Device and method for correction of infrared thermometer

A technology of infrared thermometers and calibration devices, which is applied to measuring devices, radiation pyrometry, instruments, etc., can solve problems such as the large deviation between the measured temperature and the actual temperature, and achieve the goal of ensuring accuracy, precision, and precise measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

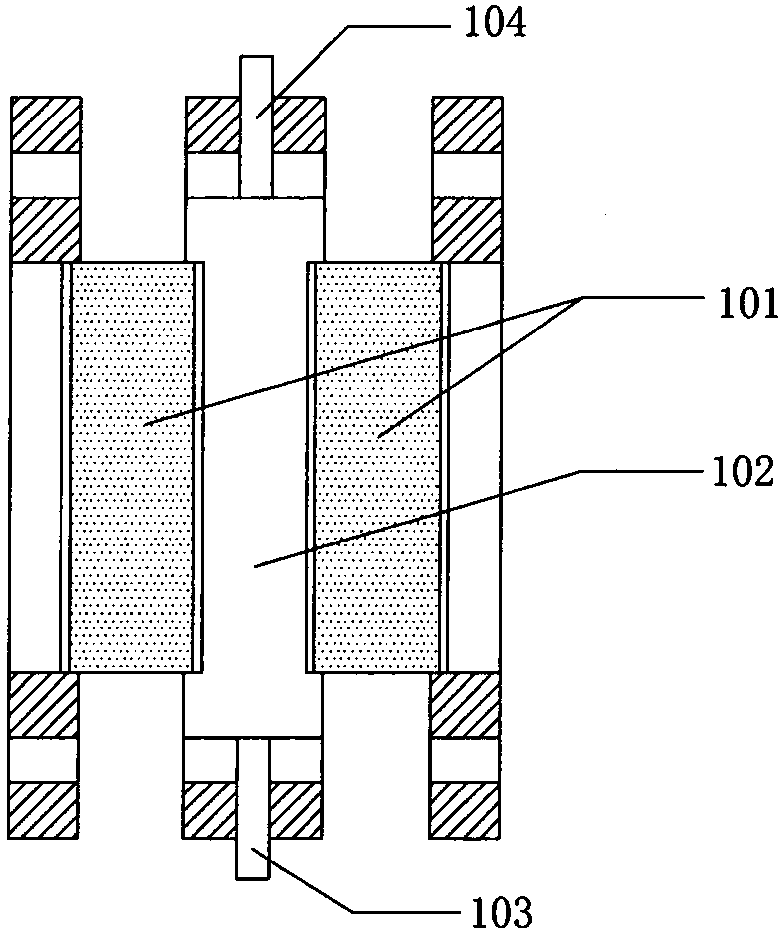

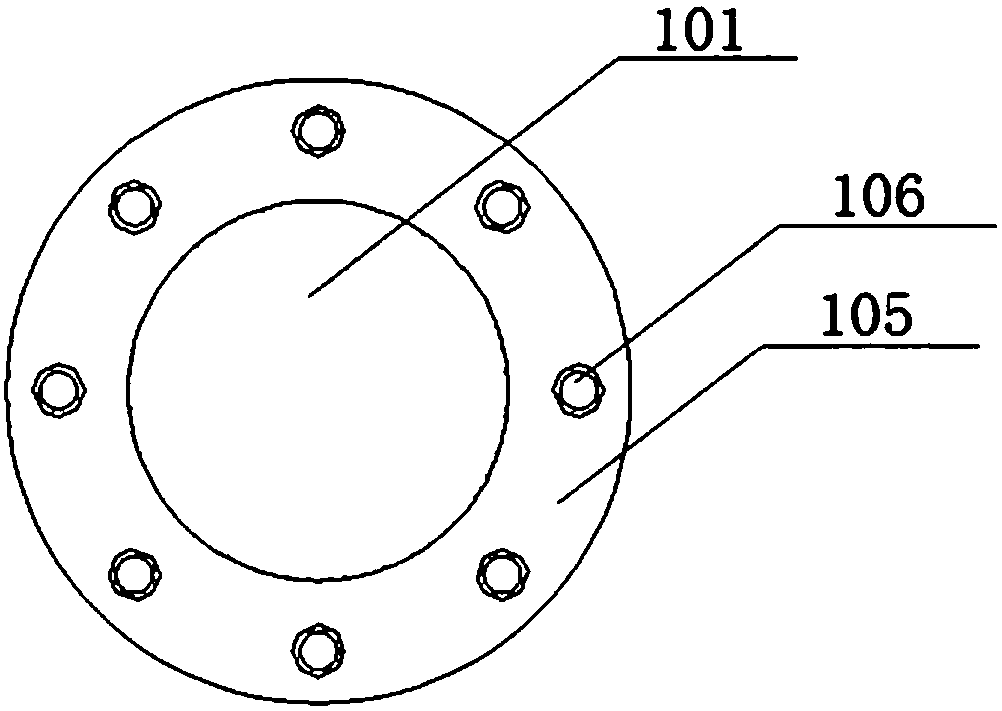

[0025] A sight glass for temperature correction of infrared thermometers, see figure 1 , comprising a double-layer mirror glass 101 and a cooling water interlayer 102 arranged between the double-layer mirror glass 101 . The sight mirror is fastened by means of flange connection; the sight mirror also includes a cooling water inlet 103 and a cooling water outlet 104 .

