Sand-clustering sound absorbing device and manufacturing method thereof

A sound-absorbing device and composition technology, which is applied in the field of building chemical materials, can solve the problems of poor sound-absorbing performance, poor air-permeability, and no anti-permeation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

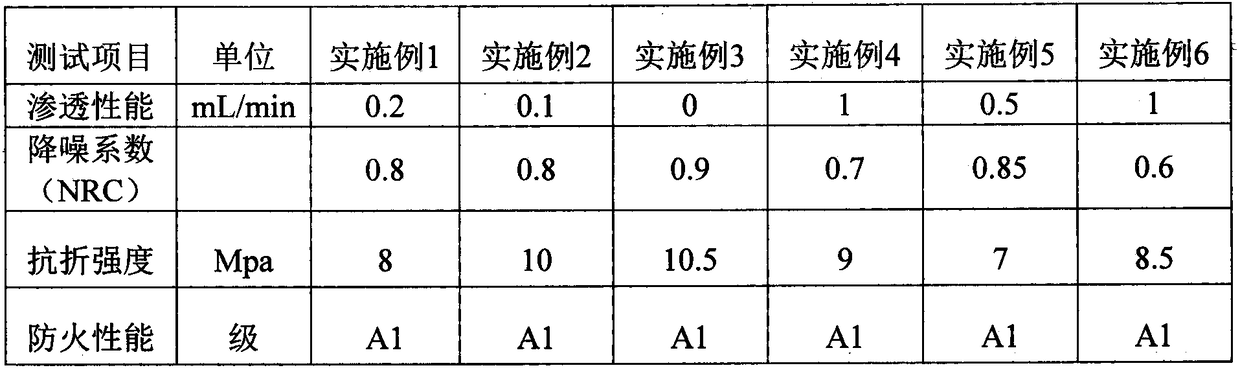

[0027] The first embodiment of the present invention provides a sand-accumulating sound-absorbing device, which is molded from a sand-accumulating composition; the sand-accumulating composition includes a base material, a binder, a curing agent, and a lubricant agent; wherein, based on the mass percentage of the substrate as 100%, the addition of the binder is 1-5%, preferably 2-4%; the addition of the curing agent is 0.05-0.5%, preferably 0.1 -0.4%; the amount of lubricant added is 0.2-0.5%, preferably 0.3-0.4%. The present invention can adjust the surface structure of the sand-gathering composition by adjusting the formula ratio of the sand-gathering composition, so that the prepared sand-gathering sound-absorbing device has sound absorption performance and air permeability, and also has the characteristics of anti-leakage and high temperature resistance .

[0028] According to the sand-accumulating sound-absorbing device of the present invention, in the present invention, ...

no. 2 approach

[0038] The second embodiment of the present invention provides a method for preparing the sand-accumulating sound-absorbing device according to the present invention, and the sand-accumulating sound-absorbing device is prepared by molding. The molding is to place the sand-accumulating composition of the present invention in a mold and shape it by heating and pressing, so as to prepare a sand-accumulating sound-absorbing device.

[0039] The preparation method according to the present invention comprises the following steps:

[0040] Preheating step: After preheating the mold, close the mold;

[0041] Sand injection step: inject the sand-accumulating composition into the mould;

[0042] Hot-pressing step: hot-press the mold injected with the sand-accumulating composition to obtain a sand-accumulating sound-absorbing device.

[0043] In the present invention, the mold is preheated to 100-180°C, preferably 120-150°C. The pressure of hot pressing is 5-8 kg, preferably 6-7 kg, a...

