Base structure of electrolysis device for separation of hydrogen and oxygen and electrolysis device with the base

An electrolysis device and electrolysis electrode technology, applied in electrolysis components, electrolysis process, chemical instruments and methods, etc., can solve the problems of no waste water and waste gas separation, waste water fouling and odor, waste water treatment, etc., to ensure practicality and stability. properties, ensuring concentration and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

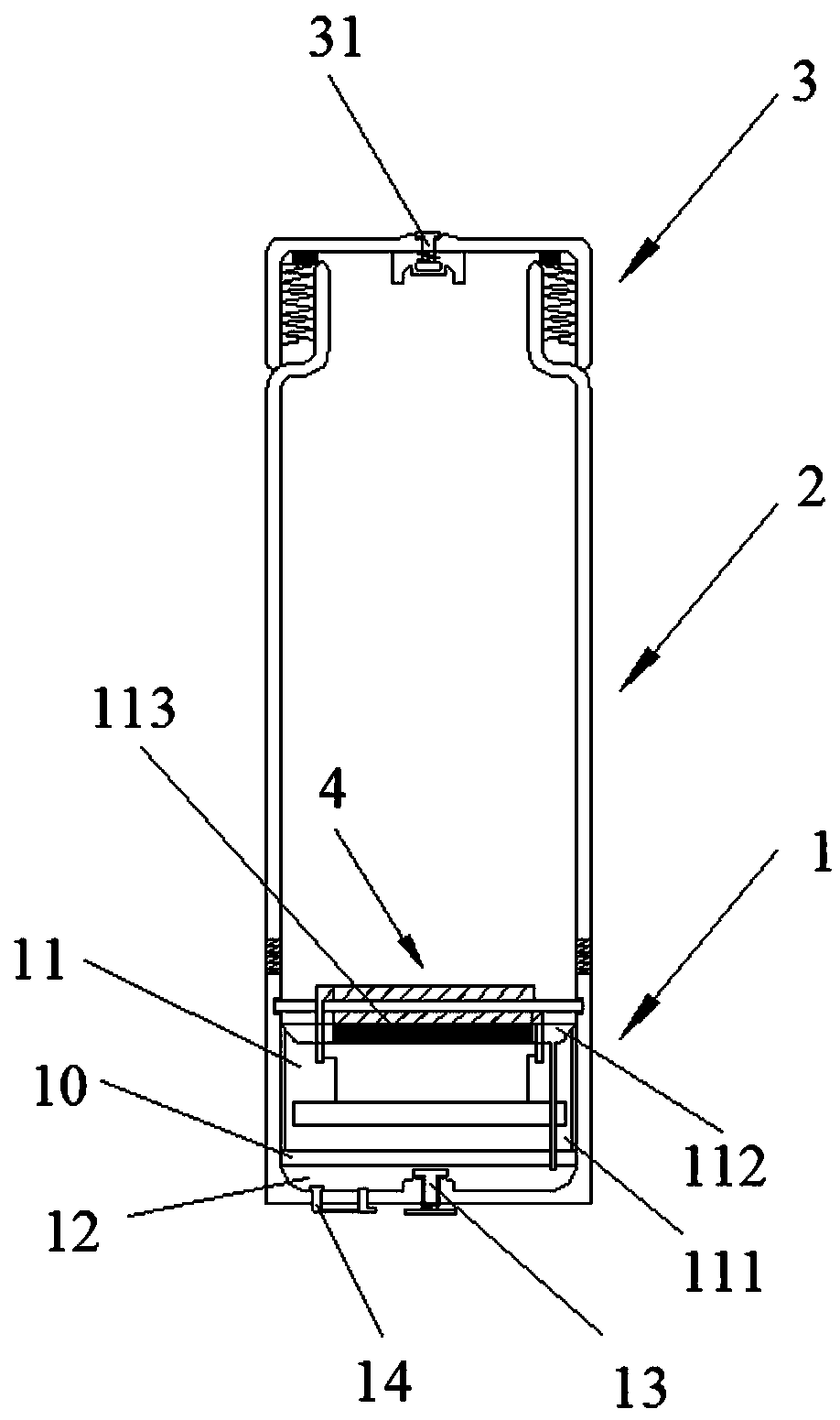

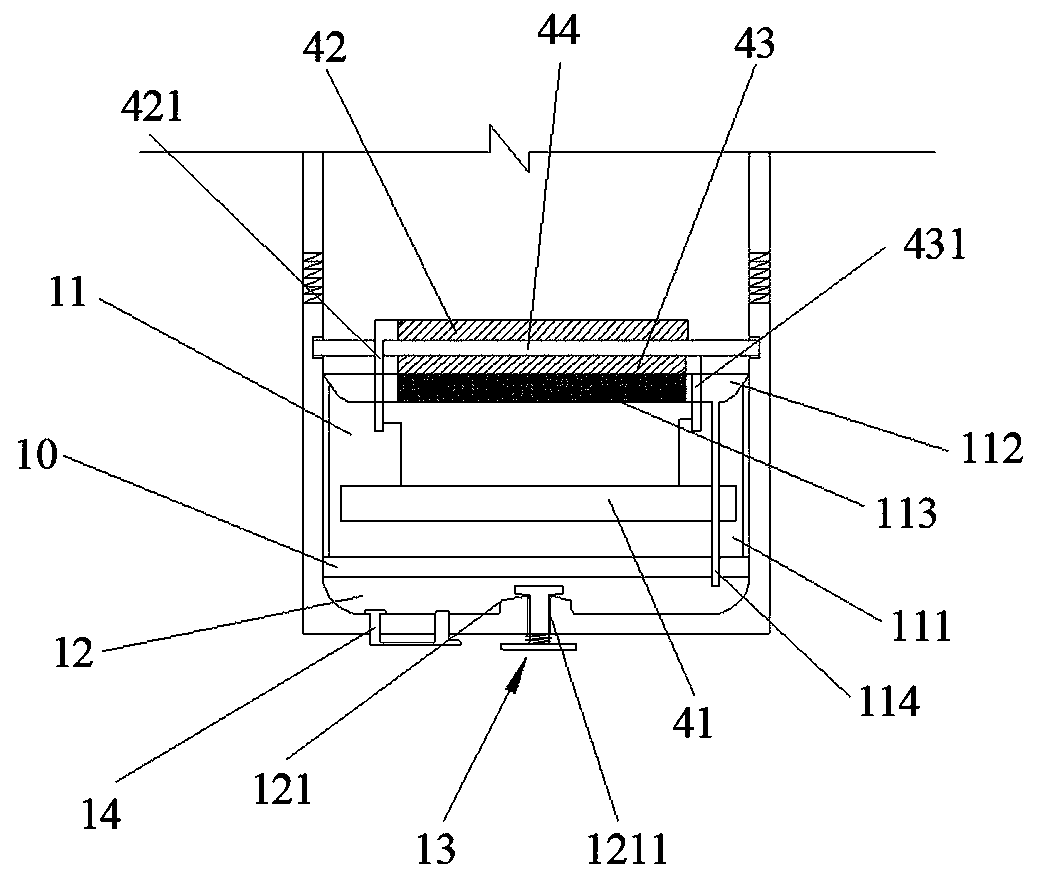

[0036] see Figure 1 to Figure 4 , an electrolysis device, including a seat body 1, a main body 2 and a cover body 3 connected in sequence; specifically, the seat body 