Hard film fixing device in greenhouse

A fixing device and hard film technology, which is applied in greenhouse cultivation, roofing and roofing using flexible materials, can solve the problems of time, manpower and cost, durability and product value reduction, and shortened life, so as to save working time Combining fixed effects with manpower and related costs, improving durability and product value, and simplifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The greenhouse hard film fixing device of the present invention will be described in detail below in conjunction with the accompanying drawings.

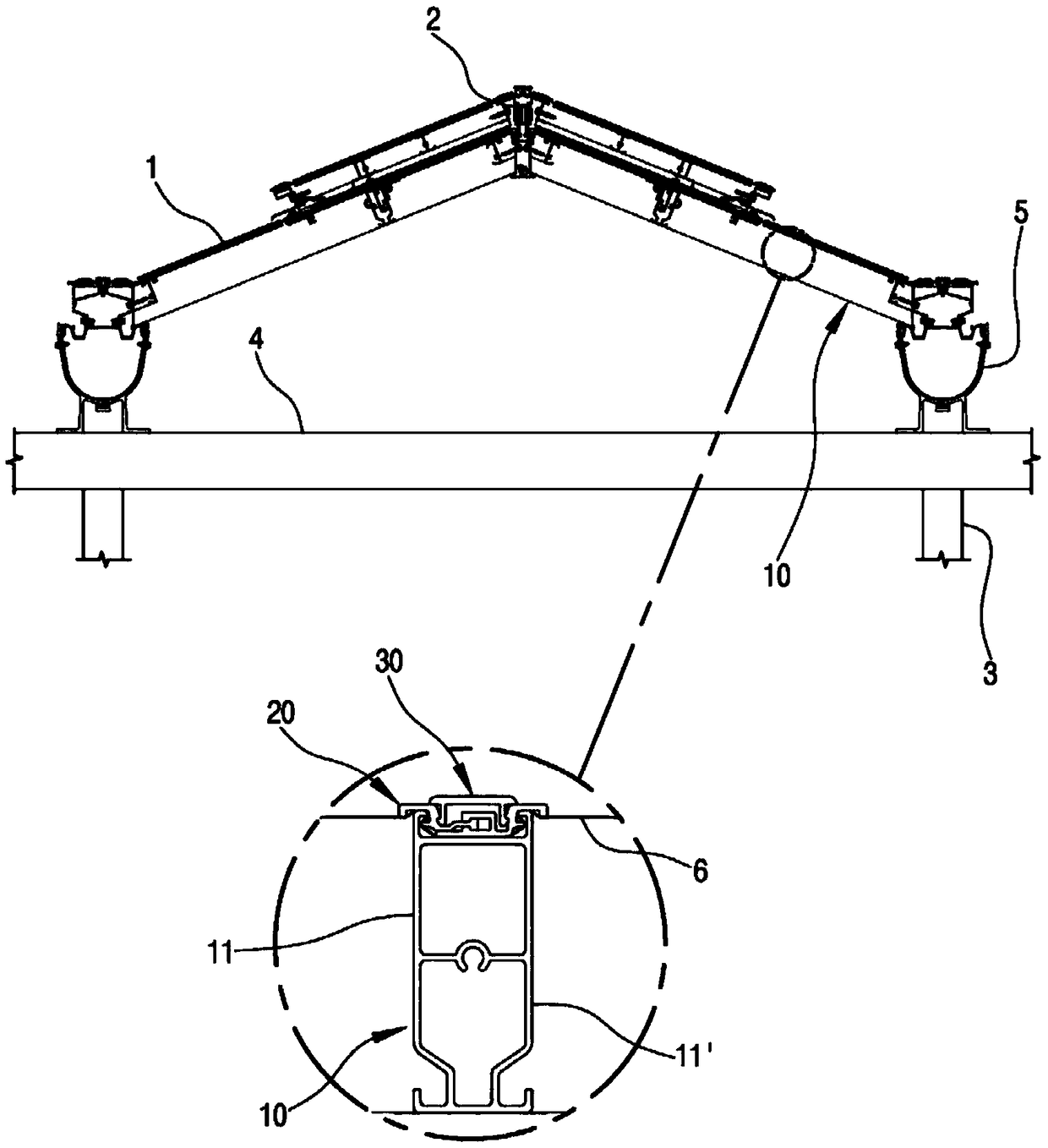

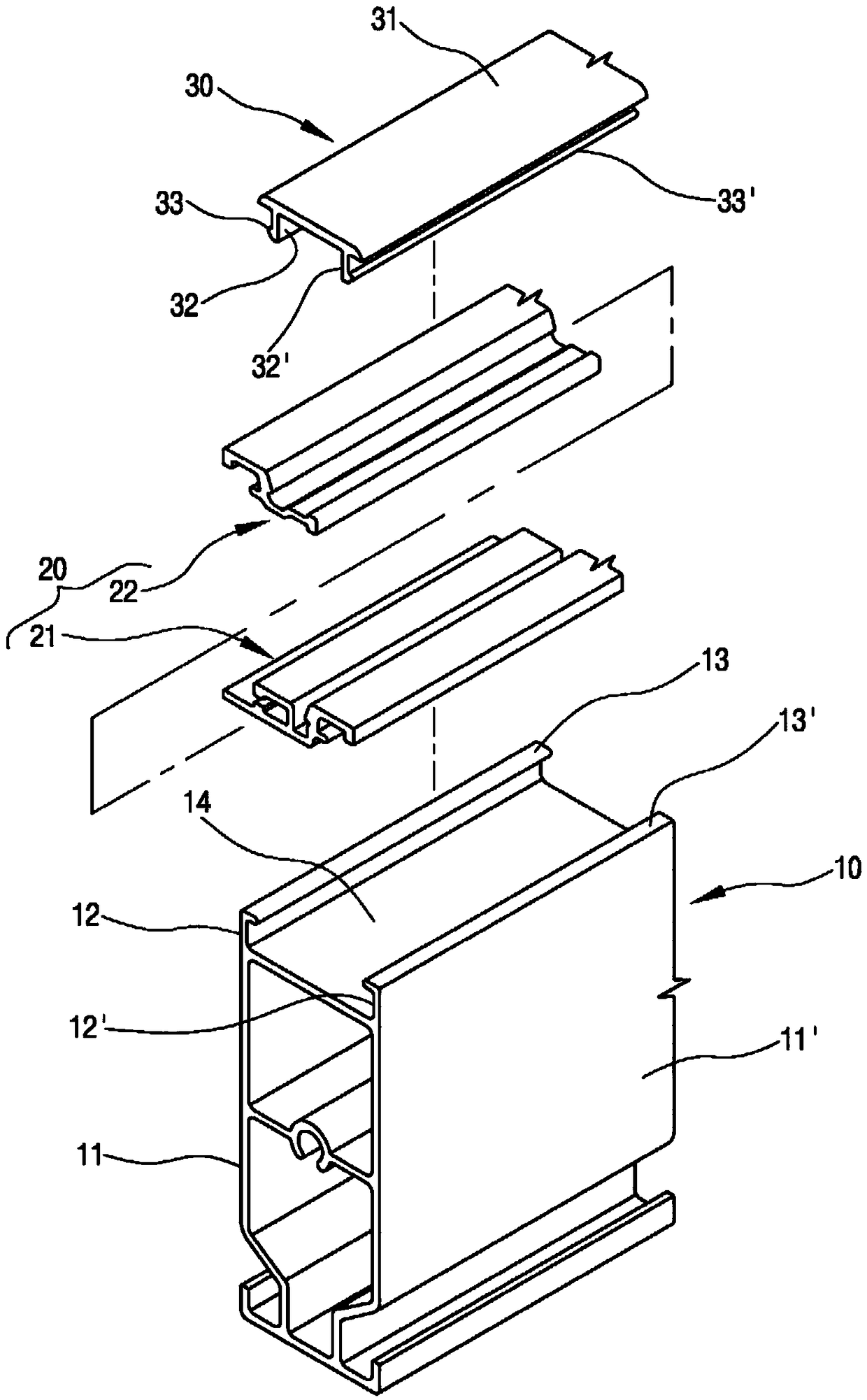

[0036] figure 1 It is a front view of selecting and displaying a part of the use state of the greenhouse dura mater fixing device of the present invention, figure 2 It is a perspective view showing the greenhouse hard film fixing device of the present invention in isolation.

