Antitheft foundation bolt for iron tower and application method of antitheft foundation bolt

A technology of anchor bolts and anti-theft bolts, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of complex screw structure, small overall size of the screw, and difficult screw manufacturing, and achieve the effects of convenient processing, prevention of disassembly, and guaranteed positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

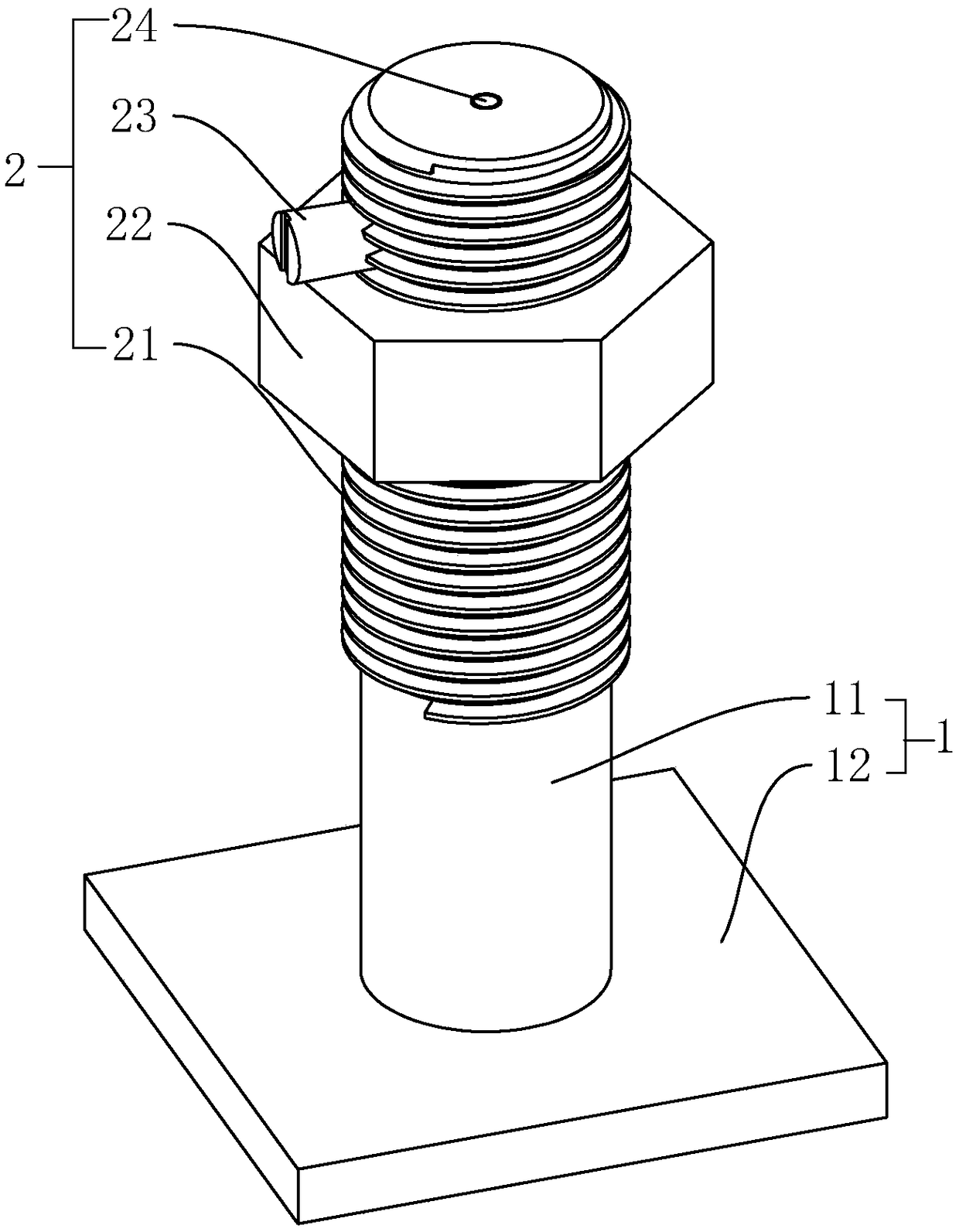

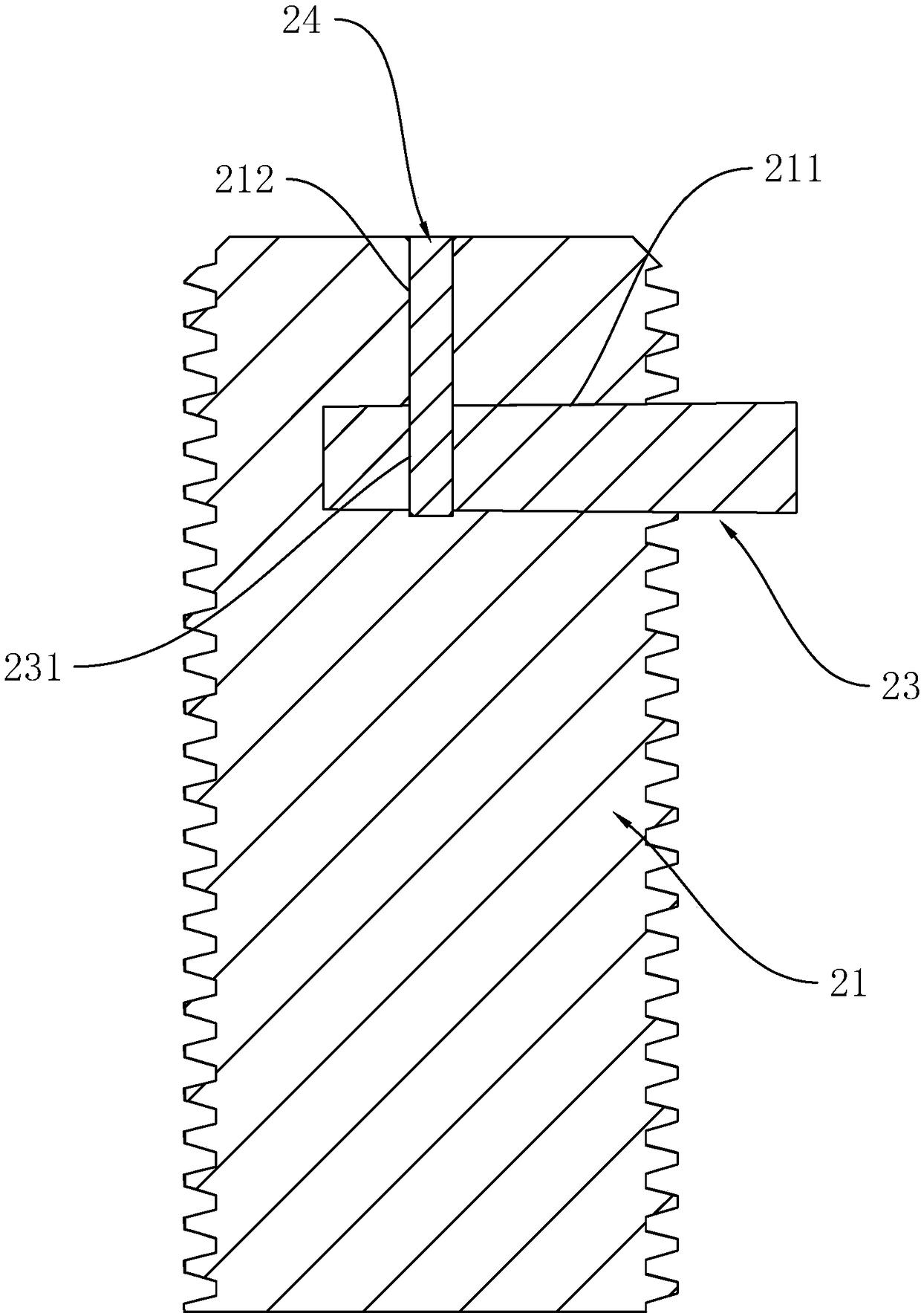

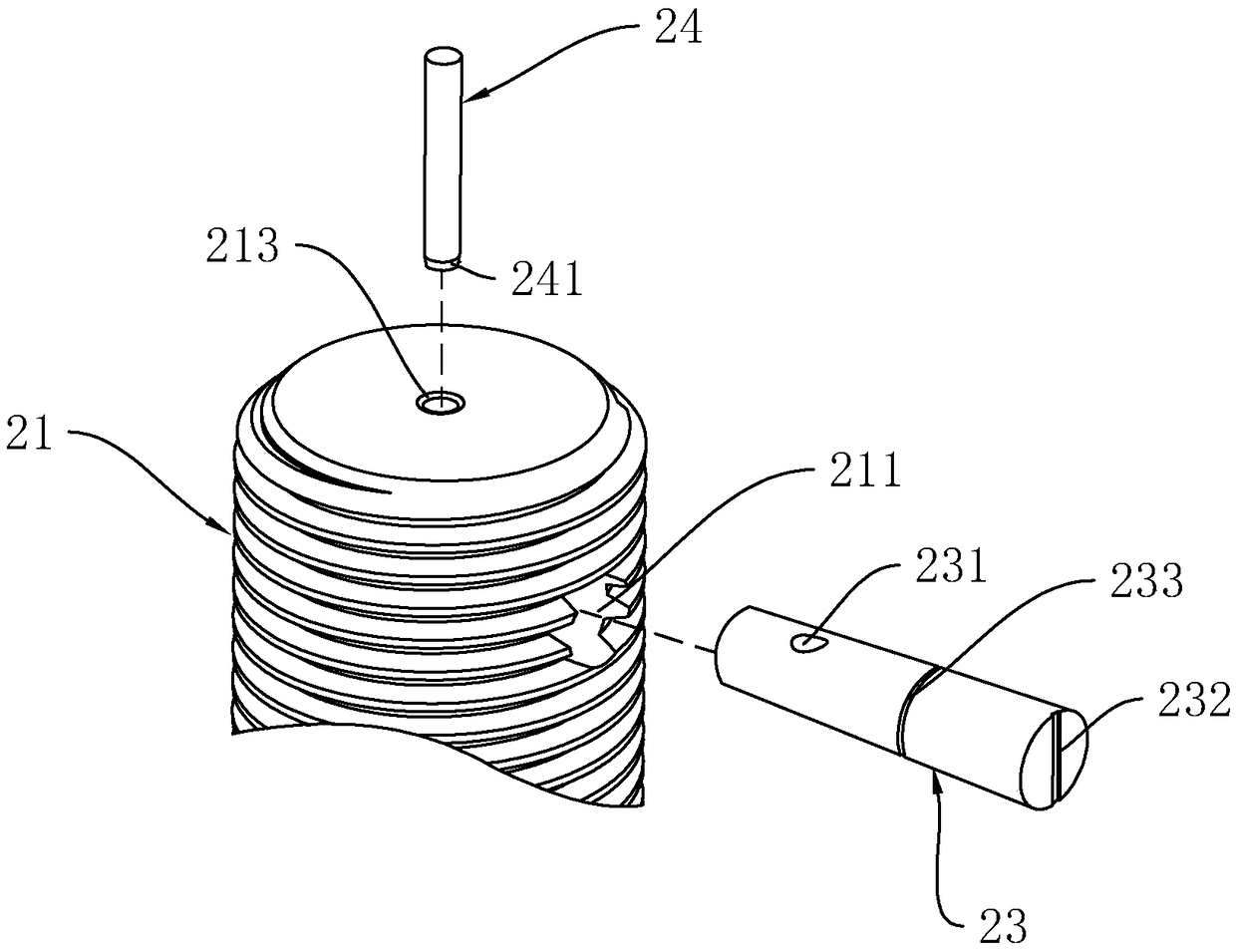

[0041] Embodiment 1: An anti-theft anchor bolt for an iron tower, combined with figure 1 , including the embedded part 1 and the connecting part 2. The embedded part 1 is used to pre-embed the anchor bolts inside the pile foundation, and the connecting part 2 is used to complete the fixing of the iron tower.