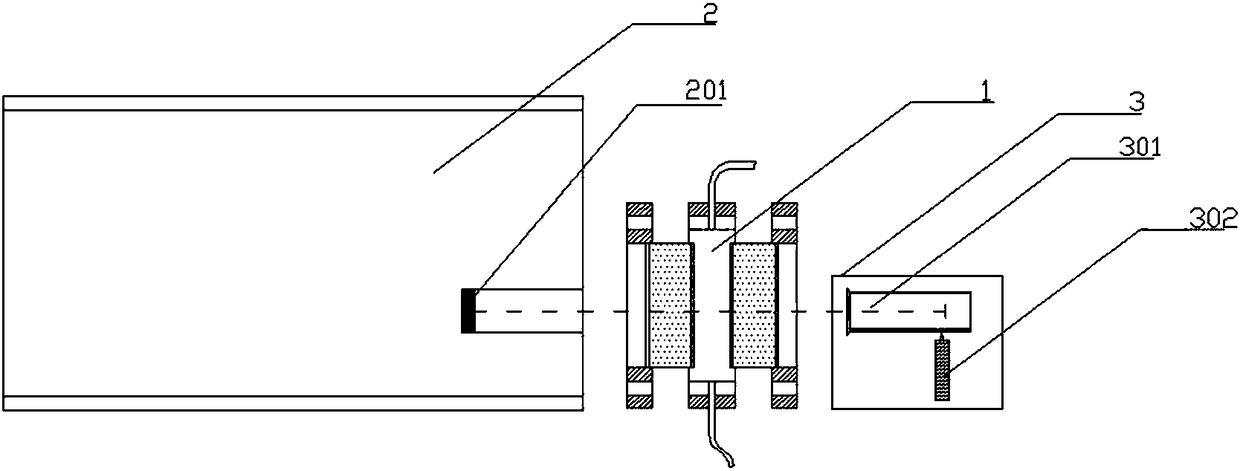

[0026] A calibration device for an infrared thermometer, see image 3 , including a black body furnace 2, a sight glass 1 and an infrared temperature measuring device 3 arranged in sequence non-contact, the black body furnace is provided with a radiator 201, and the sight mirror 1 includes a double-layer mirror glass 101 and a double-layer sight Cooling water interlayer 102 between mirror glass 101 (see figure 1 ), the infrared temperature measuring device 3 includes an infrared thermometer 301; the infrared rays emitted by the radiator 201 are gathered on the infrared thermometer 301 through the viewing mirro...

Embodiment 2

[0032]The flow rate of cooling water will affect the temperature distribution of cooling water in the sight glass. When the flow rate of cooling water is 1L / min, the actual operating condition of the reduction furnace is used as the boundary condition, and the temperature distribution of the water in the sight glass is calculated by the fluid mechanics simulation software. According to the simulation results, there is an obvious temperature gradient distribution in the mirror cooling water, see Figure 4 , If the cooling water flow rate is too small, it will cause temperature measurement errors due to the large cooling water temperature gradient, and the reasonable cooling water flow rate should be 5-10L / min.

[0033] Because the cooling water has an absorption effect on infrared rays, that is, part of the energy emitted by the silicon rod is absorbed by the cooling water after passing through the mirror, resulting in the measured temperature of the infrared thermometer being l...

Embodiment 3

[0039] According to the state of the actual operation of the reduction furnace, make such image 3 The correcting device needs to adjust the position of the infrared thermometer 301 when performing the temperature calibration of the infrared thermometer, and fix the position of the infrared thermometer 301 when the display temperature of the infrared thermometer 301 reaches the maximum value. When the lens of the infrared thermometer 301 is facing the radiator 201, the specific correction method is as follows:

[0040] (1) Set the calibration device according to image 3 Fix as shown, start the blackbody furnace 2 and set the temperature to 1000°C;

[0041] (2) Turn on the cooling water of the sight glass 1 so that the space between the two sight mirror glasses 101 is filled with water. When the water flow in the cooling water interlayer 102 reaches a steady state, the temperature of the cooling water is 30°C, and the flow rate of the cooling water is 6L / min. ;

[0042] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com