Metal separating device

A metal separation and high-temperature dissolution technology, which is applied in the field of precious metals, can solve the problems of affecting quality, affecting the color of precious metals, and poor separation of precious metal impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

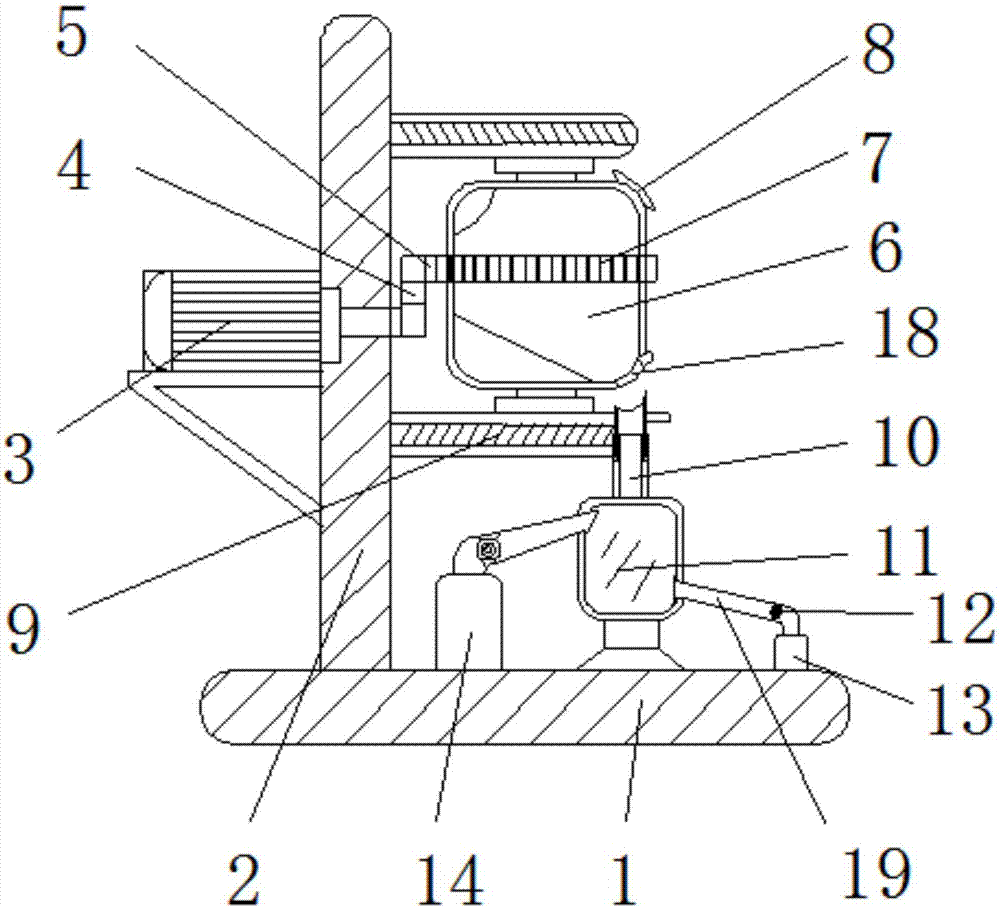

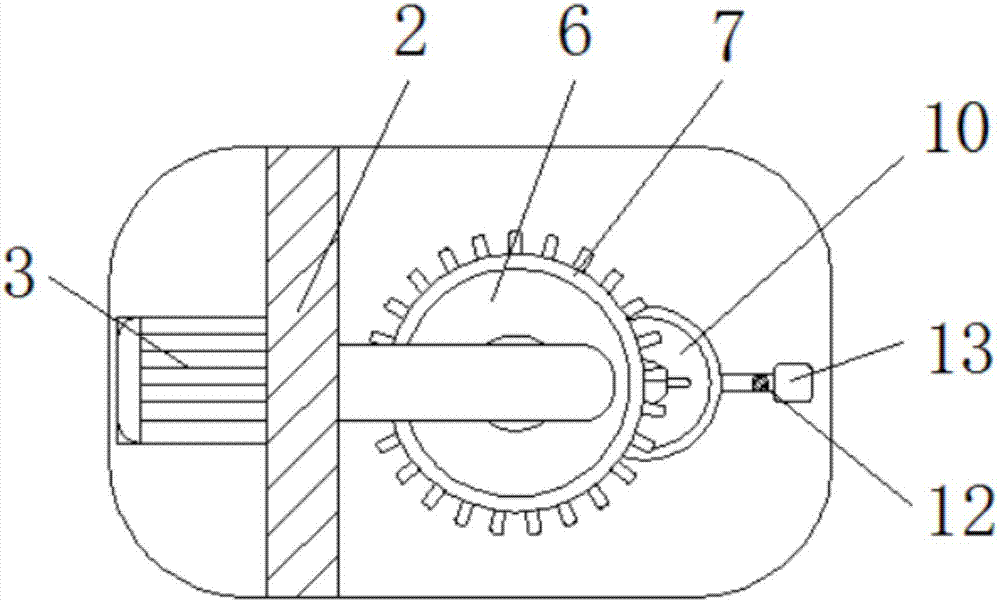

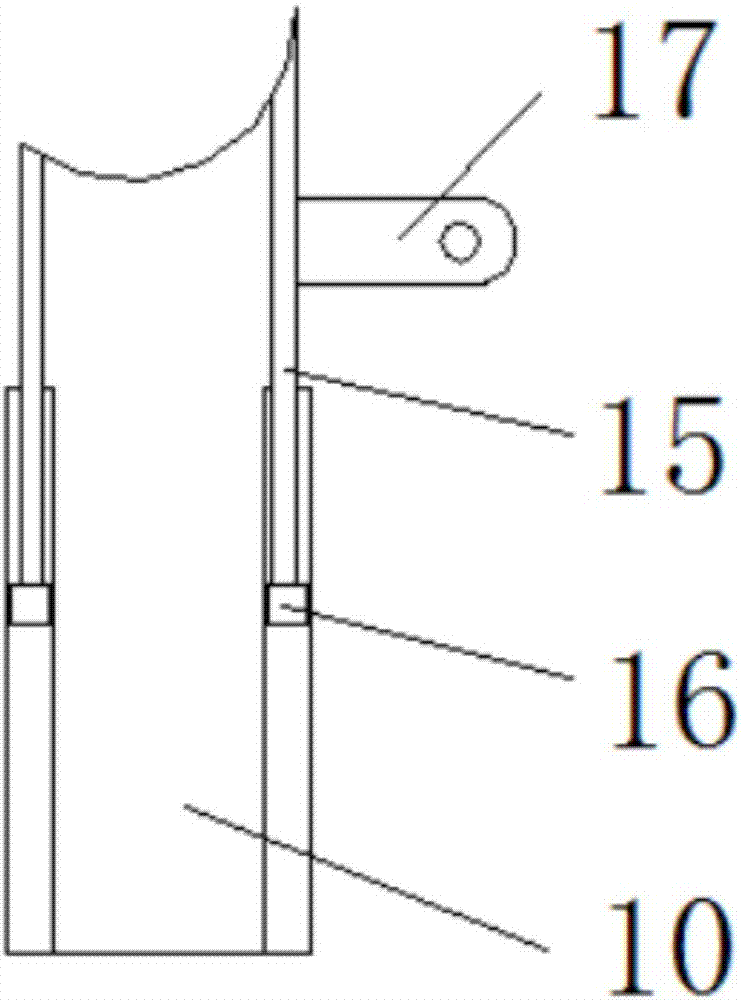

[0019] Such as Figure 1-Figure 3 As shown, a metal separation device mainly includes a base 1, a side plate 2, a motor 3, a transmission mechanism 4, a gear 5, a high temperature melting box 6, a fixing ring 7, an inlet 8, a support plate 9, a connecting pipe 10, Vacuum box 11, fan 12, metal collection box 13, impurity collection box 14, telescopic tube 15, fixed block 16, pull rod 17, outlet 18 and flow tube 19, the upper left side of base 1 is provided with side plate 2, and A motor 3 is installed on the left side of the side plate 2, a transmission mechanism 4 is connected to the right side of the motor 3, and a gear 5 is connected below the transmission mechanism 4, and a fixing ring 7 is arranged on the outside of the high temperature melting box 6, and the fixing ring 7 is in a sawtooth shape structure, and the sawtooth structure of the fixed ring 7 matches the sawtooth shape of the gear 5, and the inner diameter of the fixed ring 7 matches the outer diameter of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com