Mixing device for fruit wine brewing

A mixing device and fruit wine brewing technology, which is applied in the field of raw material mixing equipment, can solve the problems of low solid content of artesian juice, difficulty in mixing, and large monomer processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

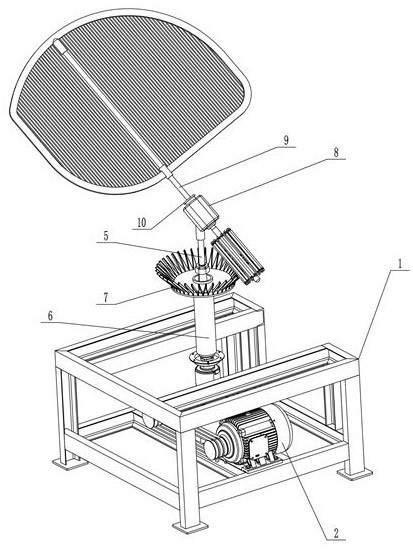

[0027] Embodiment 1: a kind of mixing device for fruit wine brewing

[0028] like Figure 1-3 As shown, the base frame 1 is included, and the base frame 1 is used to install the motor 2 and related power equipment, and is used to support the whole device.

[0029] The bottom frame 1 is a frame type frame, which can facilitate maintenance, observation and replacement of the bottom equipment, and the support is stable.

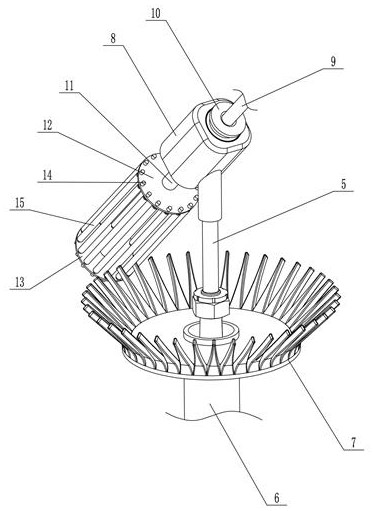

[0030] A motor 2 and a gear reduction box 3 are installed in the bottom frame 1 to reduce the output speed of the motor 2, increase the torque, and facilitate the driving of a larger stirring mechanism.

[0031] The input end of the gear reduction box 3 is driven by the motor 2, and the output end of the gear reduction box 3 is connected with a central rotating shaft 5, and the central rotating shaft 5 extends upright.

[0032] A container 4 is fixed on the bottom frame 1, and the container 4 can be a raw material processing barrel for mixing raw materials suc...

Embodiment 2

[0044] Embodiment 2: a kind of mixing device for fruit wine brewing

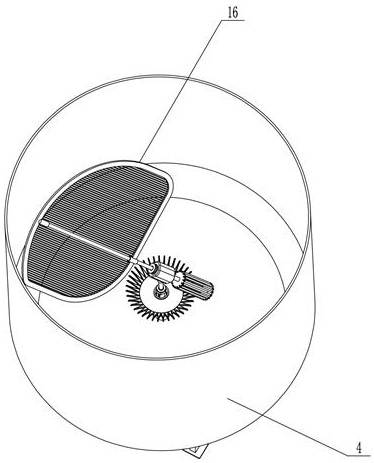

[0045] like Figure 4-7 As shown, in this example, the fermenter is used as an example to design the container 4, and the difference from Example 1 mainly includes the following two points:

[0046] 1) Selection of container 4

[0047] The container 4 in this example is a fermenter, which is a sealed tank structure with a cylindrical cavity.

[0048] 2) The structure of the rod and the rotating seat 8

[0049] The rod member in this example is an optical shaft 22 , the optical shaft 22 passes through the rotating base 8 , and the optical shaft 22 and the rotating base 8 are rotationally connected through a bearing.

[0050] Through the above-mentioned structure, in the specific application of this example, from the addition of raw materials, the device can be used all the time to mix and then continue to directly ferment.

[0051] During the fermentation of wine, the skin stalks, pomace, and fermentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com