Compass type control frame for marking ceiling rod guiding hole positions

A technology for suspended ceilings and signs, applied in the direction of construction and building structure, can solve problems such as low work efficiency and irregular construction, and achieve the effects of simple operation, improved construction efficiency and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

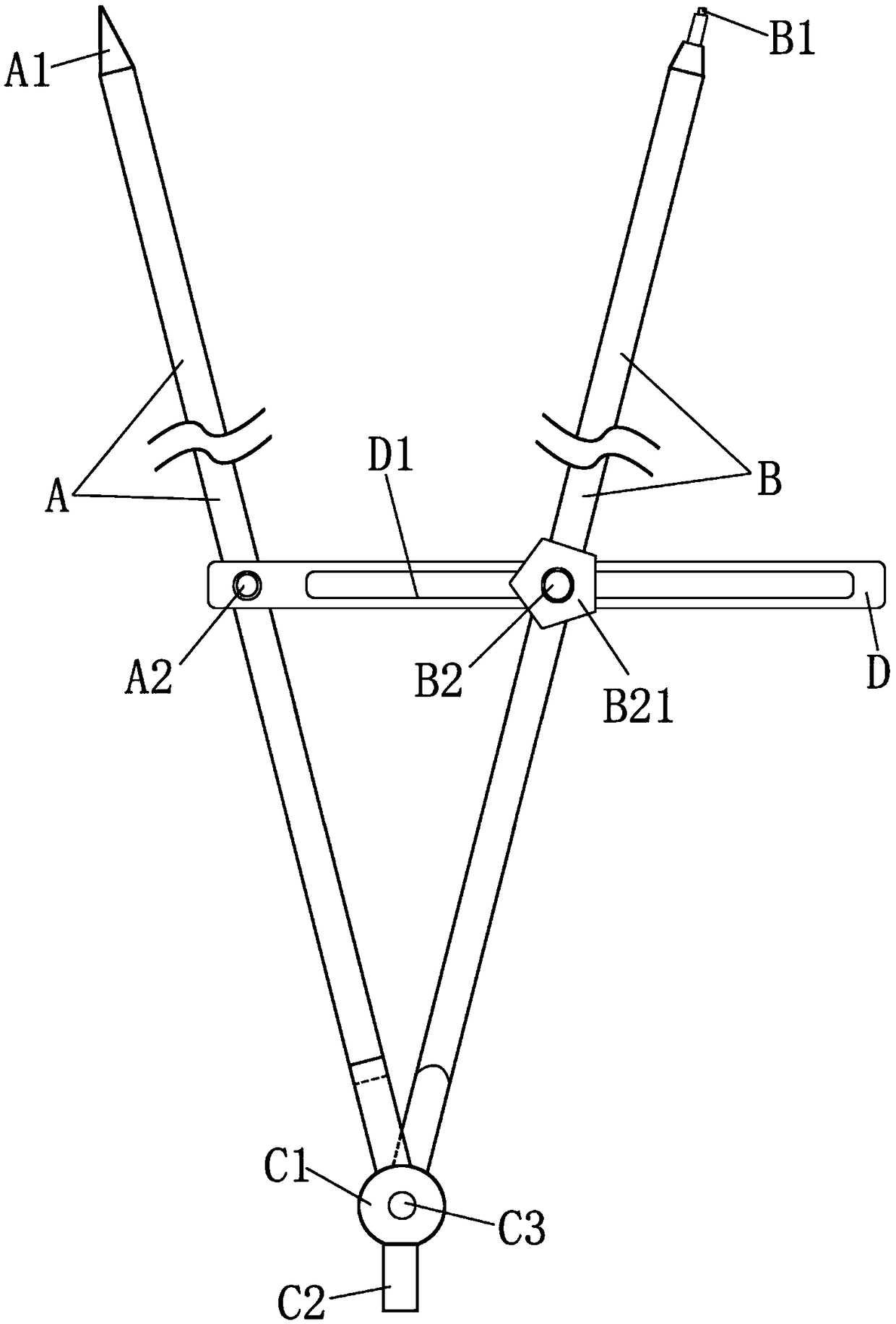

[0020] Such as figure 1 As shown, a compass type control frame for marking the position of the guide hole of the ceiling bud rod, which is composed of an oblique left rod A, an oblique right rod B, a horizontal adjustment plate D, a tightening nut B21, and a string rod base Composition, characterized in that,

