Calibrating device for calibration of glass curtain wall testing machine

A glass curtain wall and verification device technology, applied in the verification field, can solve the problems of affecting the verification results, the verification environment does not match the use environment, etc., and achieves the effect of ensuring accuracy, convenient transportation, and stable airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

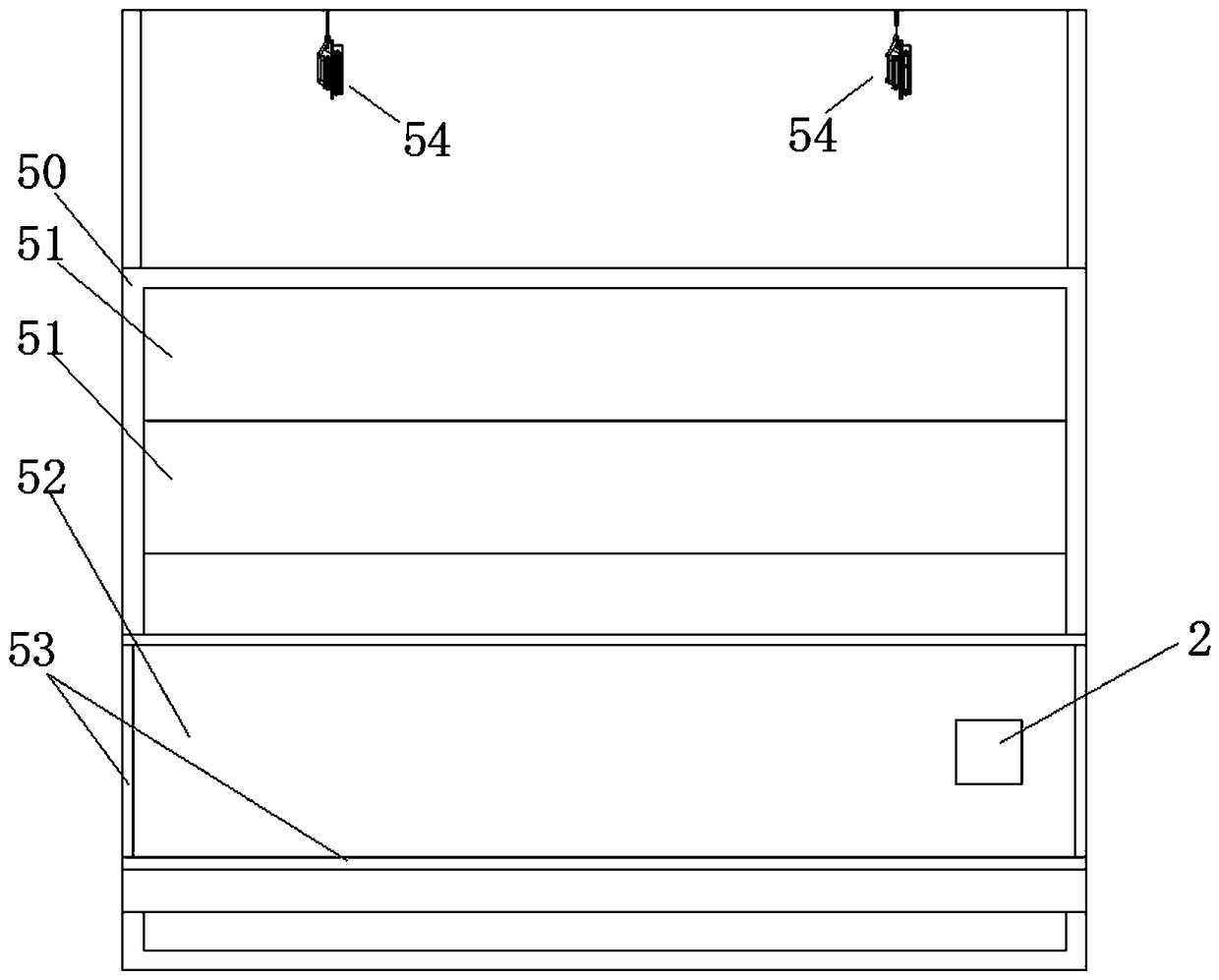

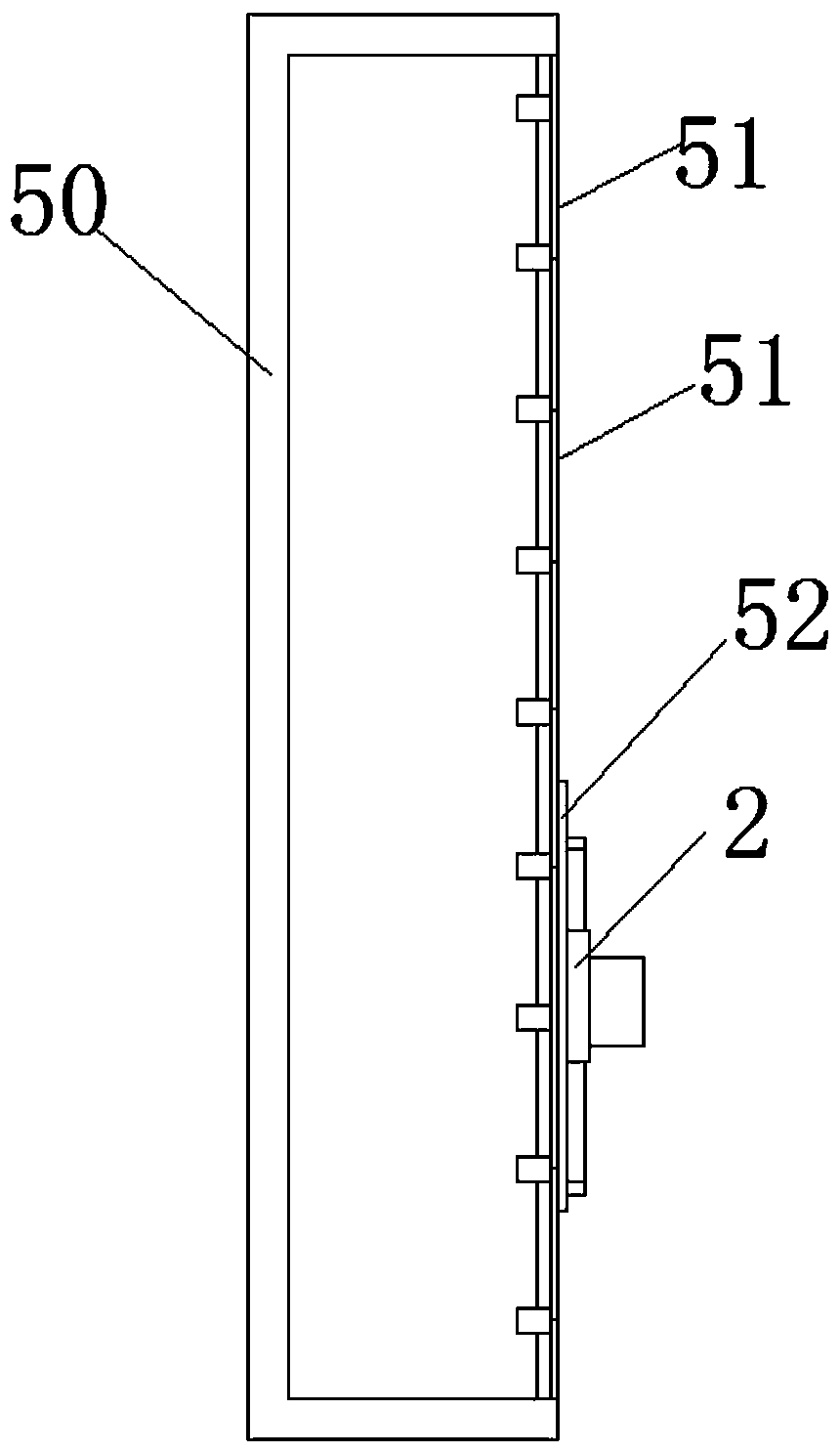

[0019] An example of a verification device for verification of a glass curtain wall testing machine Figure 1~9 As shown: Item 50 in the figure indicates the testing machine frame of the glass curtain wall testing machine, and item 51 indicates the self-equipped baffle of the glass curtain wall testing machine. When verifying the glass curtain wall testing machine, a certain number of baffles need to be installed on the test On the frame of the testing machine, a detection air outlet is formed between the baffle and the frame of the testing machine.

