A decoupling reactive ion etching equipment containing a gas flow control device

An air flow control device and reactive ion etching technology, which are applied in crystal growth, post-processing details, post-processing and other directions, can solve the problems of reduced service life of the chamber, shortened service life of the chamber, and increased maintenance costs, and achieve environmental preservation. Consistent, improved stability, stable pressure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

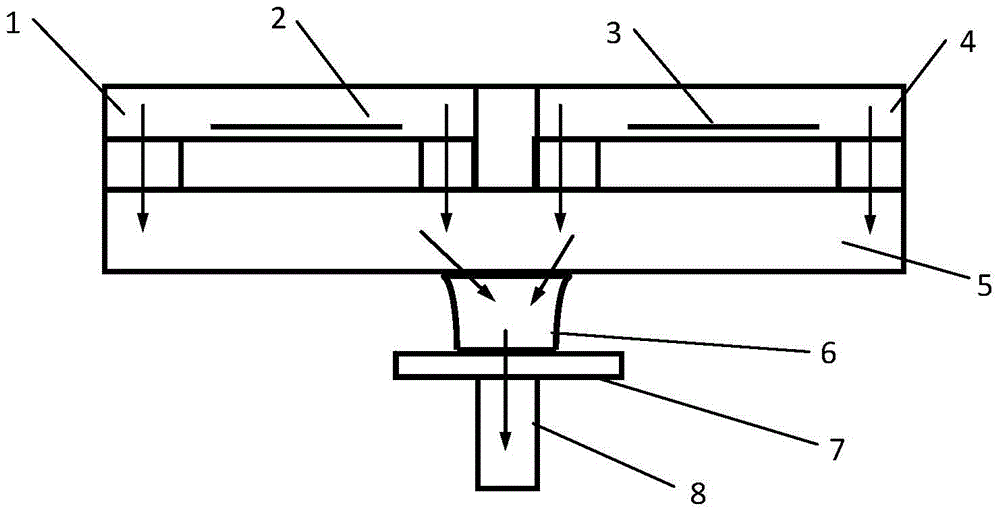

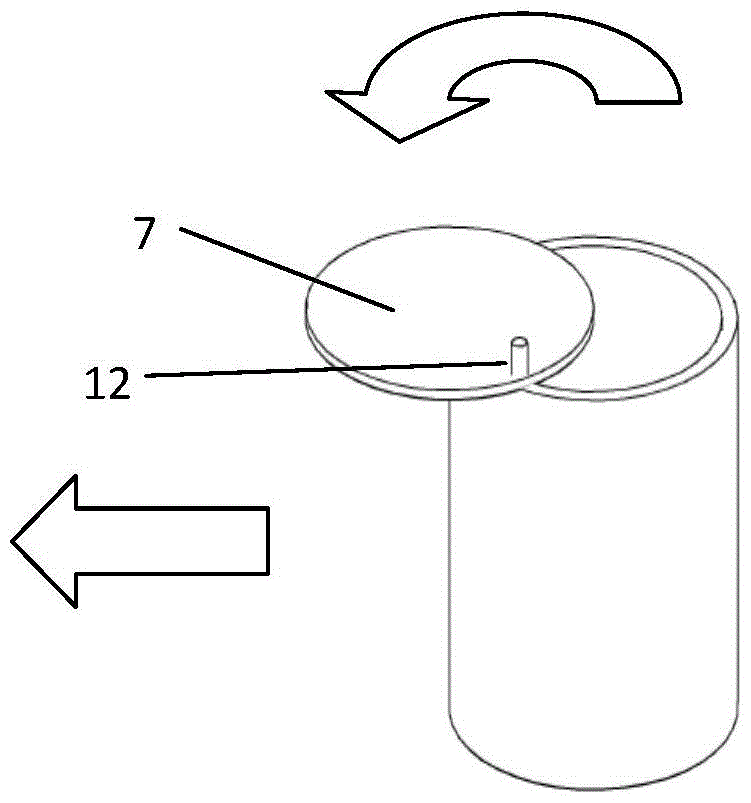

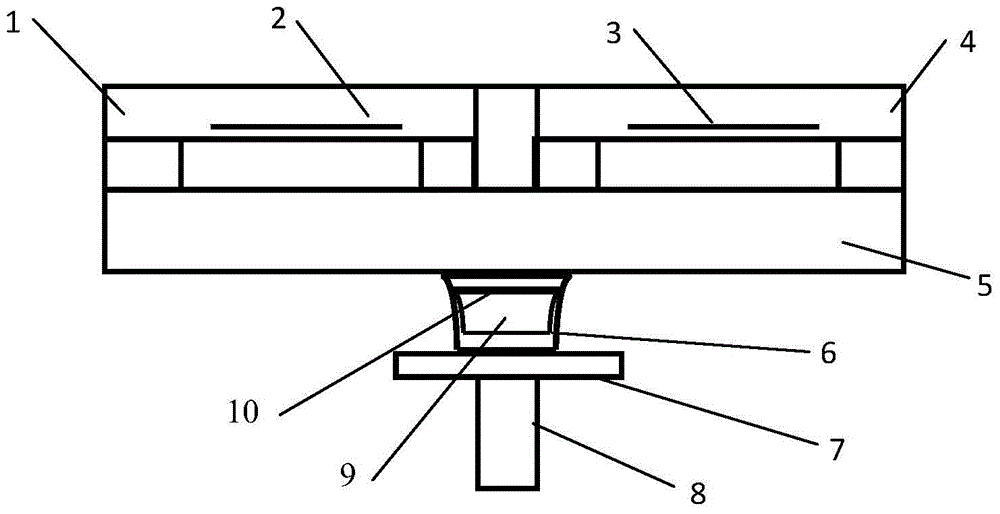

[0026] In this example, first pass figure 1 , 2 Describe the state of the art. see figure 1 , figure 1 It is a structural schematic diagram of a cavity part of a DRIE device of AMEC in the prior art. As shown in the figure, the upper part of the chamber of the device is divided into left and right chambers 1 and 4 that are independent of each other, and two wafers 2 and 3 are respectively placed in the left and right chambers and separated from each other. The two chambers are completely independent, and are only connected through the common exhaust port 6 arranged in the middle of the bottom 5 of the chamber. A servo pressure valve is provided below the exhaust port to adjust the pressure in the chamber; the exhaust pipe 8 of the exhaust system is connected to the lower part of the valve 7 . The arrows in the figure represent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com