1 is arranged below the main body 2 and the upper part of the seat body 1 and the lower part of the main body 2 are connected by thread sealing, so The cover 3 is arranged above the main body 2 and the cover 3 is connected with the upper part of the main body 2 through thread sealing; the base 1, the main body 2 and the cover 3 together form a container for holding water.

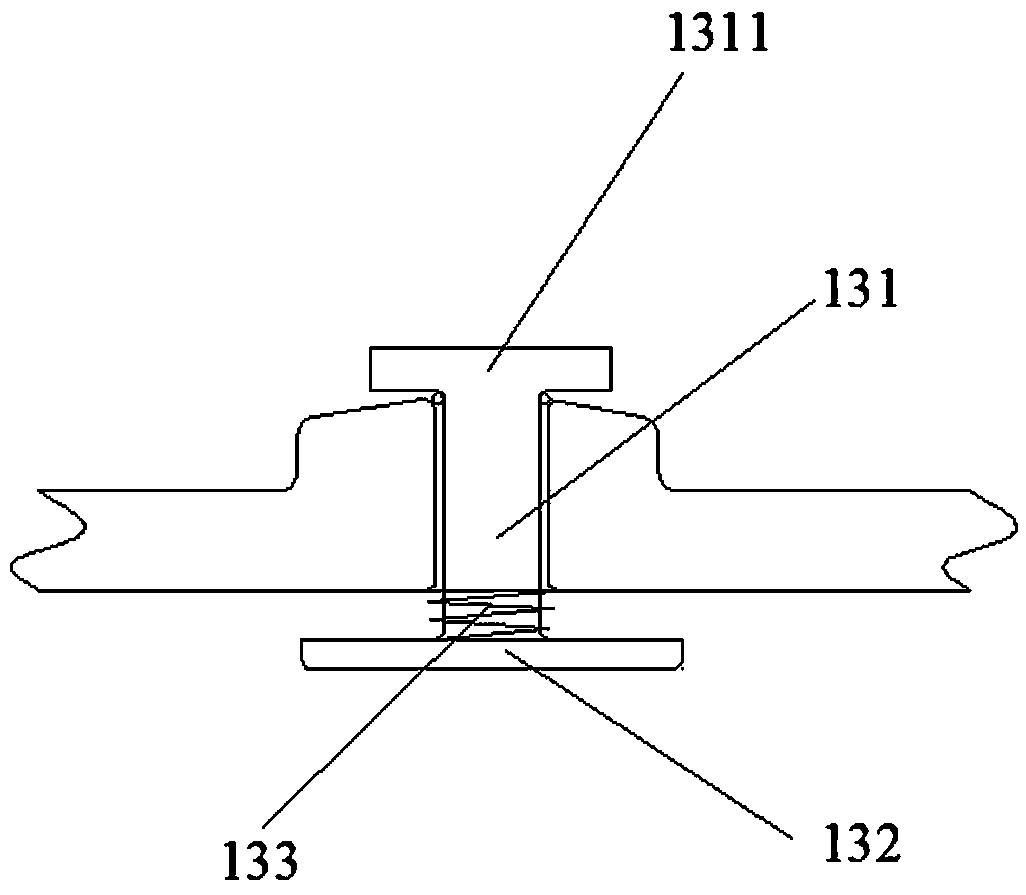

[0037] The seat body 1 includes a shell, which is divided into an upper electrolysis chamber 11 and a lower waste water and waste gas chamber 12 by an isolating device 10 arranged at the lower part of the seat body 1. In this embodiment, the isolating device 10 is a fixed Sealing is connected to the isolation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com