A self-propelled steering double-roller film hole opening machine

A self-propelled, drilling machine technology, applied to agricultural machinery and tools, shovels, plows, etc., can solve problems such as low labor efficiency, uneven hole spacing, and insufficient hole depth, so as to improve labor efficiency and reduce Less labor time and better hole opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

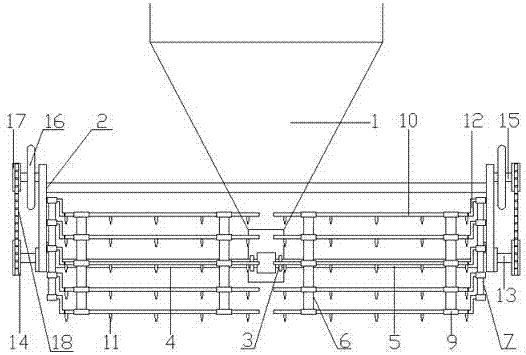

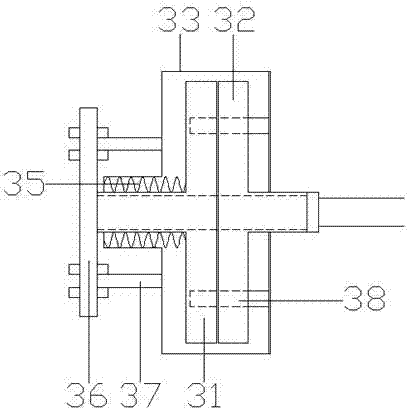

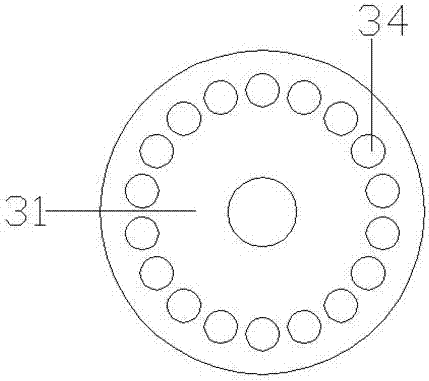

[0024] Such as figure 1 As shown, a self-propelled steering double-roller mulch opening machine includes a tiller 1 and a frame 2. Steering clutches 3 are respectively installed at both ends of the output half shaft of micro tillage machine 1, and the steering clutches 3 are respectively connected to the same left shaft 4 and right shaft 5; the left shaft 4 and the right shaft 5 are respectively equipped with corresponding walking Roller 6, the outer ends of the left shaft 4 and the right shaft 5 are respectively connected to the same eccentric roller 7; the circumferential surfaces of the traveling roller 6 and the eccentric roller 7 are respectively equipped with equidistantly distributed sleeves 9; the corresponding walking The sleeve 9 installed on the roller 6 is provided with a pinion connecting rod 10, and the pinion connecting rod 10 is provided with a pinion 11; the sleeve 9 fixed to the eccentric roller 7 is connected with an eccentric link adjusting arm 12; The ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com