Patents

Literature

34results about How to "Consistent environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

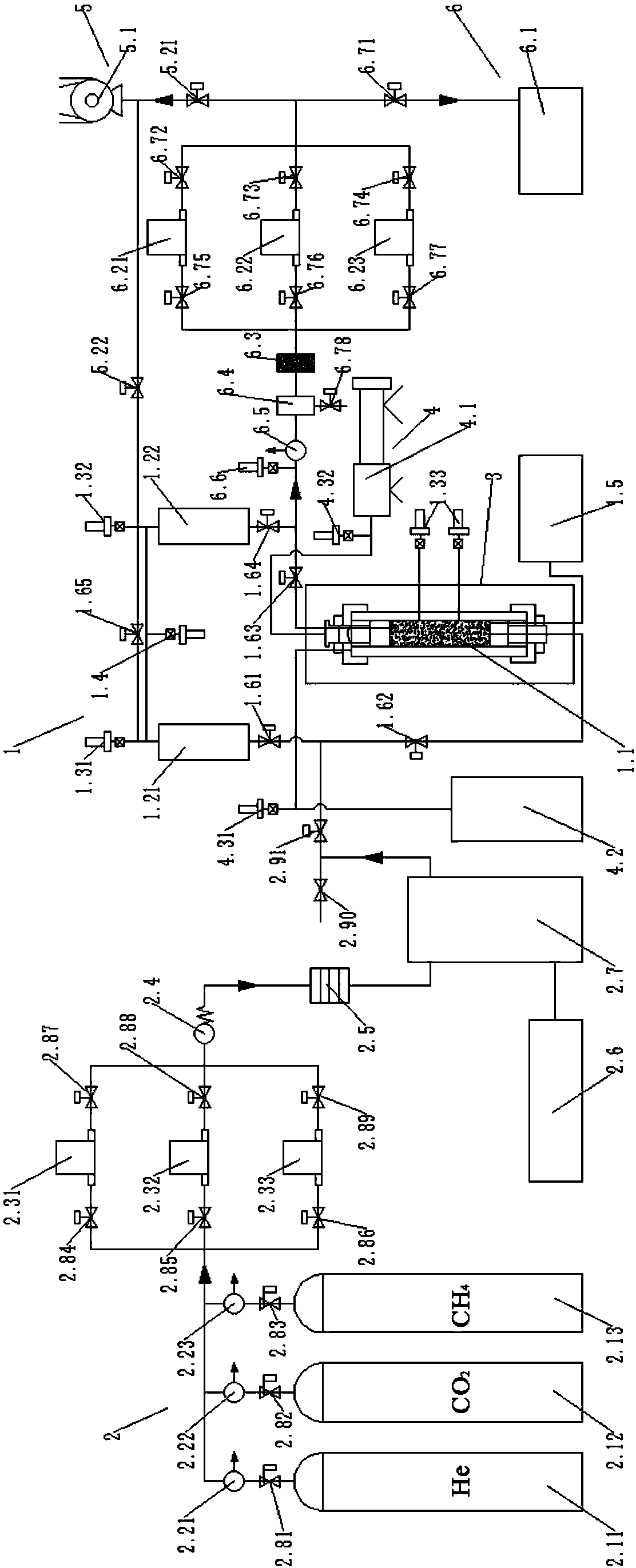

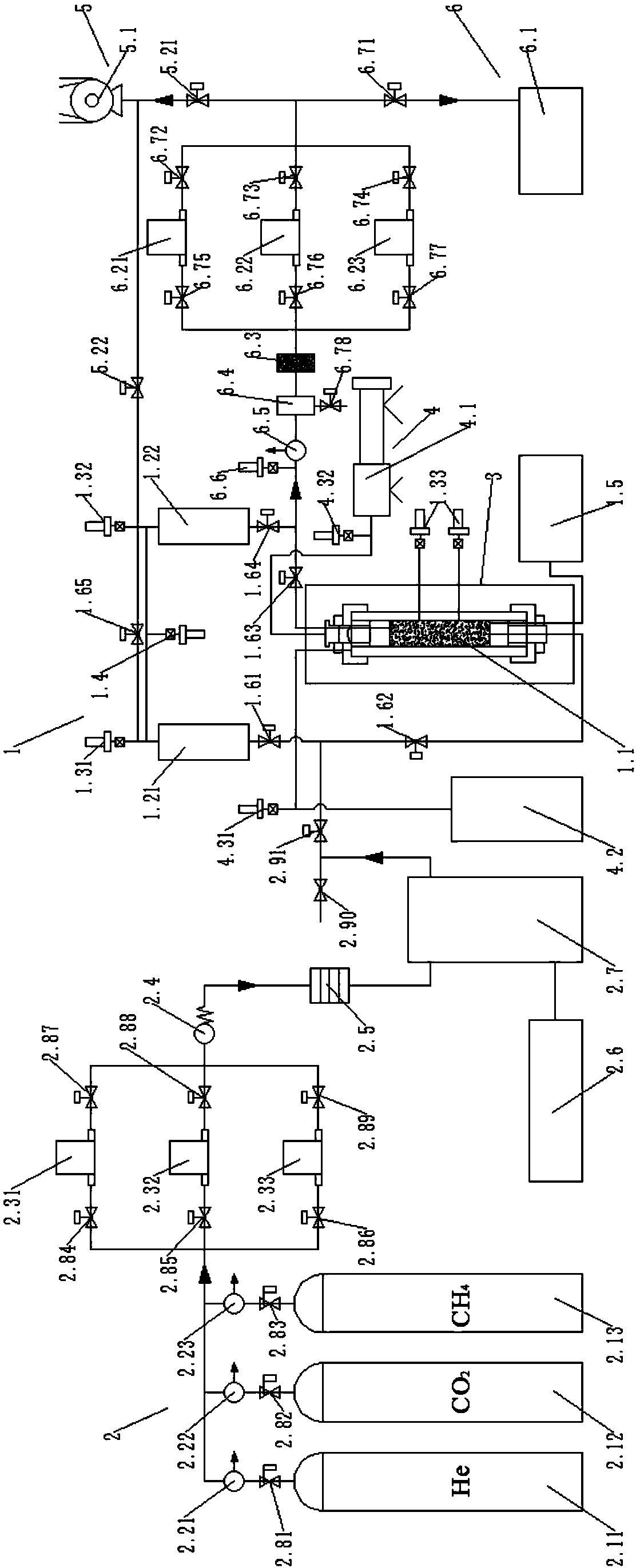

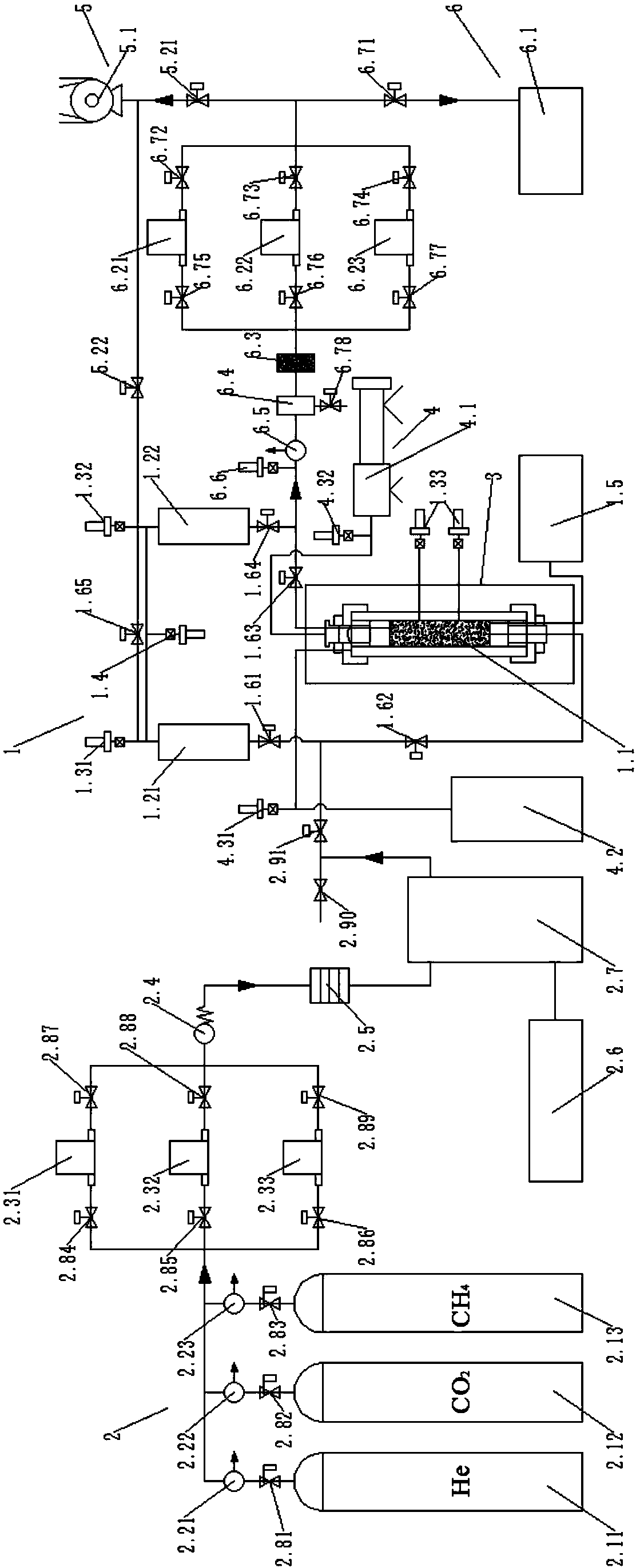

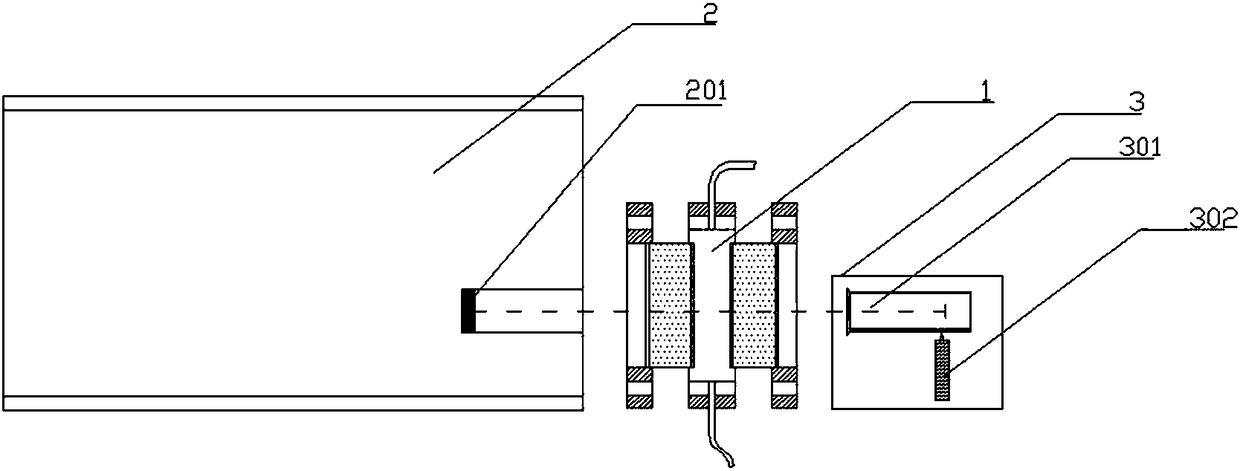

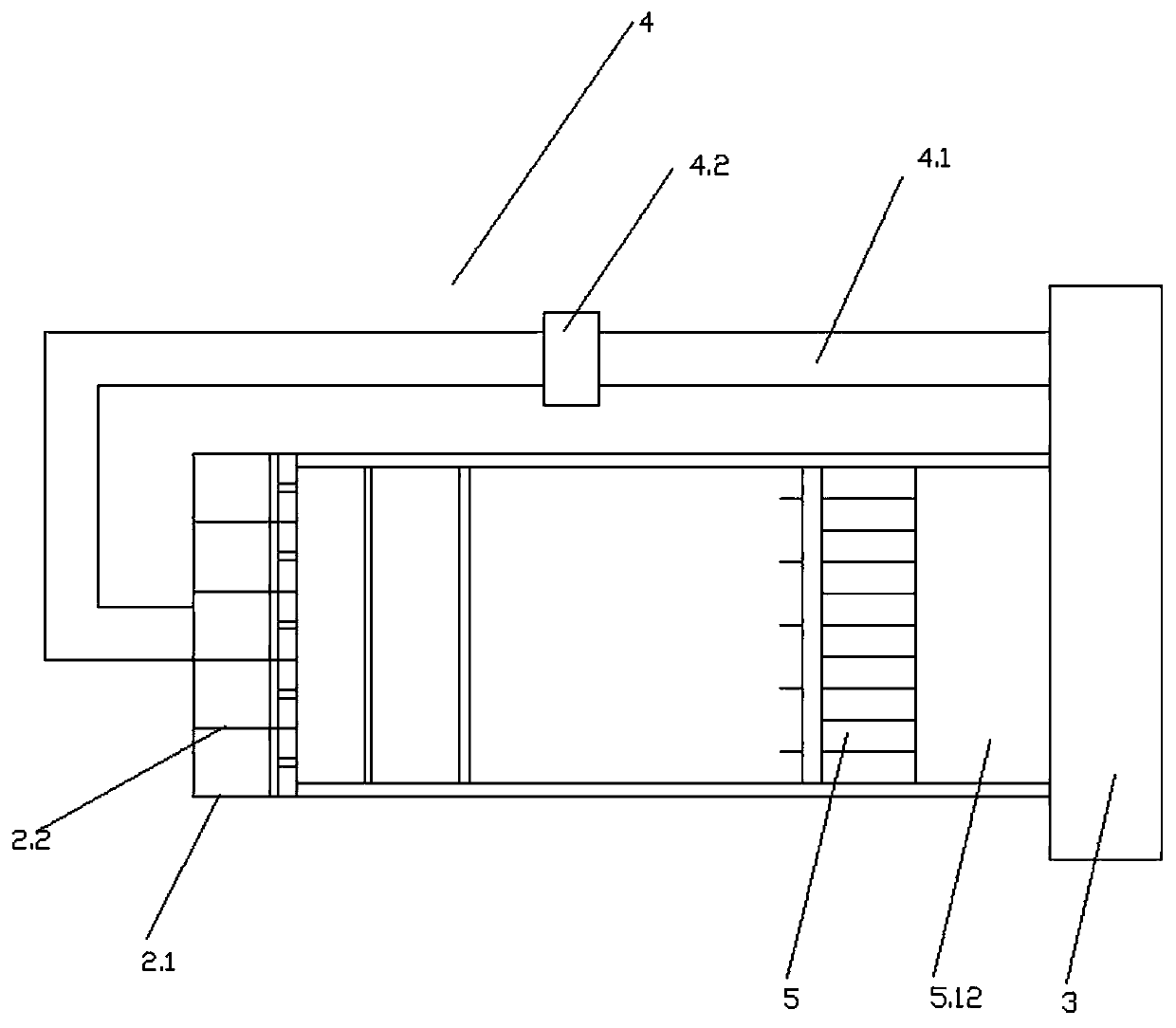

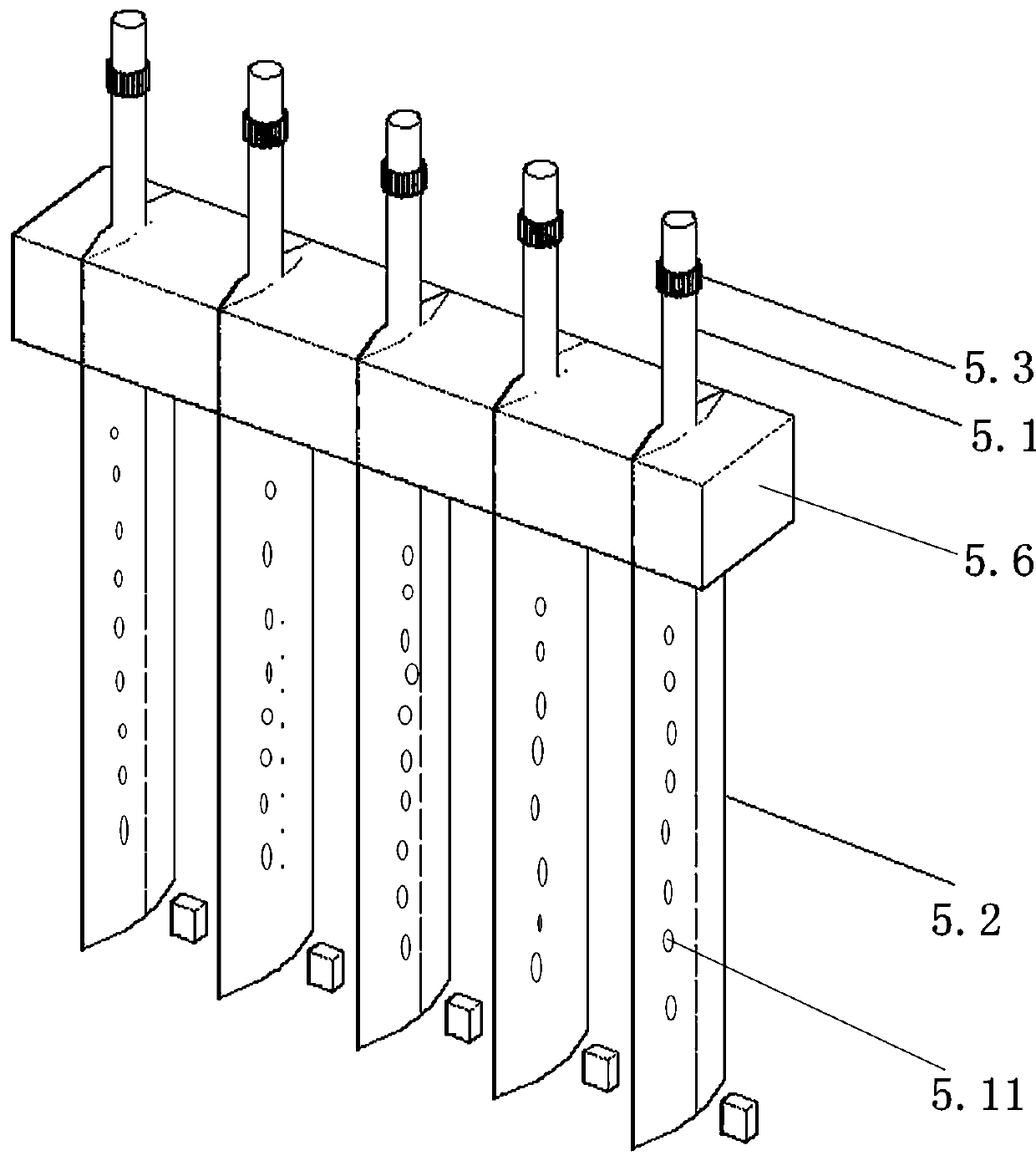

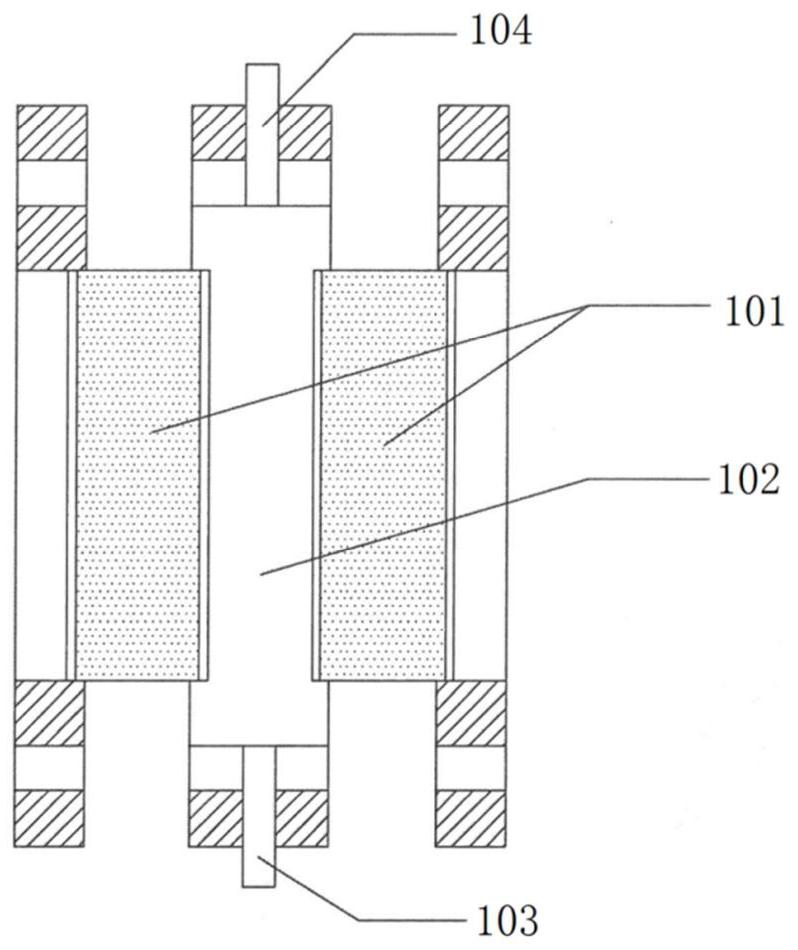

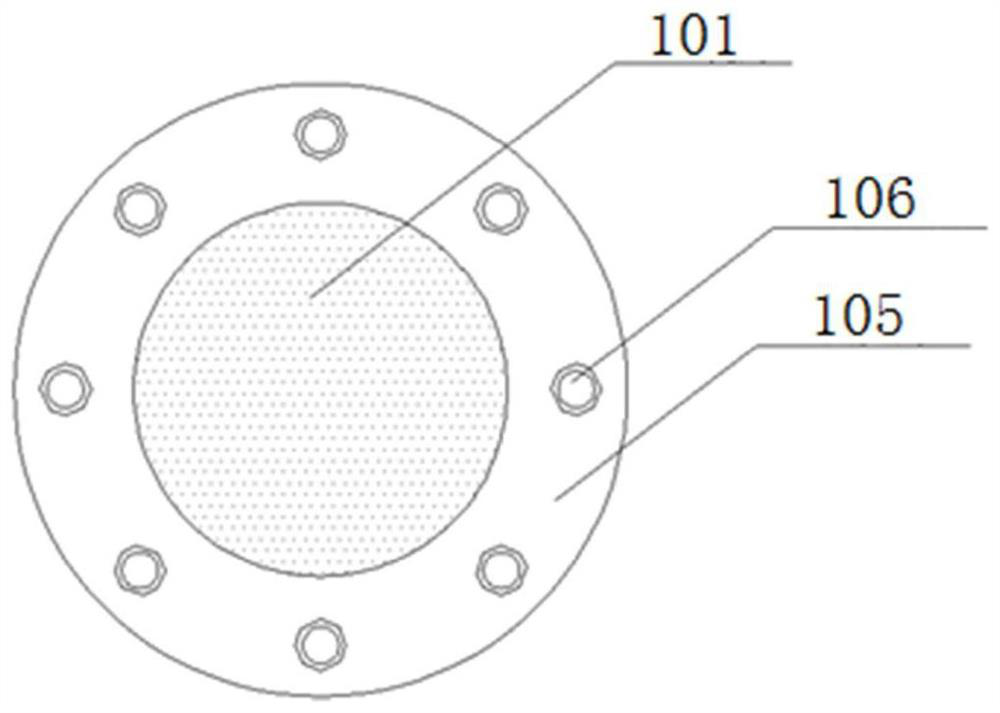

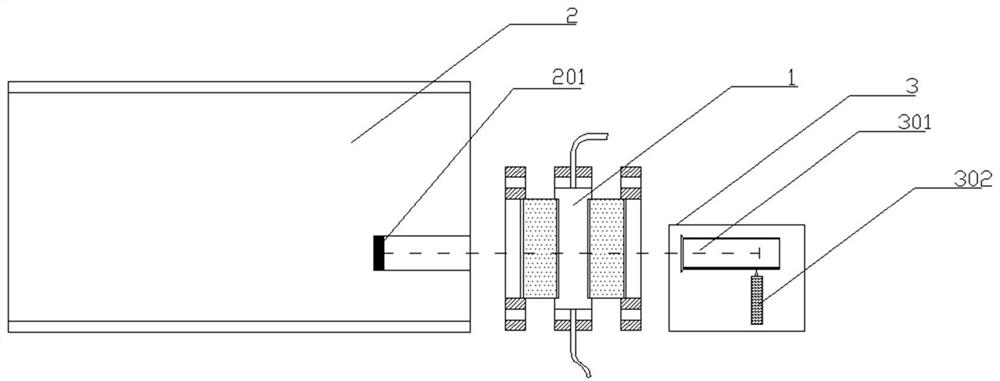

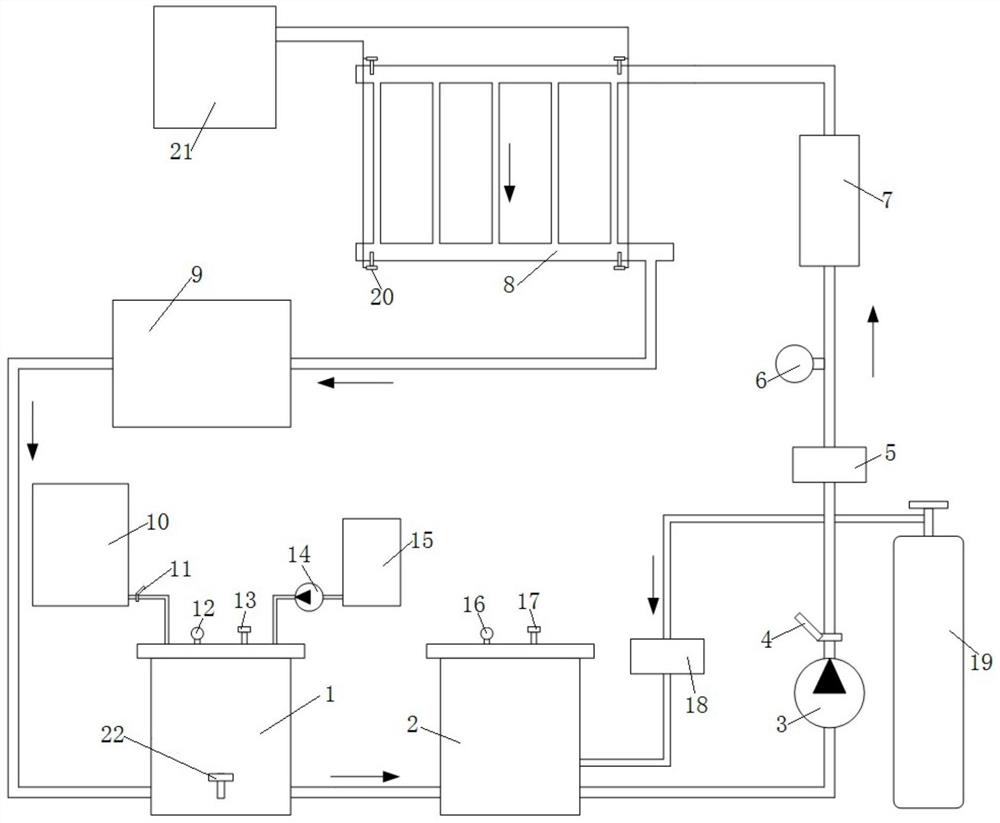

Three-axis permeability test and CO2 displacement simulation test device

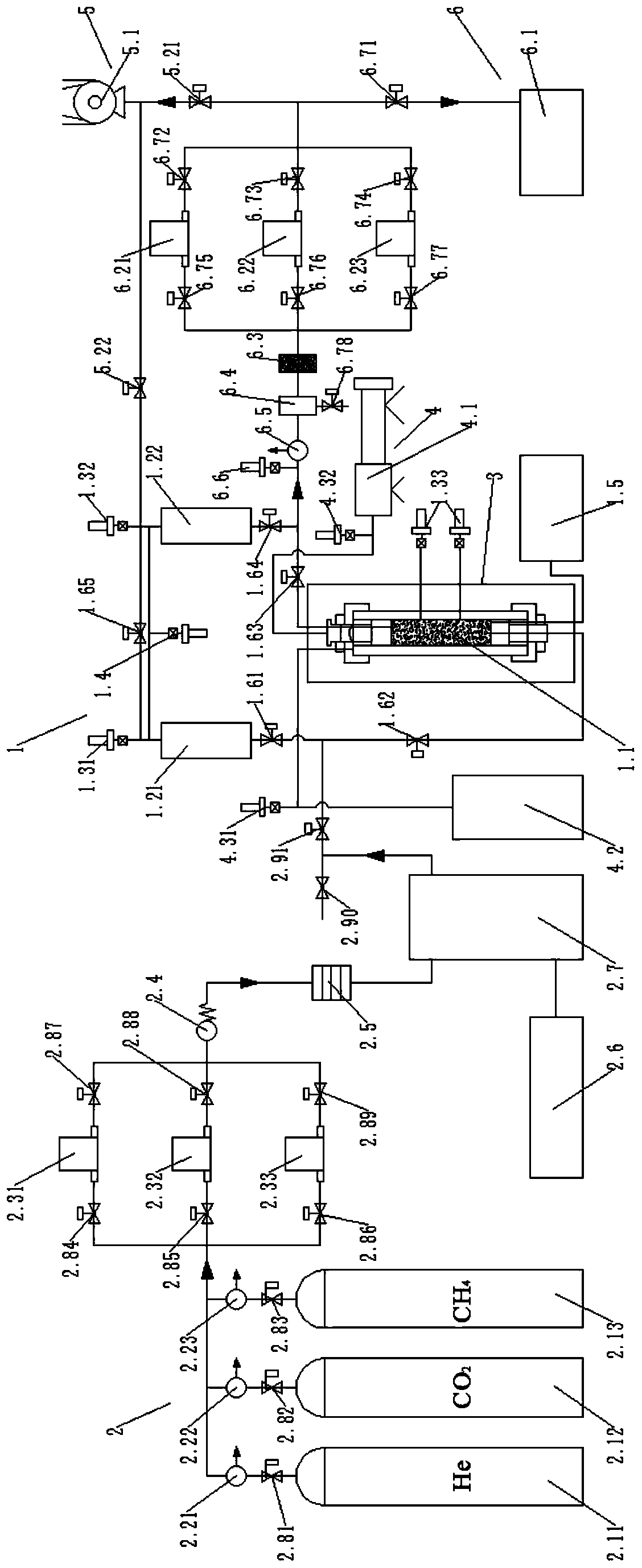

ActiveCN108414419AEasy connectionGuarantee system securityComponent separationPermeability/surface area analysisSystem monitorCoal

