On-site corrosion detecting method and device

A technology for corrosion detection and equipment, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of not considering the same chemical composition and poor corrosion resistance of materials, and achieve light weight, easy assembly, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

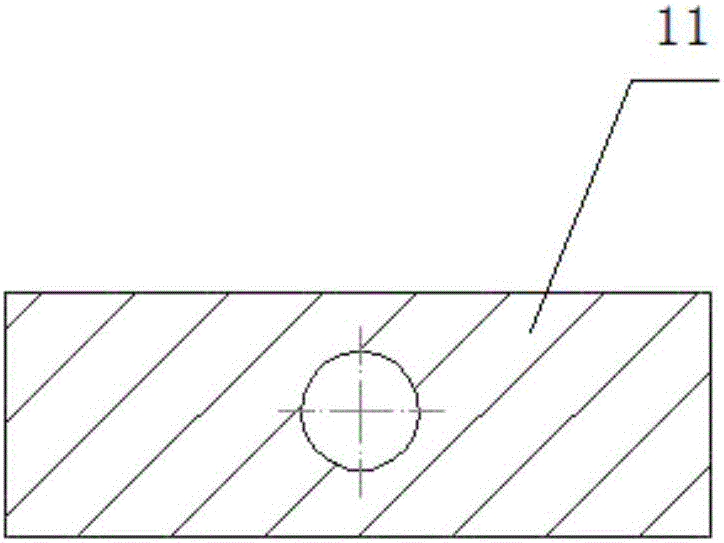

[0107] Example 1: Take two samples of 304L and 316L samples 12 in the supply state and in the deteriorated state. Among them, the supplied state uses substrate samples whose chemical composition and supply state meet the design requirements, and the deteriorated state sample 12 is obtained from the supplied state sample 11, which is kept at 650°C for 2 hours, and air-cooled to room temperature. as per Figure 10 Install as shown.

Embodiment 2

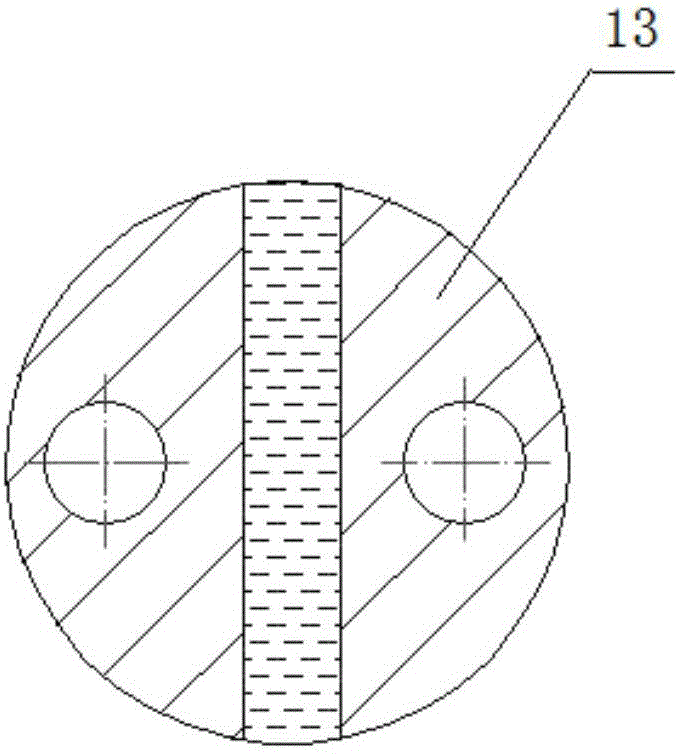

[0108] Example 2: Take two pieces of 304L and 316L welded samples 13 each. The welded sample 13 is obtained by cutting the sample 11 into slots and then welding on both sides of the slot. The welding conditions are as follows:

[0109] ① Welding method: manual flat welding, double-sided welding and double-sided forming to ensure penetration;

[0110] ② Solder material: ER308L, ER316L;

[0111] ③ Preheating temperature: None;

[0112] ④Heat treatment after welding: none;

[0113] ⑤Welding process parameters: current 120-150A, voltage 13-16V, speed 1.5-3mm / s, Ar gas flow 8-12L / min.

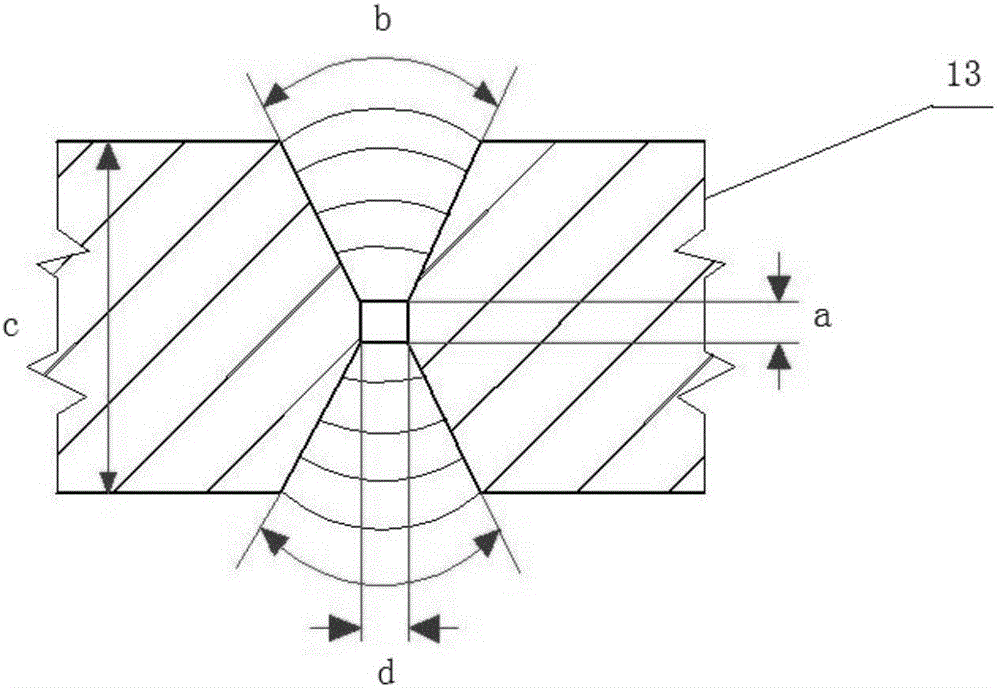

[0114] After welding, the samples are as follows Figure 11 Install as shown.

[0115] Examples of equipment

[0116] Certainly, the embodiment of the device is associated with the embodiment of the above method, and the specific content may refer to each other.

[0117] combine Figure 1 to Figure 11 As shown, the first hanging method provided by the present invention is a cantilever beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com