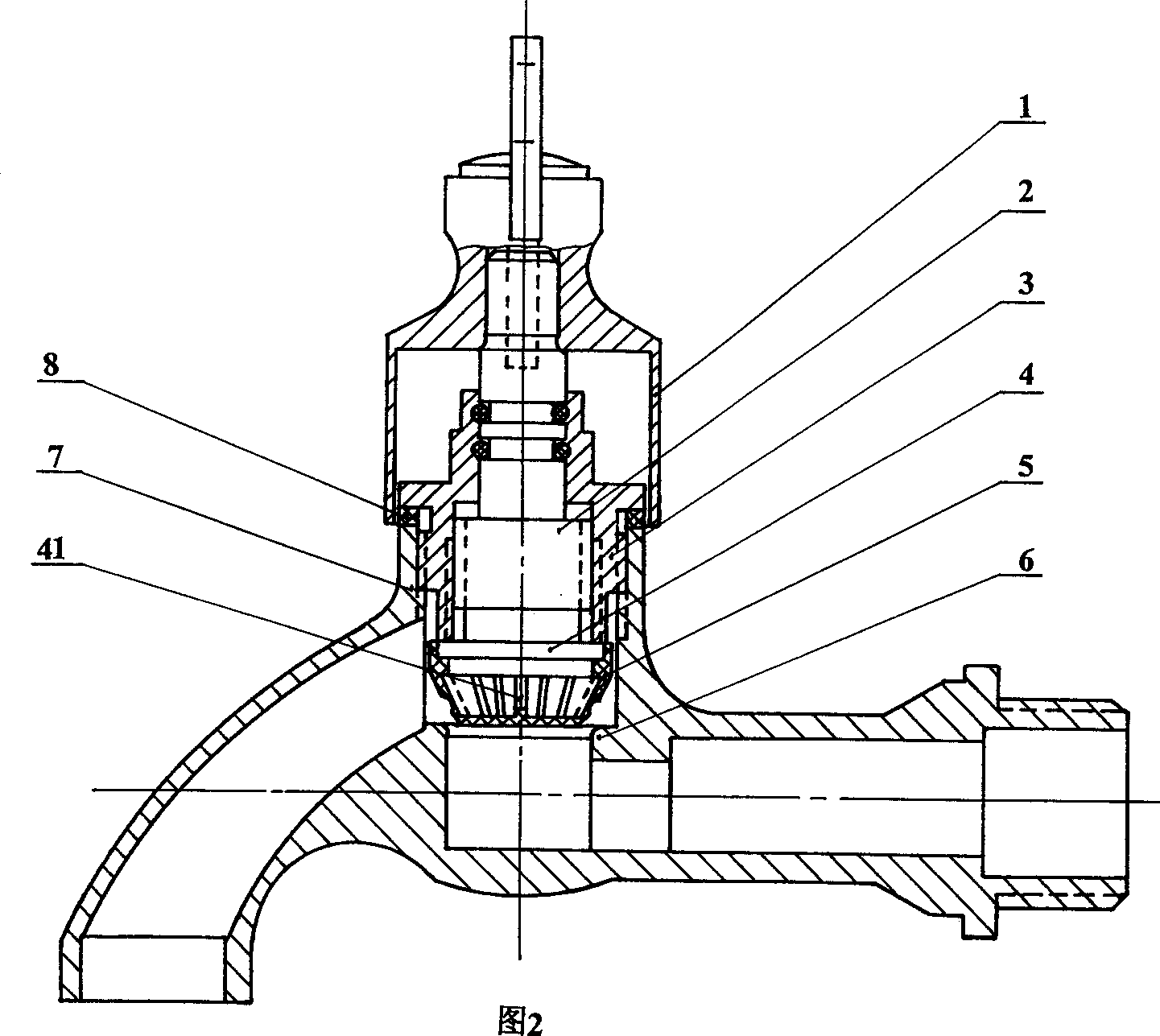

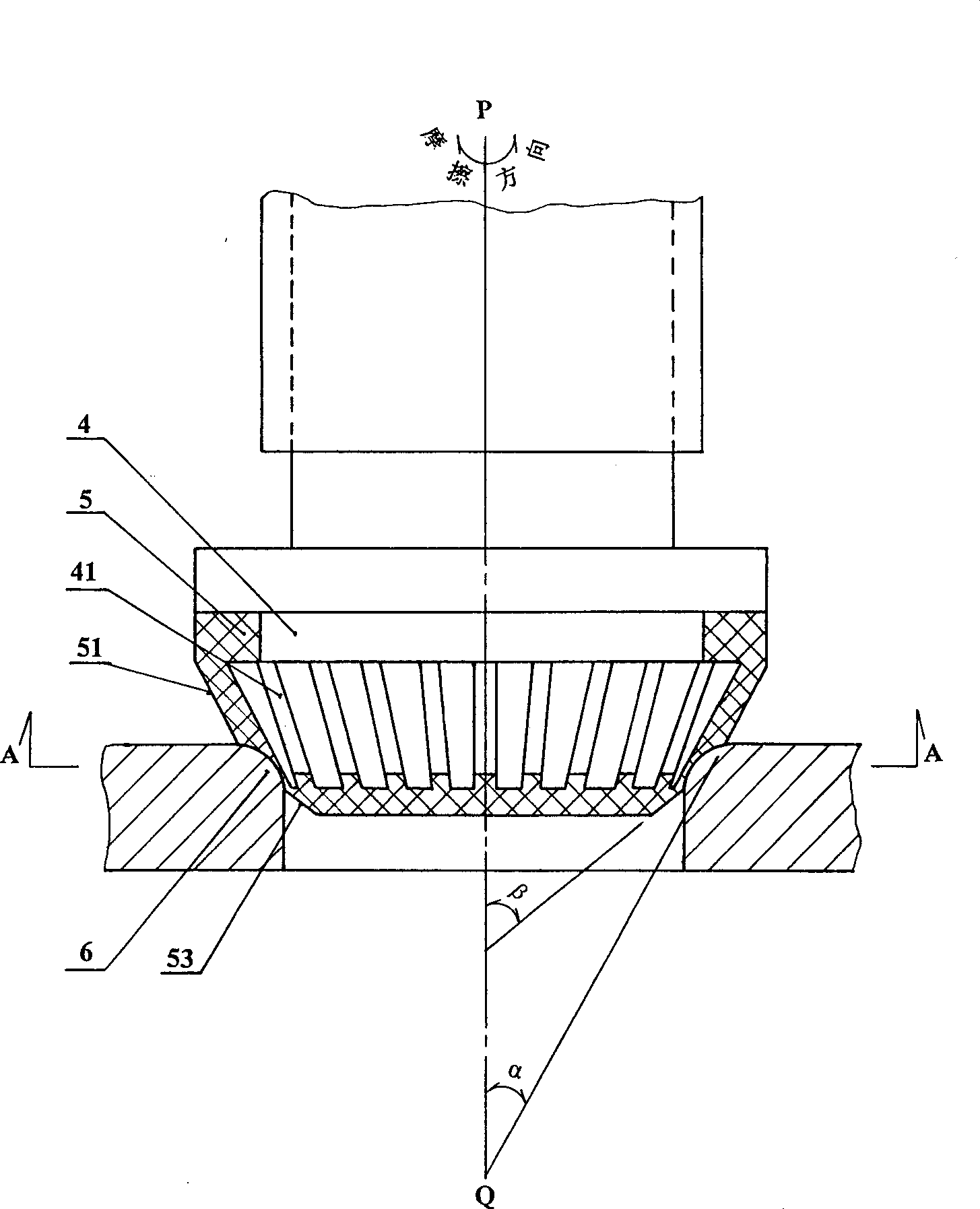

[0033] Such as Figure 1 to Figure 5As shown, it is an embodiment of the present invention applied to a faucet. In the figure, 1 is a hand wheel, 2 is a valve stem, 3 is a valve cover, 4 is a conical valve core made of metal material, and 5 is made of solid lubricating material. 6 is a metal material valve seat, 7 is a valve body, and 8 is a valve cover gasket. The valve stem 2 and the valve core 4 are connected as a whole, and the sealing bush 5 is integrally injection-molded on the valve core 4, and the thickness covering the side of the head of the valve core 4 is 0.5 mm to 5 mm, and the specific value depends on the application, diameter and use The pressure is different, and the thickness at the end face of the head of the valve core ( Figure 5 In d) it is better to be less than 0.5mm;

[0034] Such as Figure 5 As shown, the outer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com