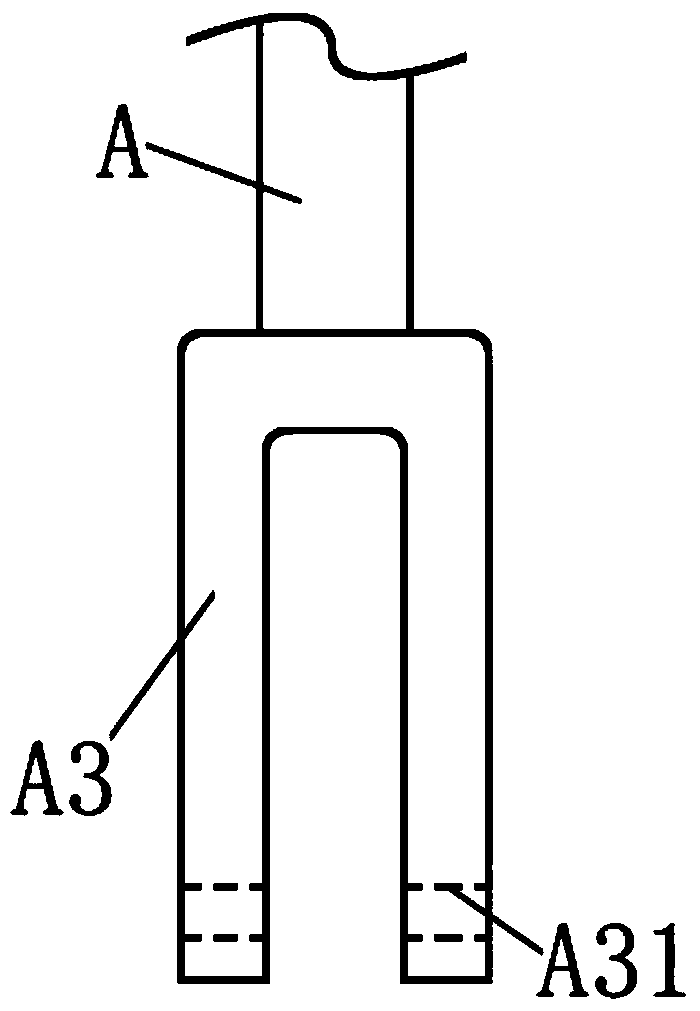

[0021] There is a tapered fixed point A1 glued to the oblique upper end of the oblique left rod A, such as figure 2 As shown, the oblique lower end A3 of the oblique left rod A is a U-shaped bifurcation, and the U-shaped bifurcation part is drilled with a rod hole A31;

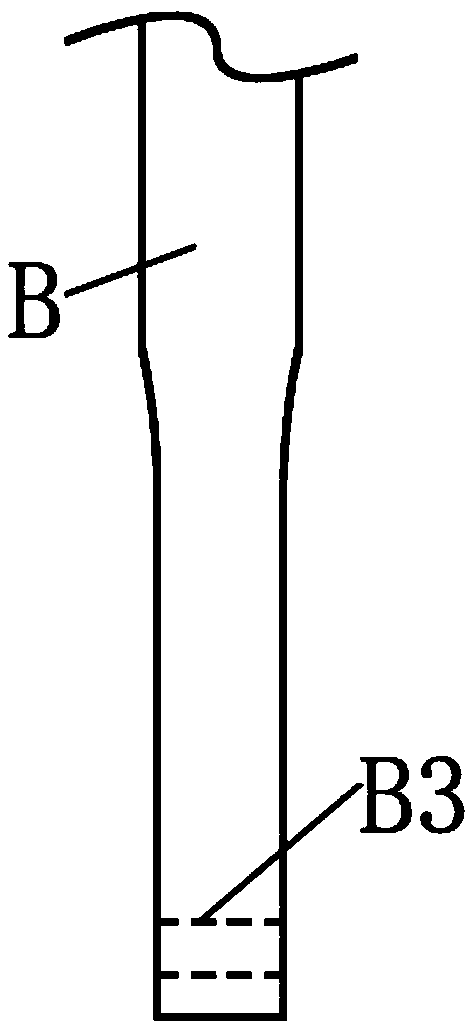

[0022] A pen cover is glued to the oblique upper end of the right rod B, and a piece of chalk B1 is built in the pen cover, such as image 3 As shown, the oblique lower end of the right rod B is narrowed and drilled with a rod hole B3;

[0023] The oblique lower end of the oblique right rod B can be embedded in the U-shaped bifurcation at the oblique lower end of the oblique left rod A. The right r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com