Owner:CHINA UNIV OF MINING & TECH

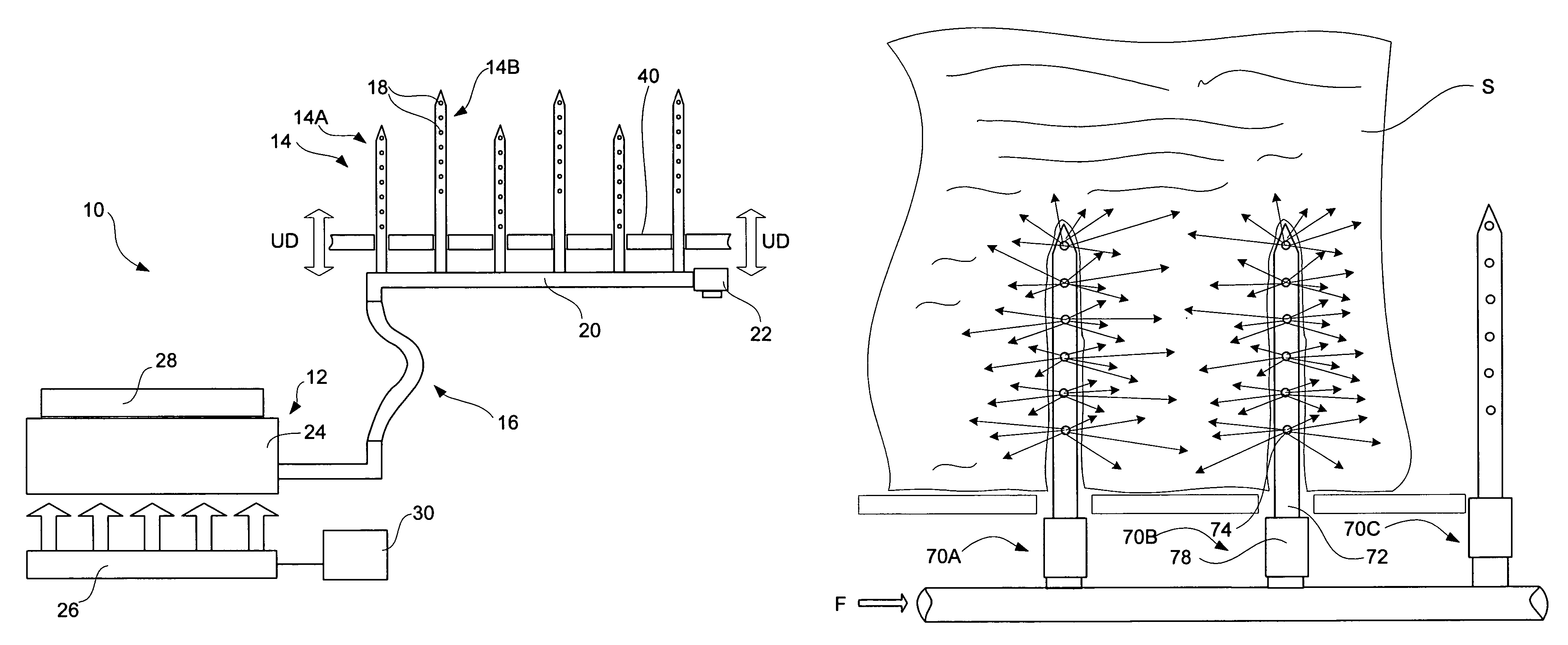

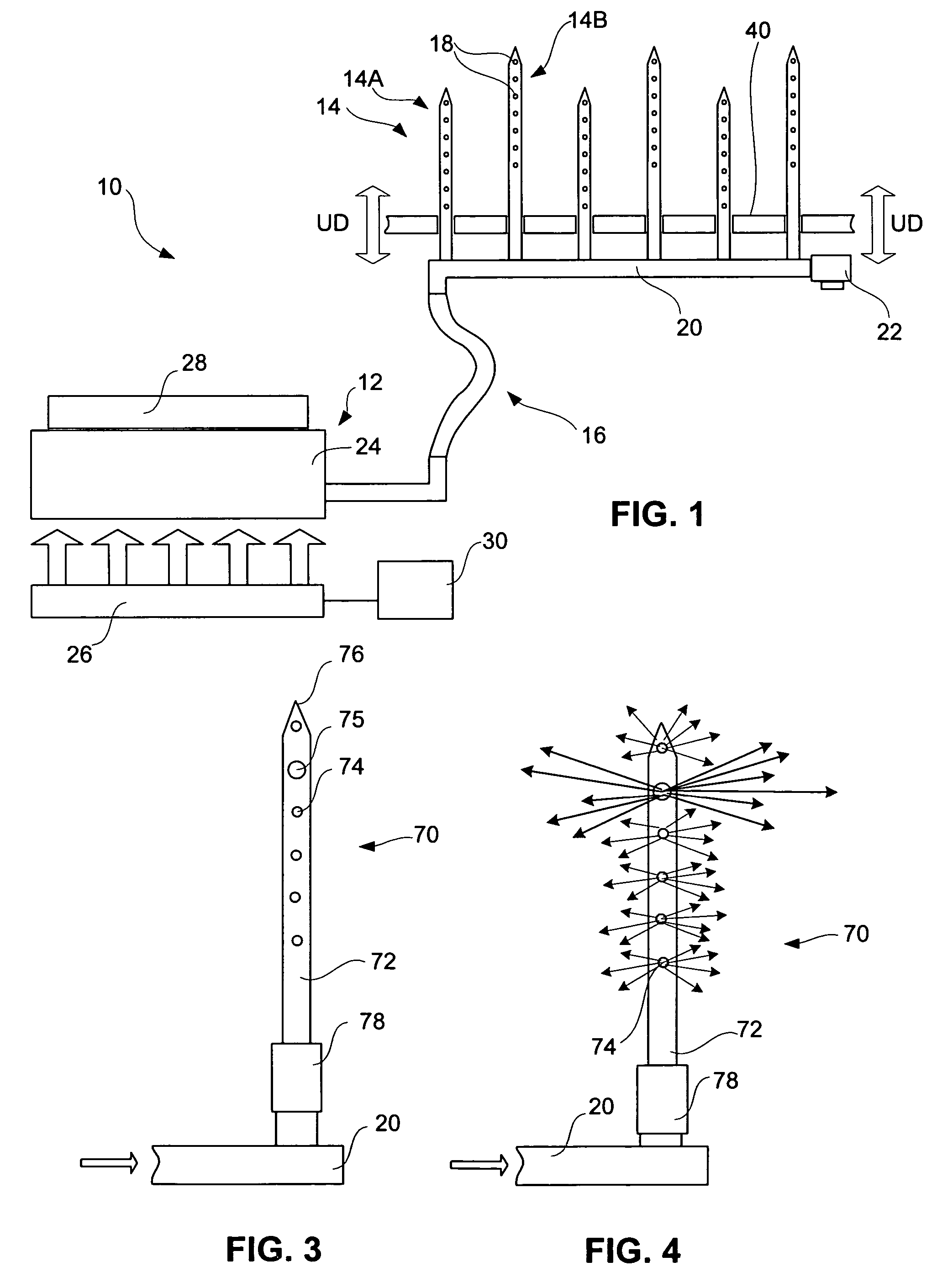

Flavor infusion cooking device and method

InactiveUS7549369B2Add flavorEasy and quick connectionGrain huskingGrain polishingFood flavorBiomedical engineering

Owner:ZIMMERMAN HARRY

CO2 displacement simulated testing method

ActiveCN108414727AEasy connectionGuarantee system securityEarth material testingSample collectionEnvironmental geology

Owner:CHINA UNIV OF MINING & TECH

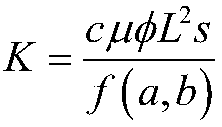

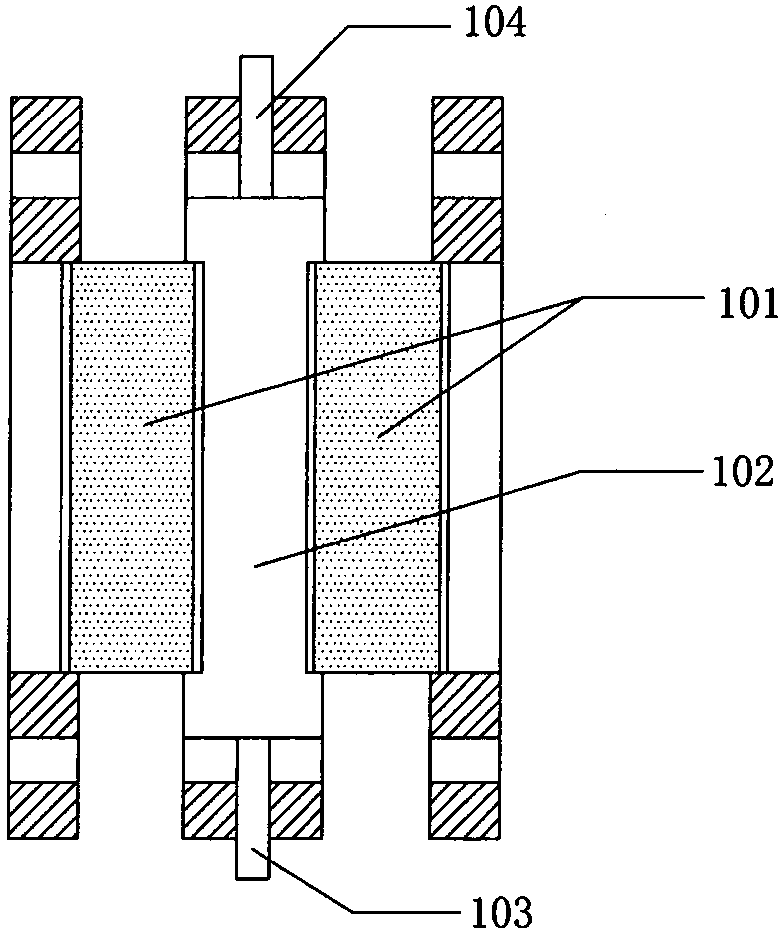

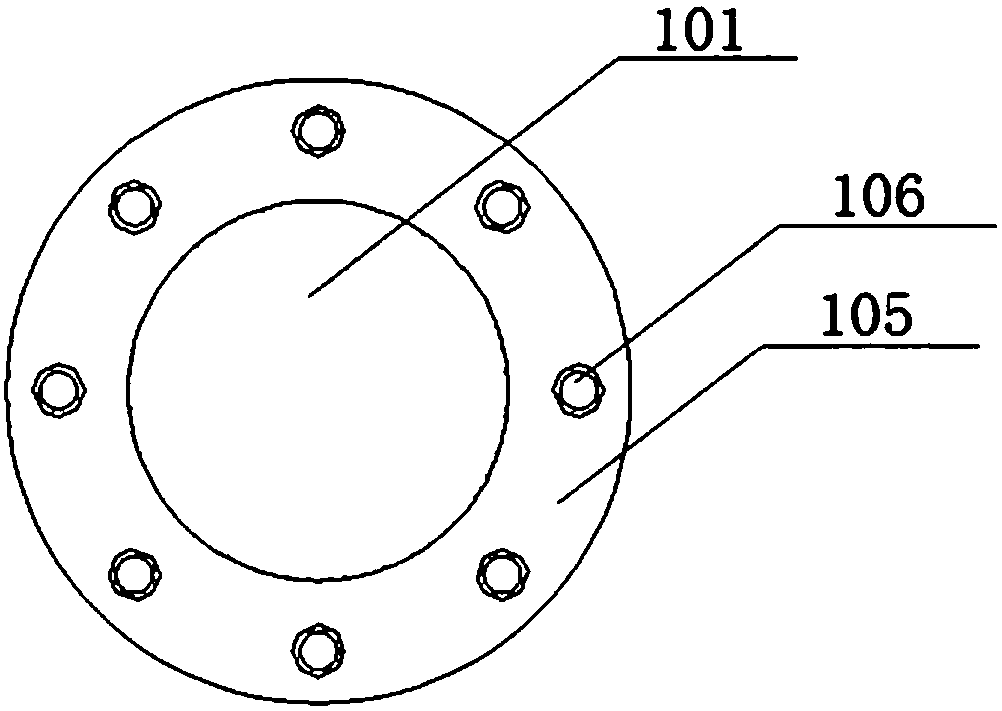

Three-axis permeability testing method

ActiveCN108414418AEasy connectionGuarantee system securityPermeability/surface area analysisPetrologyTest efficiency

