Heat dissipation device for manufacturing non-ferrous metal alloy material casting piece

A technology of alloy materials and non-ferrous metals, which is applied in the field of heat sinks for the manufacture of non-ferrous metal alloy material castings, can solve the problems of lower production efficiency, damage to manufacturing equipment, heat backflow of heat sinks, etc., to improve the utilization rate of heat, enhance Energy saving and environmental protection, the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

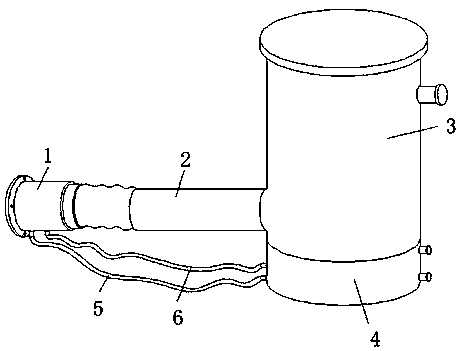

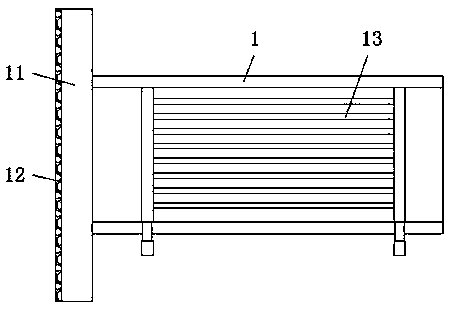

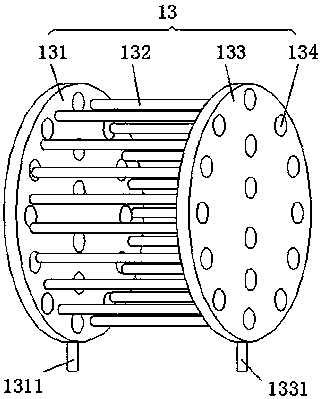

[0060] Such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, a heat dissipation device for manufacturing castings made of non-ferrous metal alloy materials, including: a heat dissipation connection pipe 1, a connecting pipe fitting 2, a heat treatment tank 3 and a coolant tank 4;

[0061] The top inner wall of the heat treatment tank 3 is embedded with a cover 31;

[0062] The outer wall of the heat treatment tank 3 is communicated with a heat recovery pipe 35;

[0063] Also includes a buffer pipe 32, the buffer pipe 32 is arranged in the inner cavity of the heat treatment tank 3, the buffer pipe 32 is a multi-section U-shaped structure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com