Triangular support and powder metallurgy brake pad with triangular support

A triangular bracket and brake pad technology, applied to brake components, brake types, mechanical equipment, etc., can solve problems such as eccentric wear of friction blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

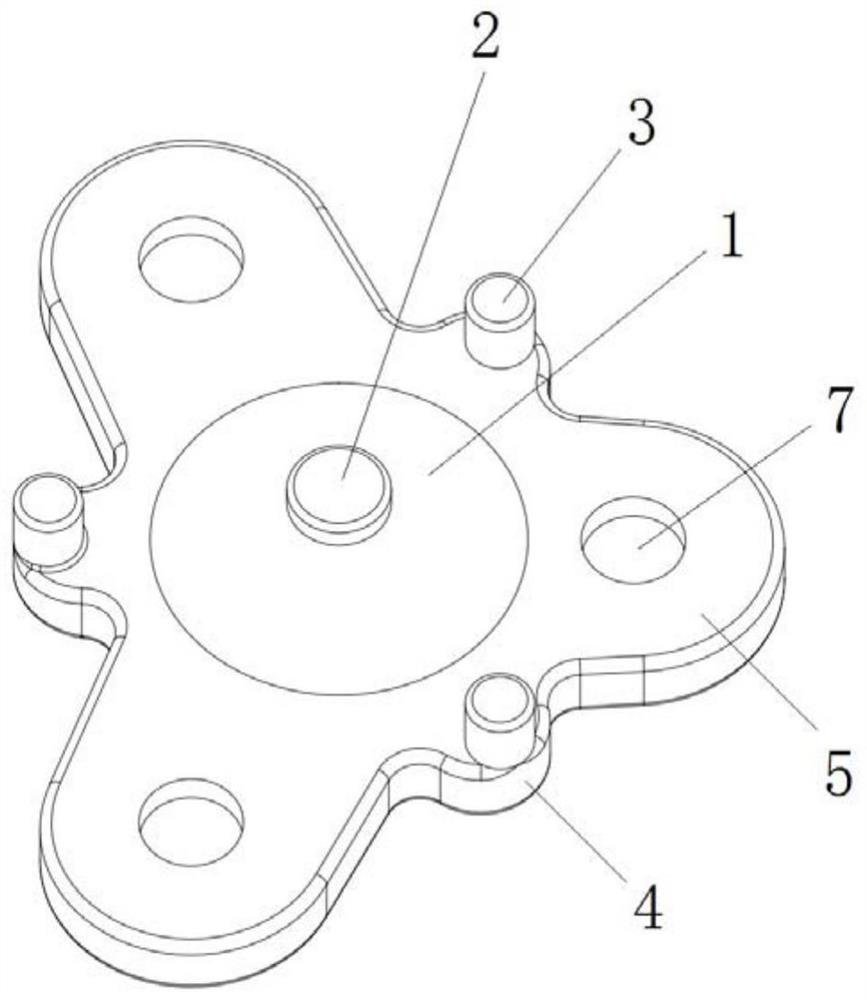

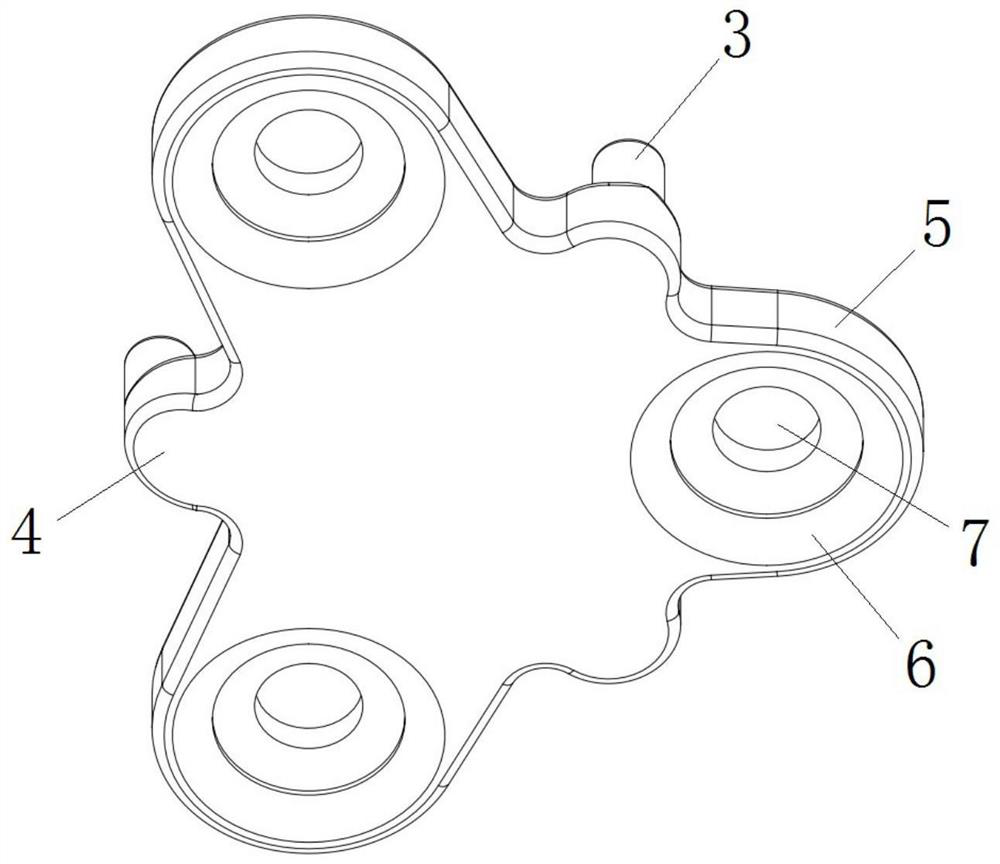

[0035] This embodiment provides a specific implementation of the triangular bracket, such as figure 1 , figure 2 As shown, it includes: a convex spherical surface 1 located on the upper surface of the triangular support, with a guide post 2 on the top of the convex spherical surface 1, the convex spherical surface 1 and the guide post 2 are used to connect with the concave spherical surface on the steel back 8; in addition, As an alternative embodiment, the positioning post 2 can be omitted, or the positioning post 2 can be a structure such as a positioning hole.

