High-effect gas boiler with gas leakage alarm device

An alarm device and gas leakage technology, which is applied to alarms, instruments, fluid heaters, etc., can solve problems such as gas leakage, poor heat preservation effect, and small heating area, so as to increase the temperature raising speed, improve heat preservation effect, and increase supply The effect of thermal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

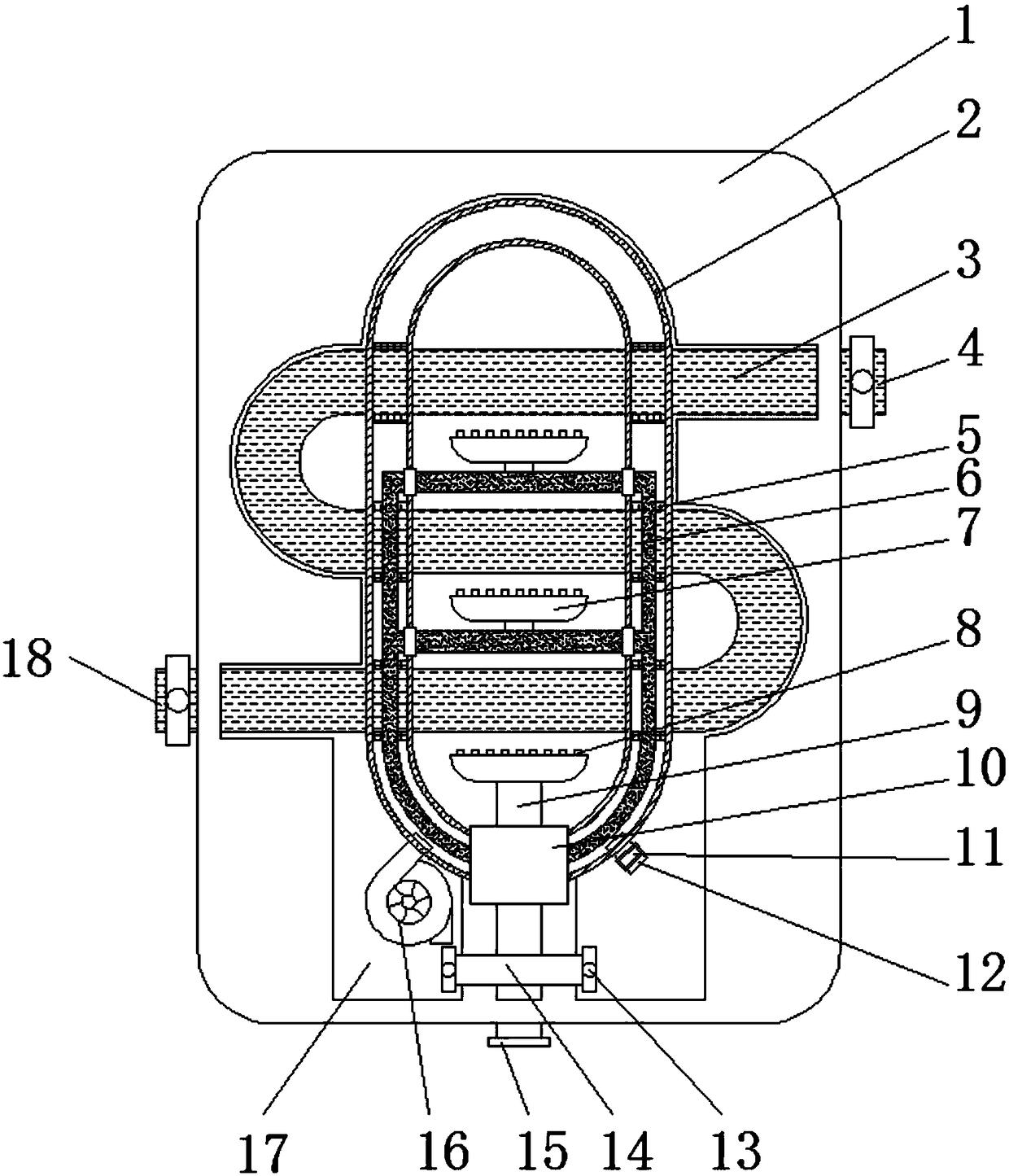

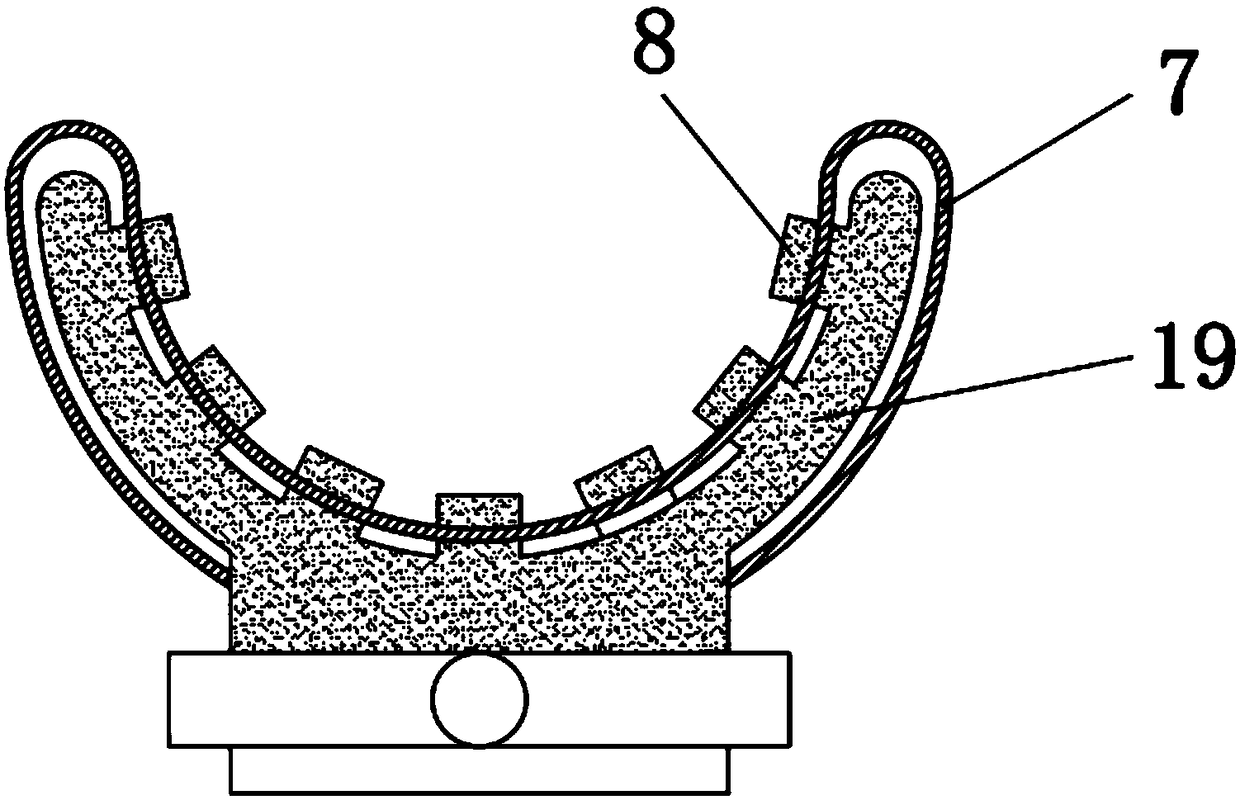

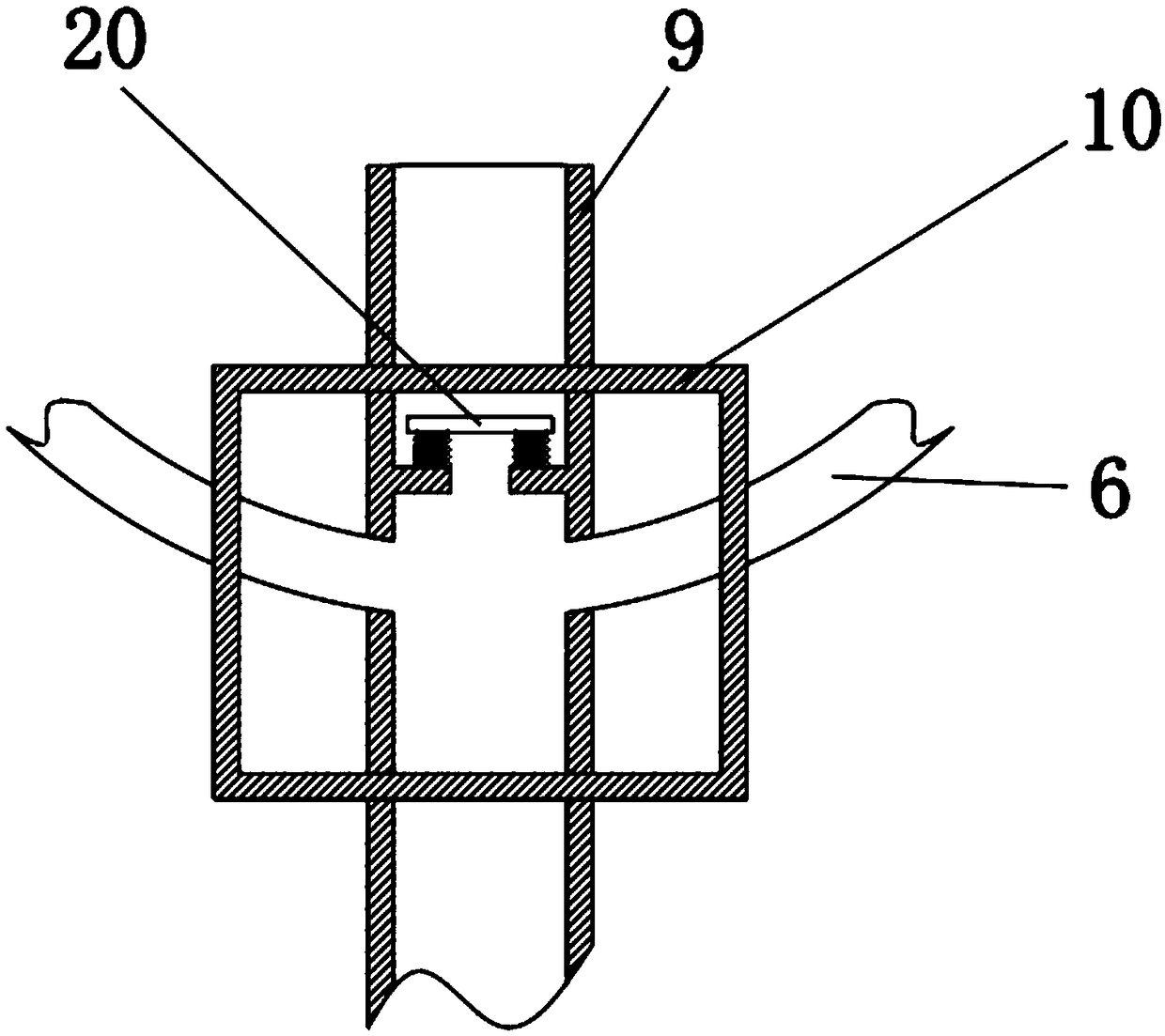

[0029] Embodiment one, with reference to Figure 1-4 , a high-efficiency gas boiler with a gas leakage alarm device, including a furnace body 1, a combustion base 7 and a gas alarm 11, and a gas flow chamber 17 is provided on both sides of the inner bottom of the furnace body 1, and two gas flow chambers There is a ventilation pipe 14 connected between the warehouses 17, and the two ends of the ventilation pipe 14 are provided with a one-way communication valve 13. A chamber 2 is welded inside the furnace