Metal winding type gasket, inner ring, centering ring and metal winding type gasket component

A metal winding and centering ring technology, which is applied to engine components, engine seals, mechanical equipment, etc., can solve the problems of expensive materials, resource waste, and waste of metal wound gasket components, and achieve broad market application prospects and easy use , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

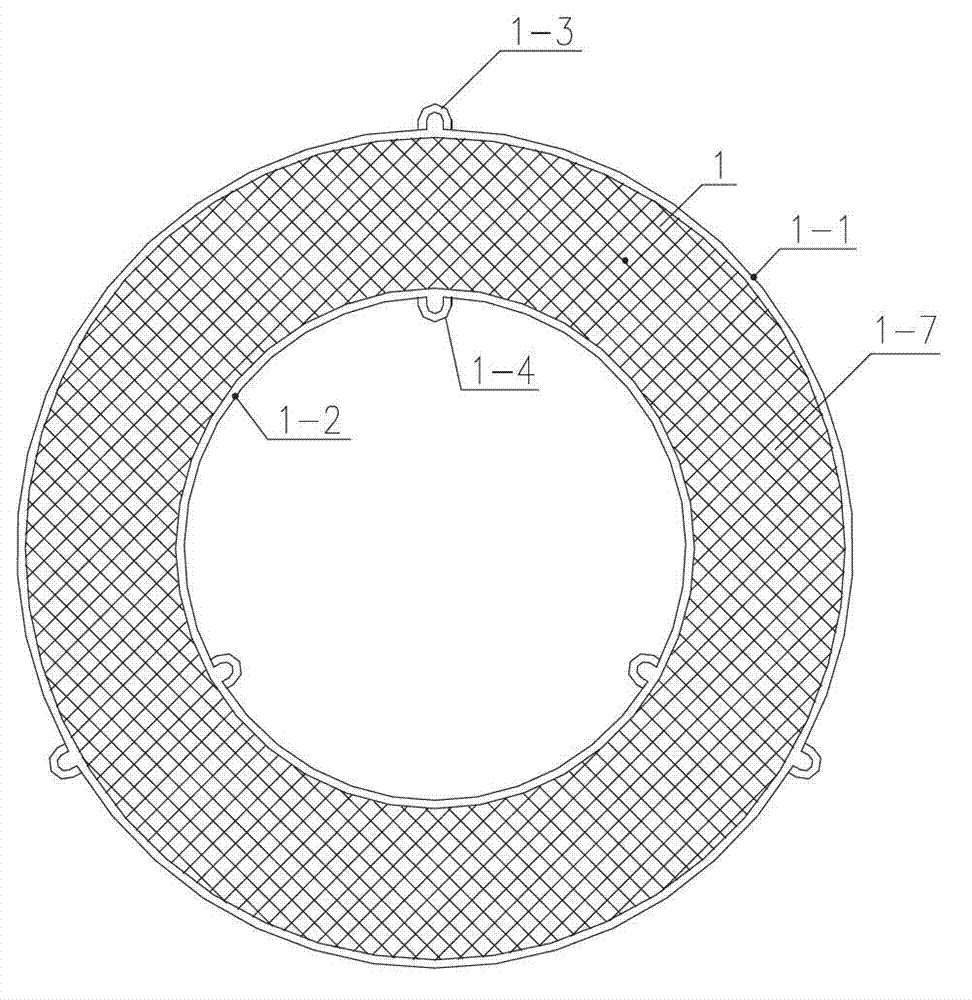

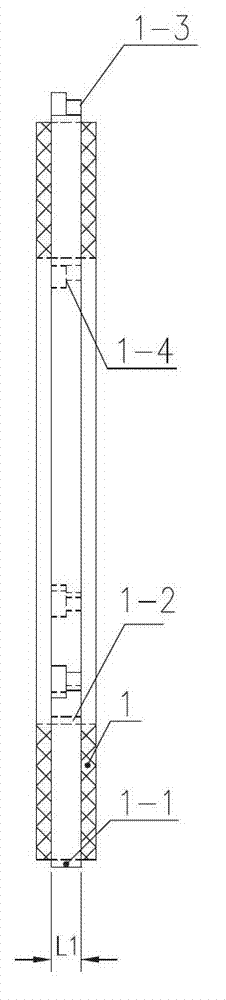

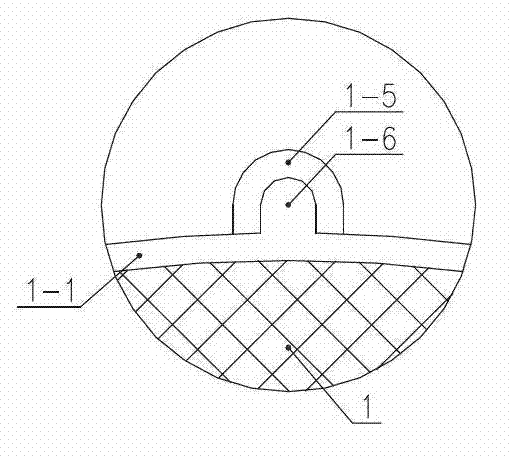

[0046] Embodiment 2 of metal wound gasket assembly (with centering ring type):

[0047] refer to Figure 14 , In this embodiment, the metal wound gasket 1 only has a support 1-3 on its outer support ring 1-1, but does not provide a support 1-4 on the inner support ring 1-2. When assembling, the centering ring 2 is covered with the metal wound gasket 1, and the bracket 1-3 on the metal wound gasket 1 and the bracket clamping hole 2-1 on the centering ring 2 are snapped in one by one, closely matching, and the rest are the same Example 1.

Embodiment 3

[0048] Embodiment 3 of metal wound gasket assembly (type with inner ring):

[0049] refer to Figure 15 , In this embodiment, the metal wound gasket 1 only has a bracket 1-4 on its inner support ring 1-2, and does not have a bracket 1-3 on the outer support ring 1-1. When assembling, the inner ring 3 is embedded in the metal wound gasket 1, and the bracket 1-4 on the metal wound gasket 1 and the bracket clamping hole 3-1 on the inner ring 3 are snapped in one by one, closely fitting, and the rest With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com