Engine connecting rod bearing bush

A technology of engine connecting rod and bearing bush, applied in the field of bearing bush manufacturing, which can solve the problems of mechanical damage, scratch and failure of bearing bushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

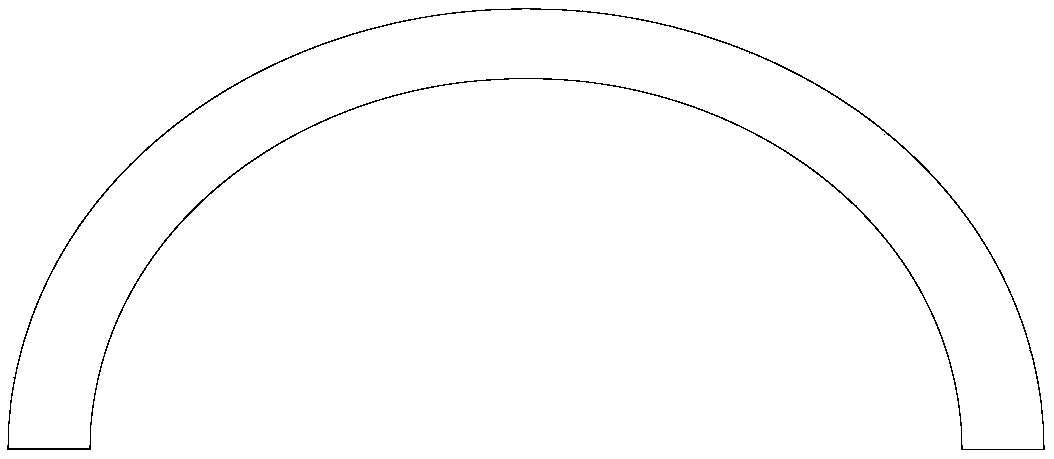

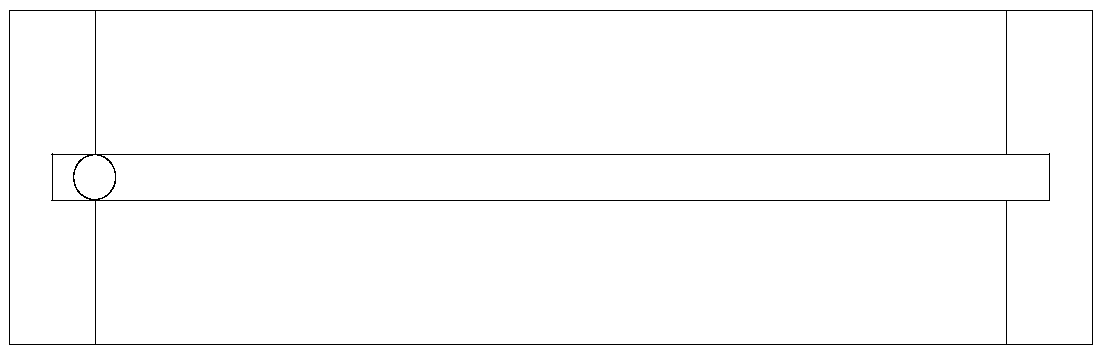

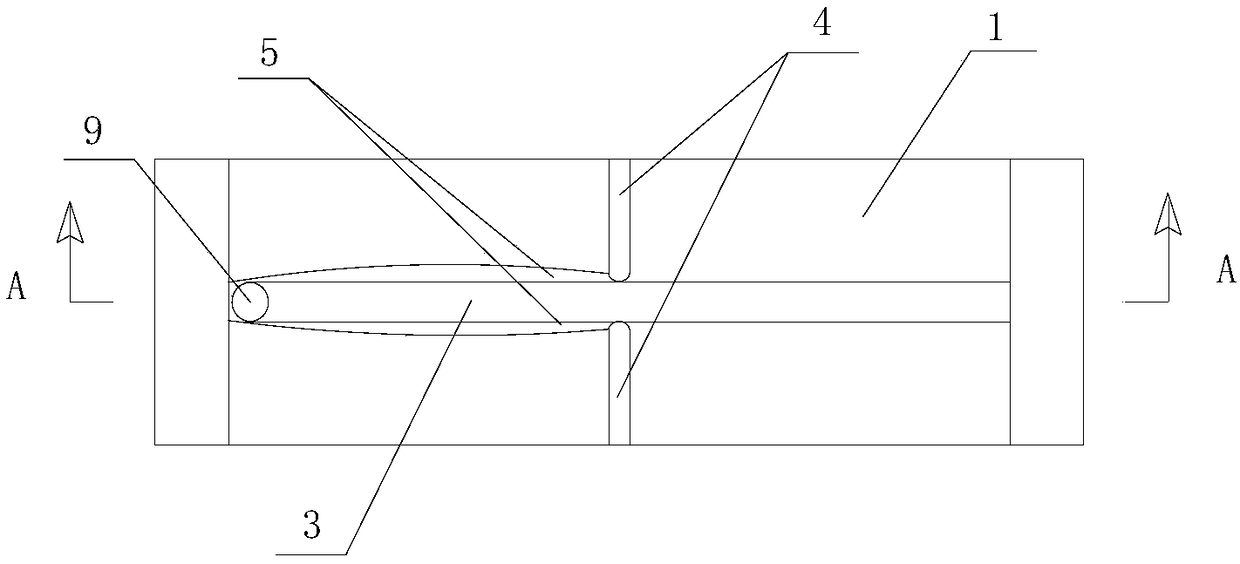

[0022] see Figures 3 to 6 , an engine connecting rod bearing, comprising an upper bearing 1 and a lower bearing 2.

[0023] The inner side of the upper bearing bush 1 is provided with an oil groove 3 along its circumferential direction. The depth of the oil groove 3 gradually deepens from both ends to the middle, and the two ends of the oil groove 3 do not penetrate the inner wall of the upper bearing bush 1 , and the two ends of the oil groove 3 extend to the two ends of the upper bearing bush 1 .

[0024] The inner side of the upper bearing bush 1 is provided with a foreign matter removal oil groove 4 along its axial direction and passing through the oil groove 3 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com