body 1, and a gas distribution box 10 is welded at the bottom of the chamber 2 to allow the gas flow A second gas communication pipe 9 is sleeved in the box 10, and both sides of the second gas communication pipe 9 are elastically connected with baffles 20 through springs. One end is connected with a heating water pipe 3 that runs through the furnace body 1 and the chamber 2, and the other end of the heating water pipe 3 is connected with a drain pipe 18. The cross section of...

Embodiment 2

[0030] Embodiment two, refer to figure 1 One end of the bottom of the chamber 2 is connected with an air pump 16, and the other end of the bottom of the chamber 2 is connected with an exhaust pipe 12, and the exhaust pipe 12 is provided with a gas alarm 11. The wall and the outer wall of the heating water pipe 3 all have a gap of 1 cm, and the part of the outer wall of the heating water pipe 3 located in the interior of the chamber 2 is sleeved with thermal insulation cotton 5. When the air pump 16 works, the gas flows in the chamber 2, and It is discharged through the exhaust pipe 12 and is detected by the gas alarm 11 during discharge. The gas discharged through the exhaust pipe 12 will flow through the gap between the furnace body 1 and the chamber 2. When the gas flows in the chamber 2, it will Through the outer wall of the heating water pipe 3, the heat loss on the heating water pipe 3 will be prevented by the thermal insulation cotton 5 socketed on the outer wall of the ...

Embodiment 3

[0031] Embodiment three, refer to figure 1 and image 3 Both sides of the second gas communication pipe 9 are elastically connected with baffles 20 through springs. Since both sides of the second gas communication pipe 9 are connected to the first gas communication pipe 6, and because the height of the first gas communication pipe 6 Higher, so a baffle 20 is provided, and the gas flow through the second gas flow pipe 9 is limited by the springs at both ends of the baffle 20, thereby ensuring the flow in the second gas flow pipe 9 and the first gas flow pipe 6 unanimous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com