Supporting device for roller way of transition roller table

A supporting device and transition roller technology, which is applied to glass transportation equipment, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as scratches, fog spots, and damage to the lower surface of the glass, so as to facilitate adjustment and replacement, reduce adjustment difficulty, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

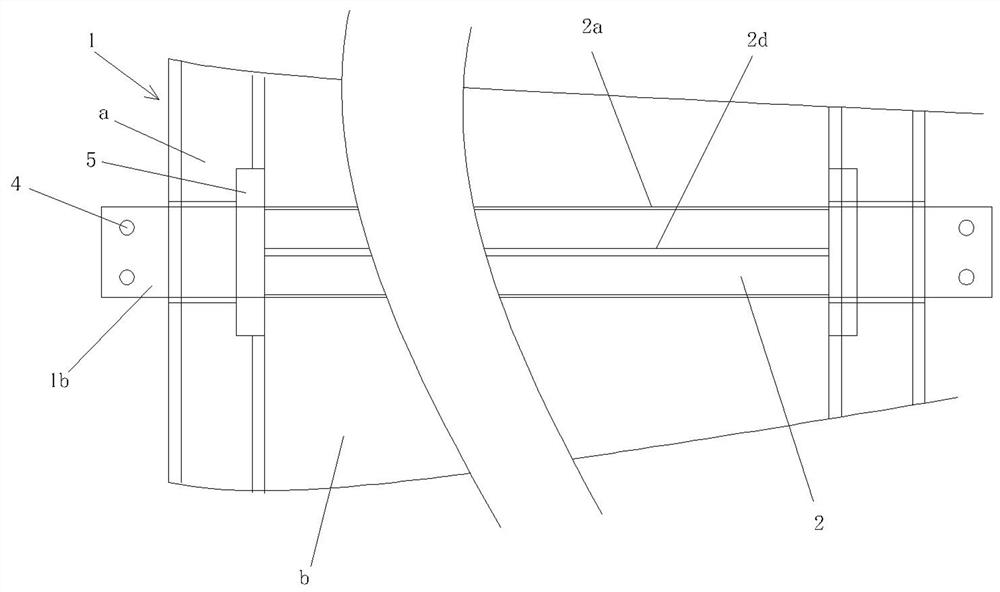

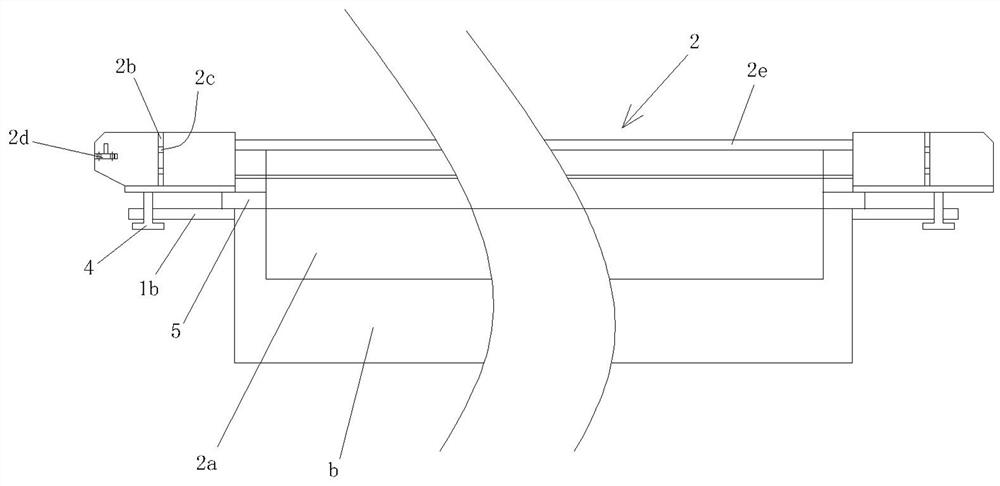

[0016] Such as Figure 1-3 As shown, a supporting device for a transition roller table roller table, it includes a slag box 1, and the slag box 1 is mainly composed of three parts: a partition wall a, a side wall b, and a bottom plate. A lifting device 4 is provided on the slag box 1, and the lifting device 4 includes a horizontally distributed steel plate 1b welded on the two side walls b of the partition wall a respectively, and a screw hole is provided on the steel plate 1b , vertically distributed jacking bolts 1c are threaded in the screw holes. The upper surface of the partition wall a is downwardly provided with slots 1a distributed along the length direction of the partition wall a.

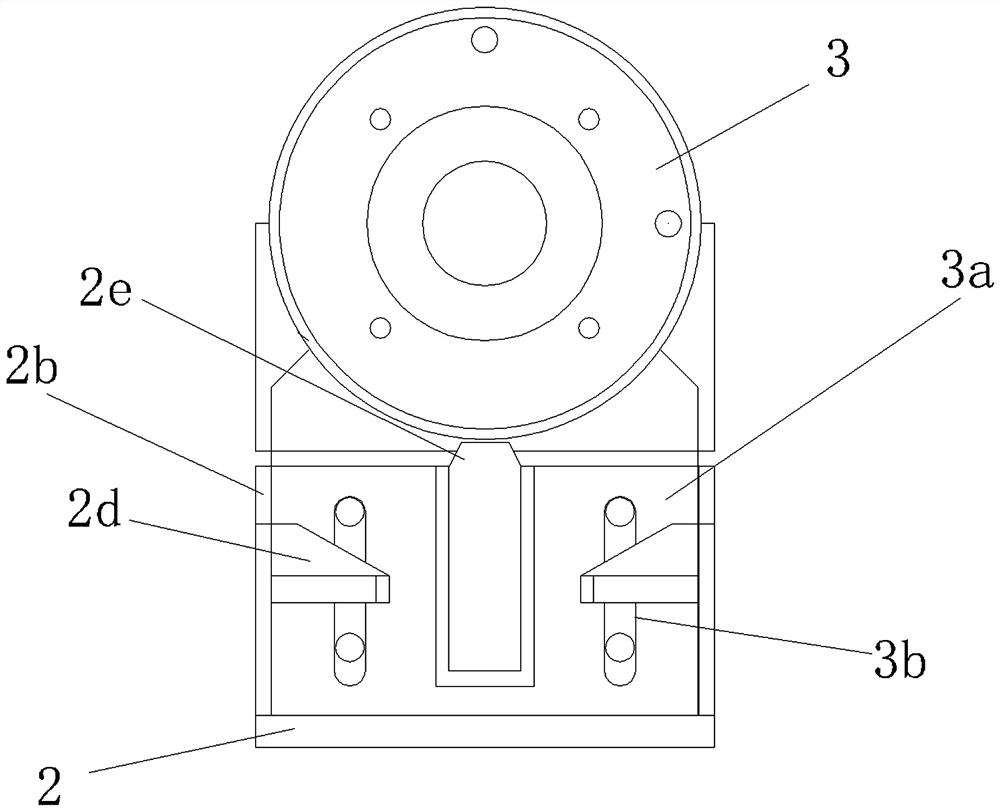

[0017] A moving frame 2 is straddled on the slag box 1, and fixed frames 2b are respectively welded at both ends of the moving frame 2, and a mounting hole 2c is provided on the fixed frame 2b, and a pair of distributed positioning frames are also welded on the fixed frame 2b. Use lugs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com