A kind of four-twist spindle upper spindle bar and its manufacturing method

A spindle bar and spindle technology, which is applied to the spindle bar on a four-twist spindle and its manufacturing field, can solve the problems of easy deviation of coaxiality, and achieve the effects of improving bonding fastness, reducing manufacturing difficulty and improving coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

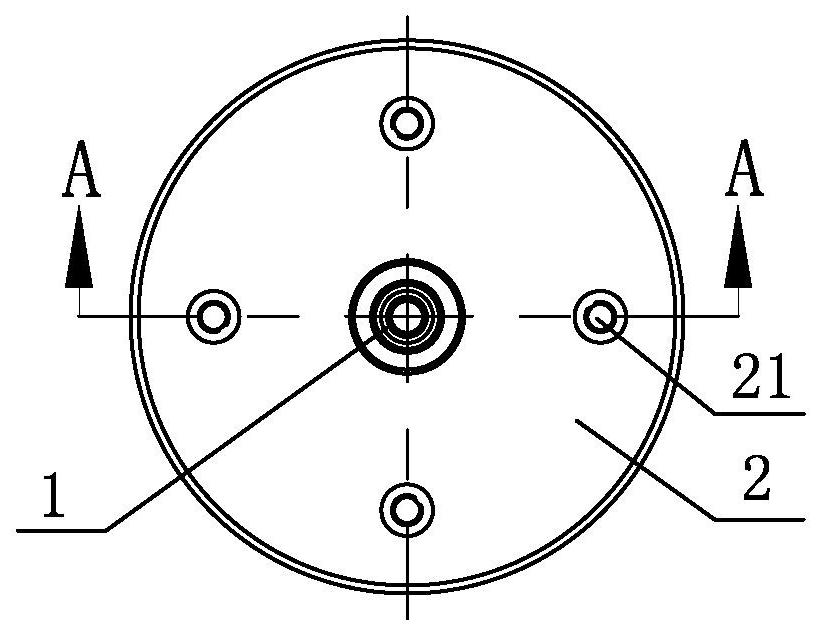

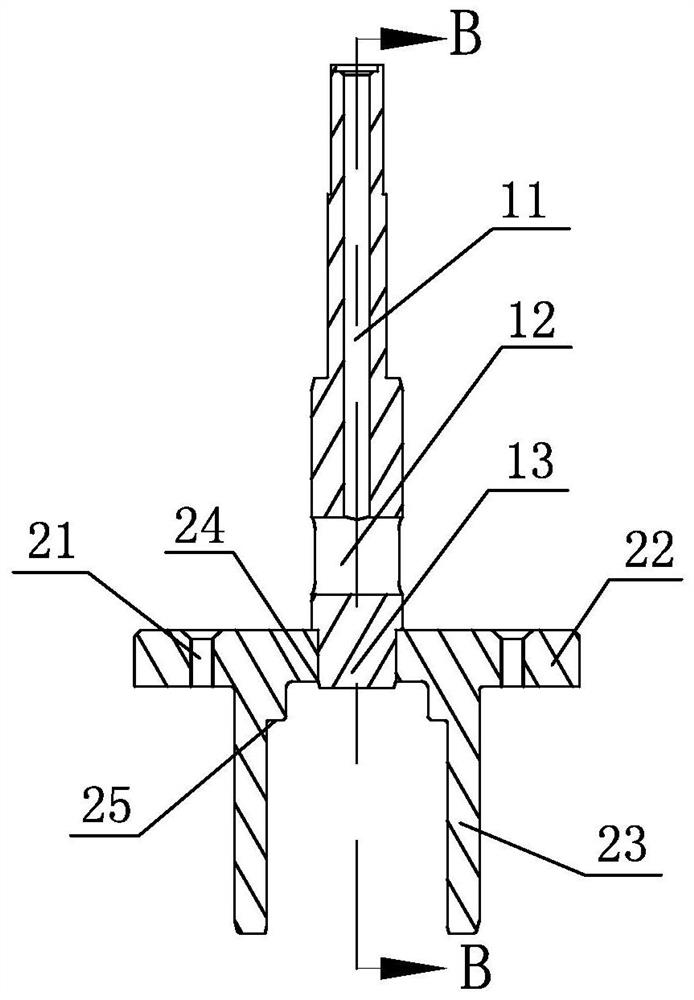

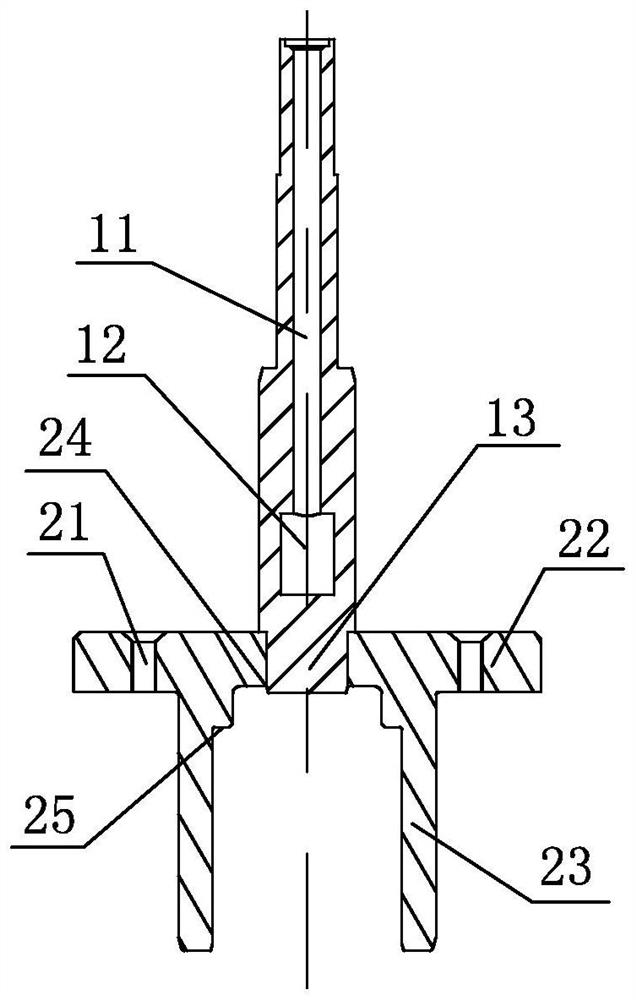

[0016] Such as Figure 1 ~ Figure 4 As shown, the upper spindle bar of the present invention includes a spindle bar 1 and a support sleeve 2; the support sleeve 2 includes a sleeve part 23 and a flange part 22, and the flange part 22 is integrally connected to the top end of the sleeve part 23, and the outer diameter of the flange part is It is larger than the sleeve part, and the center of the flange part is provided with an axial circular through hole 24, and the center line of the sleeve part 23 and the axial circular through hole 24 is coaxial; the bottom end of the spindle rod 1 is shaped as a cylindrical connection end 13 , the cylindrical connecting end 13 and the axial circular through hole 24 are inserted and connected by an interference fit; the spindle rod 1 is provided with a radial through hole 12 for installing a wire block and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com