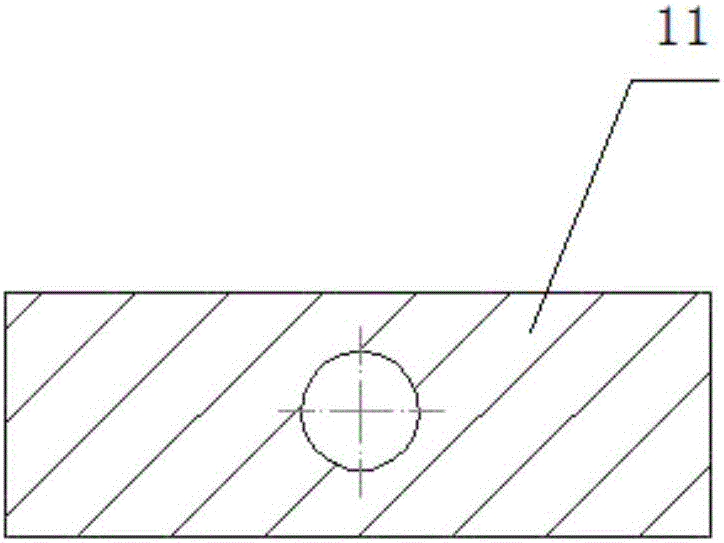

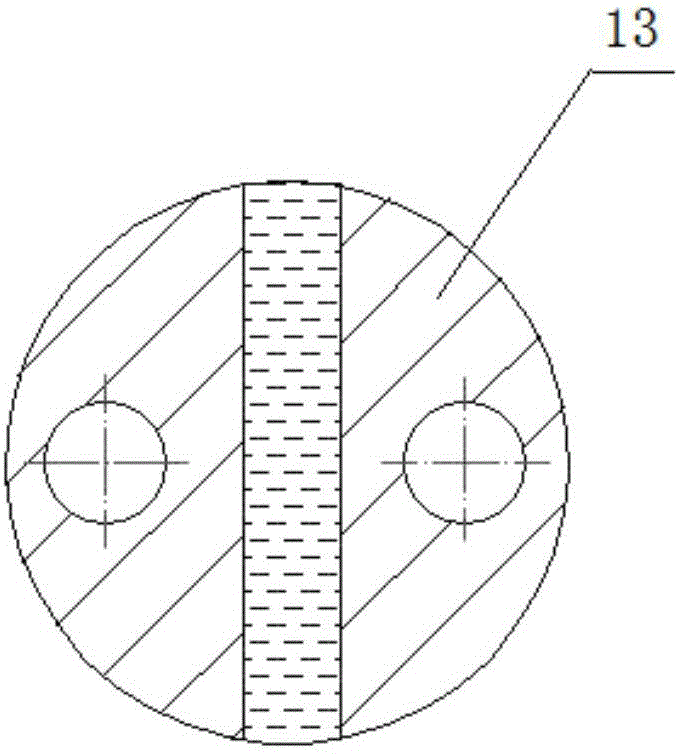

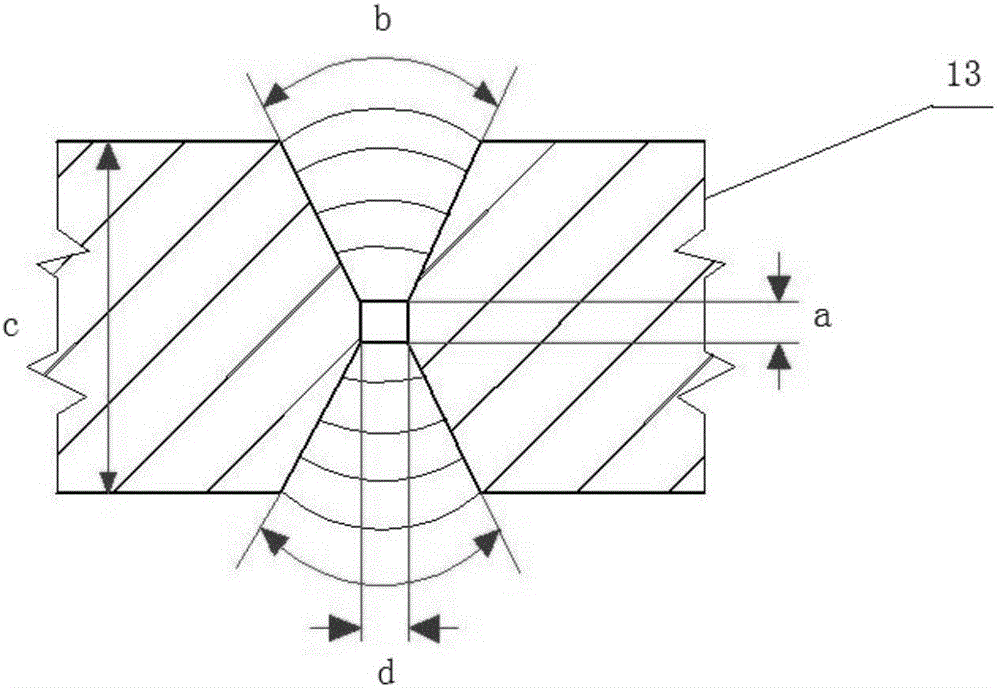

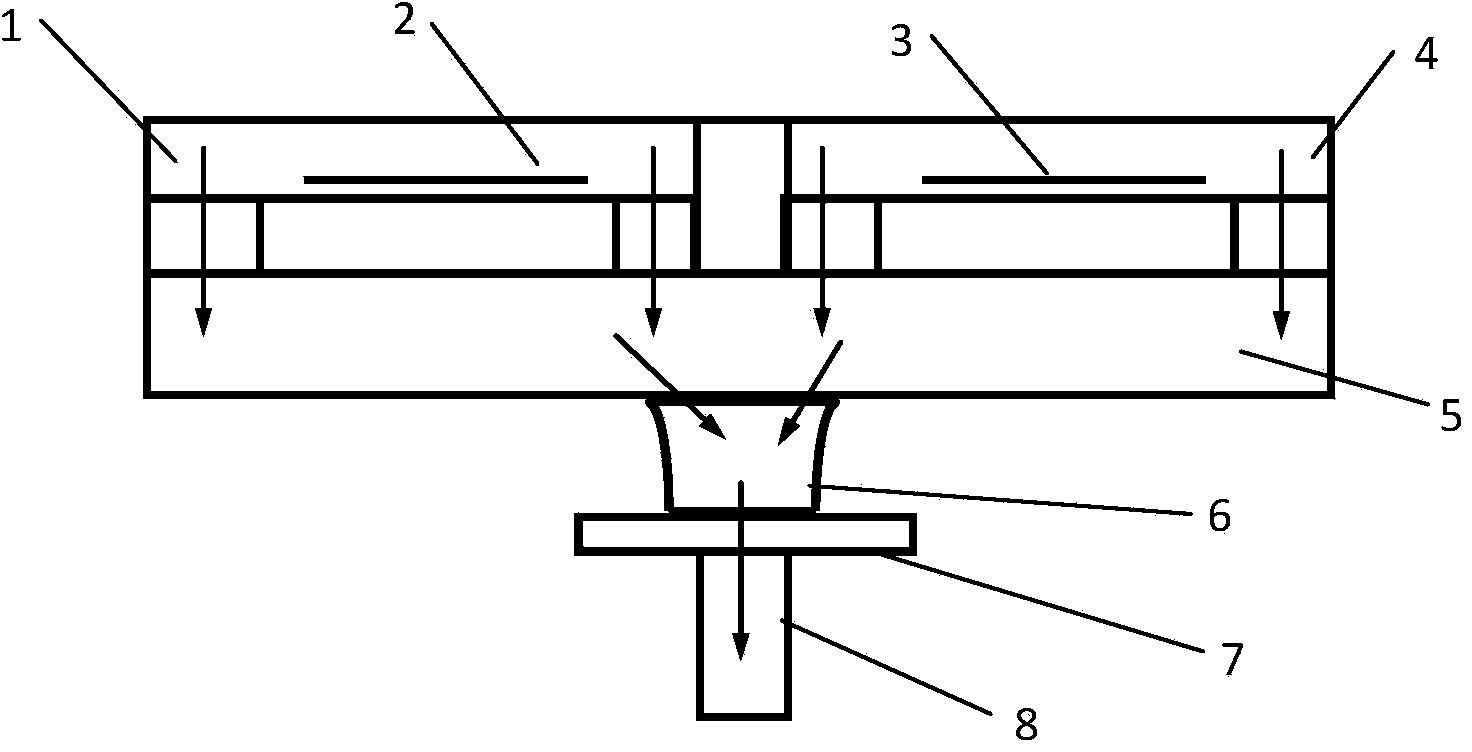

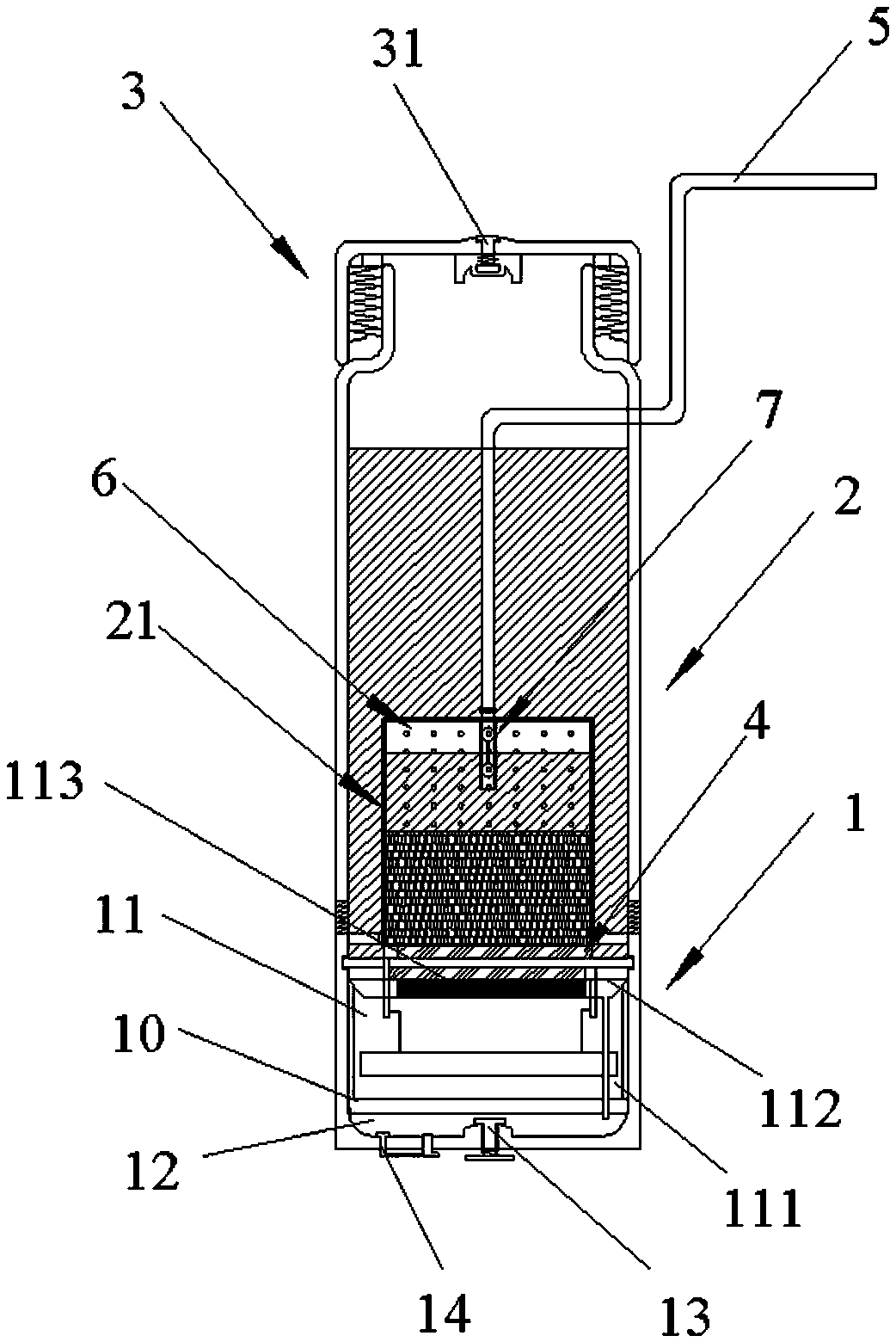

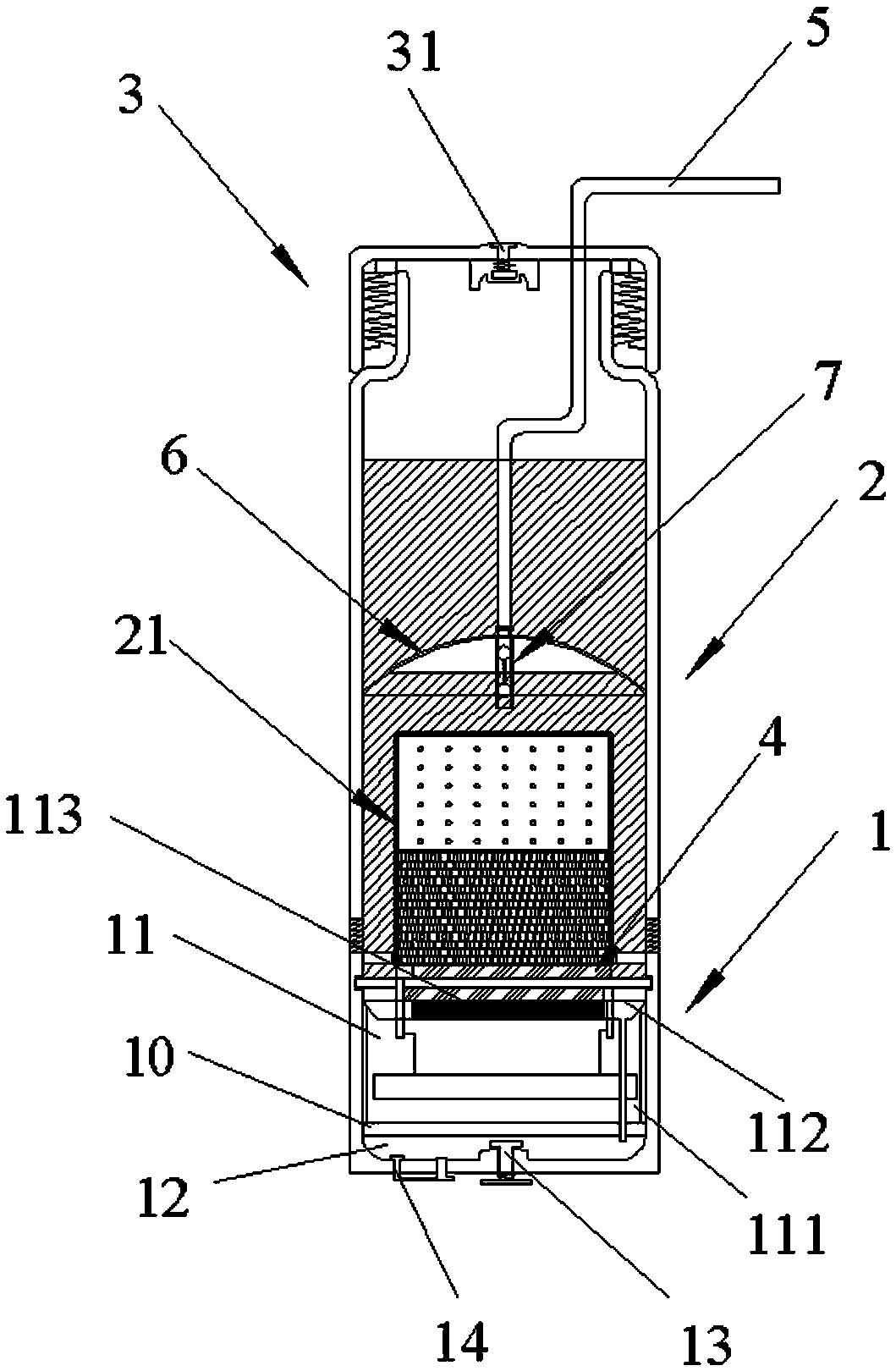

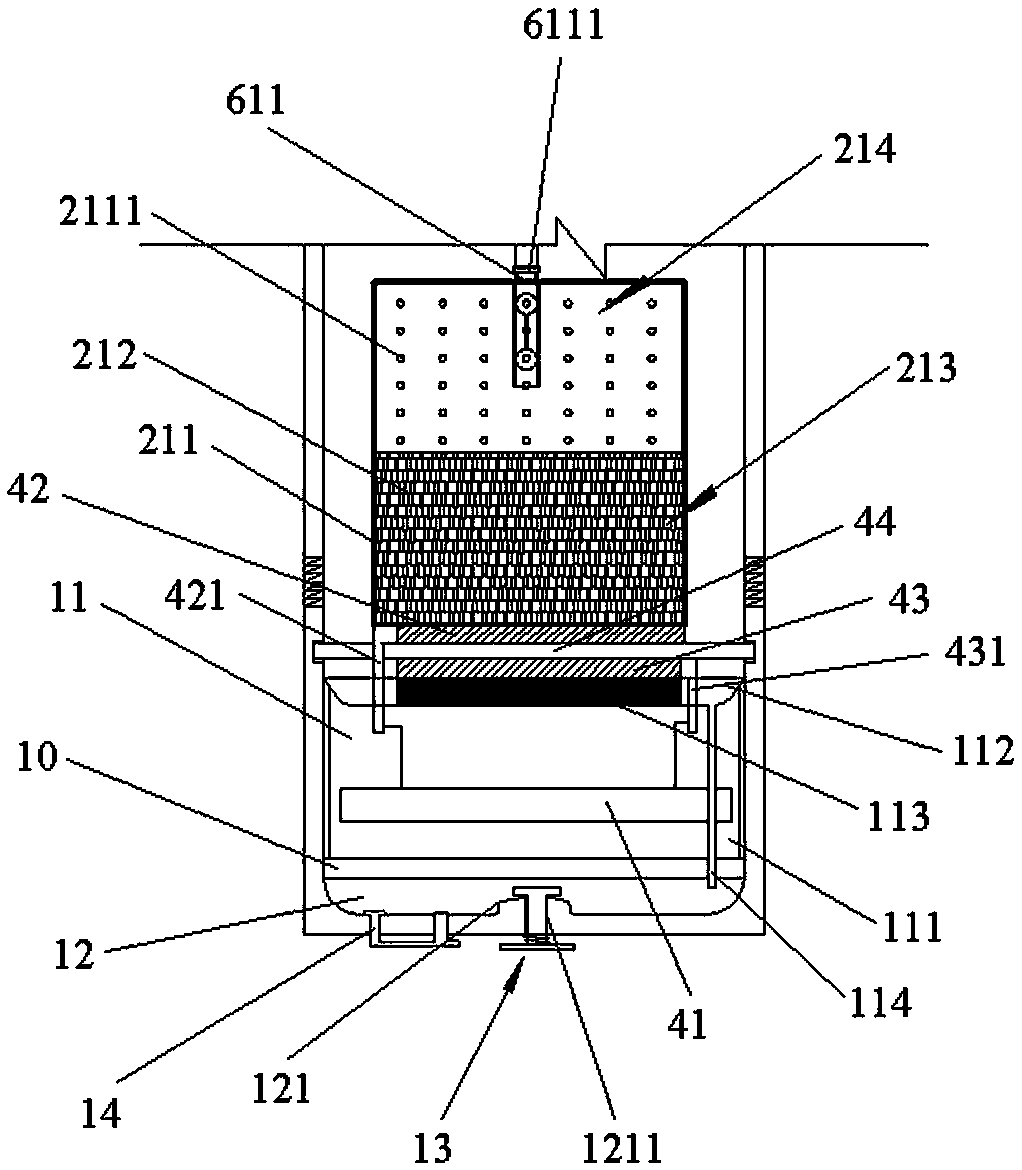

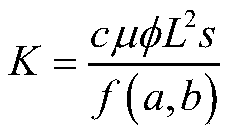

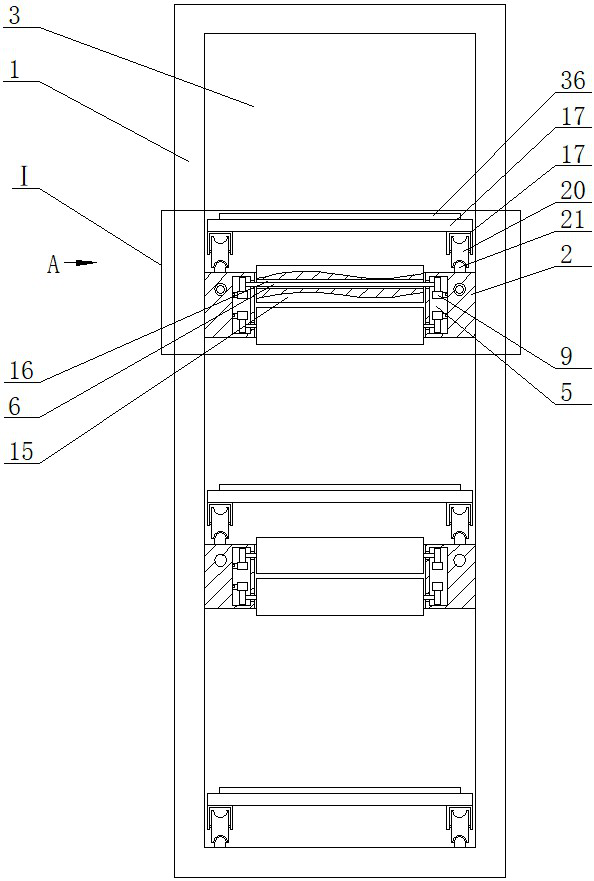

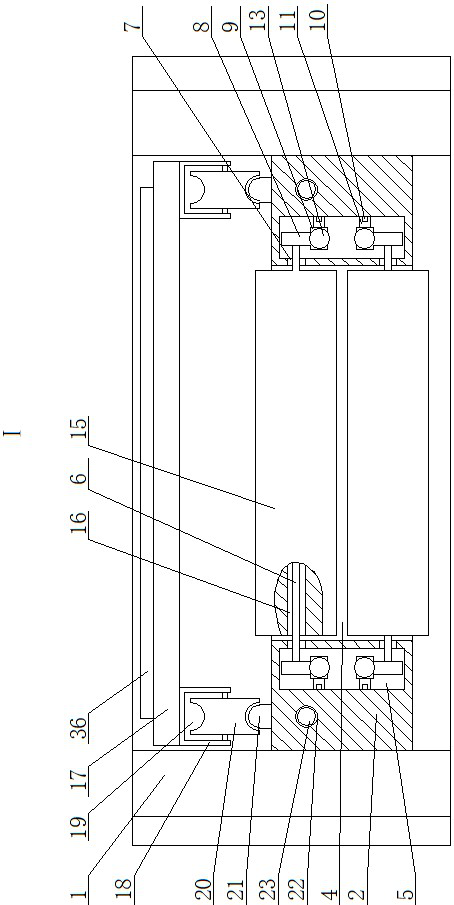

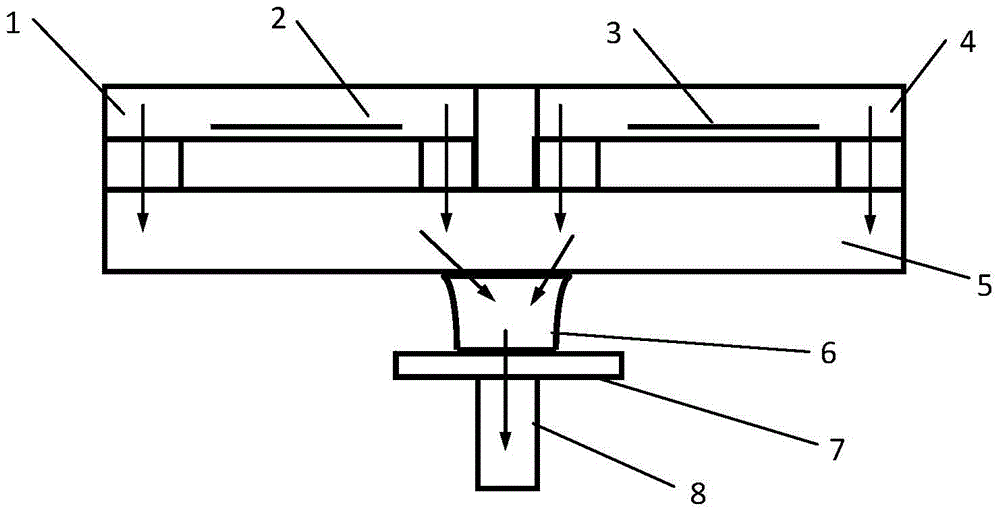

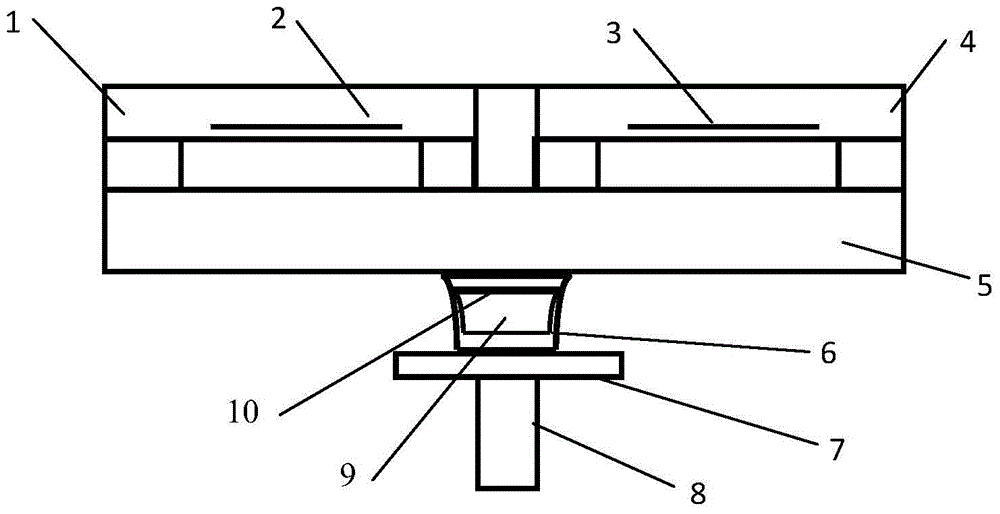

The invention discloses a three-axis permeability testing method, and belongs to the field of coal bed gas exploitation. A rock sample is placed in a model system (1), then pressure pulse is applied on the rock sample; a gas control system (2) supplies test gas to the model system (1); a temperature control system (3) controls the temperature of the model system (1); a three-axis loading system (4) applies confining pressure and axial pressure on the rock core clamper of the model system (1); a vacuumizing system (5) vacuumizes the test device; a gas sample collecting system (6) detects the gas components after the test; and an electrical controlling and monitoring system monitors the test process. The method comprises following steps: filling a sample into a tank, checking the airtightness, carrying out a permeability test, and cleaning the test system. The provided method can simulate a high temperature and high pressure environment of a deep stratum in a lab; pressure pulse is applied on the inlet end of a rock sample, the attenuation data of pressure pulse can be obtained, and then the rock sample permeability is calculated based on the attenuation data. The test efficiency ishigh, the external interference is little, and the test result is more accurate.

Owner:CHINA UNIV OF MINING & TECH

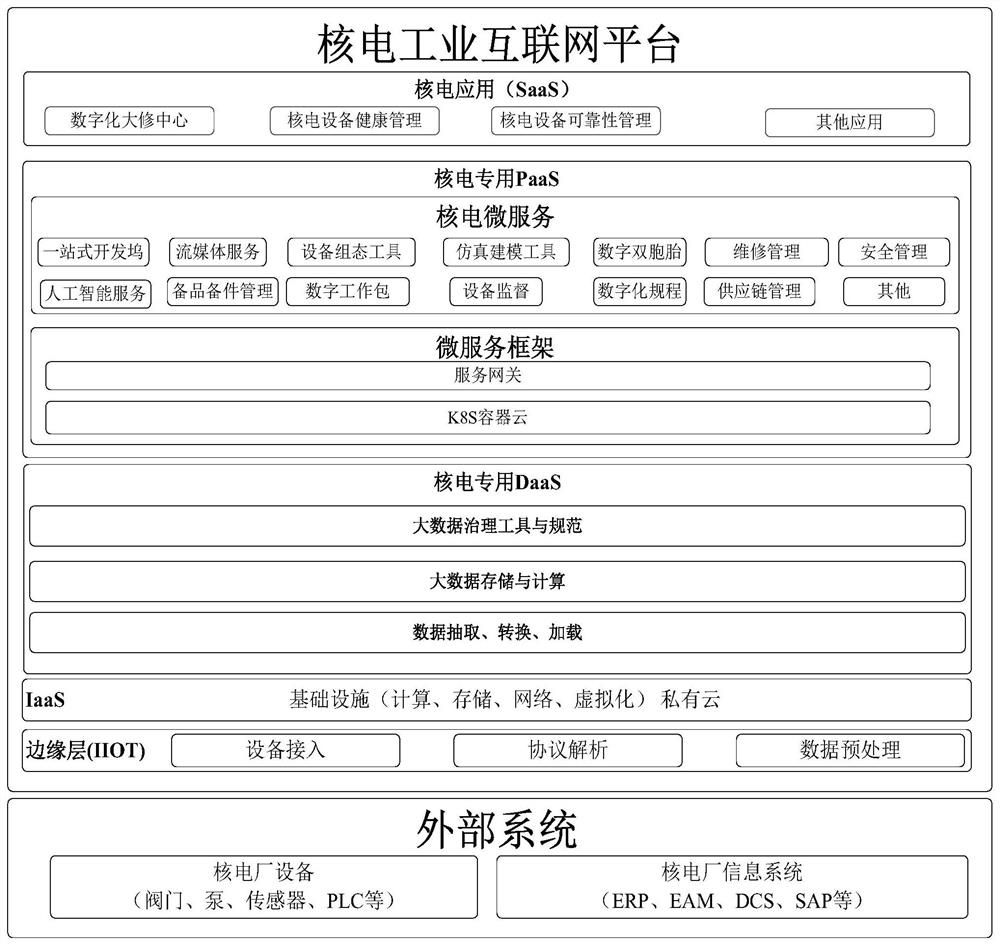

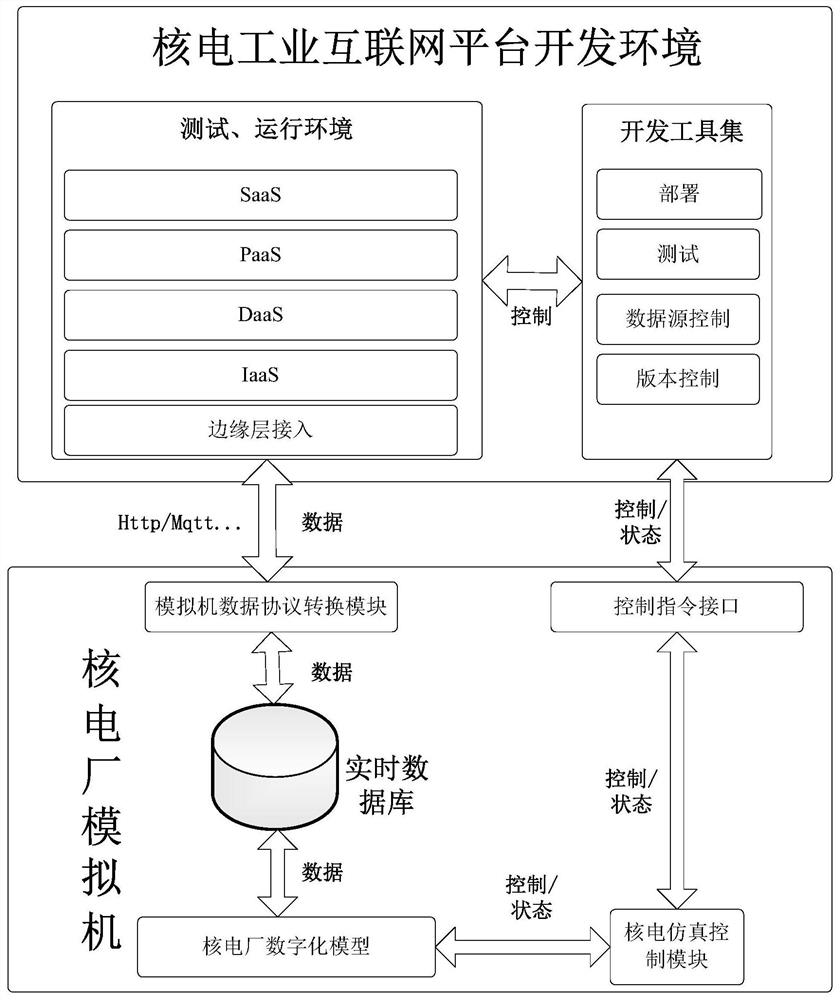

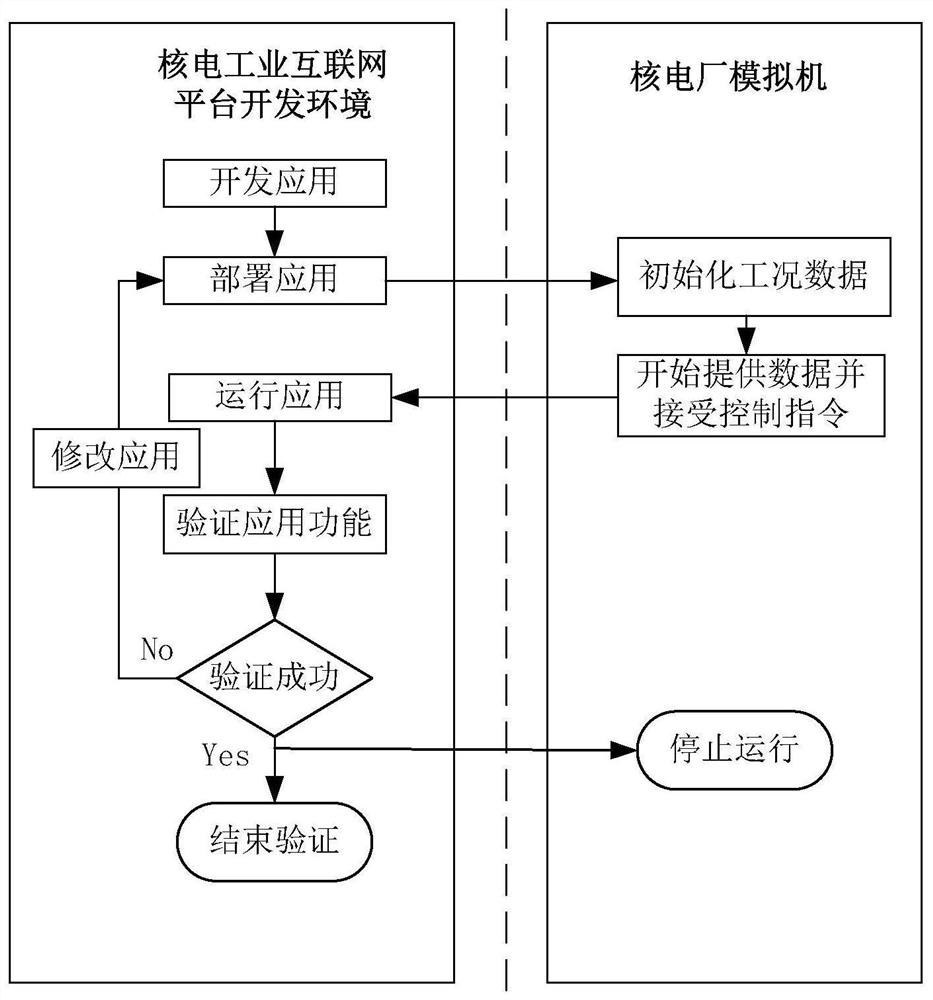

Nuclear power industry internet experiment bed based on simulation

PendingCN111767031ARapid developmentConsistent developmentVersion controlSoftware testing/debuggingMachine simulationIndustrial Internet

The invention relates to the technical field of nuclear power station analog machine simulation and industrial internet, particularly to a nuclear power industry internet experiment bed based on simulation. The nuclear power industry Internet platform comprises a nuclear power industry Internet platform development environment and a nuclear power plant analog machine, wherein the nuclear power industry Internet platform development environment comprises a test operation environment and a development tool set, and the test operation environment comprises an edge layer, an infrastructure cloud service layer, a data service layer, a micro-service support system, an operation platform layer and a nuclear power application layer. The nuclear power industry internet experiment bed is applied tolinks of development, debugging, integration, testing and the like of a nuclear power industry Internet platform, and can substantially improve the working efficiency and save the cost.

Owner:CHINA NUCLEAR POWER OPERATION TECH

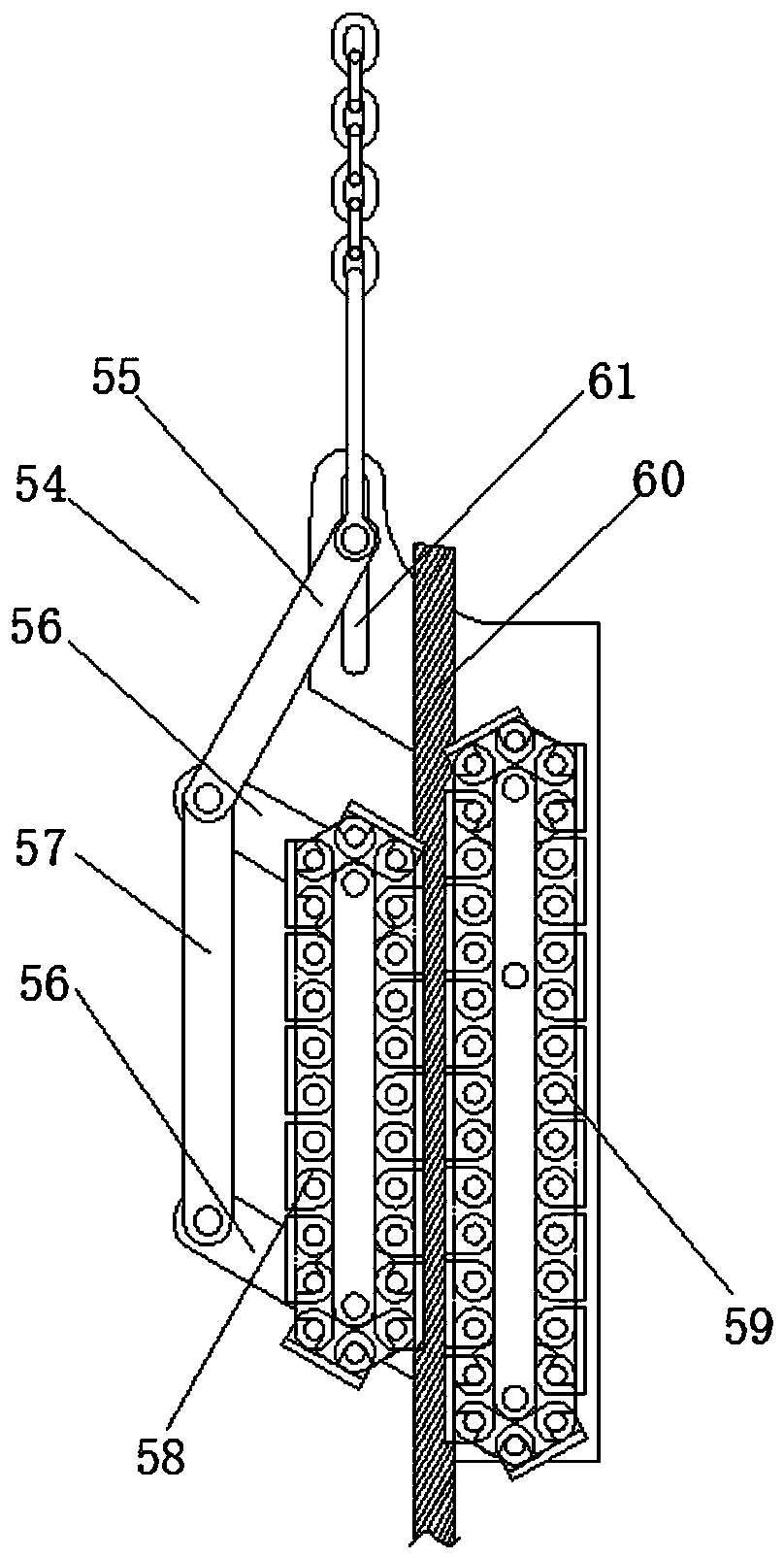

On-site corrosion detecting method and device

InactiveCN106769829ASimple structureEasy to assembleWeather/light/corrosion resistanceBiomedical engineeringCorrosion

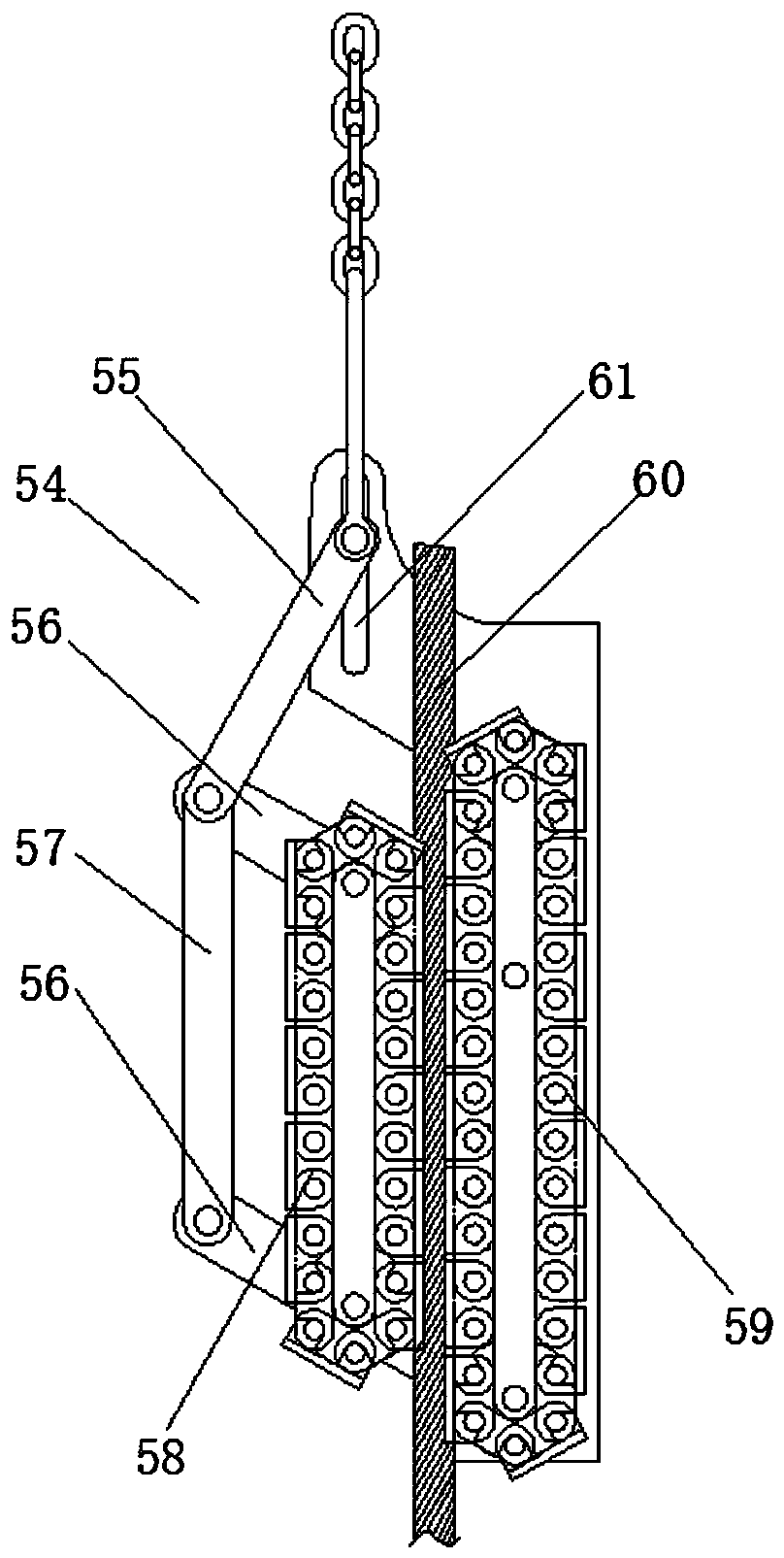

The invention provides an on-site corrosion detecting method and device. The method comprises the following steps: analyzing a corrosion environment in a position to be detected; collecting material and state information of a device in the position to be detected; selecting a sample type and a coupon rack type, and loading the selected sample on the coupon rack; arranging the loaded coupon rack in the position to be detected, and performing on-site implementation; and taking down the sample from the coupon rack, and performing corrosion evaluation on the sample. The invention has the following advantages: the device is simple in structure and convenient to assemble; multiple samples with different material and tissue states can be hung at one time; the fluid flow state on the surface of the sample conforms to the environment; the device is light in weight, and can not cause an obvious stress to a wall; and the device is convenient to mount and demount.

