High-efficiency feed mixing device for agricultural use

A technology of mixing device and feed, which is applied to mixers, feeds, applications and other directions with a rotating mixing device, can solve the problems of insufficient and comprehensive feed mixing, low mixing efficiency and high labor intensity, and achieves low labor and high mixing efficiency. , the effect of fully mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

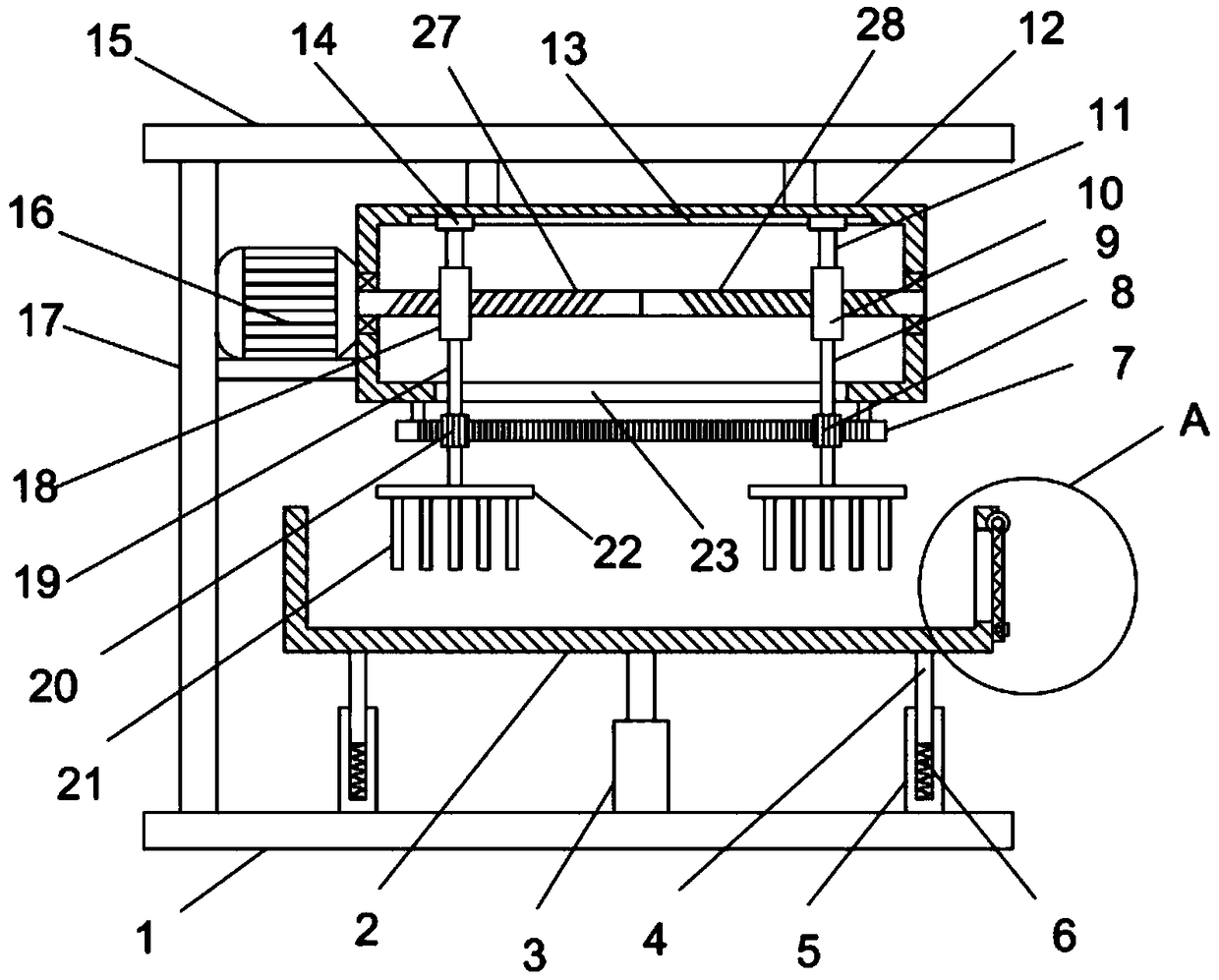

