Dimensional positioning pose simulation matching method based on two three-coordinate positioners

A three-coordinate locator and matching method technology, which is applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as error-prone, complex configuration environment steps, and unfavorable promotion of simulation applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

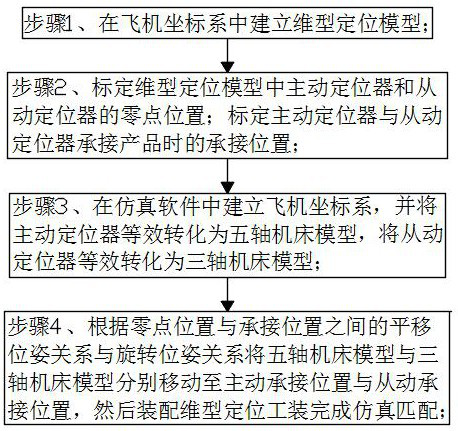

[0042] A kind of three-dimensional positioning pose simulation matching method based on two three-coordinate locators in this embodiment, such as figure 1 shown, including the following steps:

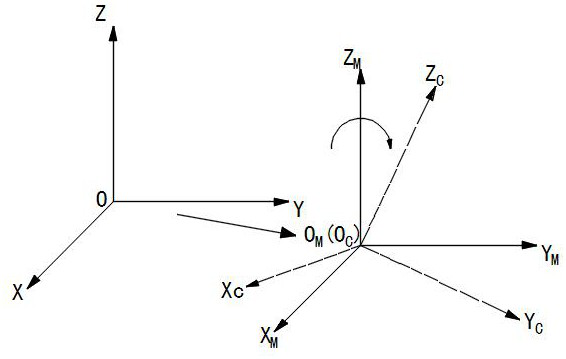

[0043] Step 1. Establish the aircraft coordinate system O-XYZ, and establish a dimensional positioning model in the aircraft coordinate system, such as Figure 7 As shown, and establish the active positioner 01 and the driven positioner 02 in the dimensional positioning model, and then establish the dimensional positioning tool 03 between the active positioner 01 and the driven positioner 02;

[0044] In the actual environment, the active positioner 01 and the driven positioner 02 are controlled by the control system, so that both the active positioner 01 and the driven positioner 02 move to the zero point, and then the laser tracker is used to calibrate the active positioner 01 and the driven positioner at this time. The zero position of locator 02 in the aircraft coordinate system. ...

Embodiment 2

[0065] This embodiment is further optimized on the basis of Embodiment 1, and the active locator 01 is equivalently transformed into figure 2 The steps for the five-axis machine tool model shown include:

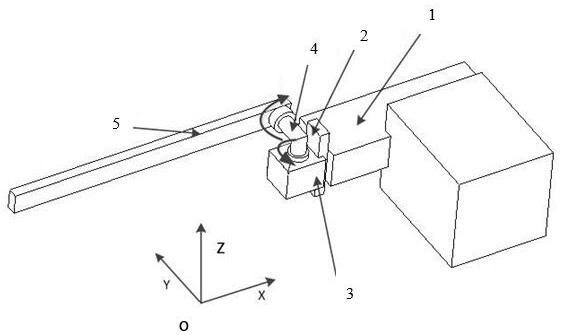

[0066] Step A1, establish the aircraft coordinate system O-XYZ in the simulation software, and set the active machine tool according to the zero position calibrated in step 1, move and set the X-axis component 1 on the active machine tool along the X-axis direction, and move the X-axis component 1 along the X-axis component 1 The Y-axis component 2 is set by moving in the Y-axis direction, and the Z-axis component 3 is set by moving along the Z-axis direction on the Y-axis component 2;

[0067] The X-axis component 1 can move along the X-axis direction to realize the translation of the simulated active positioner 01 along the X-axis direction; the Y-axis component 2 can move along the Y-axis direction to realize the simulated translation of the active positioner 01 along th...

Embodiment 3

[0073] This embodiment is further optimized on the basis of the above-mentioned embodiment 1 or 2. The step of equivalently transforming the driven positioner 02 into a three-axis machine tool model is to establish the aircraft coordinate system O-XYZ in the simulation software, and according to step 1 Set the slave machine tool at the zero position calibrated in , set the X-axis component 1 on the slave machine tool along the X-axis direction, set the Y-axis component 2 on the X-axis component 1 along the Y-axis direction, and set the Y-axis component 2 on the Y-axis component 2 along the Z axis. Axis movement sets Z-axis component 3.

[0074] The X-axis component 1 can move along the X-axis direction to realize the translation of the simulated driven positioner 02 along the X-axis direction; the Y-axis component 2 can move along the Y-axis direction to realize the simulated driven positioner 02 along the Y-axis The translation in the direction; the Z-axis component 3 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com