Owner:SINOPEC ENG GRP CO LTD

Airflow control device for decouple reaction ion etching equipment

ActiveCN103866399AImprove rectification effectImprove uniformityAfter-treatment detailsEngineeringVALVE PORT

The invention discloses an airflow control device for decouple reaction ion etching equipment. The airflow control device for the decouple reaction ion etching equipment is characterized in that a rectifying cover with uniformly densely covered air holes is arranged in an exhaust port shared by the bottoms of two reaction chambers of the equipment in a sealing manner and is used for rectifying gas above a servo pressure valve, so that the uniformity and stability of the gas above the rectifying cover are greatly improved. The airflow control device for the decouple reaction ion etching equipment has the advantages that after the gas is rectified, the pressures of the left chamber and the right chamber are kept consistent, and the uniformity of a product is improved; meanwhile, the phenomenon that polymers asynchronously assemble in the chambers does not occur, so that the environments of the chambers are kept consistent, the stability of a technology is improved, the period of equipment cleaning is prolonged, the production efficiency of the equipment is improved, and the maintenance charge of the equipment is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

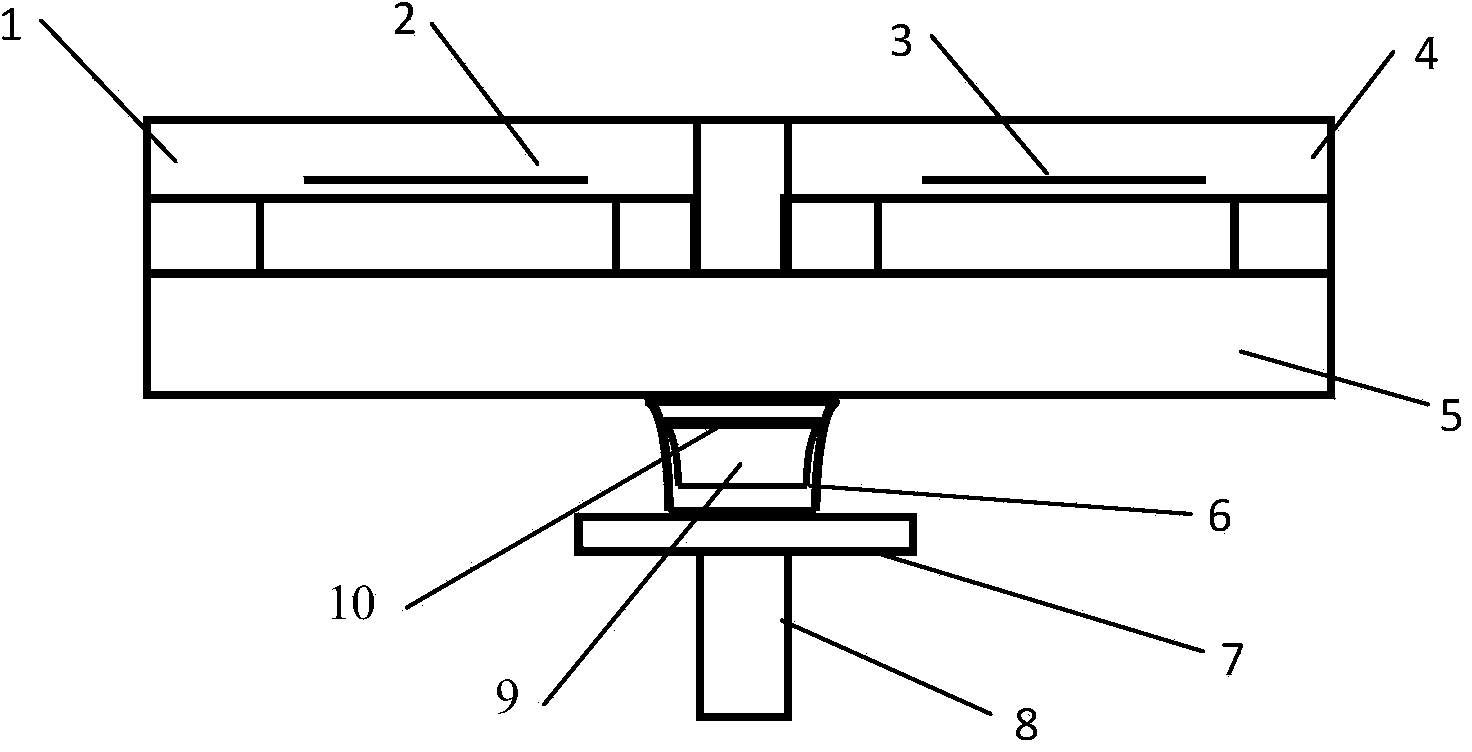

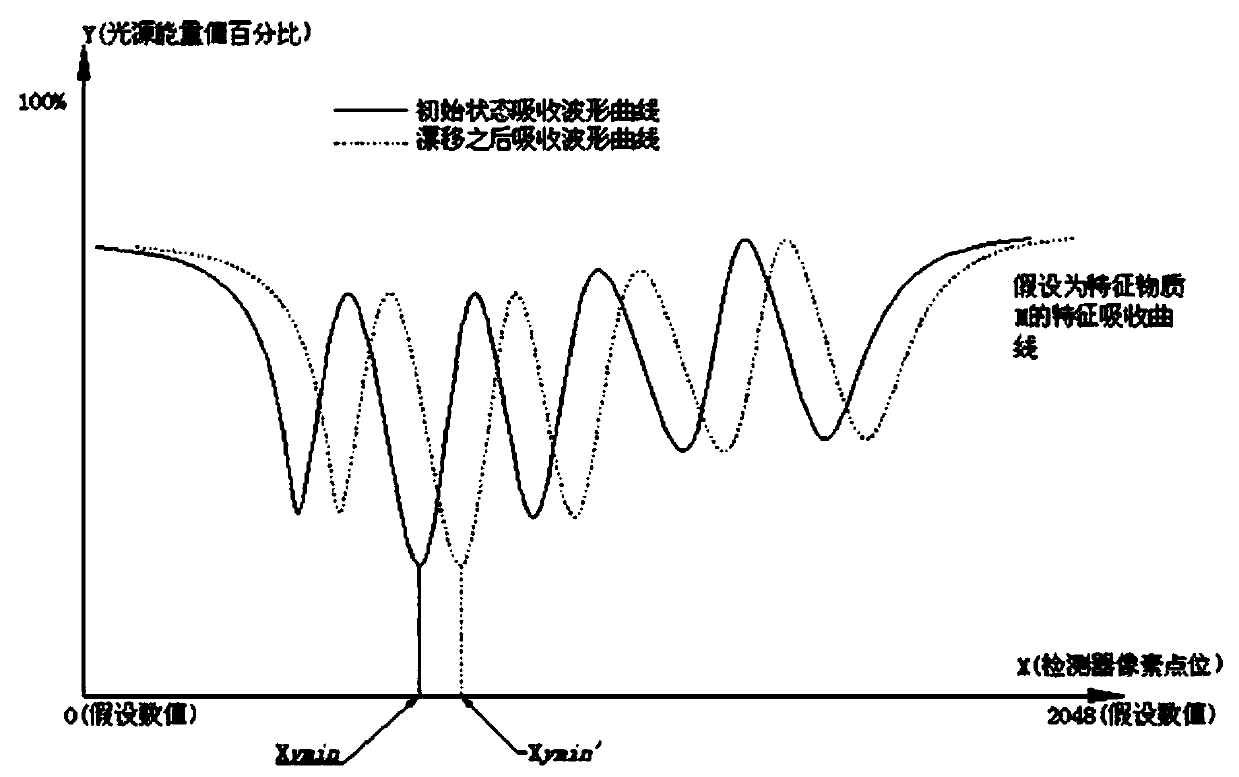

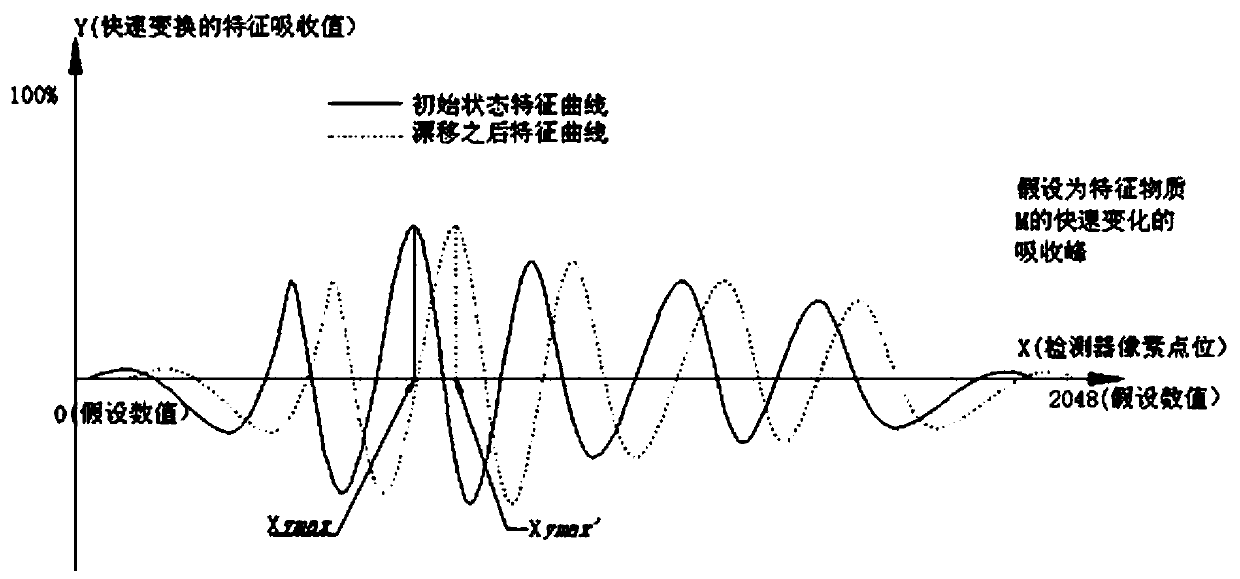

Method and system for correcting spectrograph wavelength shift

PendingCN109883962AStable projectionNo need to change the structureColor/spectral properties measurementsSpectrographComputational physics

The invention relates to a method and system for correcting spectrograph wavelength shift. The method comprises the steps that: a, to-be-corrected pixel points and corresponding spectral signals thereof of standard gas characteristic absorption bands of detected gas are collected by a to-be-corrected spectrograph; b, to-be-corrected pixel points of absorption peak points in the standard gas characteristic absorption bands are determined through the spectral signals; c, a correction factor is obtained by matching the to-be-corrected pixel points of the absorption peak points and the pixel points in reference corresponding relationship of the absorption peak points, and the datum corresponding relationship of the absorption peak points is a datum corresponding relationship of the absorptionpeak points and the pixel points in the standard gas characteristic absorption bands of detected gas collected by the corrected spectrograph; and d, the pixel points of the detected gas collected by the to-be-corrected spectrograph are corrected by the correction factor. The method for correcting the spectrograph wavelength shift has wide coverage and is suitable for wavelength correction of spectrographs with a plurality of types and wavelength ranges.

Owner:BEIJING SDL TECH

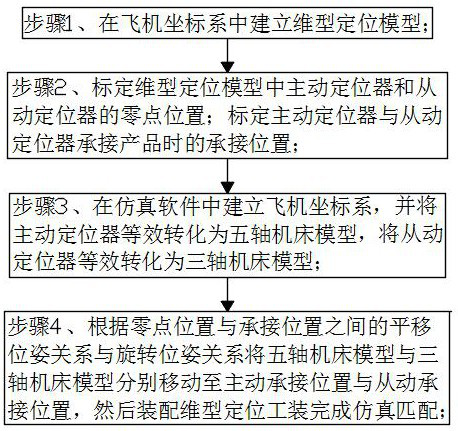

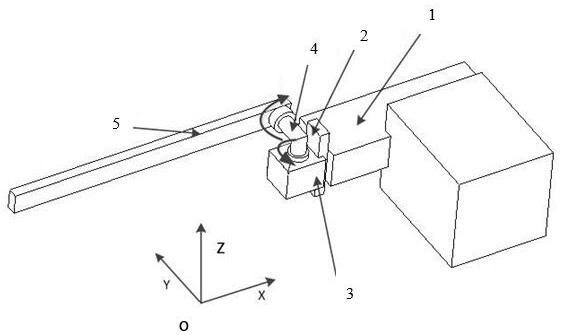

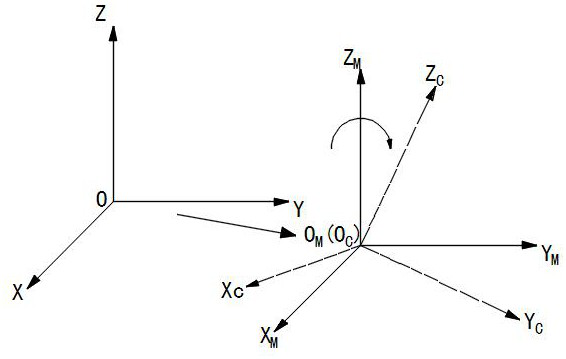

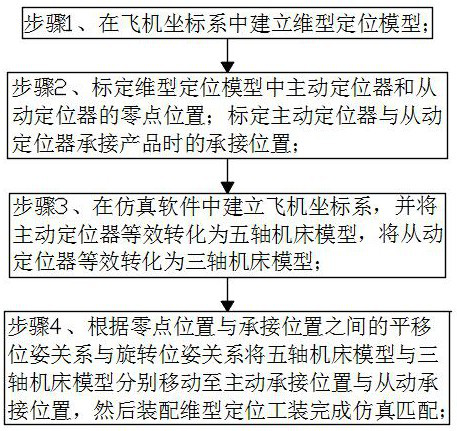

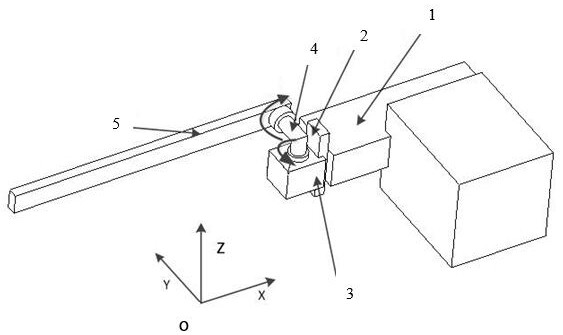

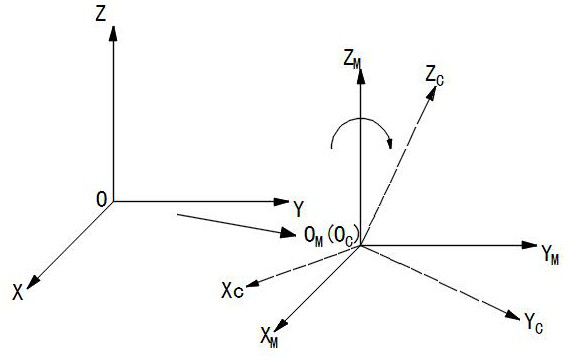

Dimensional positioning pose simulation matching method based on two three-coordinate positioners

ActiveCN112613130ARealize automatic matchingConsistent environmentGeometric CADDesign optimisation/simulationComputer graphics (images)Detent

The invention discloses a dimensional positioning pose simulation matching method based on two three-coordinate positioners. The method comprises the steps of: calibrating zero point positions, driving bearing positions and driven bearing positions of a driving positioner and a driven positioner, enabling the driving positioner to be equivalent to a five-axis machine tool model, enabling the driven positioner to be equivalent to a three-axis machine tool model, obtaining translation parameters and rotation parameters of the five-axis machine tool model by calculating a translation pose relationship and a rotation pose relationship between the zero point position and the active bearing position; and obtaining translation parameters of the three-axis machine tool model by calculating a translation pose relationship between the zero point position and the driven bearing position. Therefore, the simulation movement of a dimensional positioning tool is converted into translation rotation of the five-axis machine tool model and translation of the three-axis machine tool model, so that the simulation environment of the dimensional positioning tool is consistent with the actual environment, and automatic matching of the dimensional positioning tool and a positioner in the simulation environment is realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

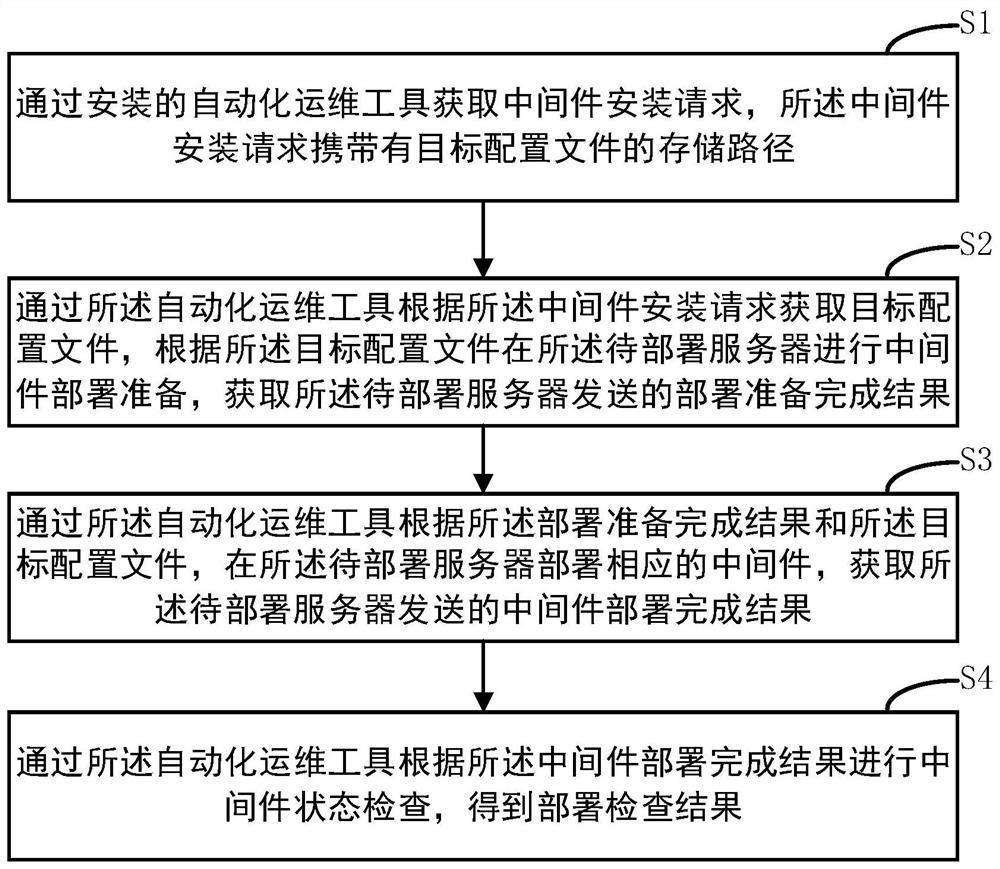

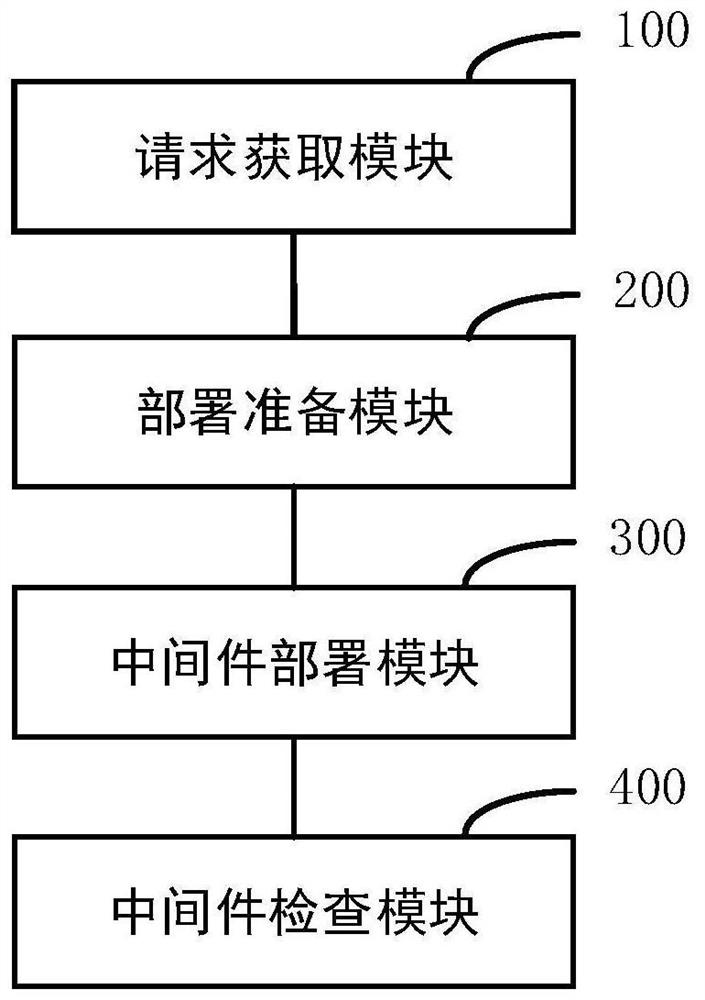

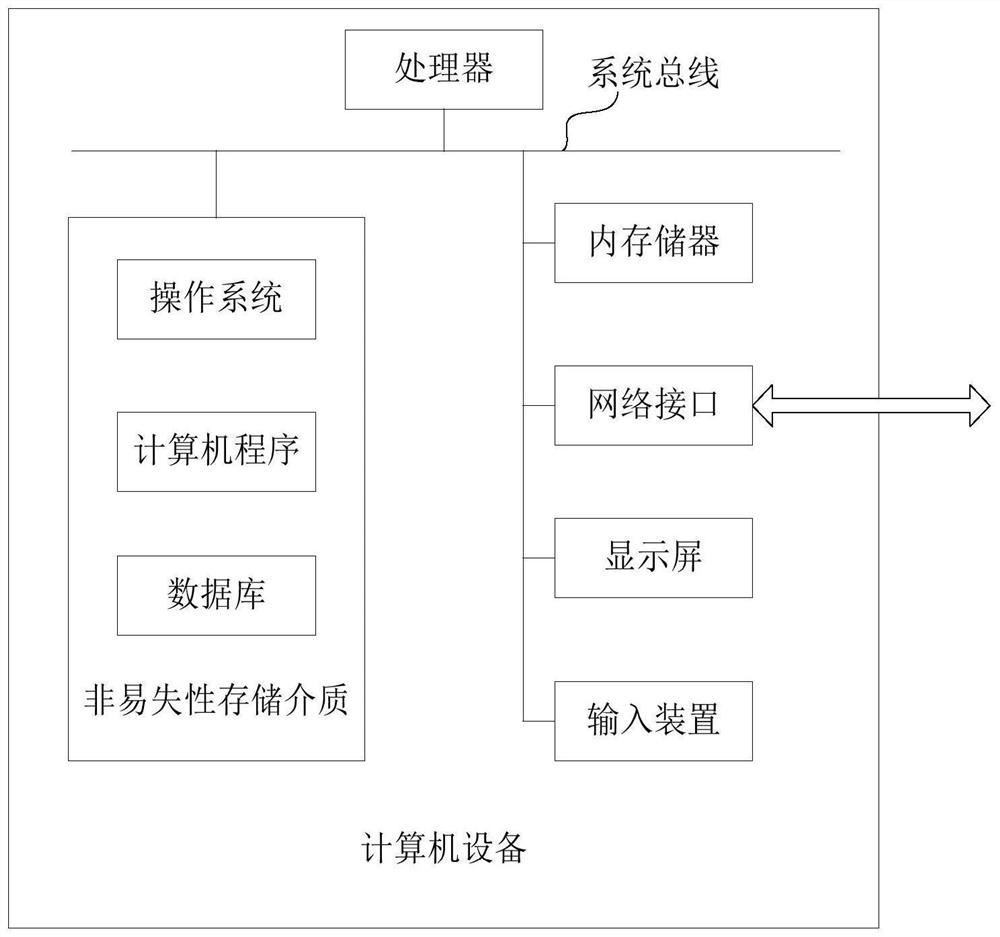

Method and device for remotely deploying middleware, computer equipment and storage medium

The invention relates to the technical field of distributed deployment, and discloses a method and device for remotely deploying middleware, computer equipment and a storage medium. The method is applied to a control server. The control server is provided with an automatic operation and maintenance tool; the control server and a to-be-deployed server achieve password-free login based on a key pairof an SSH protocol; and the to-be-deployed server is used for deploying a digital medical system; The method comprises the steps that: a middleware installation request is obtained through an automatic operation and maintenance tool, wherein the middleware installation request carries a storage path of a target configuration file; according to the middleware installation request, through the automatic operation and maintenance tool, middleware deployment preparation, corresponding middleware deployment, and middleware state inspection are performed on the to-be-deployed server to complete thedeployment of middleware, and therefore, a deployment inspection result is obtained. Therefore, the operation is simple, the deployment efficiency is improved, the environment of the deployed middleware is consistent, the operation and maintenance cost and the operation and maintenance difficulty are reduced, and the problem can be quickly analyzed and positioned.

Owner:深圳平安医疗健康科技服务有限公司

Device and method for correction of infrared thermometer

ActiveCN108132100AAccurate measurementGuaranteed accuracy and precisionRadiation pyrometryZone meltingCorrection method

The present invention discloses a sight glass used for temperature correction of an infrared thermometer, and a device for correction of an infrared thermometer. The device comprises a black-body furnace, a sight glass and an infrared temperature measurement device which are arranged in order at intervals. The black-body furnace is internally provided with a radiator; the sight glass comprises dual-layer glass of the sight glass and a cooling water interlayer between the dual-layer glass of the sight glass; and the infrared temperature measurement device comprises an infrared thermometer. Thepresent invention further discloses a method for correction of an infrared thermometer. Through correction of the infrared thermometer, an error between a measured temperature and an actual temperature of a silicon rod is controlled in a range of -3 DEG C to 3 DEG C, accurate measurement of the temperature of the silicon rod in a reducing furnace is achieved, and a requirement for accurate and stable control of the surface temperature of the silicon rod is met when zone-melting silicon production is performed; and moreover, the effect of the sight glass is to simulate a measurement condition that the infrared thermometer measures a production temperature of a polycrystalline silicon or a zone-melting silicon in the reducing furnace to allow the correction environment to be consistent to the actual measurement environment, and therefore the accuracy and the precision of the measured temperature of the infrared thermometer are ensured.

