Ceramic tile decoration production system capable of distributing uniform ink-splashing patterns

A production system and technology for ceramic tiles, which are applied in ceramic molding machines, ceramic molding workshops, supply devices, etc., can solve the problems of inability to mass-produce dry-grain ceramic tiles, rough decorative texture of ceramic tiles, and single decorative effect, and achieve rich decorative effects. , rich decorative means, decorative texture clear and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manners of the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to the following implementation manners.

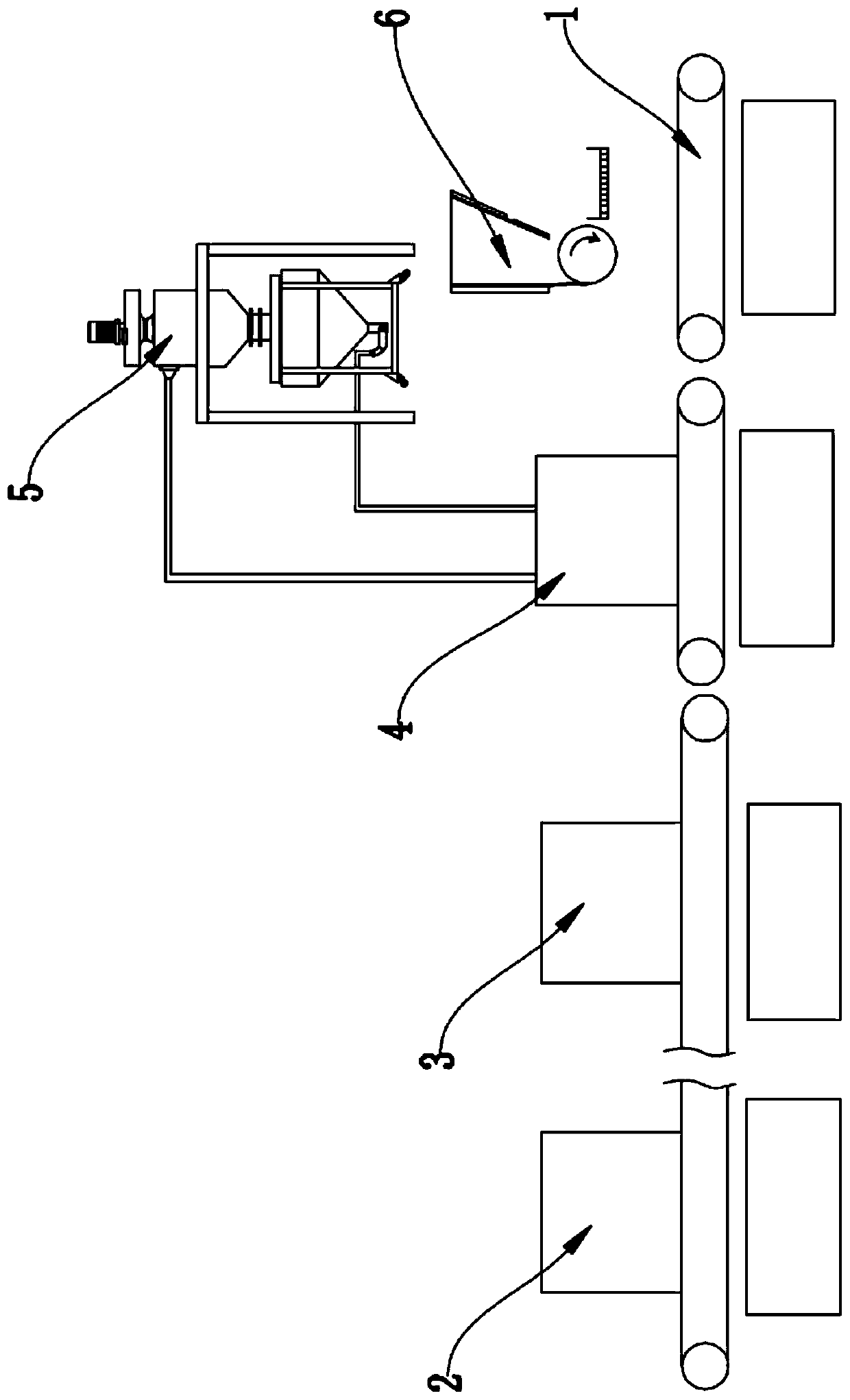

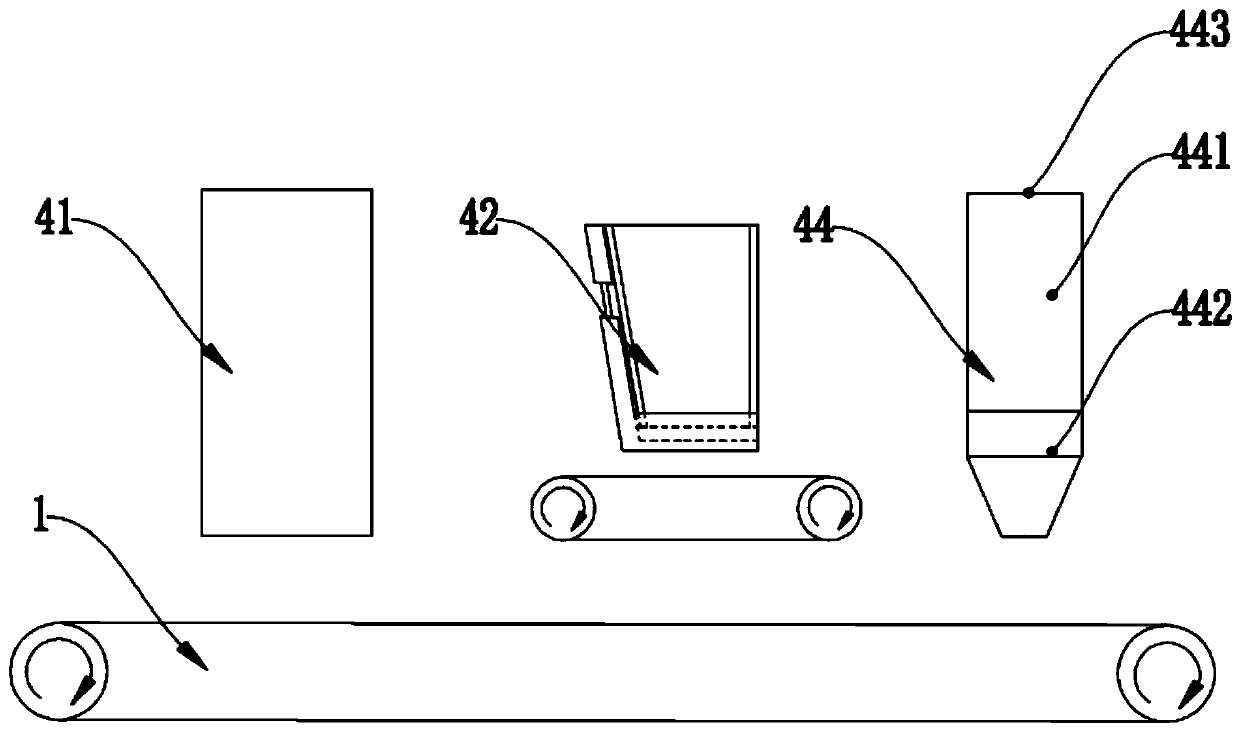

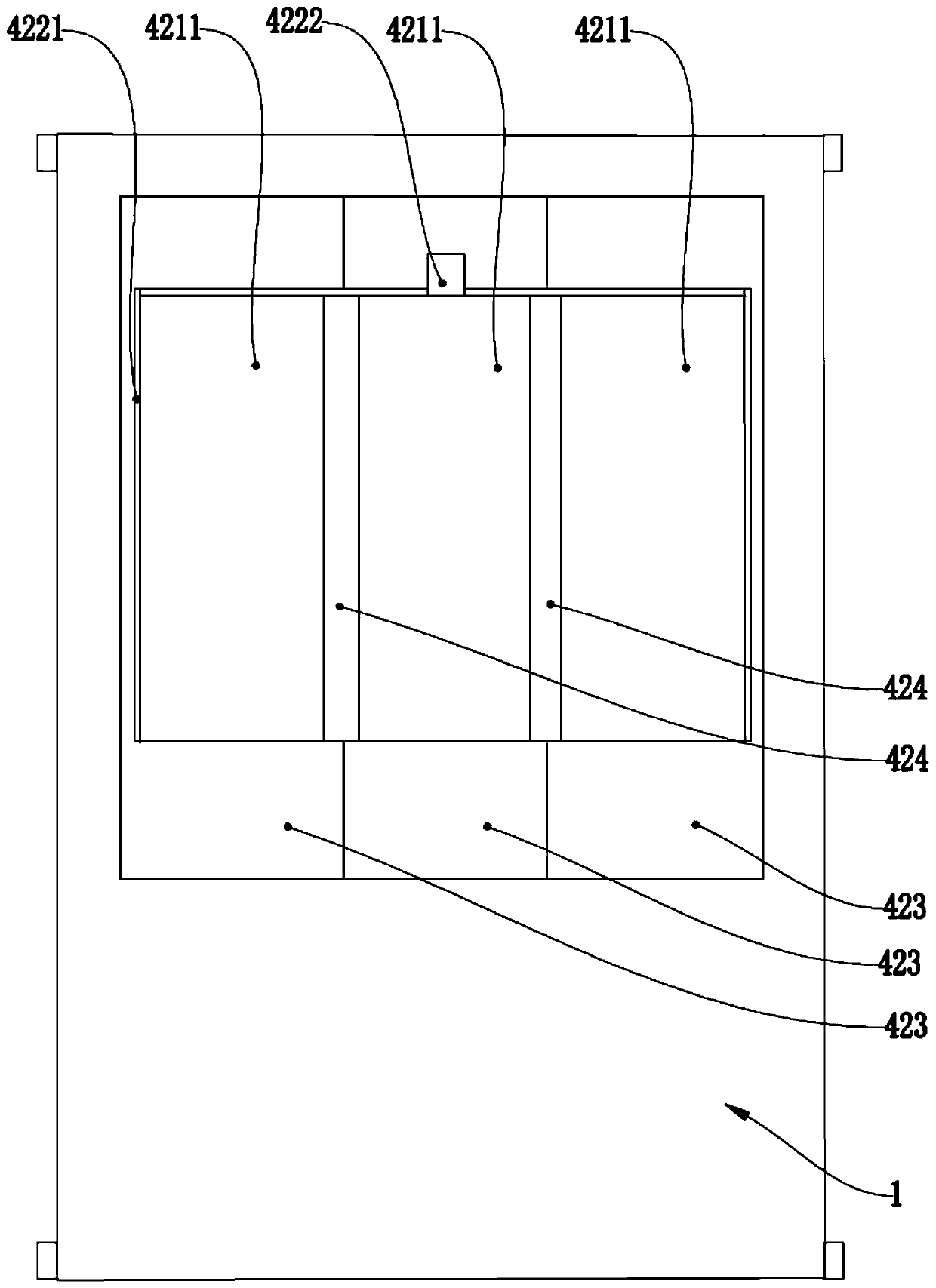

[0052] Such as Figure 1 to Figure 11 As shown, a ceramic tile decoration production system capable of distributing uniform ink-splashing patterns, including a main belt 1, a glaze printer 2, an inkjet printer 3, a dry grain distributing machine 4, a feeding machine 5 and a dry grain flake distributing machine 6 , the main belt 1 is used to transport ceramic bricks, and the glaze printer 2, inkjet printer 3, dry grain distribution machine 4 and dry Granule distribution machine 6, the feeding end of described dry grain distribution machine 4 is connected with the discharge end of described feeder 5, the feed end of described dry grain distribution machine 4 is connected with the inlet of described feeder 5 Material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com