Special cylinder oblique oil hole angle detecting tool

An angle detection, inclined oil hole technology, applied in the direction of angle/taper measurement, measuring device, using mechanical device, etc., can solve the problems of low work efficiency, waste of time waiting, affecting the production progress, etc., to achieve simple structure and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0025] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

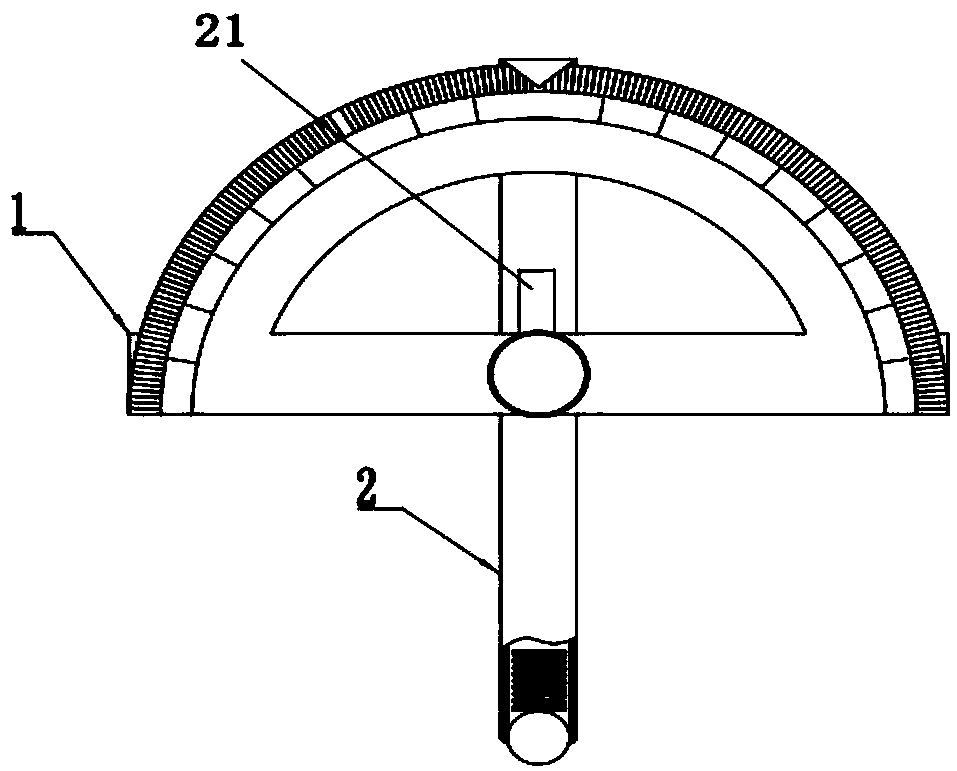

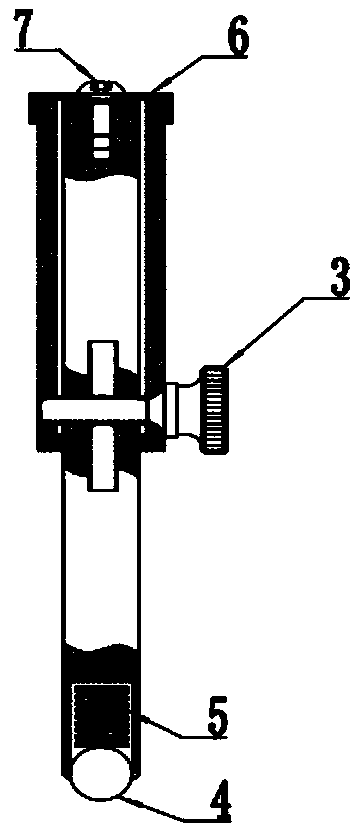

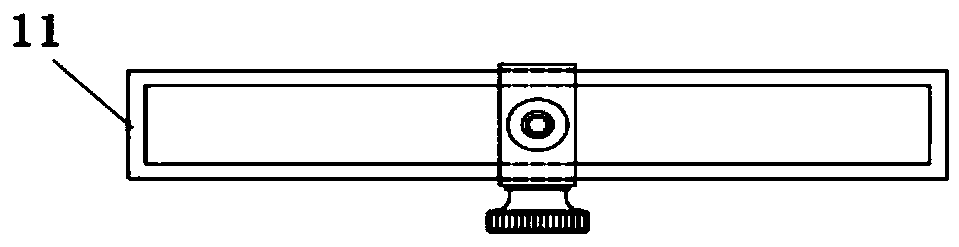

[0026] refer to Figure 1-3 The special inspection tool for measuring the angle of the oblique oil hole of the cylinder block shown includes a measuring tool, an adjusting bolt 3, a testing rod 2, a spring 5, and a steel ball 4. The measuring tool is composed of two protractors and a connecting piece 11 of the same size. The connecting piece 11 is located at the two ends of the protractor, that is, at 0° and 180°, so as to prevent the connecting piece from interfering with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com