Owner:江苏鑫华半导体科技股份有限公司

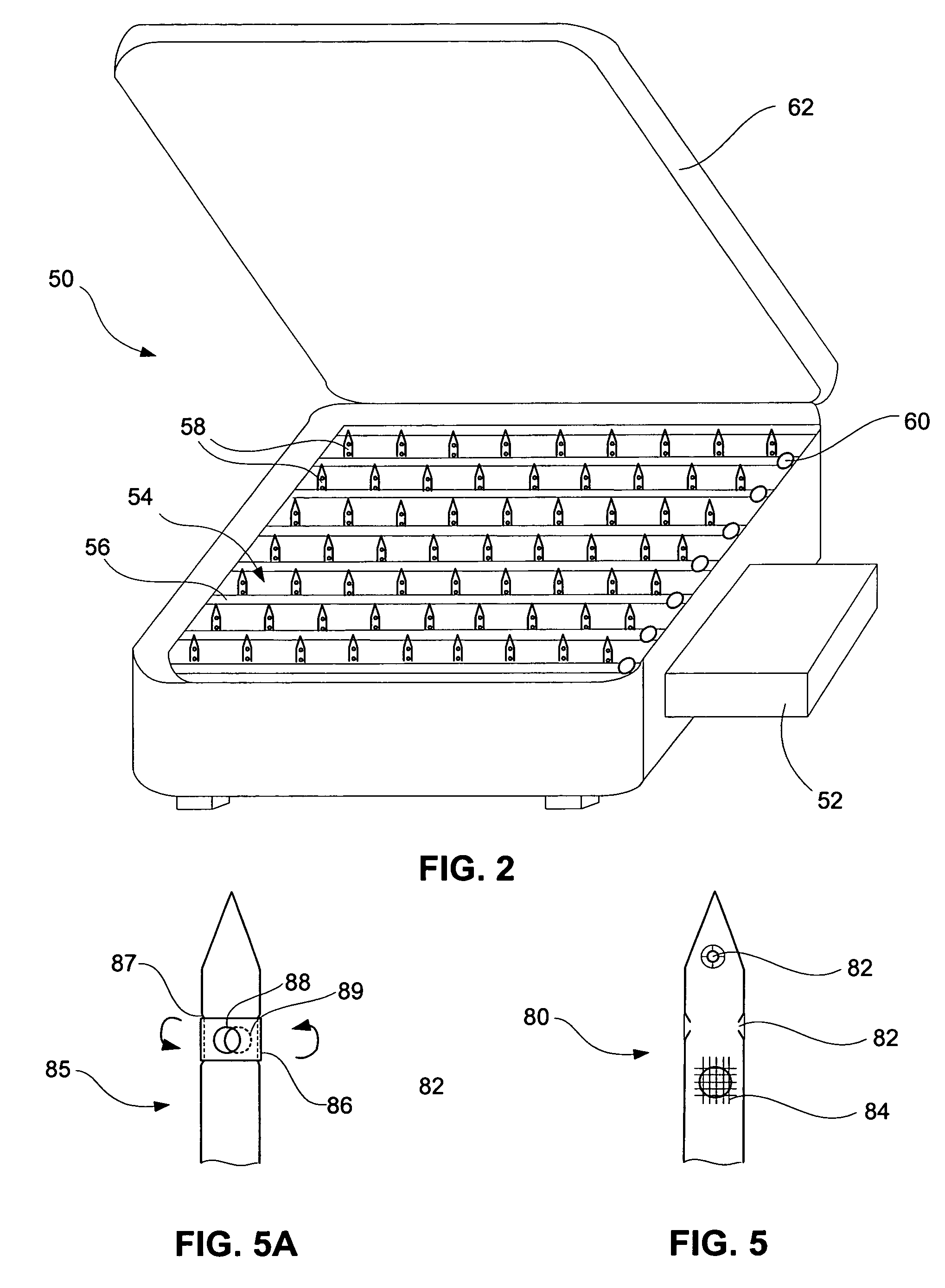

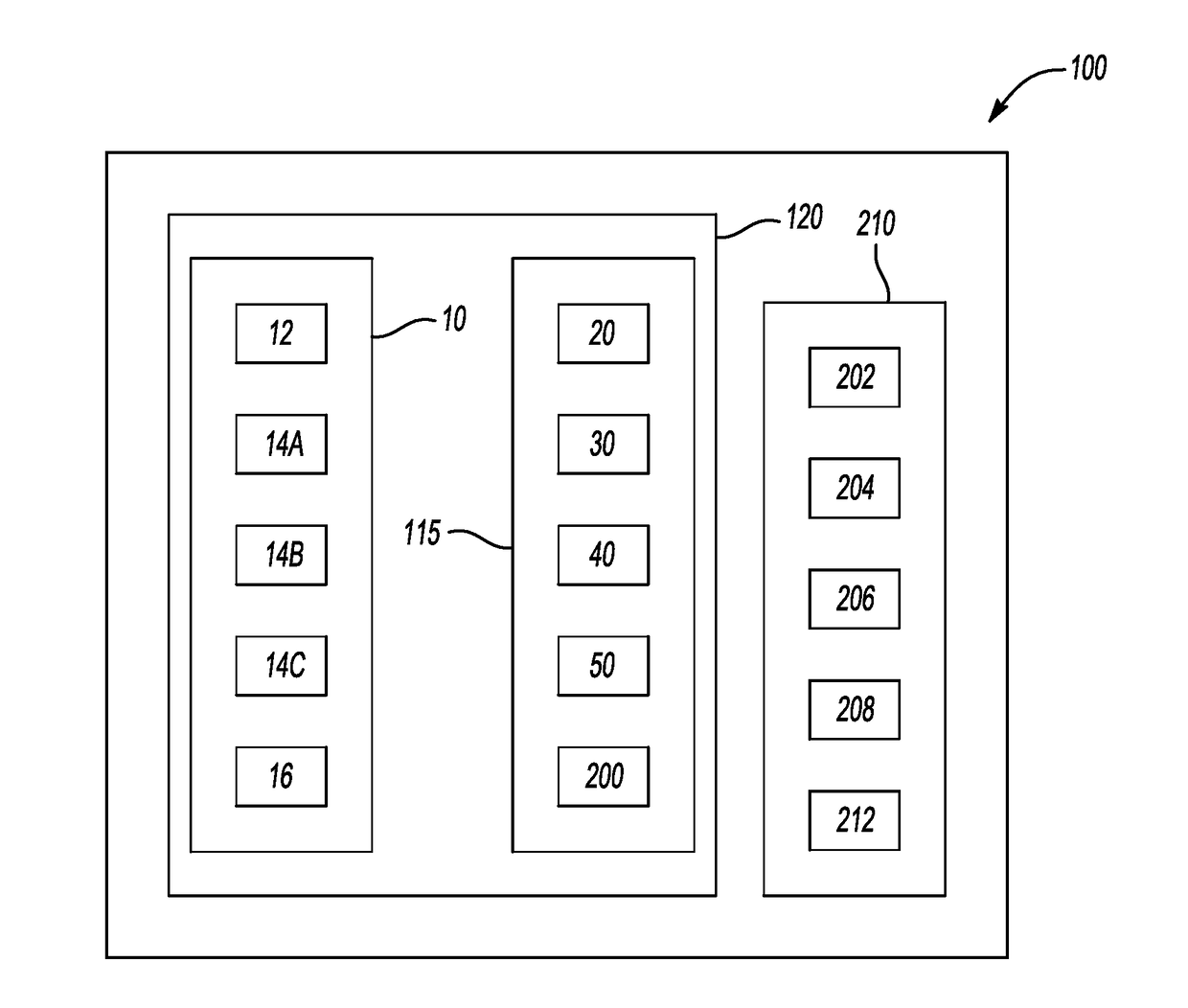

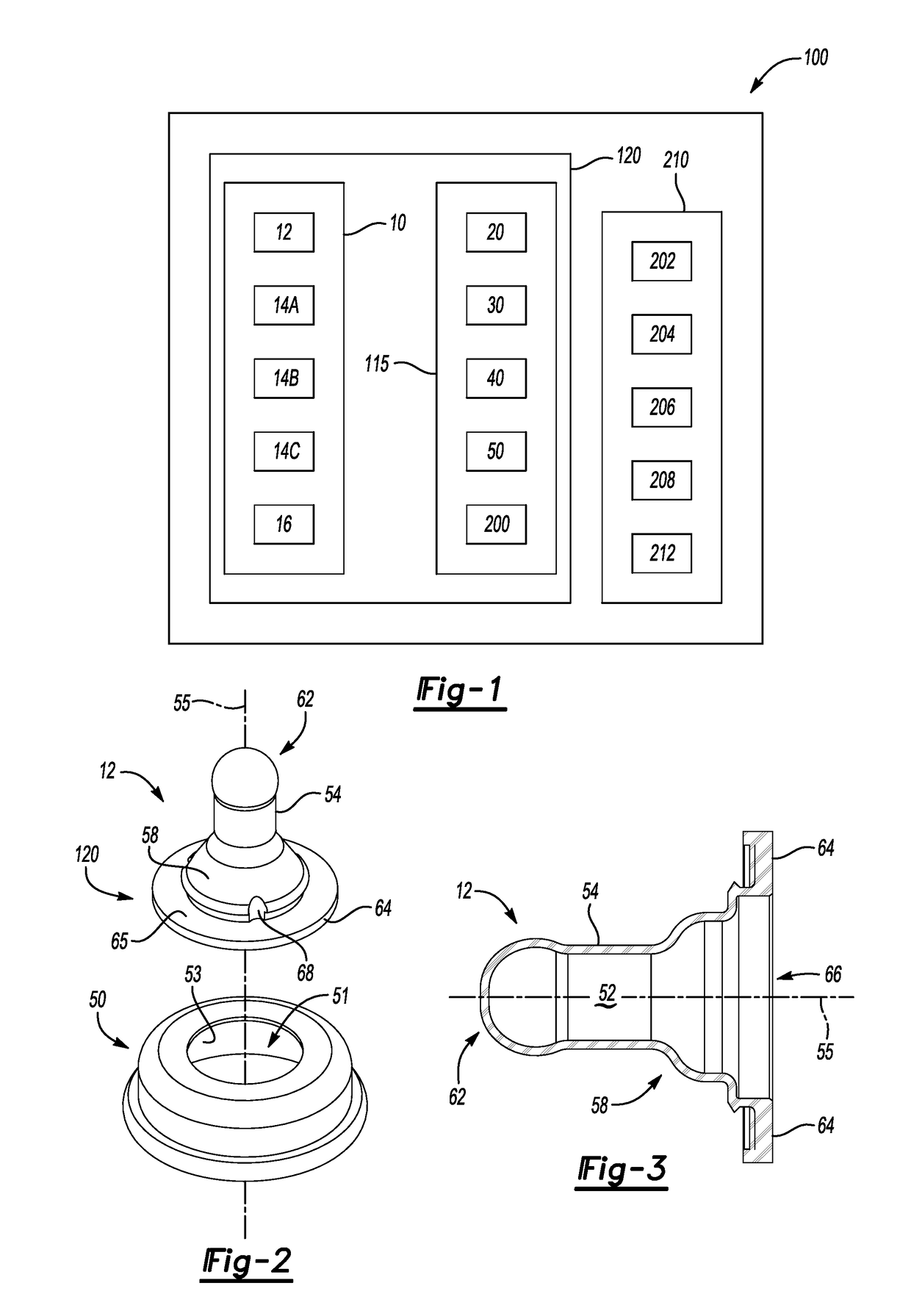

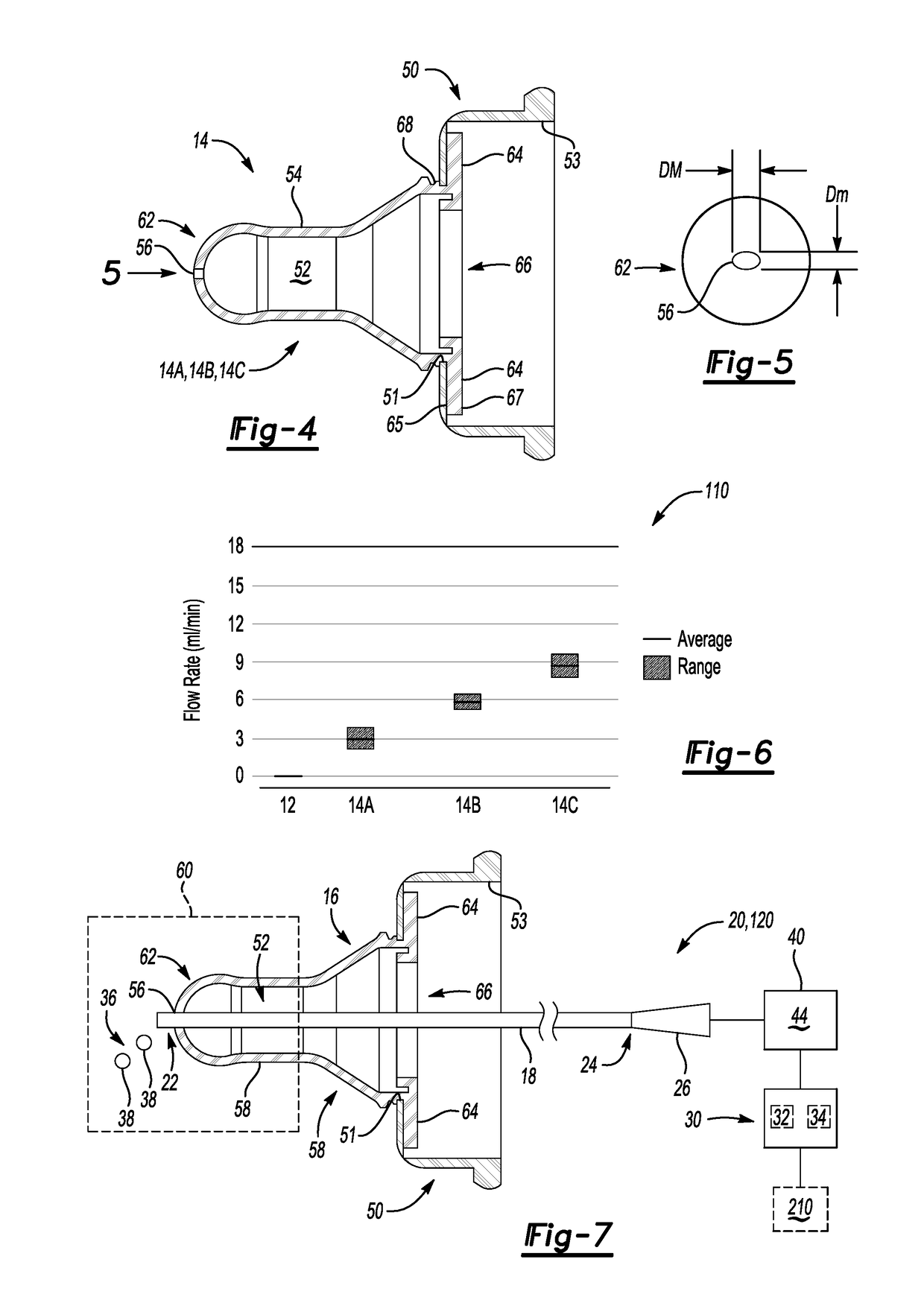

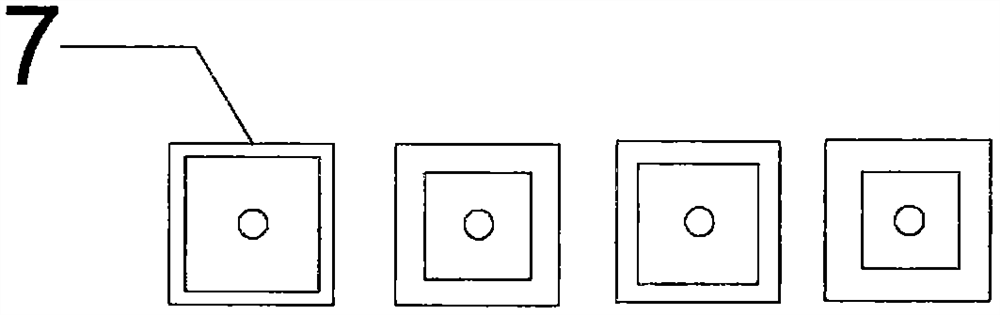

Feeding transition nipple mechanism and system

A feeding transition system for transitioning an infant subject to oral feeding includes at least one no-flow nipple and at least one flow nipple. The no-flow nipple has a fully enclosed tip portion such that no fluid can flow directly from the nipple cavity through the nipple wall. The flow nipple is formed of a no-flow nipple having an aperture formed in the tip portion for flowing fluid from the nipple cavity through the nipple wall. The system includes a bolus delivery nipple formed of a no-flow nipple including a bolus delivery conduit disposed in the nipple cavity and in fluid communication with a reservoir of fluid. The bolus delivery conduit includes a conduit outlet attached to the nipple wall to output a bolus of fluid from the tip portion of the bolus delivery nipple via the outlet. A method for transitioning an infant subject to oral feeding is provided.

Owner:NFANT LABS LLC

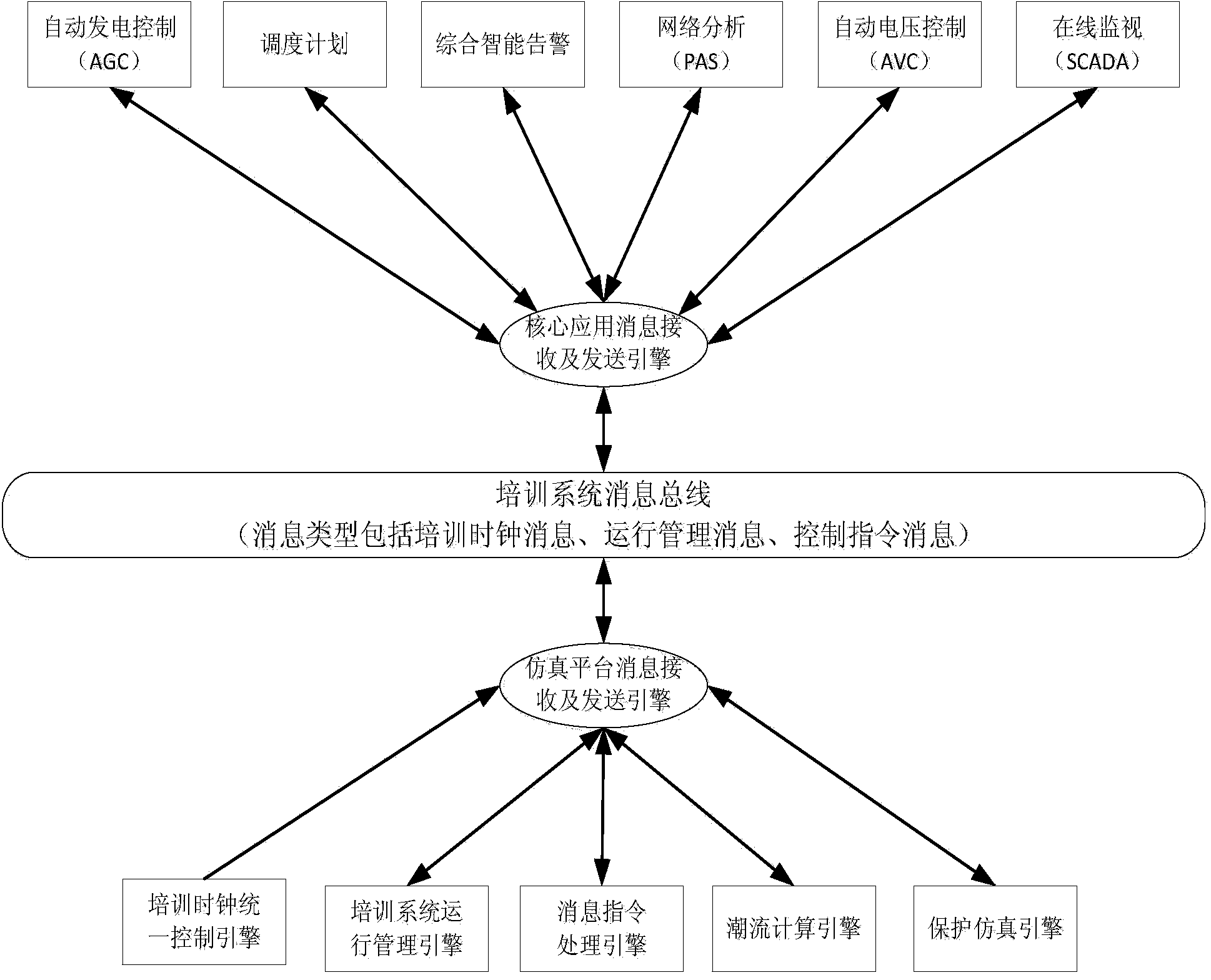

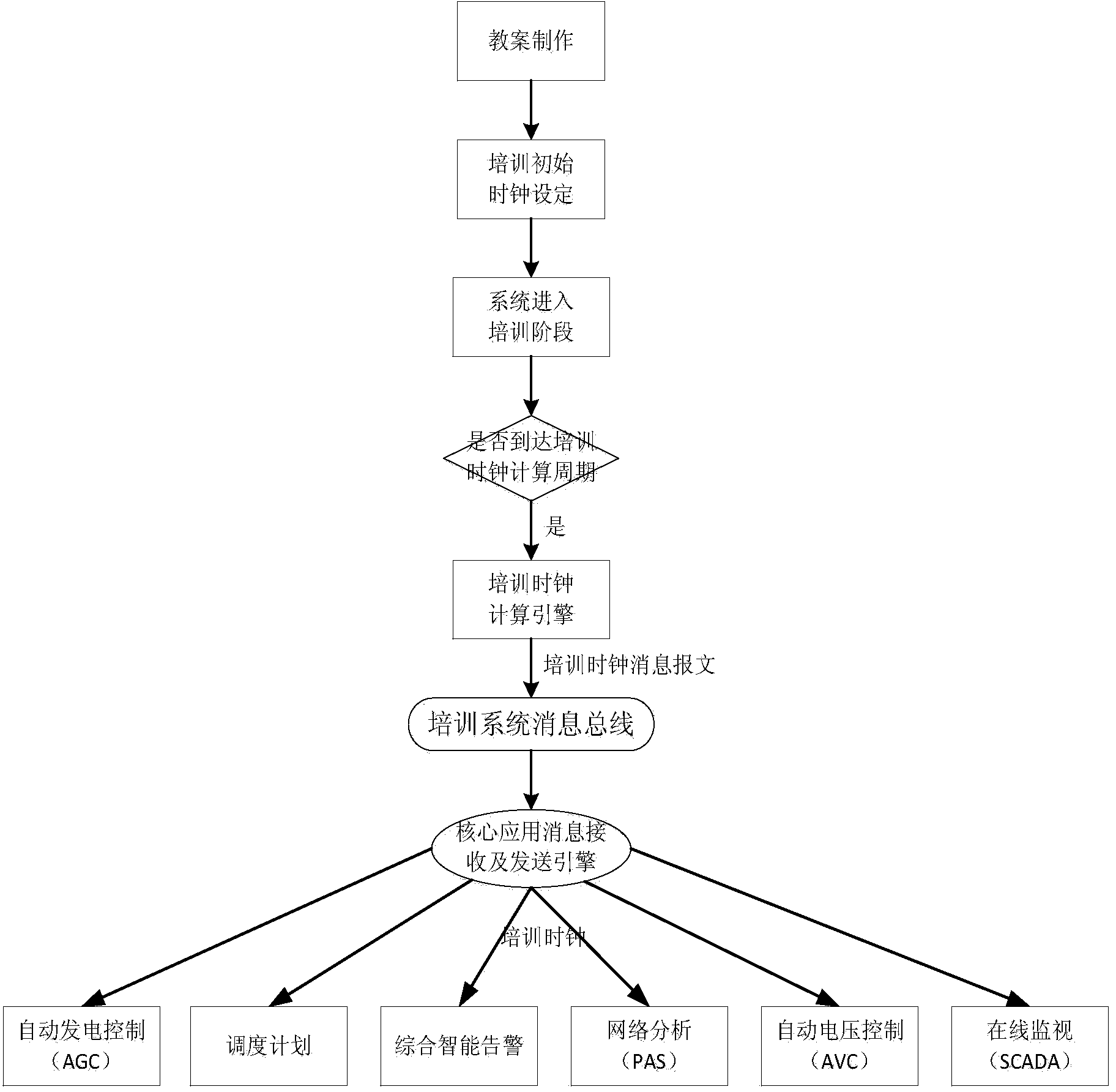

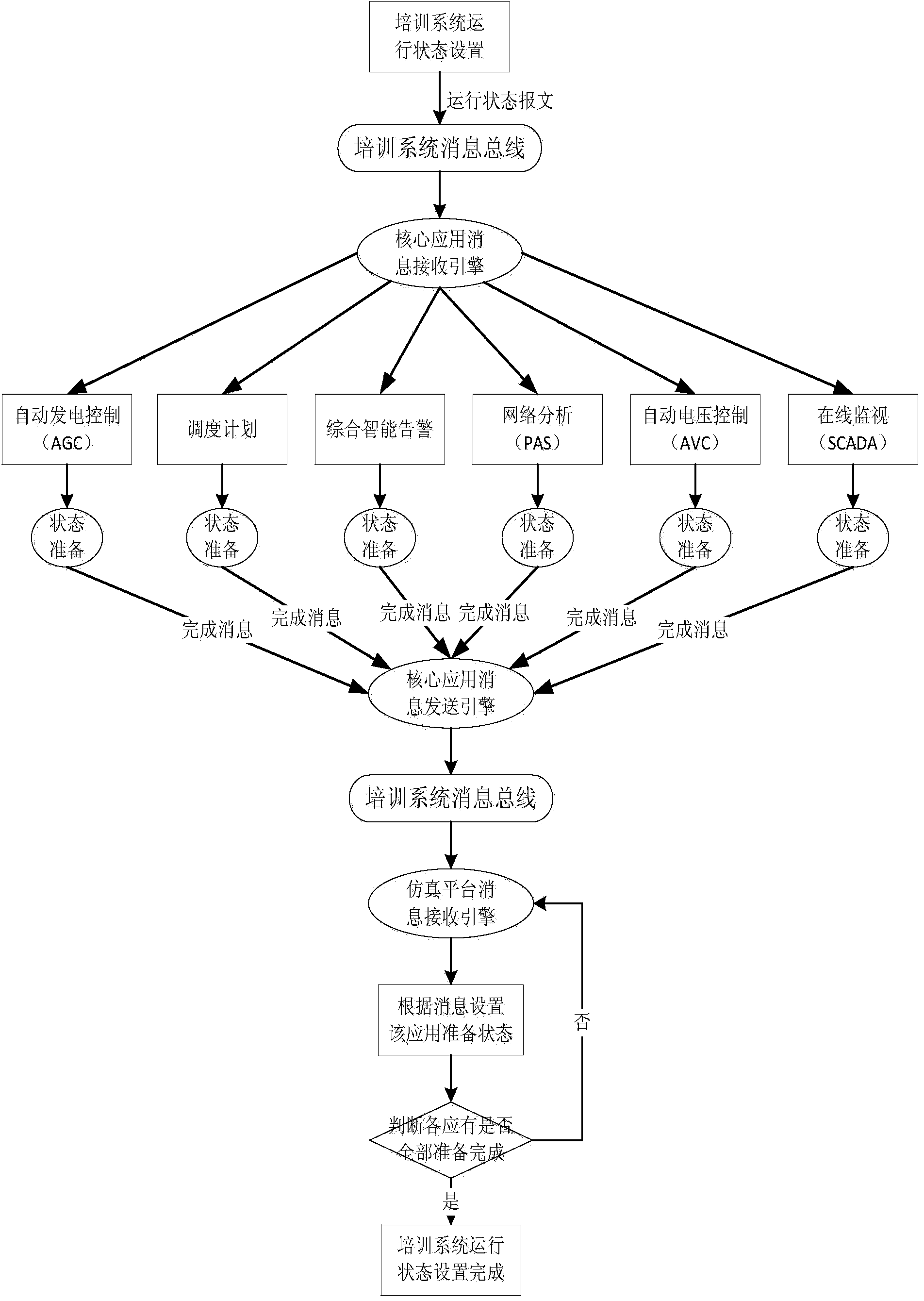

Power scheduling training system and message processing method of core applications thereof

ActiveCN104298538AIncrease authenticityImprove effectivenessResourcesSoftware simulation/interpretation/emulationSimulationClosed loop

The invention discloses a power scheduling training system. The power scheduling training system comprises core applications, a core application message receiving and transmitting engine, a message bus, a simulating platform message receiving and transmitting engine and a simulating platform core computation engine; by means of the simulating platform message receiving and transmitting engine, the message bus and the core application message receiving and transmitting engine, the simulating platform core computation engine and the core applications achieve training platform clock uniformity, operation management of core applications in the training system, control of the core applications and alarming instruction processing. By means of message management and processing between various simulating engines and the core application in the training system, the power scheduling training system achieves a mode of closed-loop operation and unified management of the core applications inside the training system as well as integration of simulating environments and application environments of every core application inside the training system, thereby being high in practicality, flexibility and feasibility and well improving the use authenticity and effectiveness of the training system.

