Transplanting machine cultivating arm

A technology for planting arms and rice transplanters, applied in the field of planting arms, can solve the problems of planting arm cover wear and other problems, and achieve the effects of avoiding damage to seedlings, reducing wear and increasing the area of pushing seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

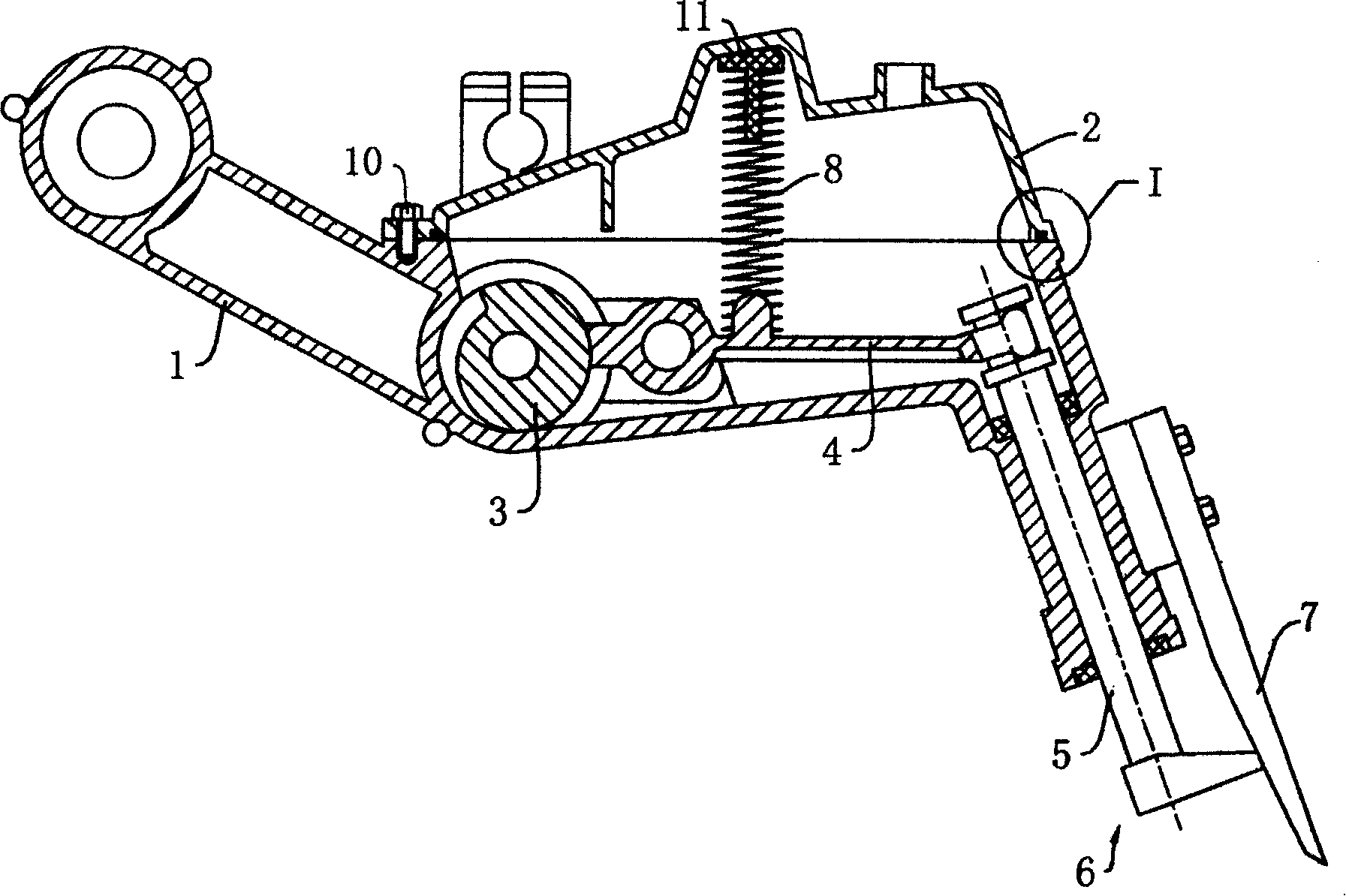

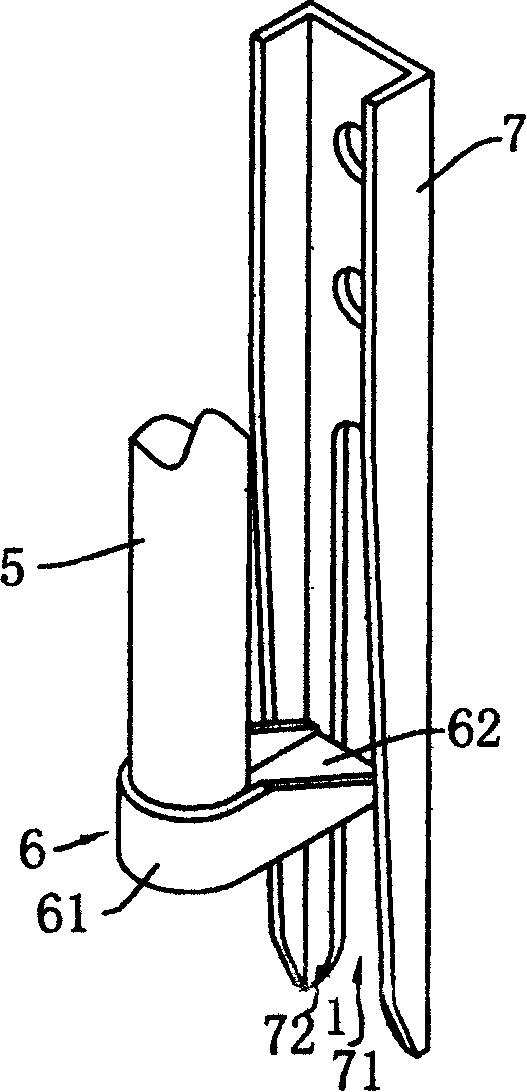

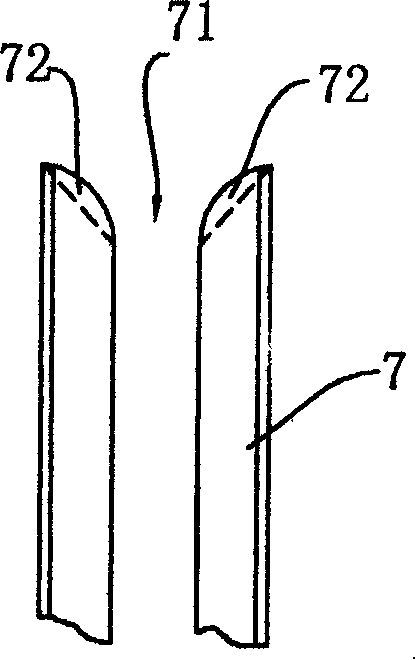

[0023] figure 1 It is a cross-sectional view of an embodiment of the present invention, the planting arm shell 1 and the planting arm cover 2 are fixedly connected together by screws 10, and a cavity for installing other components is formed inside it. Planting arm shell 1 and planting arm cover 2 are all made of metal material, compared with the planting arm cover of plastic material, not only improved the intensity of the planting arm shell that is made up of planting arm shell 1 and planting arm cover 2, make it not suitable for Damaged and broken, and anti-aging, long service life, avoiding the influence of temperature difference. A cam 3 and a shift fork 4 that can swing around a fixed axis are installed in the planting arm shell 1, and the cam 3 can be connected with a power input shaft. One end of the shift fork 4 leans against the cam surface of the cam, and the other end is hinged with the seedling pusher bar 5, or other flexible connection methods are possible. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com