Anti-leakage durable structure of cut-off valve

A leakage-proof and durable shut-off valve technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve problems such as short service life, leakage, and difficulty in changing production of valve factories, and achieve the effect of improving leak-proof and durable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

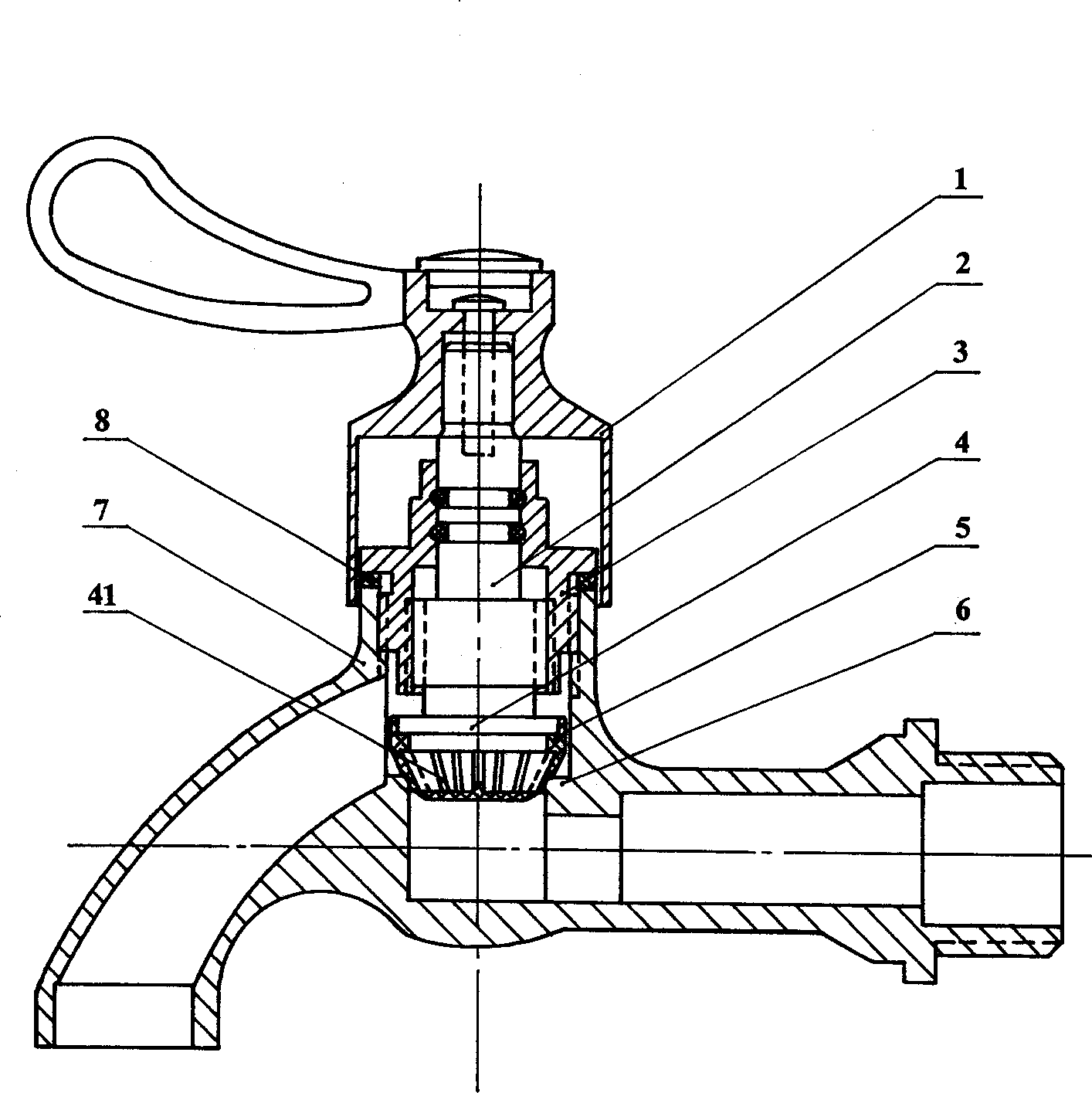

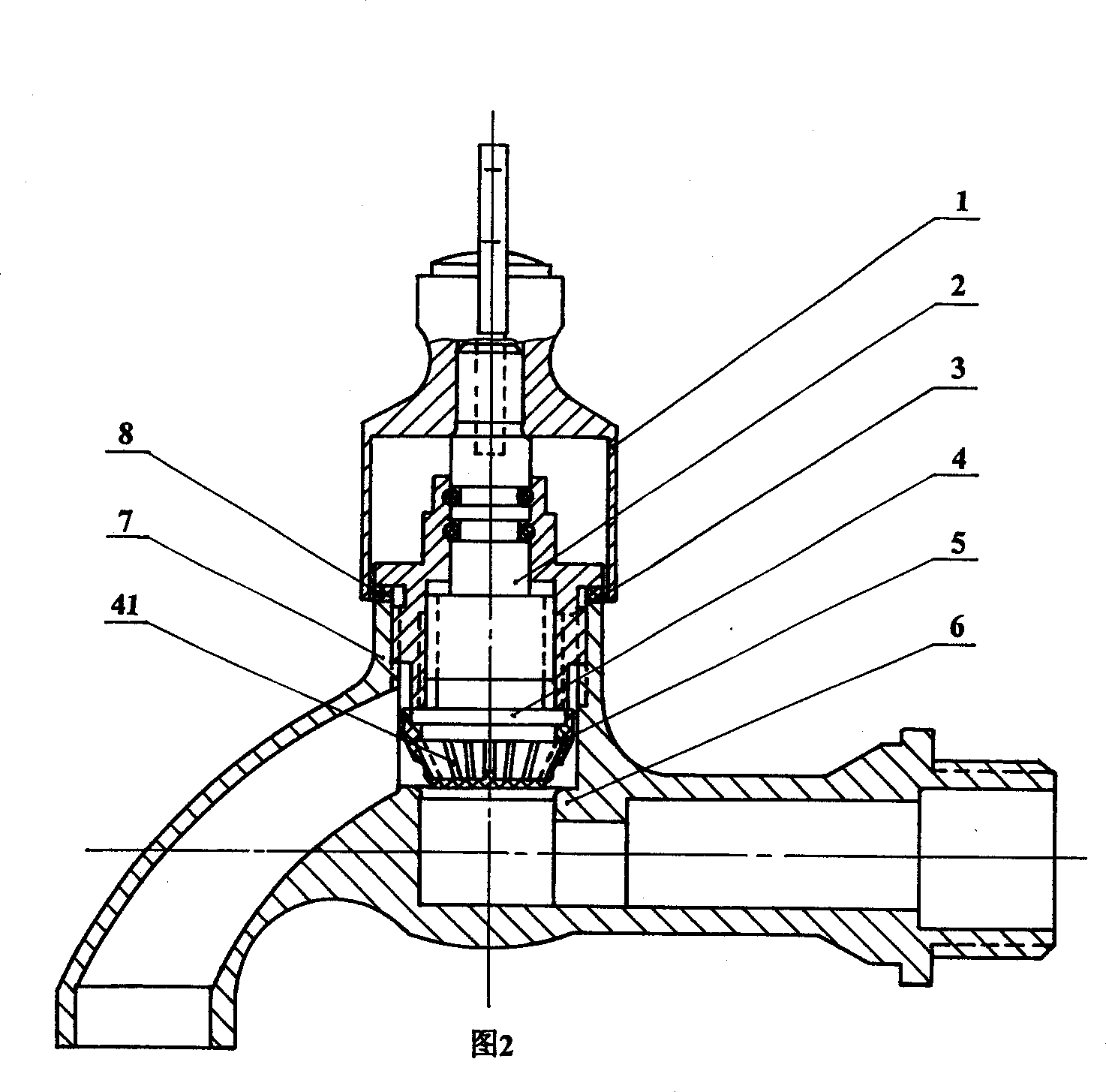