[0036] Such as figure 1 As shown, on the upper surface of the triangular bracket, three positioning posts 3 are arranged around the convex spherical surface 1, and the three positioning posts 3 are arranged rotationally symmetrically around the center of the convex spherical surface 1, and the three positioning posts 3 The column 3 is arranged on the boss 4 extending away from the convex spherical surface 1 . Wh...

Embodiment 2

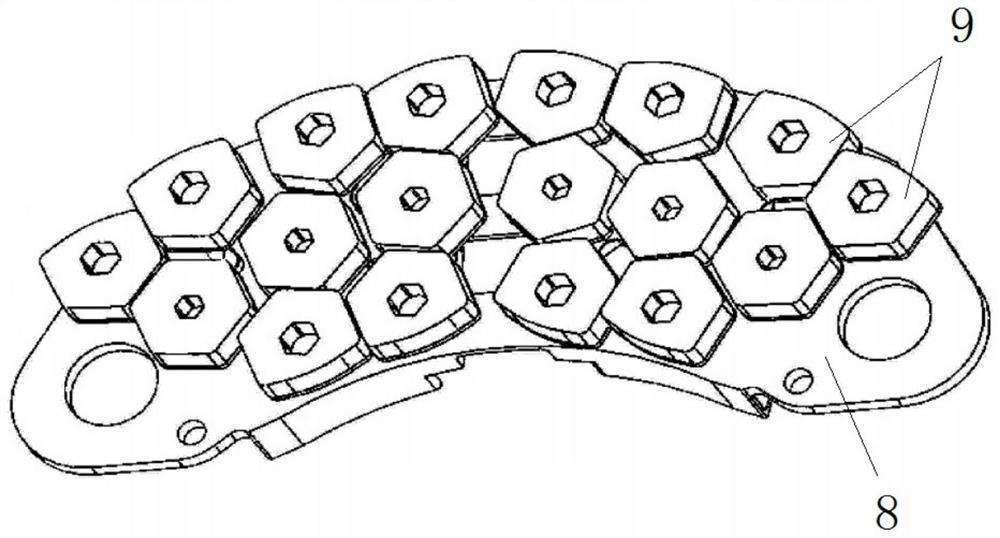

[0040] This embodiment provides a specific implementation of a powder metallurgy brake pad, including the triangular bracket described in Embodiment 1, and the triangular bracket is installed between the steel back 8 and the friction block 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com