Intelligent inspection method

A technology of intelligent inspection and inspection tasks, which is applied in the direction of inspection time patrols, instruments, computer parts, etc., can solve problems such as equipment damage, and achieve the effect of avoiding poor circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

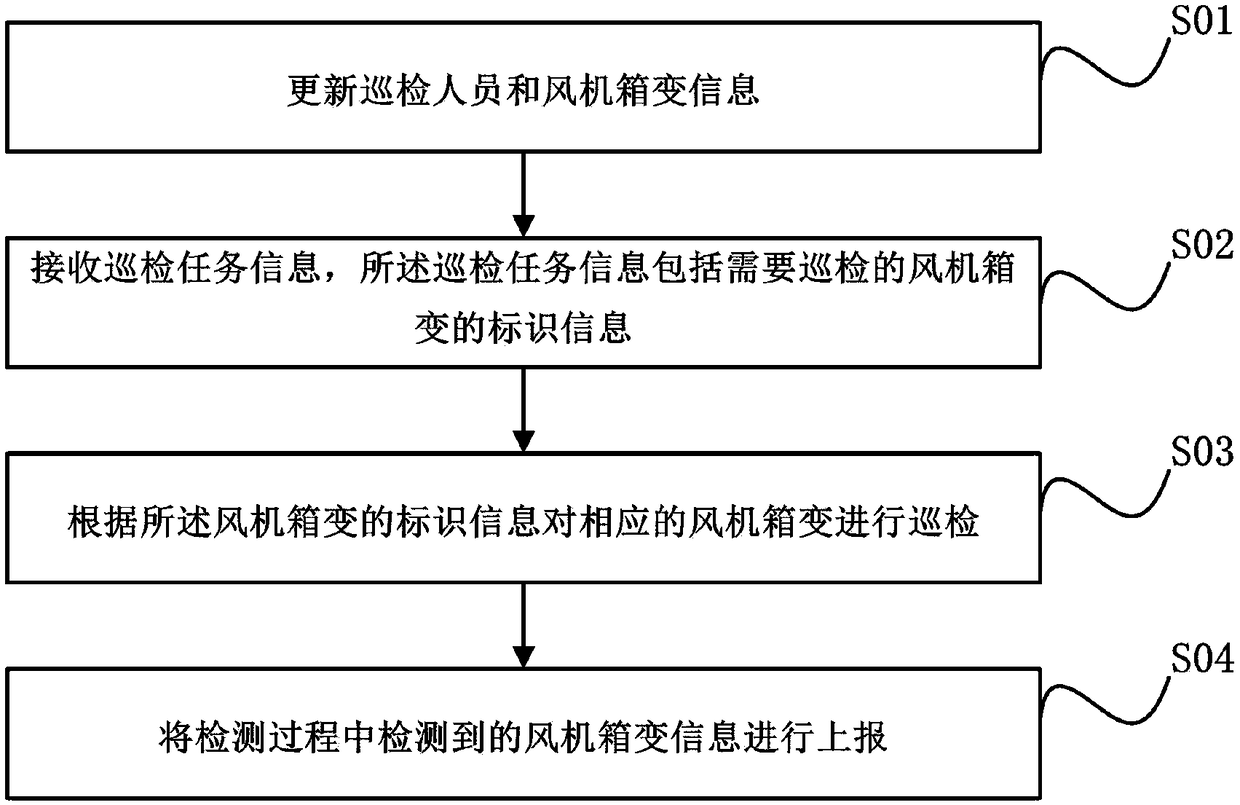

Method used

Image

Examples

Embodiment Construction

[0032] At present, the inspection of the wind box substations in traditional wind farms uses paper-based inspection books, and randomly inspects the wind box substations, and mainly uses the form of defect record books to make statistics on equipment defects and hidden dangers. At present, traditional wind farms conduct inspections of the entire wind chassis, and use regular inspections. The number of wind turbines in a single inspection is limited, and it often takes multiple inspections to inspect all the wind chassis in the wind farm. Due to the wide and scattered distribution of wind turbines, the wind turbines in the wind farm have a wide distribution range and a relatively large number of scattered ones. Traditional paper inspection books are used to record defects. Some equipment has repeated defects. Defects are not summarized for a long time and cannot be obtained. Effective treatment. Once the defects and hidden dangers of the fan and box transformer are enlarged, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com