Irrigation gate of farmland canal for preventing cutting of water stop belt in internal groove

A technology for farmland canals and waterstops, applied in irrigation pipelines, agriculture, applications, etc., can solve problems such as affecting the sealing effect, the sealing effect of the gate, and the damage of the waterstop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

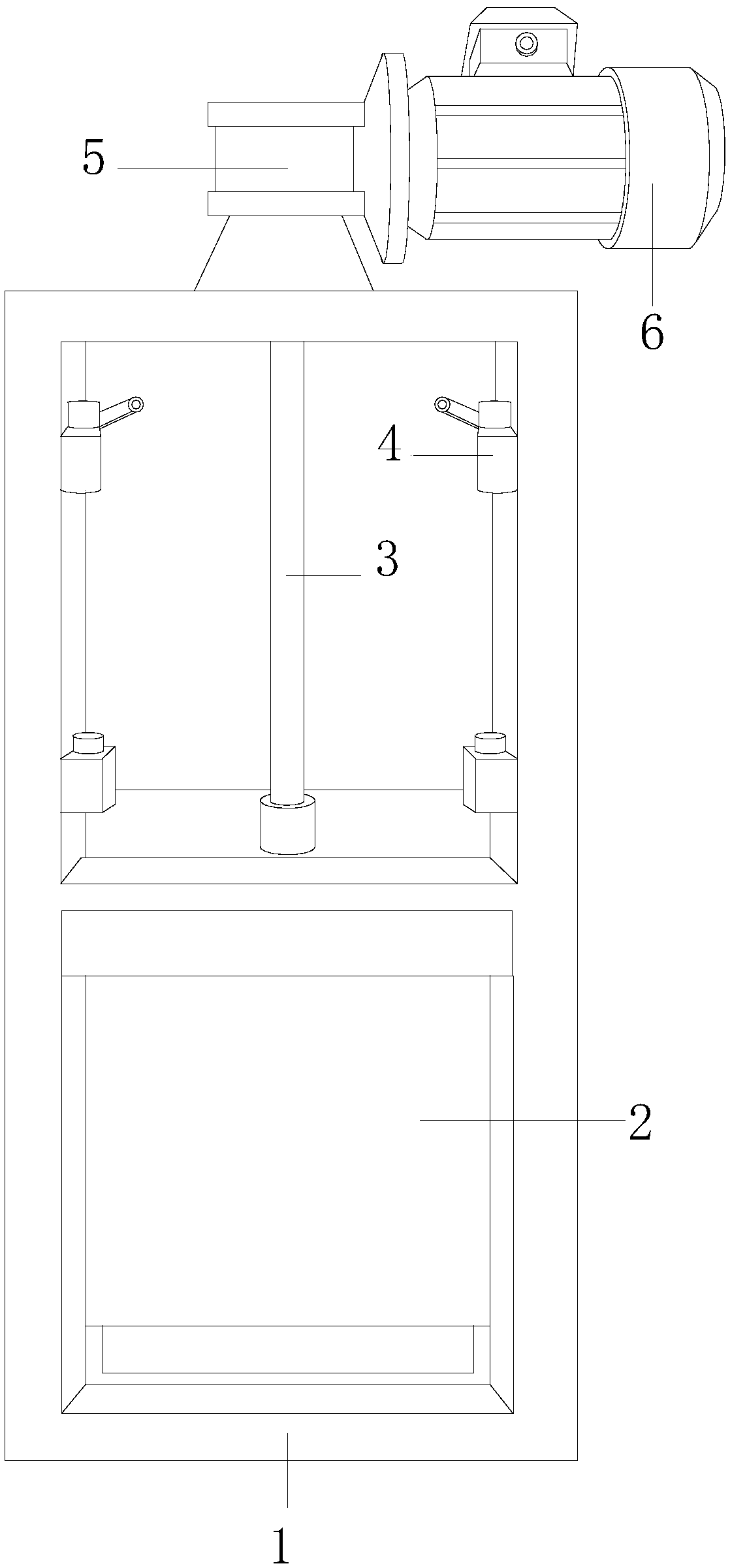

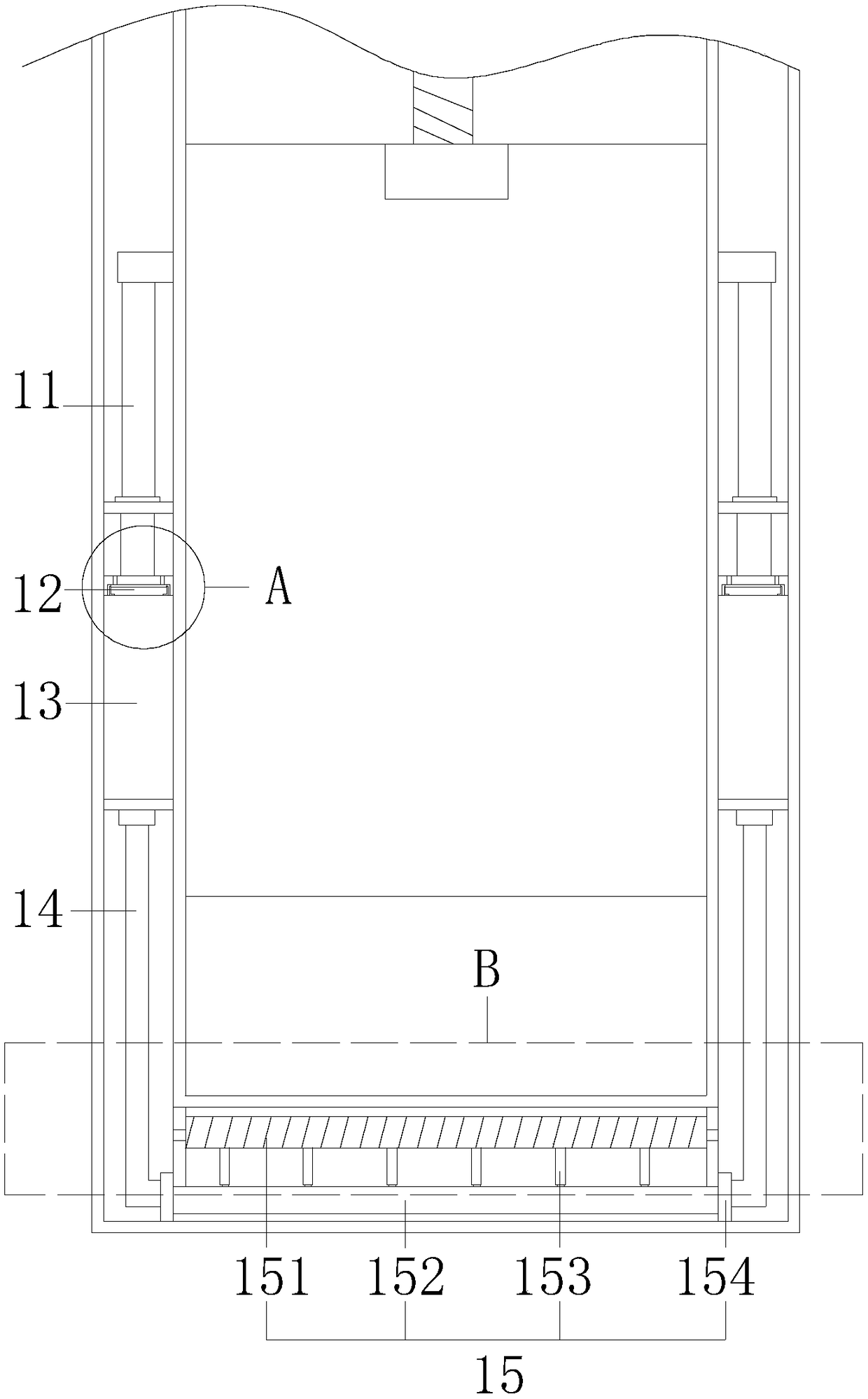

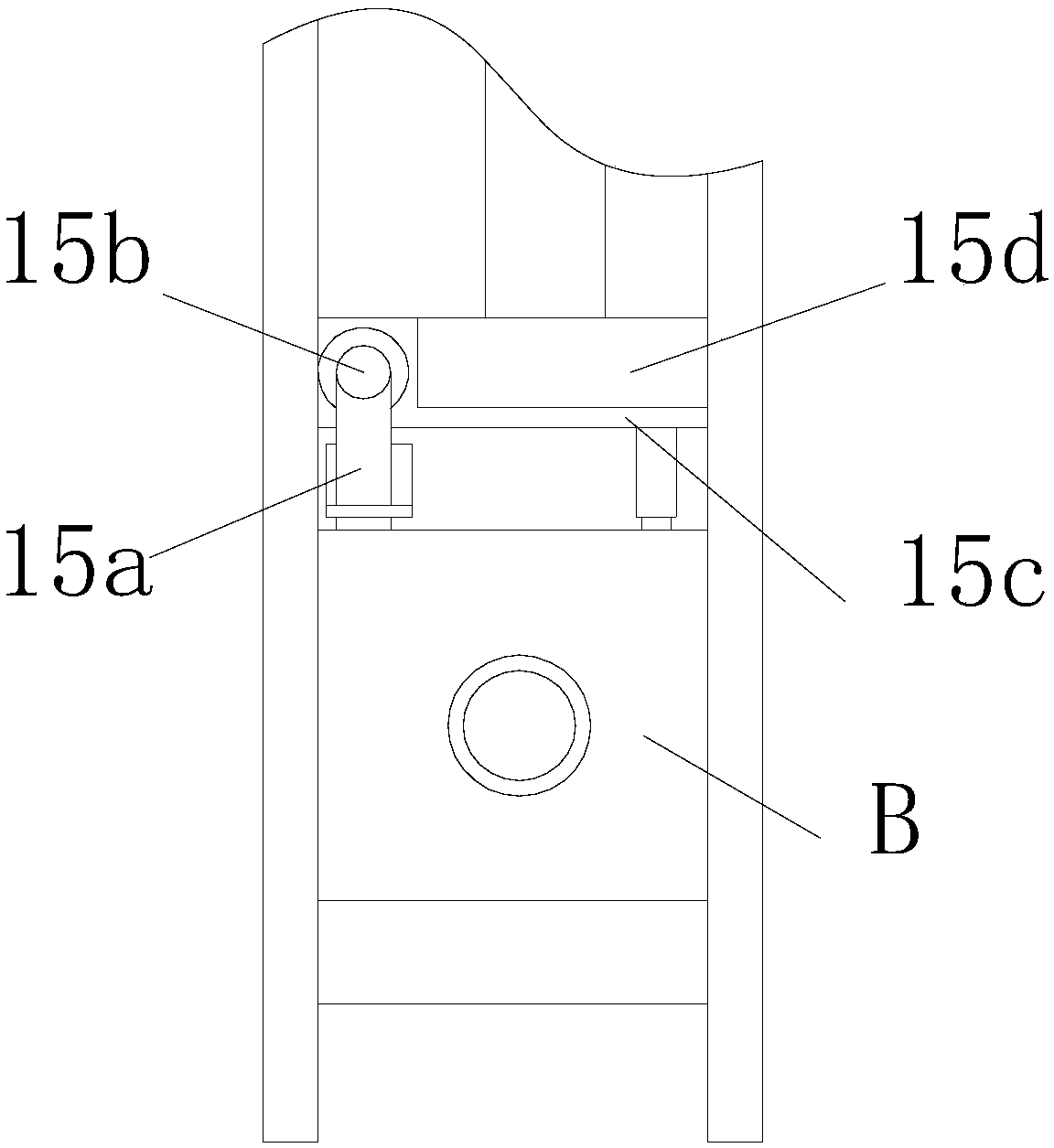

[0021] Such as Figure 1-Figure 4 As shown, the present invention provides a farmland canal irrigation gate that prevents cutting of the waterstop in the inner tank, and its structure includes: a fixed frame 1, a waterstop 2, a lifting screw 3, a limit switch 4, a gear box 5, a The motor 6, the water stop plate 2 is vertically embedded in the isolation grooves on the left and right sides of the fixed frame body 1, the rotating block at the bottom end of the lifting screw 3 is welded and fixed at the center of the top of the water stop plate 2, and the limit switch 4 There are four of them, and they are installed on the inner wall of the fixed frame body 1. The fixed flange on the left side of the drive motor 6 is installed on the right side of the drive shaft of the gear box 5 through bolts, and the lifting screw 3 runs through the The center of the gear box 5, and the interior is interlocked by threads, the internal structure of the fixed frame 1: extrusion rod 11, one-way pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com