Concrete sprayer feed hopper device with height-adjustable discharge port for building construction

A technology of building construction and concrete injection machine, which is applied in the direction of shaft equipment, shaft lining, mining equipment, etc., to achieve superior effect and increase the scope of application

Pending Publication Date: 2022-06-10

中青建安建设集团有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002]Traditional concrete spraying machines work alone, and each spraying machine needs to be equipped with four workers: one is responsible for the feeding of the accelerator, and three are responsible for the spraying material Generally, two to three concrete injection machines are required for each cycle of injection of the initial support of the full section, and 8 to 12 workers are required. Since the injection material is stored on the steel plate on the ground, the injection machine needs to be manually shoveled into the hopper. This method Time-consuming and labor-intensive, low efficiency, seriously affecting the construction efficiency of sprayed concrete

Therefore, there are existing feeding hoppers specially designed to improve the feeding, but the outlet ends of the existing feeding hoppers are fixed, and there are limitations when using different concrete injection machines. The height of the discharge end cannot be adjusted according to the demand, therefore, the scope of use is reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] Through the above specific implementation manners, those skilled in the technical field can easily realize the present invention. However, it should be understood that the present invention is not limited to the specific embodiments described above. On the basis of the disclosed embodiments, those skilled in the art can arbitrarily combine different technical features, so as to realize different technical solutions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

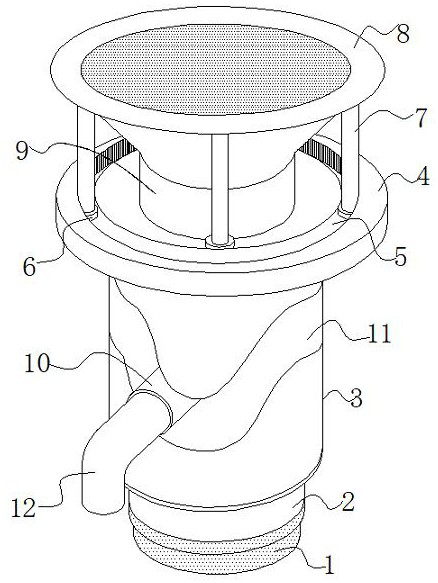

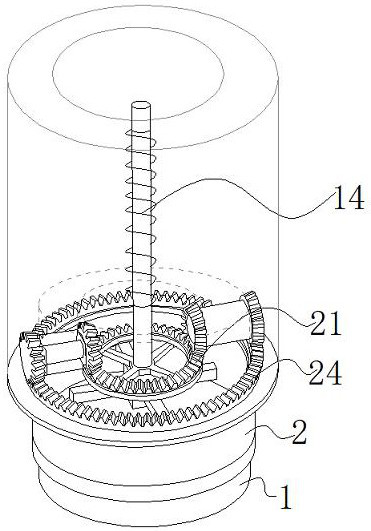

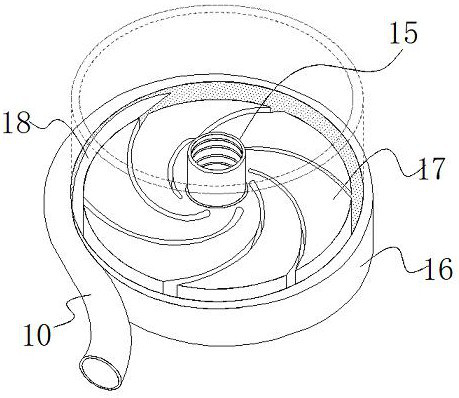

The invention discloses a building construction concrete sprayer feed hopper device with a height-adjustable discharge port, which comprises a support cylinder, a rotary inner cylinder is arranged on the support cylinder, a driving device is arranged on the inner side of the rotary inner cylinder, a rotary outer cylinder is arranged at the top of the rotary inner cylinder, and a top tray is arranged at the top of the rotary outer cylinder. A groove is formed in the periphery of the top of the top disc, a plurality of gravity base plates are arranged in the groove, supporting rods are arranged at the tops of the gravity base plates, the feeding hopper is arranged between the tops of the supporting rods, a feeding channel is formed in the bottom of the feeding hopper, and the feeding channel penetrates through the top disc and extends into the rotary outer cylinder; according to the scheme, the effect is more excellent, besides height adjustment is achieved, in the rotating process of the lead screw, the material collecting box can be driven, the material collecting box is promoted to generate the centrifugal effect, and the rapid discharging effect is achieved.

Description

technical field [0001] The invention relates to the technical field of concrete injection machine feeding, in particular to a concrete injection machine feeding hopper device for building construction with an adjustable outlet height. Background technique [0002] Traditional concrete injection machines work alone, and each injection machine needs to be equipped with four workers: one is responsible for the feeding of the accelerator, and three are responsible for the injection material. Generally, two to three sets are required for each cycle of injection for the initial support of the full section. Concrete spraying machine needs to be equipped with 8 to 12 workers. Since the spraying material is stored on the ground steel plate, the spraying machine needs to be manually shoveled into the hopper. This method is time-consuming, laborious and inefficient, which seriously affects the construction efficiency of sprayed concrete. Therefore, there are existing feeding hoppers sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D11/10

CPCE21D11/105

Inventor 王晓平杨昆贾杨赵福龙李兆龙

Owner 中青建安建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com