A kind of graphite core column material and preparation method thereof

A technology of graphite core column and graphite layer, which is applied in the field of superhard material graphite core column synthesis, can solve the problems of insufficient penetration, influence, and impact on the output and quality of artificial diamond, and achieve the purpose of increasing output and quality, improving catalytic performance, increasing The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

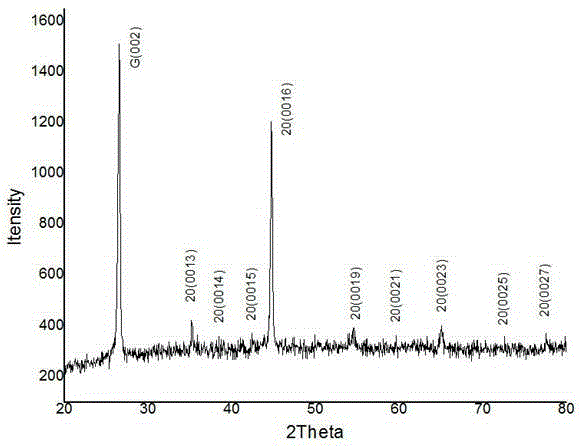

[0019] A kind of preparation method of graphite core column material, concrete steps are as follows:

[0020] The first step: using the sol-gel method to prepare nano-iron oxide powder with uniform particle size; 2 In the atmosphere, using 99.93% pure nickel block as raw material, nano-nickel powder with uniform particle size was prepared by plasma arc method; nano-iron oxide powder, nano-nickel powder and nano-graphite powder were taken and mixed to obtain nano-mixed powder; , in terms of Fe / Ni, the molar ratio of iron oxide powder to nickel powder is 1:1; the mass percentage of graphite powder in the mixed powder is 60%.

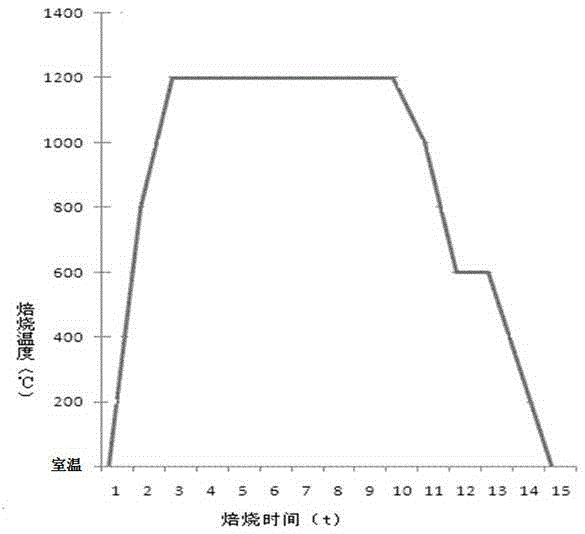

[0021] The second step: place the nano-mixed powder in a closed system for vacuuming, at a vacuum degree of 10 -3 Pa, filled with hydrogen, heated to 1200 ° C for 8 hours to achieve reduction treatment, remove the oxygen content in it, and improve the catalyst activity.

[0022] Step 3: After the heat preservation heat treatment in the second step, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com