Owner:STATE GRID CORP OF CHINA +3

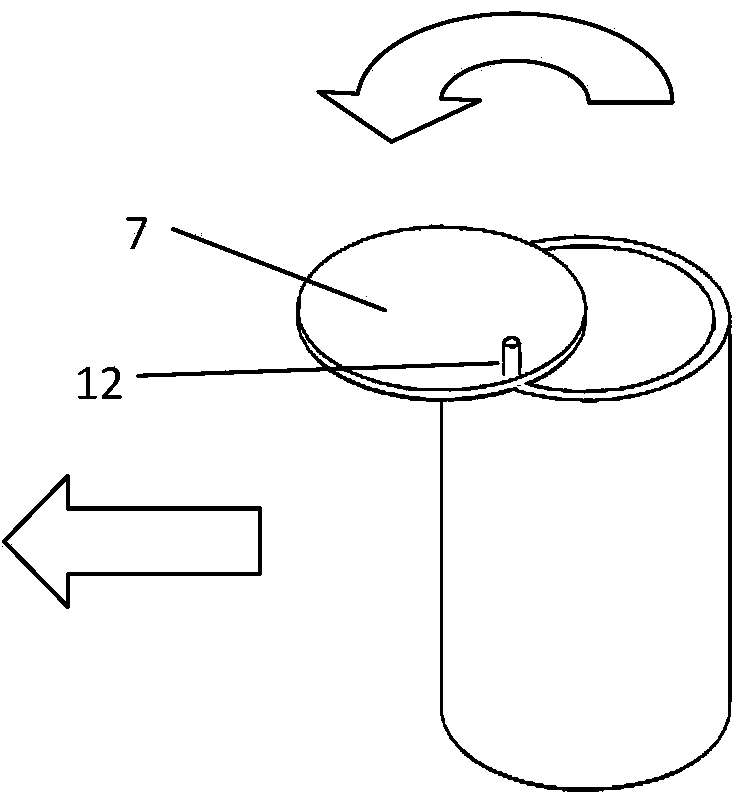

Full-automatic modular fish ethology experiment device

ActiveCN110999844AAvoid damageReduce experimental errorClimate change adaptationPisciculture and aquariaWater circulationExperimental Devices

The invention discloses a full-automatic modular fish ethology experiment device. The device comprises an experiment zone flume; the front side of the experiment zone flume is provided with an automatic fish release device; the rear side of the experiment zone flume is provided with a water storage tank; a water circulating device is arranged between the experiment zone flume and the water storagetank; and a rotary gate plate which has on-off action and can drive fishes is further arranged between an outlet of the experiment zone flume and an inlet of the water storage tank. The full-automatic modular fish ethology experiment device can solve the problems that an existing fish ethology experiment device has single functions, injury is caused by manually driving and catching the fishes andthe fishes are frightened by artificial operation in the experiment process.

Owner:CHINA THREE GORGES UNIV

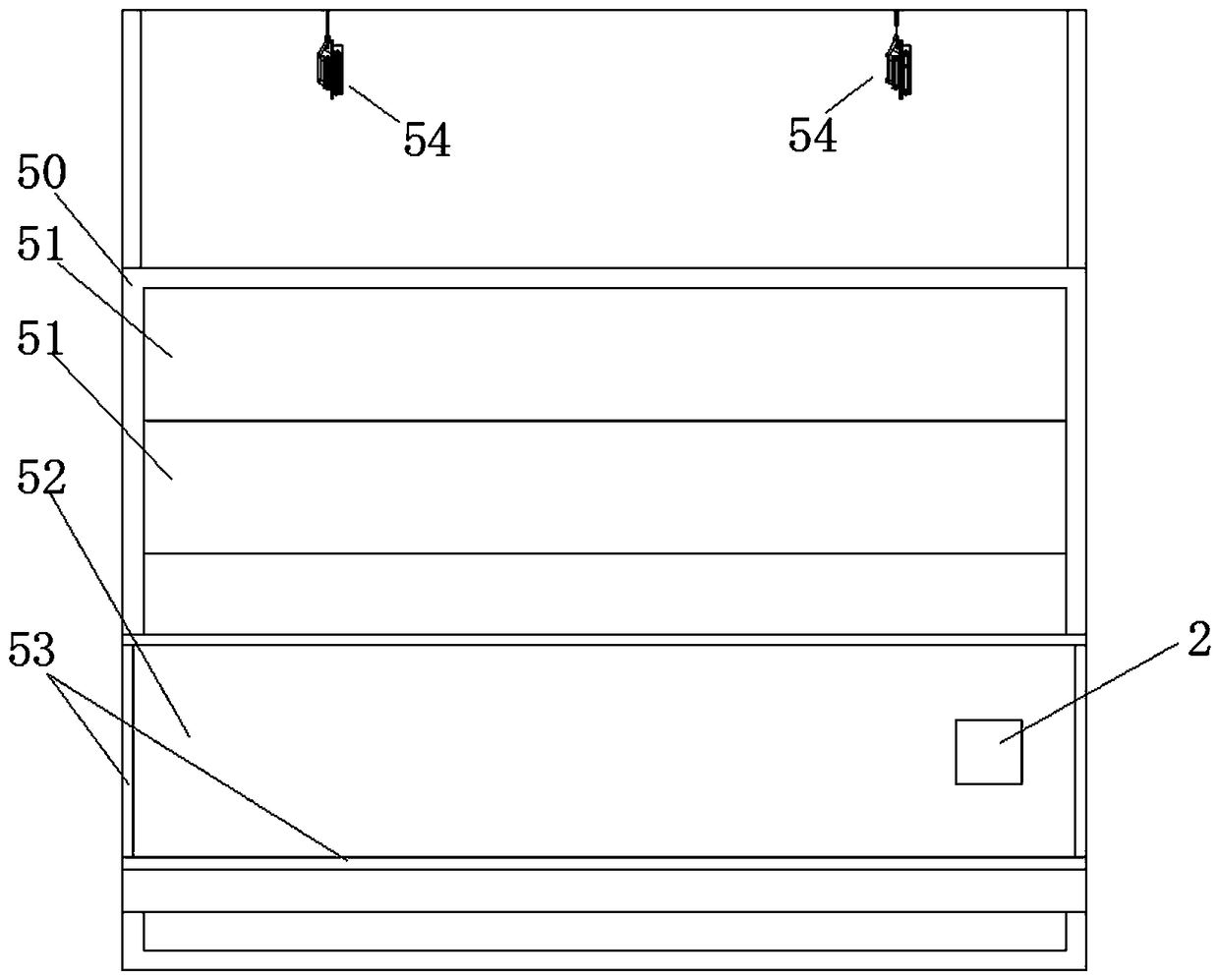

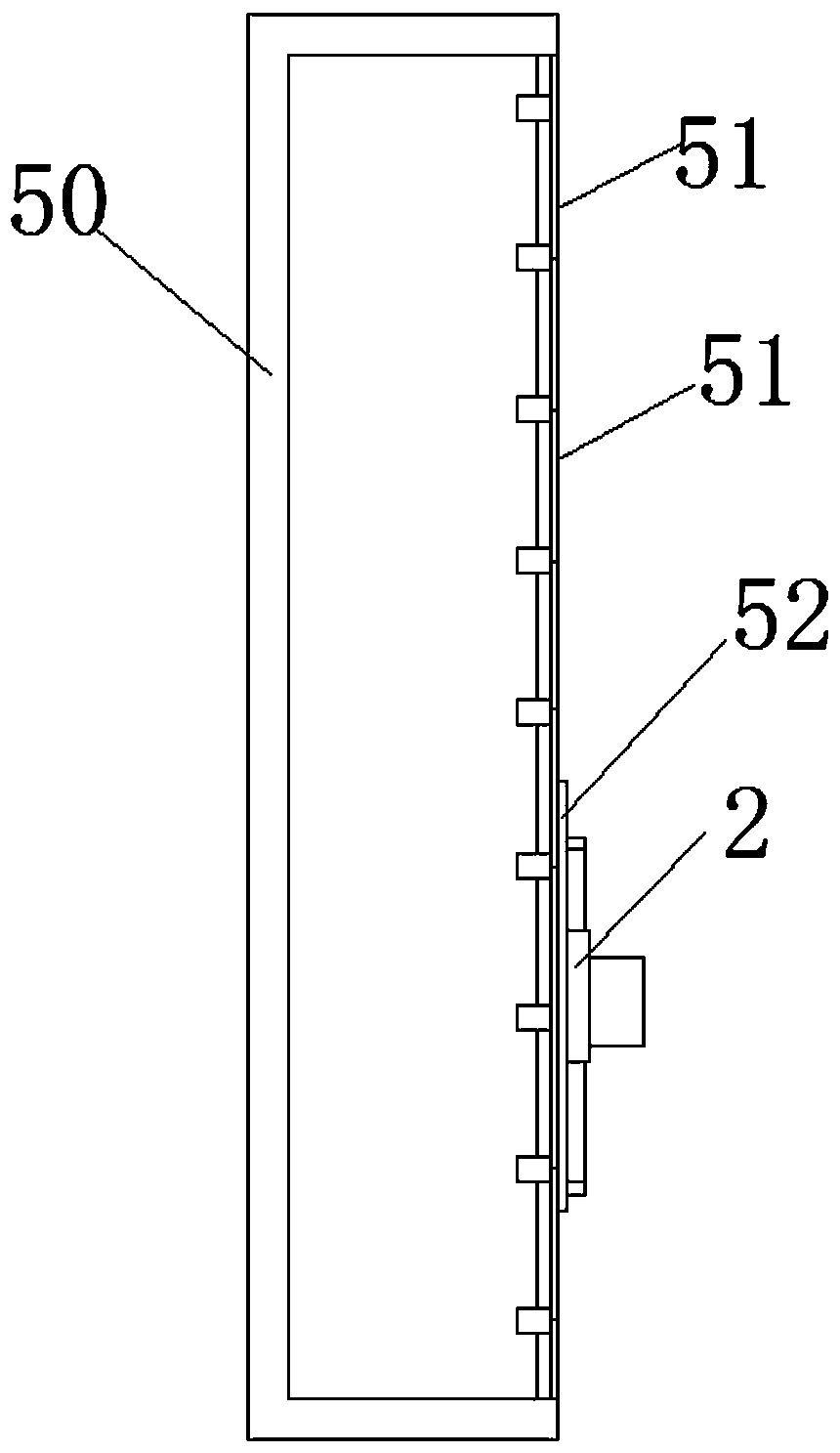

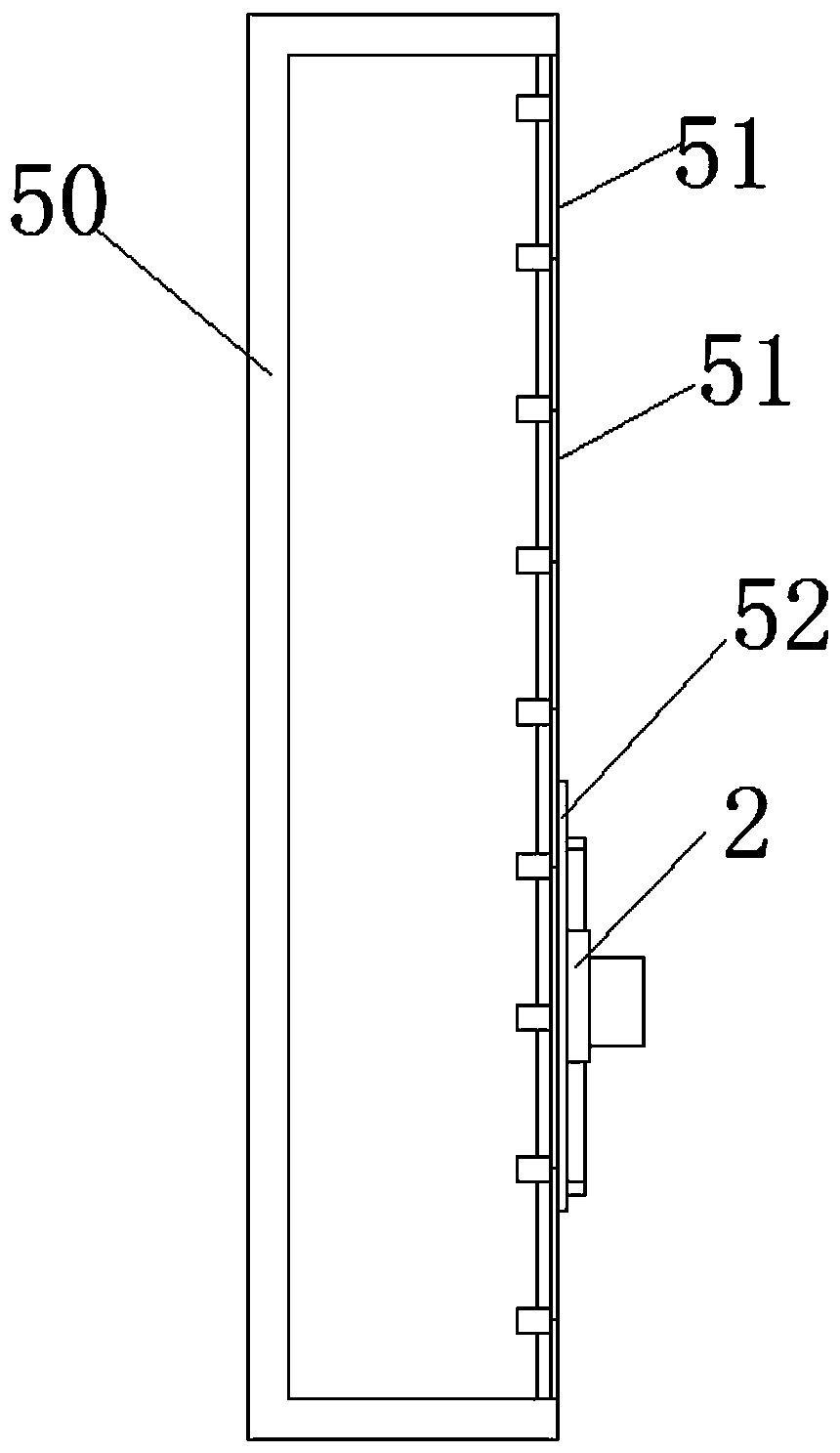

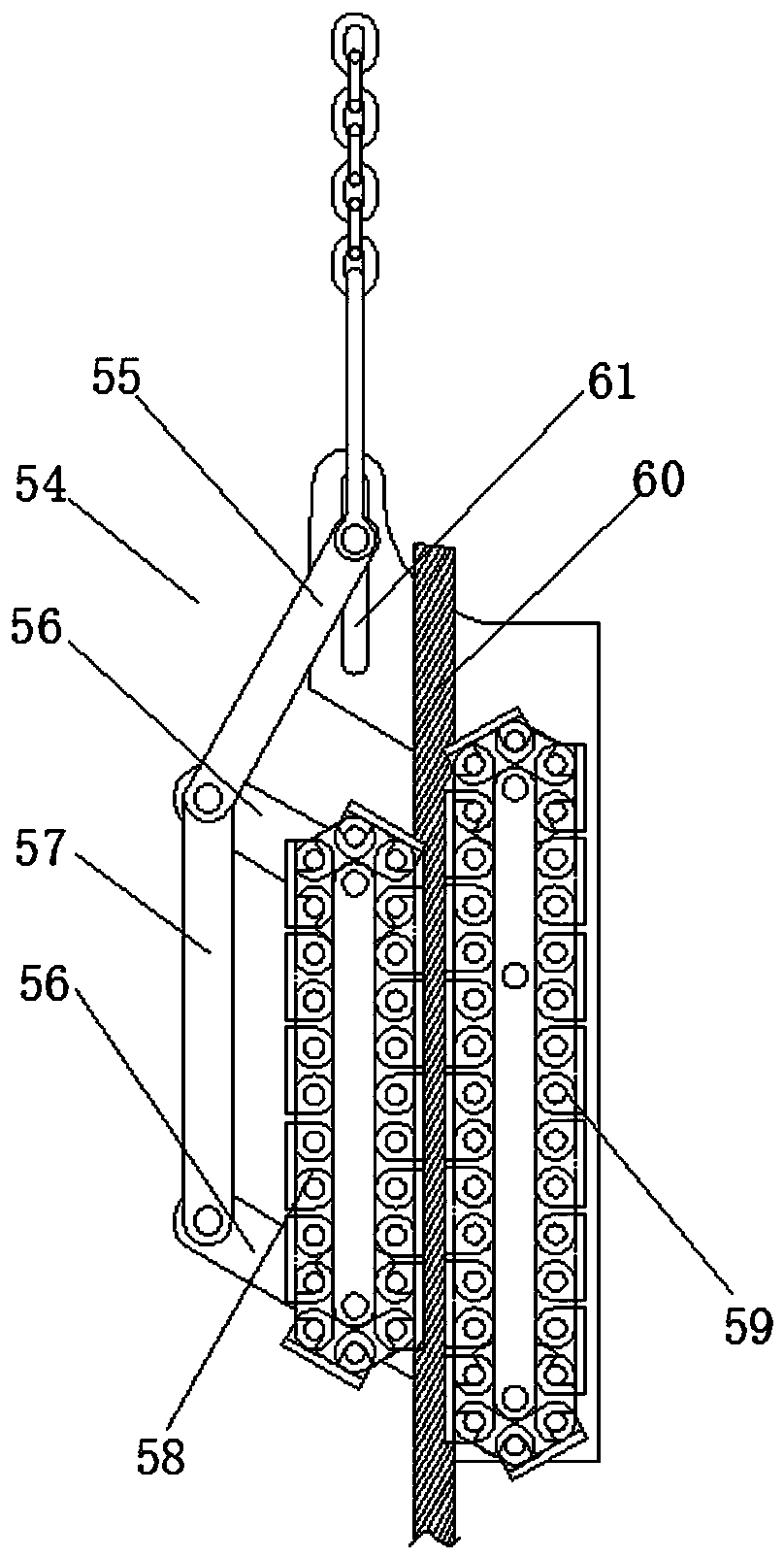

Calibrating device for building curtain wall testing machine

PendingCN108709699AConsistent environmentEasy to carry and transportMeasurement of fluid loss/gain rateTesting/calibration apparatusEngineeringLaboratory facility

The invention relates to a calibrating device for a building curtain wall testing machine. The calibrating device comprises a simulation curtain wall installed at a detection air gap of a corresponding glass curtain wall testing machine. The simulation curtain wall is made of a flexible material which can be curled; an air vent is formed in the simulation curtain wall; a simulation window is disposed on the air vent; a pressure sampling channel and a flow rate sampling channel are formed in the simulation window; a gas flowmeter calibrating unit for calibrating a gas flowmeter of the glass curtain wall testing machine and a pressure sensor calibrating unit for calibrating a pressure sensor of the glass curtain wall testing machine are connected to the simulation window. The invention solves the problem that the laboratory calibrating environment and the field use environment are inconsistent in the prior art.

Owner:HENAN PROVINCE INST OF METROLOGY +1

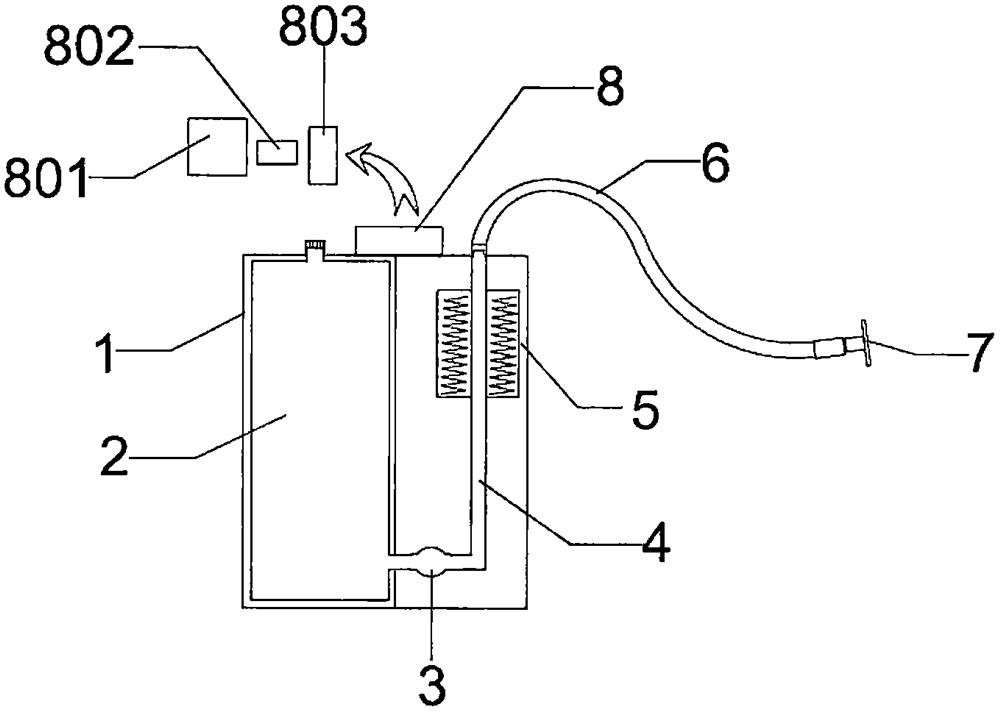

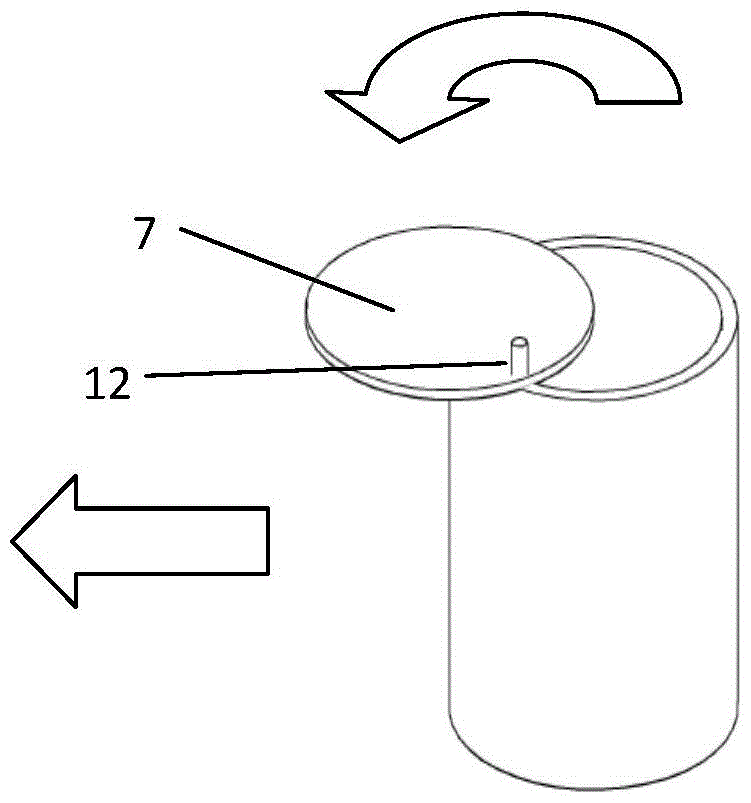

Electrolytic hydrogen breathing and drinking cup

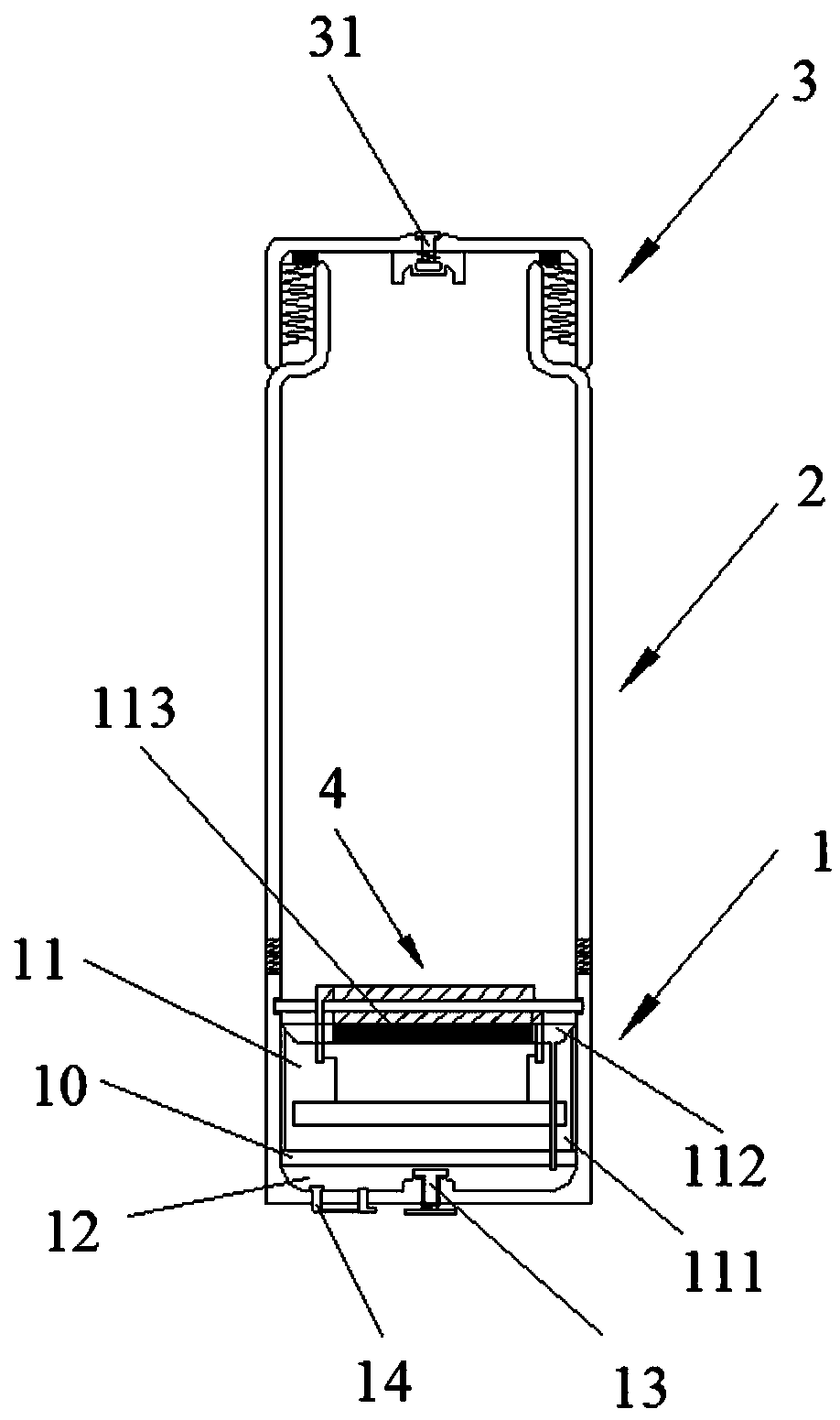

PendingCN107687000AGuaranteed air tightnessEnsure practicalityCellsTreatment involving filtrationElectrolysisHydrogen

The invention relates to an electrolytic hydrogen breathing and drinking cup, comprising a base body, a main body, a cover body and a straw, wherein the base body, the main body and the cover body aresequentially connected so as to form a container used for containing water; the base body is internally provided with an electrolysis electrode; the electrolysis electrode comprises a cathode piece,an anode piece and a gas / water isolating membrane clinging to the position between the cathode piece and the anode piece; the gas / water isolating membrane is blocked on the inner wall of the base body; the main body is internally provided with a filter element; the filter element comprises a filter element shell and a filtering material, wherein the filter element shell is internally filled with the filtering material; a plurality of water through holes are evenly formed in the filter element shell; the lower end of the filter element shell covers the cathode piece; the filtering material is prepared from reducing minerals; a hydrogen collecting device used for collecting pure hydrogen is arranged above the filter element in the main body; a through hole is formed in the top of the hydrogen collecting device; the straw passes through the main body or the cover body and is communicated with the hydrogen collecting device through the through hole. The electrolytic hydrogen breathing anddrinking cup can be used for obtaining the pure hydrogen, and is simple in structure and easy to popularize and apply.