[0042] The embedded part 1 includes a reinforcing rod 11 and an embedded part 12 fixedly connected to one end of the reinforcing rod 11. The embedded part 12 can be a circular plate, a square plate, a spiral steel bar, a U-shaped steel bar, etc. The embedded part used in this embodiment The embedded part 12 is illustrated as a square plate. When in use, the embedded part 12 and the reinforcing rod 11 can be vertically embedded in the pile foundation, and the anti-theft anchor bolt and the inner contact area of the pile foundation can be increased through the installed embedded part 12, so that the anti-theft anchor bolt firmly fixed on the pile foundation.

[0043] ...

Embodiment 2

[0047] Embodiment 2: A method of using an anti-theft anchor bolt, comprising the following steps:

[0048] Step 1. Distance measurement: first measure the height of the anti-theft bolt screw 21 exposed to the ground according to the thickness of the foot of the iron tower to be connected and the thickness of the fastening nut 22, and paint the logo on the screw 21;

[0049] Step 2. Pre-embed the pre-embedded part 1 of the anti-theft anchor bolt: when pouring the pile foundation, pre-embed the pre-embedded part 1 of the anti-theft bolt in the pile foundation vertically downwards, and make the pre-embedded part 1 of the anti-theft bolt 21 The logo protrudes 1-2cm from the upper surface of the pile foundation. After the pile foundation is solidified, the part of the screw rod 21 of the anti-theft bolt protruding from the surface of the pile foundation is the part of the anti-theft bolt used to connect the foot of the iron tower;

[0050] Step 3. Installation of the tower foot: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com