Embodiment 1-6

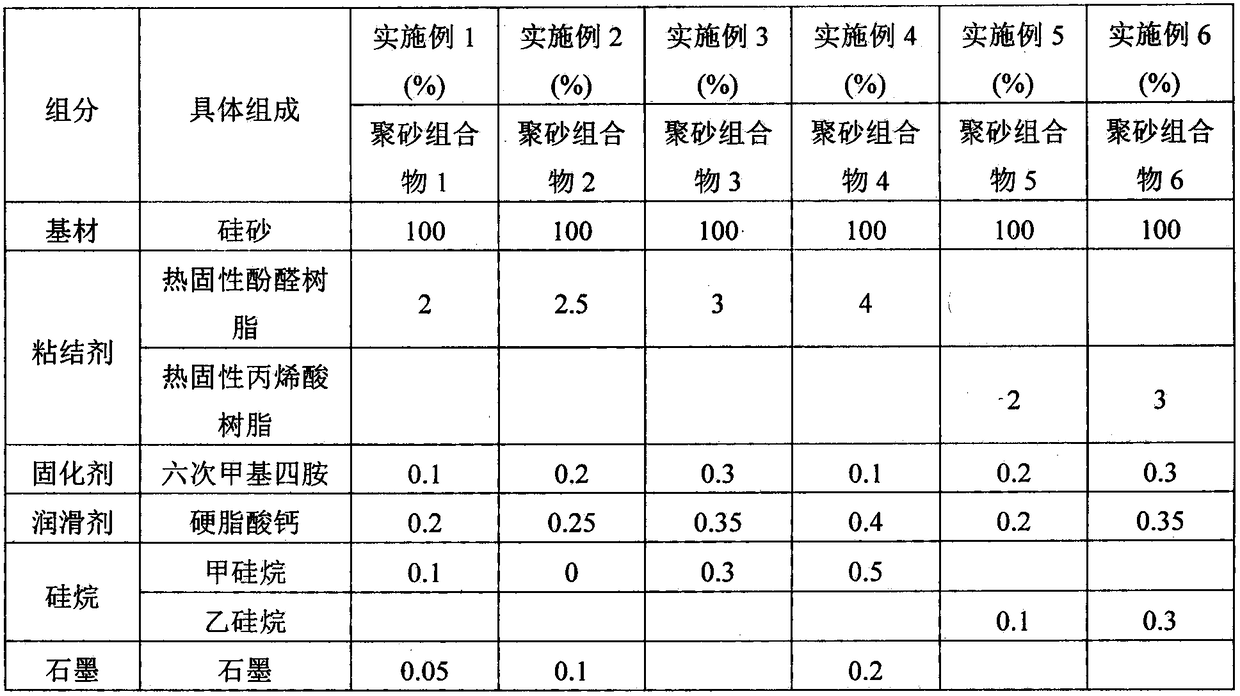

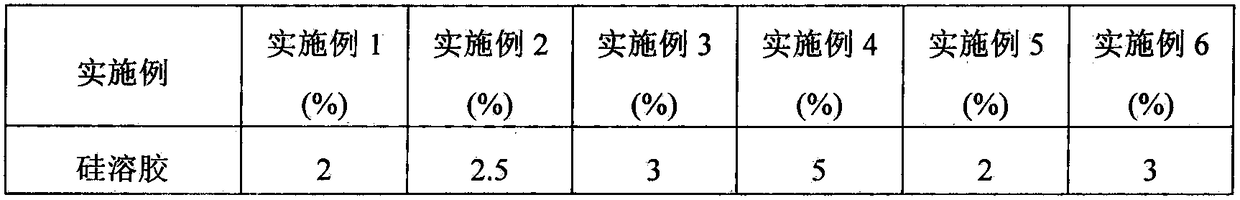

[0058] According to the formula ratio in Table 1 below, the mass percentage of the base material is used to prepare the sand gathering composition according to the following preparation method, wherein the average particle size of the base material is 50-60 mesh.

[0059] The preparation method of poly-sand composition comprises the following steps:

[0060] Step 1. Preheat the base material to 130±5°C and then mix and stir with the binder to obtain coated sand grains; the time for coating, mixing and stirring is 40s.

[0061] When silane is contained, after the substrate is preheated, it is mixed with silane for 5 seconds, and then mixed with the binder to obtain coated sand grains.

[0062] When graphite is included, add graphite at 55-60 seconds after the substrate is preheated and mixed with the binder.

[0063] Step 2, mixing the aqueous solution of the curing agent with the coated sand, the resulting water evaporates to rapidly cool the sand (55 ± 5 seconds), and cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com