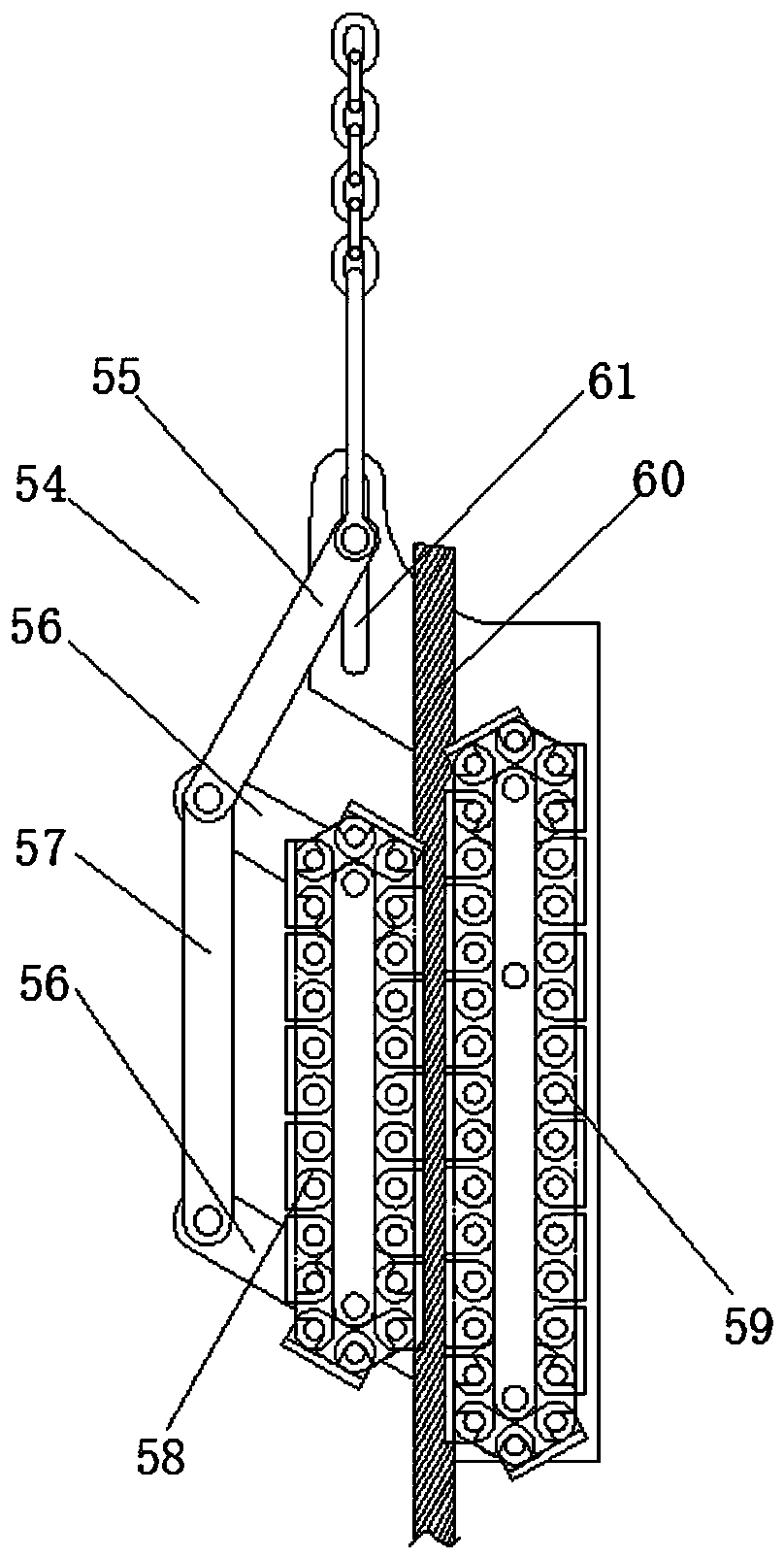

[0020] The verification device of the glass curtain wall testing machine includes a simulated curtain wall 52 installed at the detection tuyere. The simulated curtain wall is a bar-shaped structure whose length is arranged along the horizontal direction. In this embodiment, the simulated curtain wall is made of a rollable flexible sealing plate. The flexible sealing plate The surrounding area of the wall is sealed by pressing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com