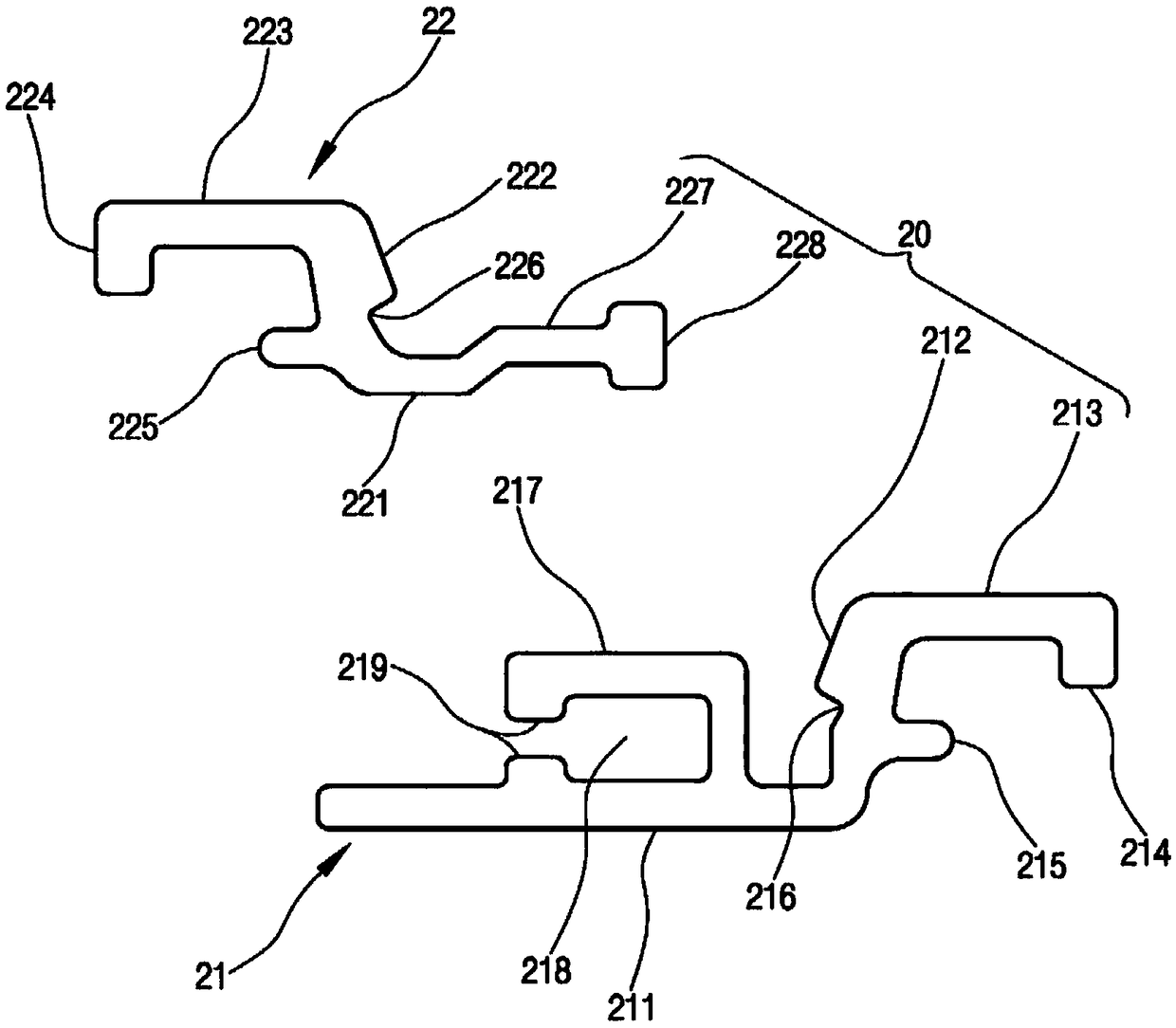

[0037] according to figure 1 , 2 The structure of the greenhouse hard film fixing device of the present invention includes: the top frame 10 , the fastening device 20 and the covering member 30 respectively formed in the same length.

[0038] The structure of the top frame 10 includes: the left and right supporting parts 12, 12' vertically extending at the same height on the upper ends of the separated left and right sides 11, 11'; , 13'; the upper part and both ends are openly formed on the upper fixing groove part 14 through the left and right su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com