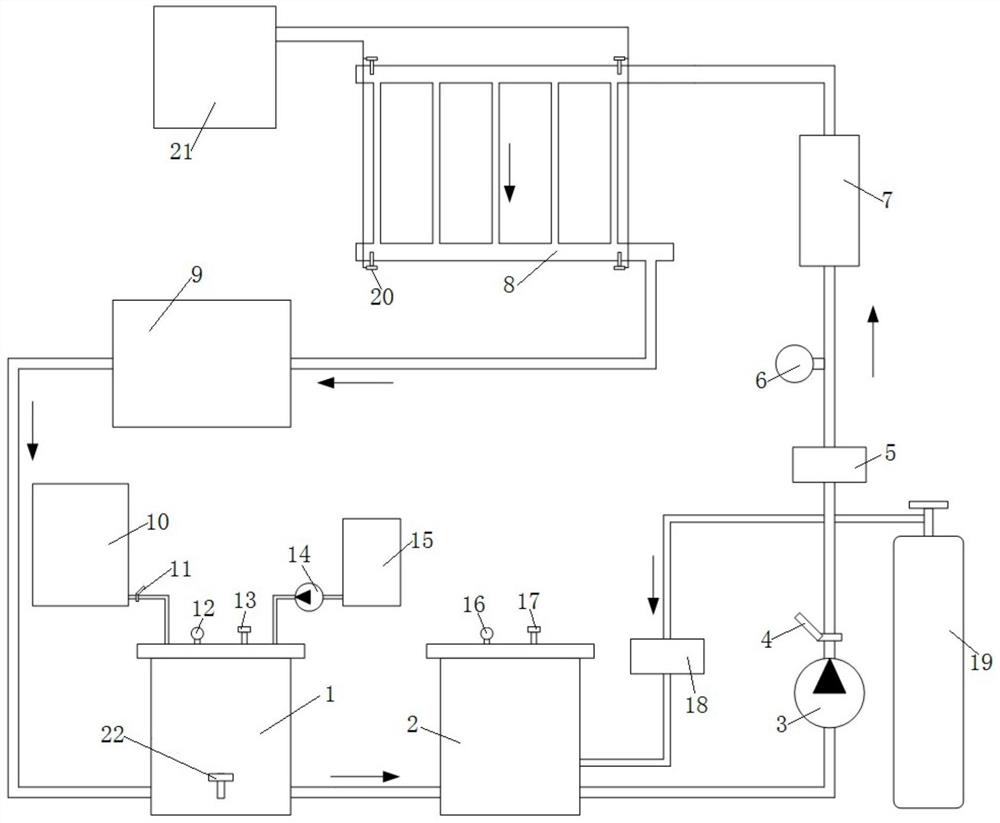

A test platform for fouling and descaling of the equalizing electrode in the cooling water system of the converter valve

A technology of cold water system and voltage equalizing electrode, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of scaling and descaling test platform with single function, and achieve the effect of perfect function, ensuring test data and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: In this case, an experimental study was carried out on the influence of carbon dioxide on the fouling degree of the voltage equalizing electrode;

[0034] Before the test, the deionized water replenishment tank 10 was used to replenish the circulating water to the storage tank 1. After the replenishment, the second valve 11 was closed, the first valve 4 was opened, and the circulating water pump 3 was used to fill the various devices and pipelines with water. Deionized water with a conductivity lower than 0.5μS / cm should be used as supplementary water; the test is divided into two groups, and the gas cylinders are all closed during the first group of tests. Apply voltage, the descaling device 9 is in the non-working state and only plays the role of waterway conduction; turn on the micro pump 14, start the first set of fouling test; take out the voltage equalizing electrode 20 after the test is over, dry and weigh, microscopic Observation and other treatment; ...

Embodiment 2

[0035] Example 2: This case conducts experimental research on the influence of the operating parameters of the descaling device on the descaling effect;

[0036] The test is divided into several groups, and the control variable method is adopted, that is, in each group of tests, except for a certain specific operating parameter of the descaling device 9 (such as applied current density, voltage, etc.), all other operating parameters of the test platform are kept constant. Remain unchanged; the steps of each group of tests are all consistent: before the test starts, the deionized water replenishment tank 10 is used to supplement the circulating water to the water storage tank 1, after the replenishment, the second valve 11 is closed, the first valve 4 is opened, and the circulation is opened. The water pump 3 utilizes the circulating water pump 3 to make each device and the pipelines full of water, and the initial replenishment water should adopt deionized water with a conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com