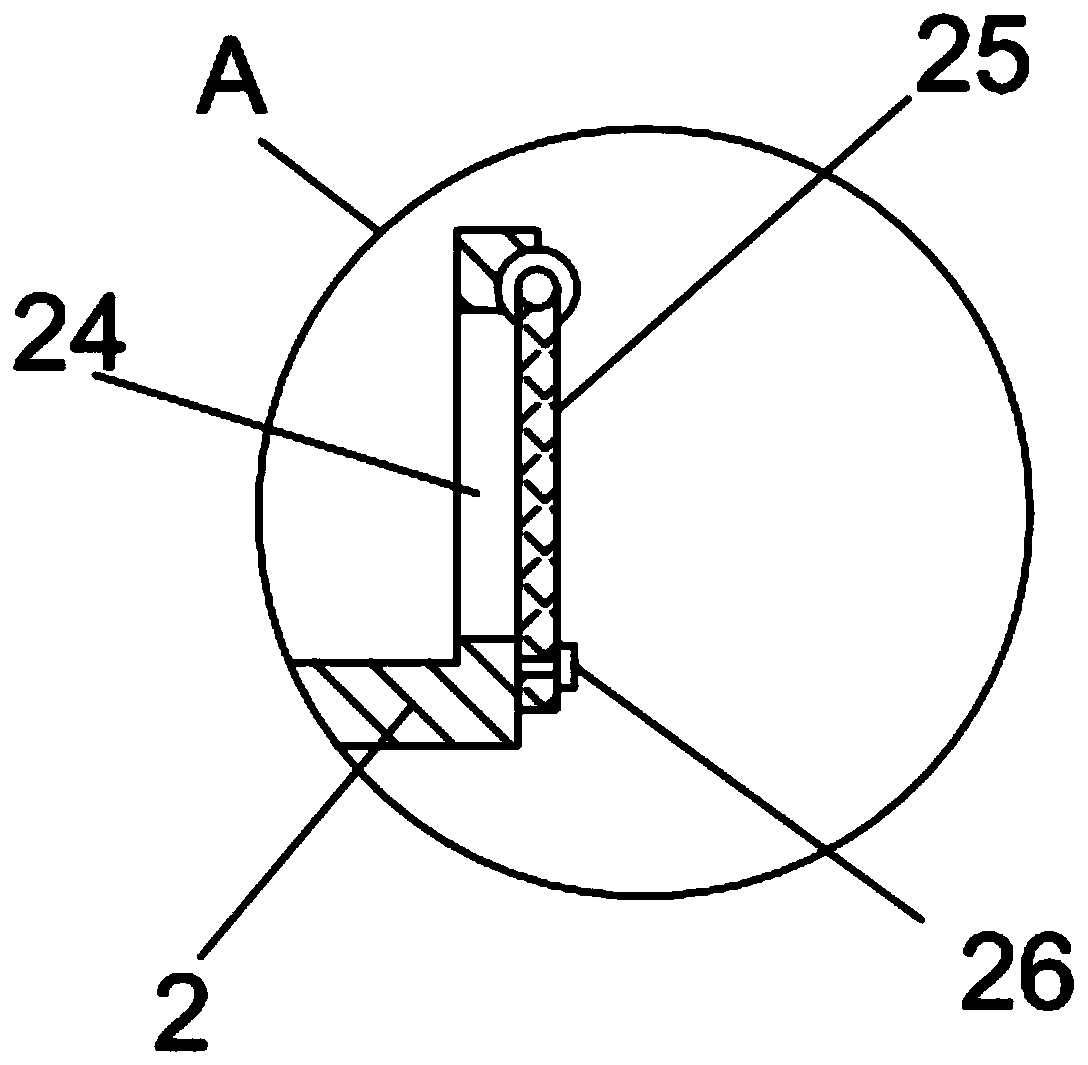

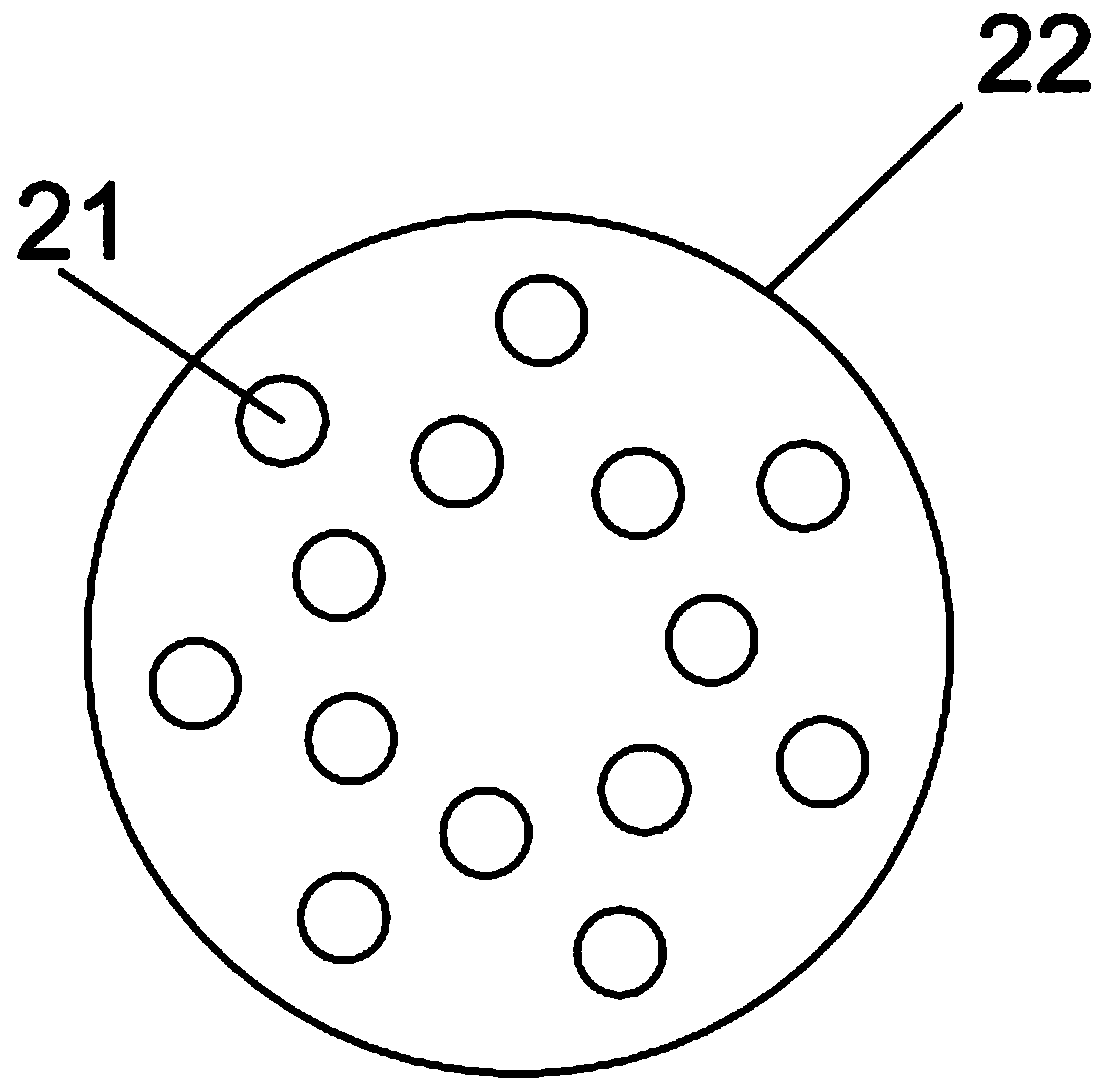

[0020] see Figure 1-3 , An efficient mixing device for agricultural feed, comprising a bottom plate 1, a supporting vertical plate 17 is vertically fixedly installed on the bottom plate 1, a top plate 15 is fixed horizontally and fixedly installed on the upper end of the supporting vertical plate 17, and the bottom surface of the top plate 15 is fixed horizontally through the There is an operation box 12, a forward and reverse rotation motor 16 is fixedly installed on the right side wall of the support vertical plate 17, and the output shaft of the forward and reverse rotation motor 16 is fixedly installed with a second screw rod 27 extending to the inside of the operation box 12. The right end of the rod 27 is coaxially and fixedly installed with a first screw rod 28; the surfaces of the first screw rod 28 and the second screw rod 27 are respectively th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com