Owner:FUZHOU PINXING TECH DEV

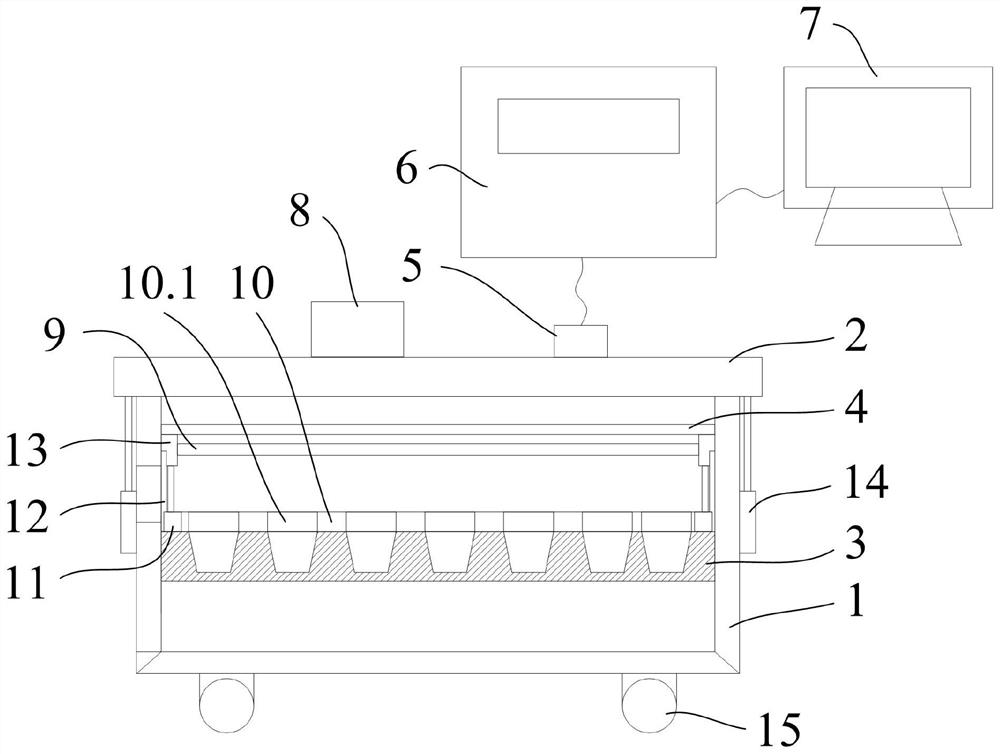

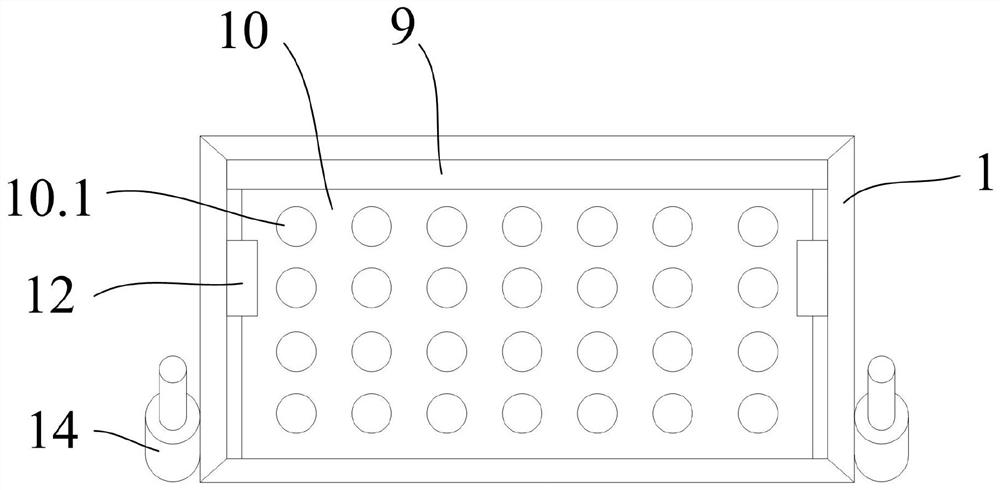

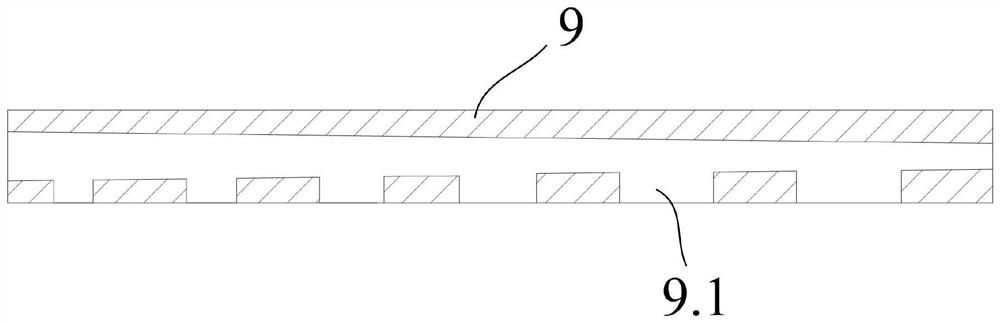

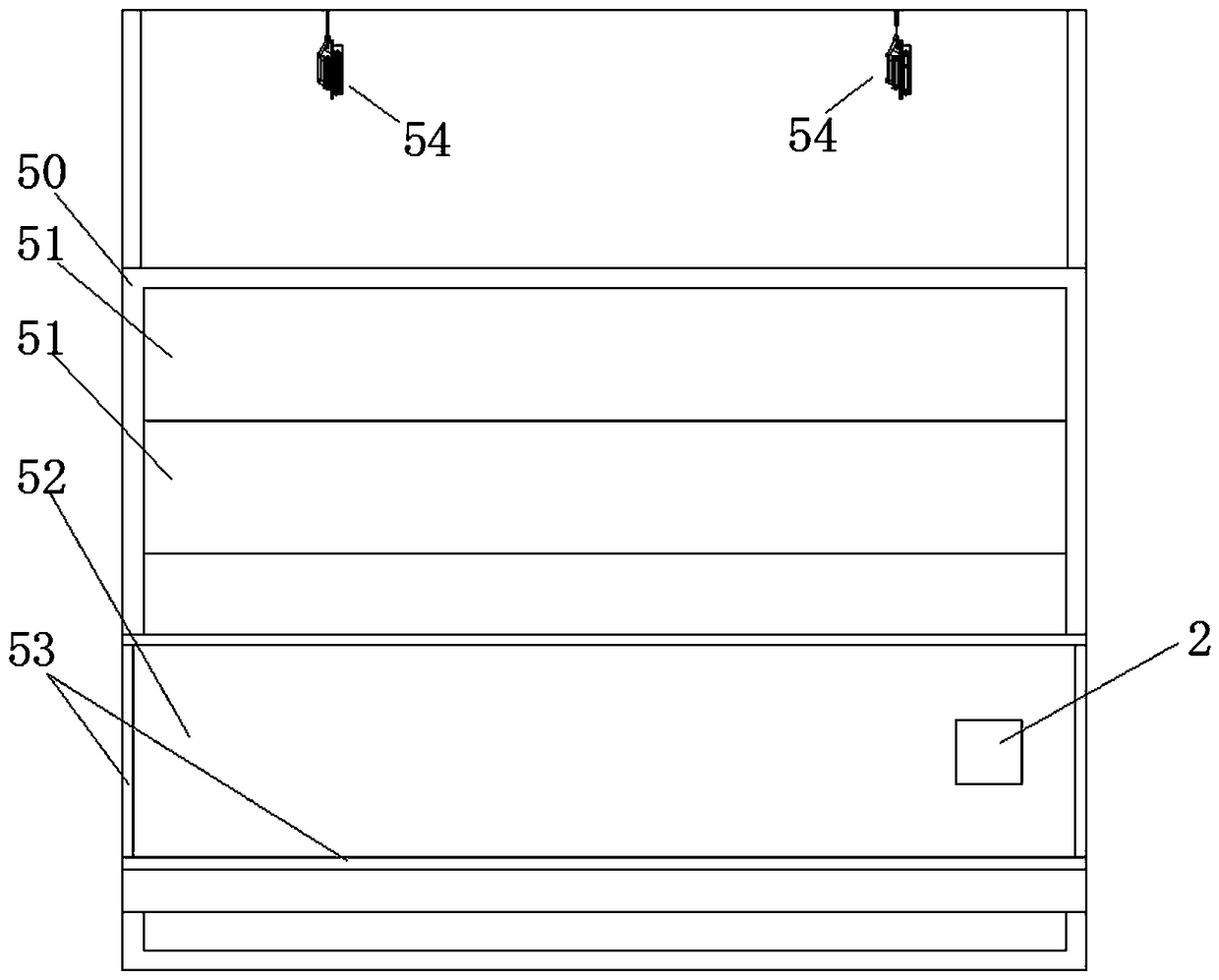

Experimental device for detecting corn germination rate

InactiveCN111802018AUniform humidityEfficient and even germinationGerminating apparatusDisplay deviceTouch panel

The invention relates to an experimental device for detecting corn germination rate. The experimental device comprises a transparent box body, a transparent box cover and a water absorption plate; thetransparent box cover is placed at the upper end of the transparent box body; the water absorption plate is horizontally placed inside the transparent box body; the water absorption plate is providedwith a plurality of planting holes; the experimental device further includes a touch panel, a micro pressure sensor and a PLC, and the touch panel is placed in the transparent box body; the micro pressure sensor is placed at the upper end of the transparent box cover; the signal input end of the micro pressure sensor is connected to the control panel through a circuit; the PLC is connected with the signal output end of the micro pressure sensor; the PLC is connected with a display; the experimental device further includes an atomizer which is placed at the upper end of the transparent box cover; the transparent box body is internally provided with a tube body; the mist outlet end of the atomizer is connected with the tube body; and a plurality of mist outlet holes are formed in the lowerend part of the tube body. Compared with the prior art, the germination rate detection process is high in degree of automation, the calculation data are accurate, and the convenience is improved; moreefficient and uniform germination of corn seeds is guaranteed; and the detection speed and accuracy are guaranteed.

Owner:LIAONING ACAD OF AGRI SCI

Calibrating device for testing machine for external glass curtain wall of building

PendingCN108709703AConsistent environmentMeasurement of fluid loss/gain rateTesting/calibration apparatusEngineeringLaboratory facility

The invention relates to a calibrating device for a testing machine for an external glass curtain wall of a building. The calibrating device for the testing machine for the external glass curtain wallof the building comprises a simulated curtain wall which is mounted at the position of a detecting wind opening of a corresponding glass curtain wall testing machine, a simulated curtain wall is a rigid plate, an air opening is formed in the simulated curtain wall, a simulated window is arranged on the air opening, a pressure value getting channel and a flow value getting channel are formed in the simulated window, the simulated window is connected with a gas flowmeter calibrating unit for calibrating a gas flowmeter of the glass curtain wall testing machine and a pressure sensor calibratingunit for calibrating the pressure sensor of the glass curtain wall testing machine. The problem that in the prior art, a calibrating environment of a laboratory is inconsistent to a field calibratingenvironment is solved.

Owner:HENAN PROVINCE INST OF METROLOGY +1

Multifunctional disease animal model manufacturing device based on steam injury

PendingCN113170764AIneffective in avoiding burnsConsistent temperatureSurgical veterinaryAnimal husbandryBiotechnologyWater storage

The invention discloses a multifunctional disease animal model manufacturing device based on steam injury. The device is characterized by comprising a box body, a water storage tank, a small suction pump, a conveying pipeline, a steam generator, a steam pipe, a scald mold and a control part. According to the device, water can be rapidly heated and evaporated into water vapor through the steam generator, the water vapor can directly form a burn model on animal epidermis, and a high-temperature and high-humidity environment can also be formed so that an animal in the environment can form a heat stroke model. The device can accurately set the generation temperature of water vapor and high-temperature and high-humidity environmental parameters, and the most ideal temperature and humidity can be set according to professional requirements. Injury molds with different functional models and sizes are selected according to actual requirements so as to prepare animal models meeting different requirements.

Owner:中国人民解放军联勤保障部队第九二〇医院

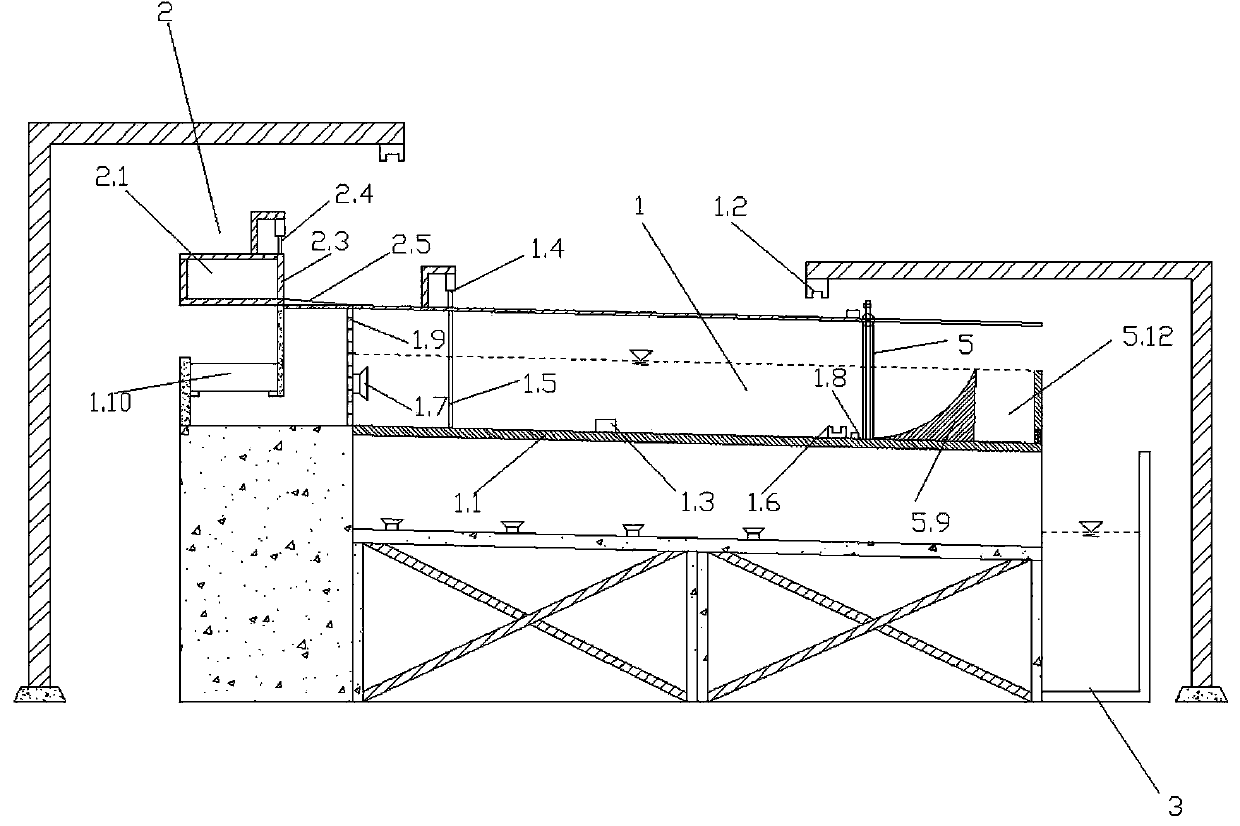

A kind of triaxial permeability testing method

ActiveCN108414418BFirmly connectedGuarantee the environmentPermeability/surface area analysisAxial pressureModel system

The invention discloses a three-axis permeability testing method, and belongs to the field of coal bed gas exploitation. A rock sample is placed in a model system (1), then pressure pulse is applied on the rock sample; a gas control system (2) supplies test gas to the model system (1); a temperature control system (3) controls the temperature of the model system (1); a three-axis loading system (4) applies confining pressure and axial pressure on the rock core clamper of the model system (1); a vacuumizing system (5) vacuumizes the test device; a gas sample collecting system (6) detects the gas components after the test; and an electrical controlling and monitoring system monitors the test process. The method comprises following steps: filling a sample into a tank, checking the airtightness, carrying out a permeability test, and cleaning the test system. The provided method can simulate a high temperature and high pressure environment of a deep stratum in a lab; pressure pulse is applied on the inlet end of a rock sample, the attenuation data of pressure pulse can be obtained, and then the rock sample permeability is calculated based on the attenuation data. The test efficiency ishigh, the external interference is little, and the test result is more accurate.

Owner:CHINA UNIV OF MINING & TECH

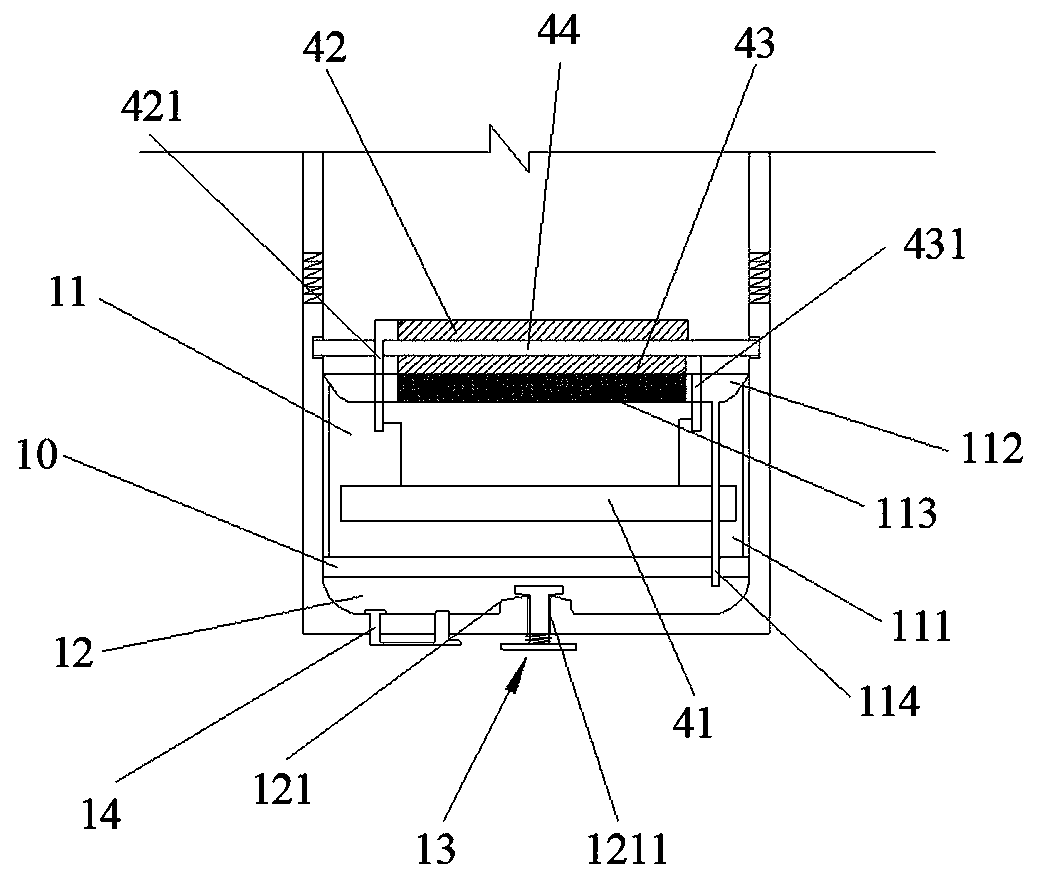

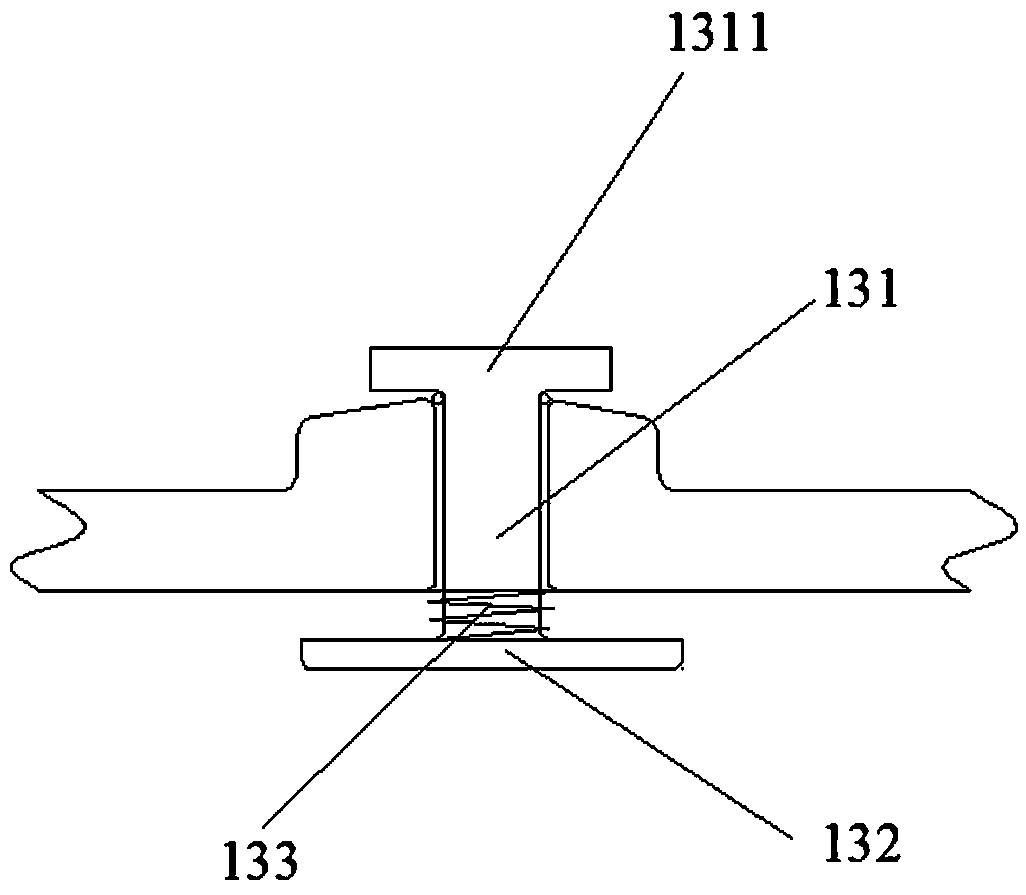

Base structure of electrolysis device for separation of hydrogen and oxygen and electrolysis device with the base

ActiveCN107540055BGuaranteed air tightnessGuarantee stabilityCellsWater/sewage treatmentElectrolysisAutomatic control

The present invention relates to a seat body structure of an electrolysis device for separating hydrogen and oxygen and an electrolysis device with the seat body. The seat body structure includes a housing, an electrode tank and an electrolysis electrode are arranged in the housing, and liquid adsorbents are contained in the electrode tank. The liquid adsorbent is adsorbed with water used for preliminary electrolysis of the electrolysis electrode; the bottom of the electrode tank is provided with an opening, and the electrolysis electrode includes a cathode sheet, an anode sheet, and a gas / water separation film closely arranged between the cathode sheet and the anode sheet, and the gas The water / water isolation membrane is clamped on the inner wall of the housing above the electrode tank. The gas / water isolation membrane has the characteristics of passing water and not ventilating when the electrolysis electrode is electrolyzed, and not passing water and not ventilating when the electrolysis electrode is non-electrolyzed; the anode piece is close to the liquid adsorbent The bottom of the casing is provided with a gas-water separation and discharge device for separating the waste water and waste gas generated on the anode sheet side of the electrolysis electrode and then discharging them to the outside of the casing. The device can fully ensure the airtightness of the structure or device, and can automatically control the air pressure inside the device.

Owner:FUZHOU PINXING TECH DEV

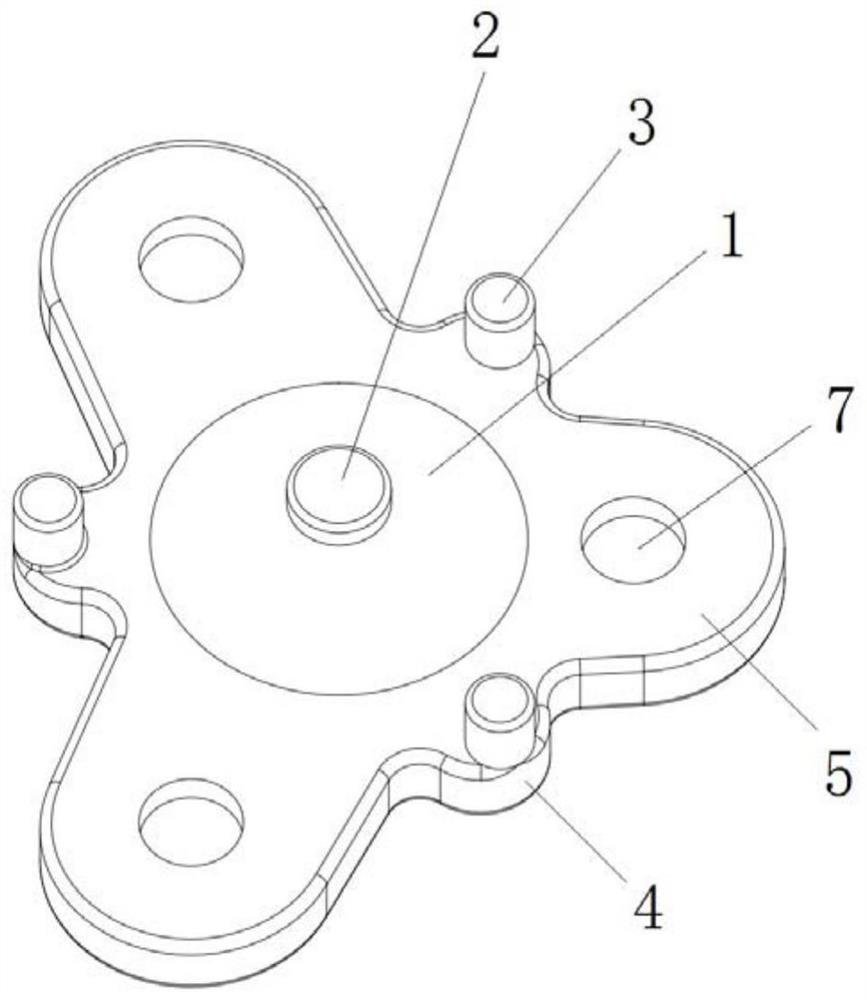

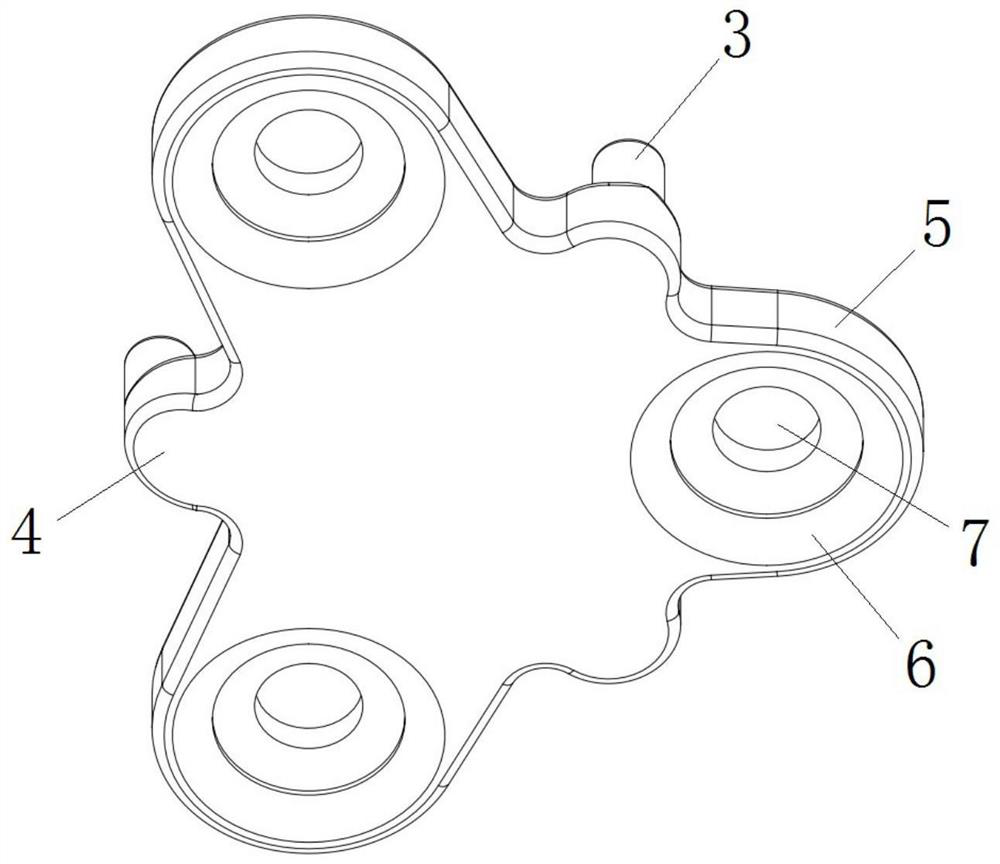

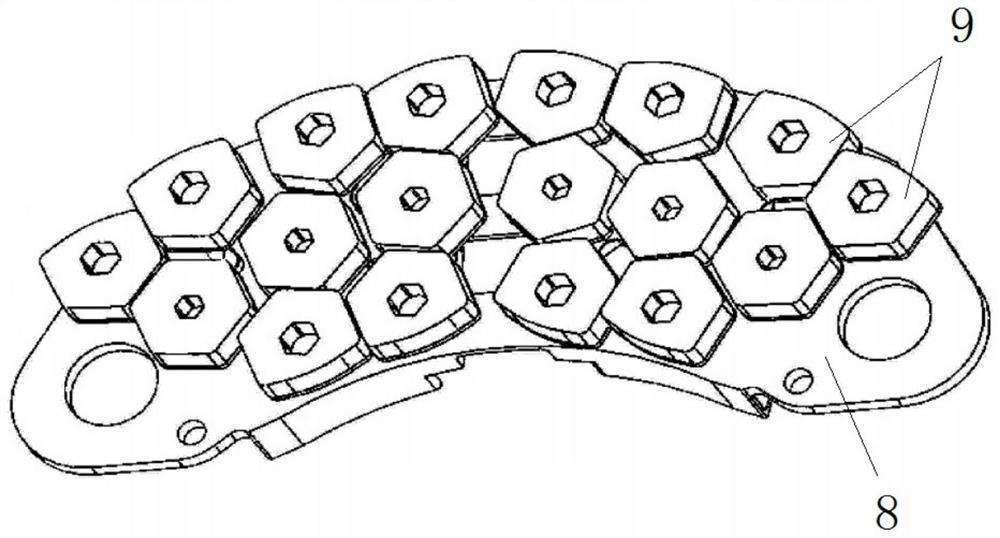

Triangular support and powder metallurgy brake pad with triangular support

PendingCN111795089AConsistent environmentReduce eccentric wearBraking elementsPowder metallurgyStructural engineering

The invention provides a triangular support and a powder metallurgy brake pad with the triangular support and belongs to the technical field of friction linings. A protruding ball face connected witha steel back is arranged on the upper surface of the triangular support, multiple positioning pillars are arranged around the protruding ball face, and the multiple positioning pillars are rotationally and symmetrically arranged around the center of the protruding ball face. An extending end extending out in the direction away from the protruding ball face is arranged between every two adjacent positioning pillars, wherein a spherical face groove connected with a friction block is arranged on the lower surface of the extending end. By means of the triangular support, the multiple positioning pillars are arranged on the upper surface and are rotationally and symmetrically arranged, it can be ensured that the environments where the friction blocks are located on the triangular support are consistent, stress and heat transfer of the friction blocks during braking are uniform and consistent, and therefore eccentric wear of the friction blocks is relieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

A calibration device and calibration method for an infrared thermometer

ActiveCN108132100BGuaranteed accuracyAccurate measurementRadiation pyrometryTemperature controlInfrared thermometry

The invention discloses a sight glass used for temperature correction of an infrared thermometer; and also discloses a correction device for an infrared thermometer, which comprises a black body furnace, a sight glass and an infrared temperature measuring device arranged at intervals in sequence. A radiator is arranged in the furnace, the sight glass comprises a double-layer sight-glass glass and a cooling water interlayer arranged between the double-layer sight-glass glasses, and the infrared temperature measuring device comprises an infrared thermometer; the invention also discloses an infrared thermometer. Thermometer calibration method. Through the calibration of the infrared thermometer, the error between the measured temperature and the actual temperature of the silicon rod can be controlled within ±3°C, and the accurate measurement of the temperature of the silicon rod in the reduction furnace can be realized, which can meet the requirements of the surface of the silicon rod during the production of zone melting silicon. The requirements of accurate and stable temperature control; the function of the sight glass is to simulate the measurement conditions of the infrared thermometer when measuring the production temperature of polysilicon or district melting silicon in the reduction furnace, so that the calibration environment is consistent with the actual measurement environment, and the infrared thermometer measures the temperature. Accuracy and Precision.