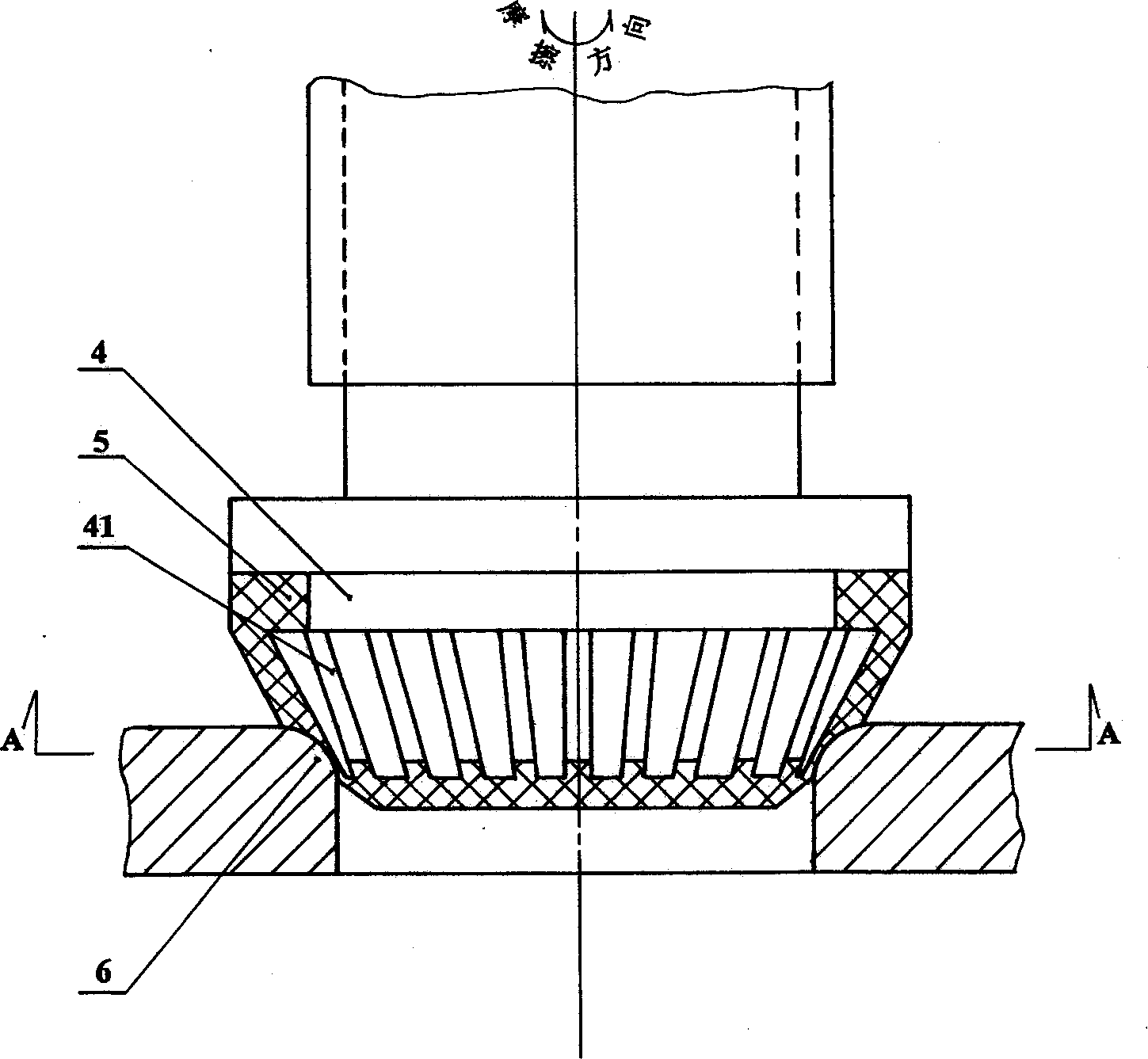

[0026] Such as Figure 1 ~ Figure 4 As shown, it is an embodiment of the present invention applied to a faucet. In the figure, 1 is a hand wheel, 2 is a valve stem, 3 is a valve cover, 4 is a conical valve core made of metal, 5 is a solid lubricating material layer, 6 It is a metal material valve seat, 7 is a valve body, and 8 is a valve cover gasket. The valve stem 2 and the valve core 4 are connected as a whole, and the solid lubricating material layer 5 is integrally injected on the valve core 4, with a thickness of 0.5 mm to 5 mm, and its specific value varies depending on the application, diameter and operating pressure; It can be seen that the spool 4 has uneven grooves or holes on the surface in contact with the solid lubricating material layer 5, and the grooves can be longitudinal strips 41 (see image 3 ), or gridded 42 (see Figure 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com