Owner:江苏鑫华半导体科技股份有限公司

A test platform for fouling and descaling of the equalizing electrode in the cooling water system of the converter valve

Owner:GUANGZHOU BUREAU CSG EHV POWER TRANSMISSION +2

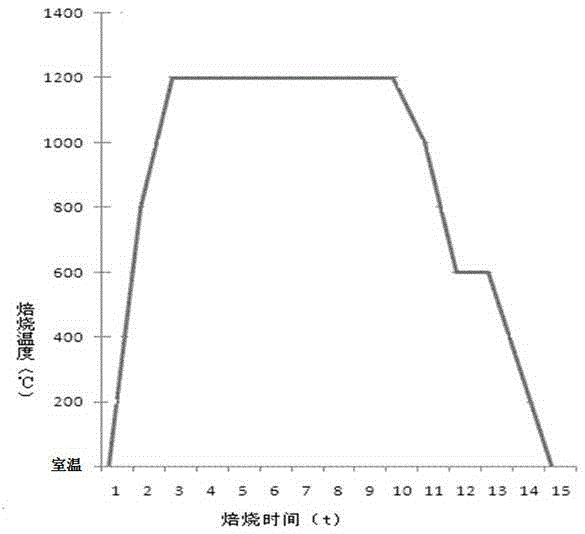

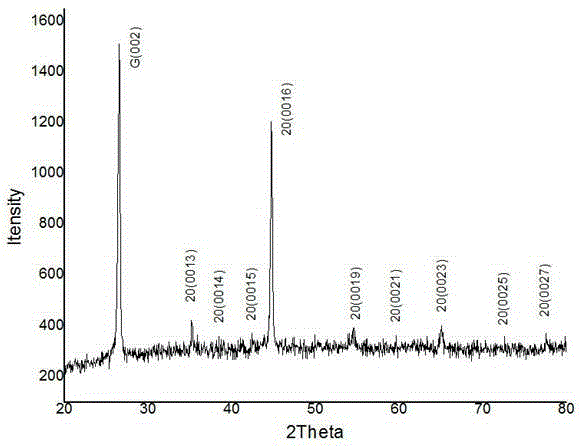

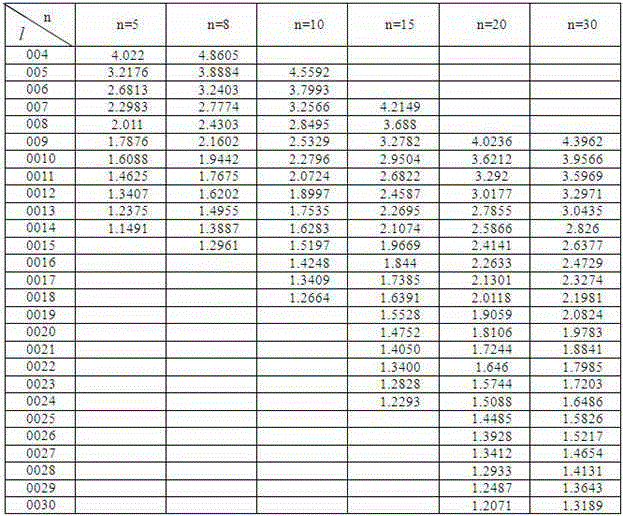

A kind of graphite core column material and preparation method thereof

The invention belongs to the technical field of superhard material graphite core column synthesis, and discloses a graphite core column material and a preparation method thereof. The material is composed of graphite layers and metal catalyst molecule layers, and the metal catalyst molecule layers are interposed between the graphite layers. Take iron oxide powder, nickel powder and graphite powder and mix them evenly to obtain a mixed powder; place the mixed powder in a closed system to evacuate, then fill it with hydrogen, heat it to 1000-1500°C for 7-15 hours for reduction treatment, first Lower the temperature to 200-700°C and keep it warm for 1-5h to realize intercalation. When the temperature is lowered to less than 200°C, cool down to room temperature while introducing air to obtain the graphite core column material. The invention inserts a layer of metal catalyst molecules every 20 graphite layers, fully makes the graphite atoms contact with the metal catalyst molecules, and effectively improves the catalytic performance of the metal catalyst.

Owner:ZHONGNAN DIAMOND CO LTD

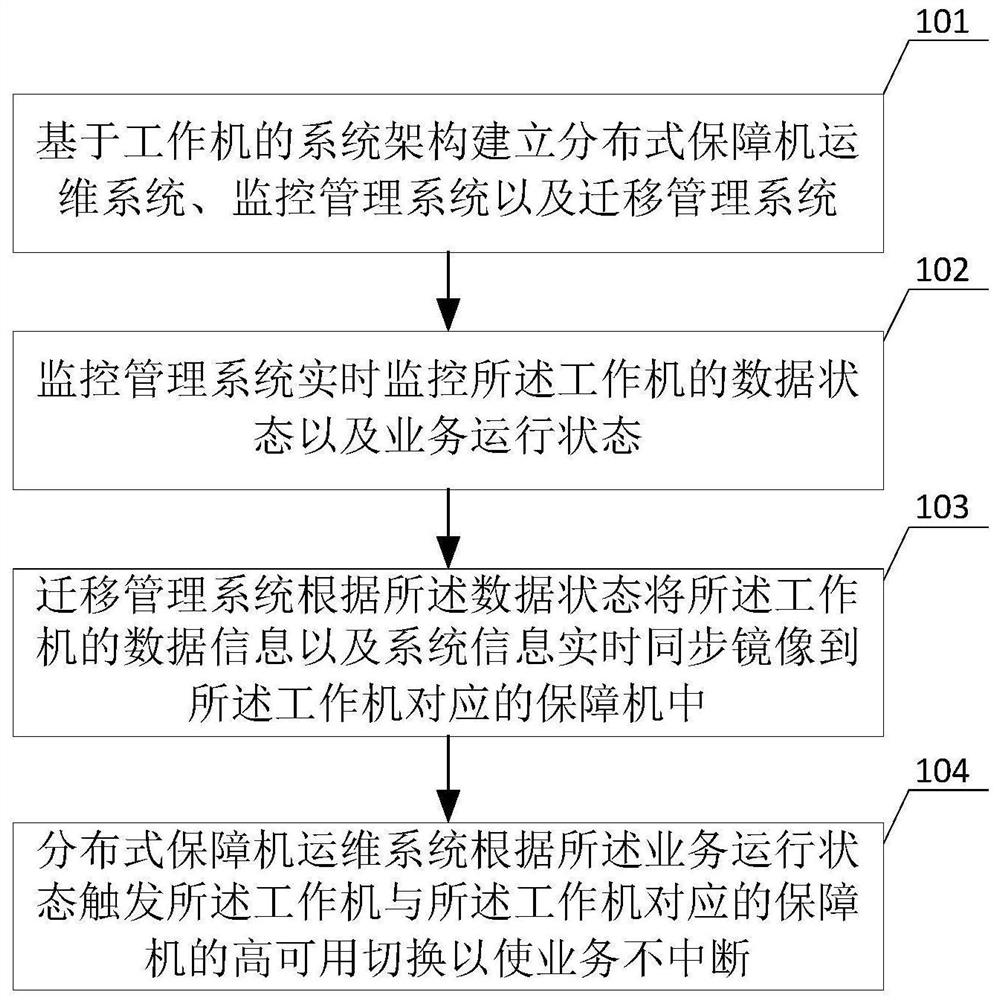

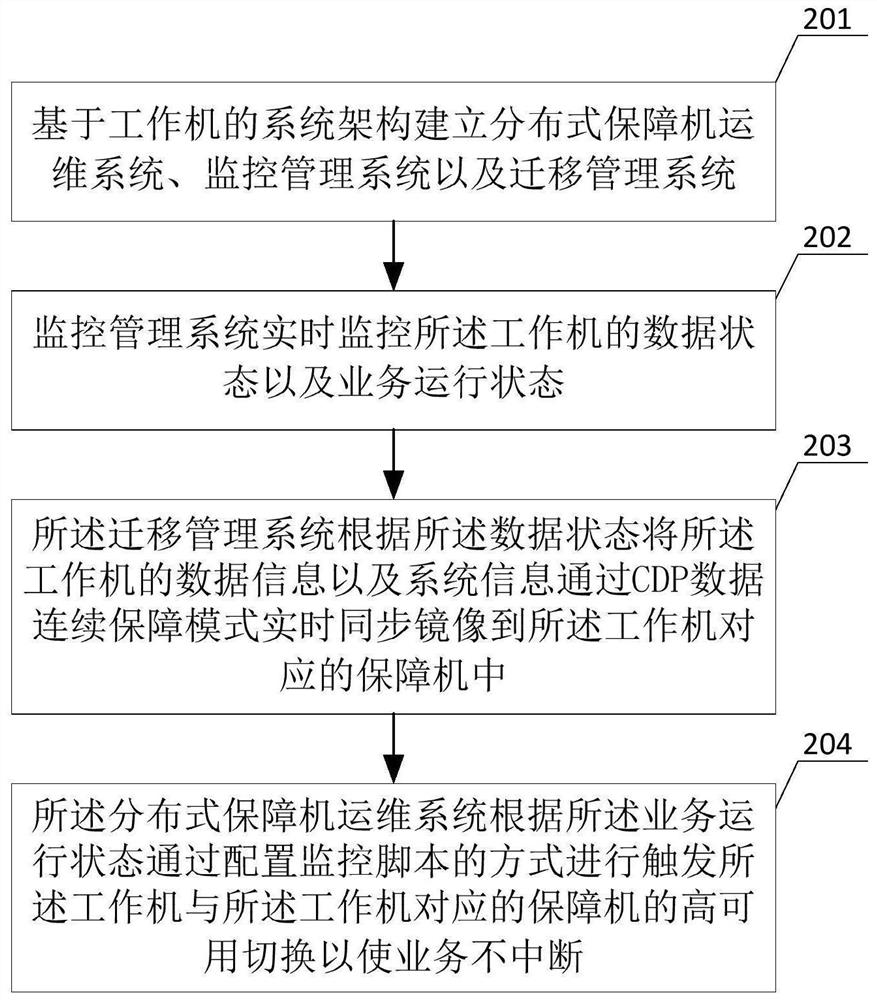

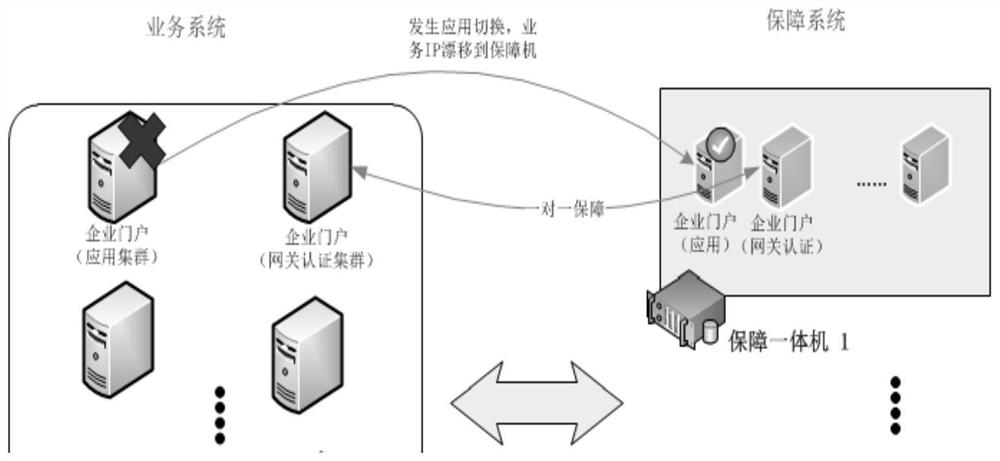

Operation and maintenance guarantee method and system for multi-service non-stop maintenance

PendingCN112306761AGuaranteed uninterruptedA one-to-one guarantee is formed between the guarantee machine and the working machine without interruptionSoftware simulation/interpretation/emulationRedundant hardware error correctionMachineSystem monitoring

The embodiment of the invention discloses an operation and maintenance guarantee method for multi-service non-stop maintenance. The method comprises the steps: building a distributed guarantee machineoperation and maintenance system, a monitoring management system and a migration management system based on the system architecture of a working machine, wherein the distributed guarantee machine operation and maintenance system is a virtual system built in a physical server, the virtual system creates a plurality of guarantee machines, working machines are a business system guaranteed by operation and maintenance, and the guarantee machines and the working machines form a one-to-one guarantee mode; the monitoring management system monitors the data state and the service operation state of the working machines in real time; the migration management system synchronously mirrors the data information and the system information of a working machine to a guarantee machine corresponding to theworking machine in real time according to the data state; and the distributed guarantee machine operation and maintenance system triggers high-availability switching of the working machines and the guarantee machines corresponding to the working machine according to the service operation state so as to enable the service not to be interrupted. The method is used for realizing automatic switching between a working machine and a guaranteeing machine when the working machine has service interruption, and guaranteeing that a service system is continuous.

Owner:STATE GRID CORP OF CHINA

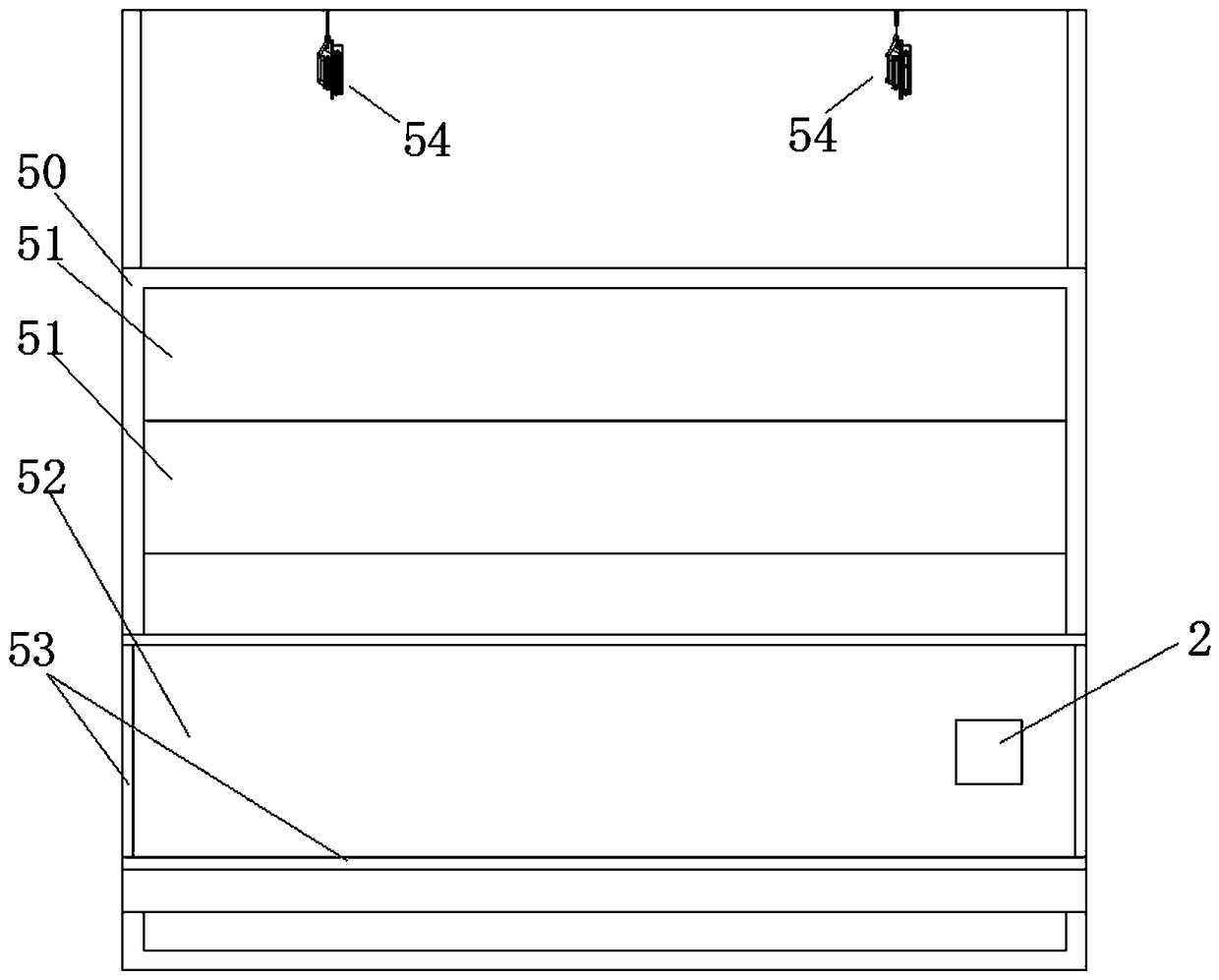

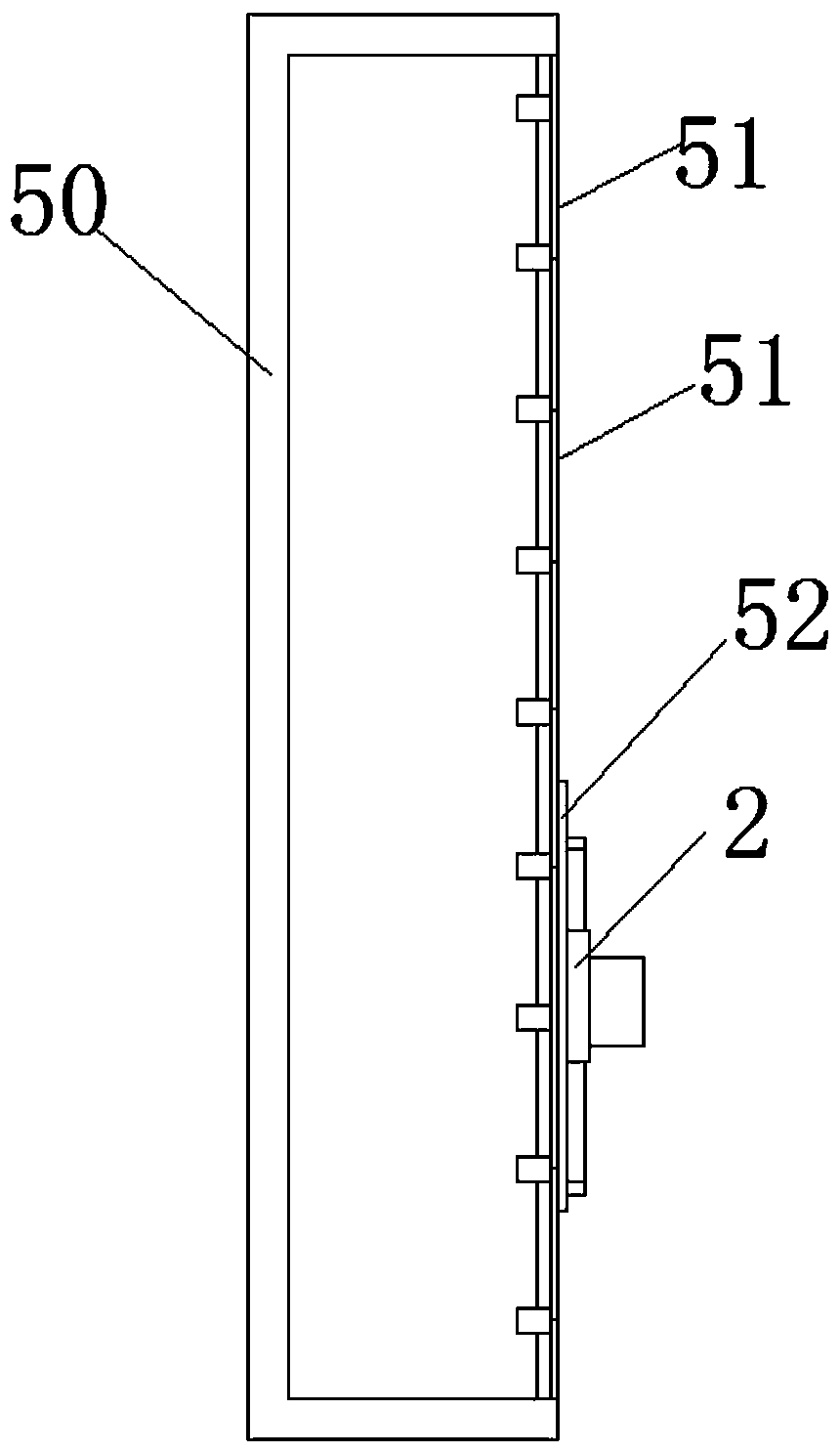

A device for automatically adjusting the temperature in a prefabricated building maintenance kiln

ActiveCN111906911BAvoid destructionEasy to useCeramic shaping apparatusEngineeringMechanical engineering

A device for automatically adjusting the temperature in a prefabricated building maintenance kiln, comprising several curing kiln shells arranged side by side, with an opening at the front end of the shell, and two first horizontal plates are arranged inside the shell, and the two first horizontal plates divide the inside of the shell into three First cavities distributed up and down, first rectangular through-holes are set on the top surface of the first horizontal plate, the length direction of the first through-holes is along the front-to-back direction, second cavities are set on the left and right sides of the first through-hole, the first through-holes Two sets of closing devices arranged up and down are arranged in the through holes. When the first cavity is opened, the present invention can automatically close the opened first cavity to prevent the external air from communicating with other first cavities, and at the same time, when the cover plate is closed, the closing device can be automatically opened, The first cavities in the same curing kiln are connected to each other, so that the environment in the same curing kiln is consistent, and the prefabricated parts can be placed in the curing kiln one by one through the rollers and tracks, which greatly saves manpower.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Calibrating device for calibration of glass curtain wall testing machine

PendingCN108709697AConsistent environmentGuaranteed accuracyMeasurement of fluid loss/gain rateTesting/calibration apparatusCalibration resultEngineering

The invention relates to a calibrating device for the calibration of a glass curtain wall testing machine. The calibrating device includes a simulation curtain wall installed at a detecting wind gap of a corresponding glass curtain wall testing machine. The simulation curtain wall is made of a flexible material which can be curled, and the simulation curtain wall has a simulation curtain wall windgap which is provided with a simulation window; the simulation window includes a simulation window body having a windward side on the front side thereof and mounted on the simulation curtain wall; the simulation window body has a relaxation cavity; the windward side of the simulation window body has air inlets communicating the simulation curtain wall wind gap and he relaxation cavity; a leewardside of the simulation window has a flow value sampling channel; and the flow value sampling channel is connected to a gas flow meter calibrating unit for calibrating a gas flow meter of the glass curtain wall testing machine. The problem that when the gas flow meter is calibrated in the prior art, the calibration environment does not conform to the use environment and affects the calibration result can be solved.

Owner:HENAN PROVINCE INST OF METROLOGY +1

A decoupling reactive ion etching equipment containing a gas flow control device

ActiveCN103866399BImprove uniformityImprove stabilityAfter-treatment detailsProcess engineeringDouble bottom

The invention discloses a decoupling reactive ion etching equipment containing a gas flow control device. By sealing and setting a fairing with evenly densely distributed air holes in the common exhaust port at the bottom of the double reaction chamber of the equipment, the gas flow above the servo pressure valve can be controlled. The rectification is carried out first, which greatly improves the uniformity and stability of the gas above the fairing. After the gas is rectified, the pressure in the left and right chambers can be kept consistent, which improves the uniformity of the product. At the same time, the polymer will not accumulate out of sync between the chambers, so that the environment between the chambers remains consistent and improves It improves the stability of the process and prolongs the cleaning cycle of the equipment, thus improving the production efficiency of the equipment and reducing the maintenance cost of the equipment.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Pose Simulation Matching Method for Dimensional Positioning Based on Two Three-coordinate Locators

ActiveCN112613130BRealize automatic matchingConsistent environmentGeometric CADDesign optimisation/simulationComputer visionControl theory

The invention discloses a three-dimensional positioning pose simulation matching method based on two three-coordinate locators, which calibrates the zero point position, the active receiving position and the driven receiving position of the active locator and the driven locator, and then the active locator is equivalent As a five-axis machine tool model, the driven positioner is equivalent to a three-axis machine tool model, and the translation parameters of the five-axis machine tool model are obtained by solving the relationship between the translation pose and the rotation pose between the zero position and the active receiving position and rotation parameters; by solving the translation pose relationship between the zero position and the driven receiving position, the translation parameters of the three-axis machine tool model are obtained; and then the simulation movement of the dimensional positioning tool is converted into the translation and rotation of the five-axis machine tool model And the translation of the three-axis machine tool model, so that the simulation environment of the dimensional positioning tool is consistent with the actual environment, and realizes the automatic matching of the dimensional positioning tool and the locator in the simulation environment.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com