Novel environment-friendly plate cutting device

A cutting device and an environment-friendly technology, which is applied in the field of new environment-friendly plate cutting devices, can solve the problems of bulky, difficult to move, labor-intensive and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

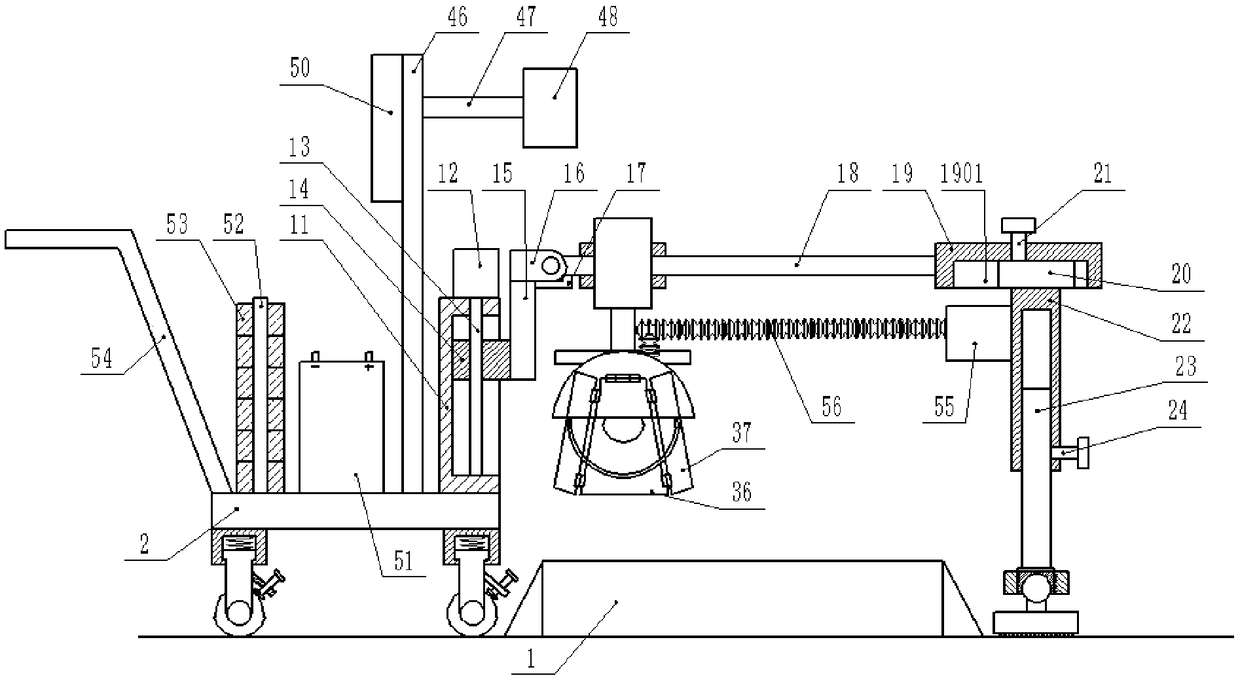

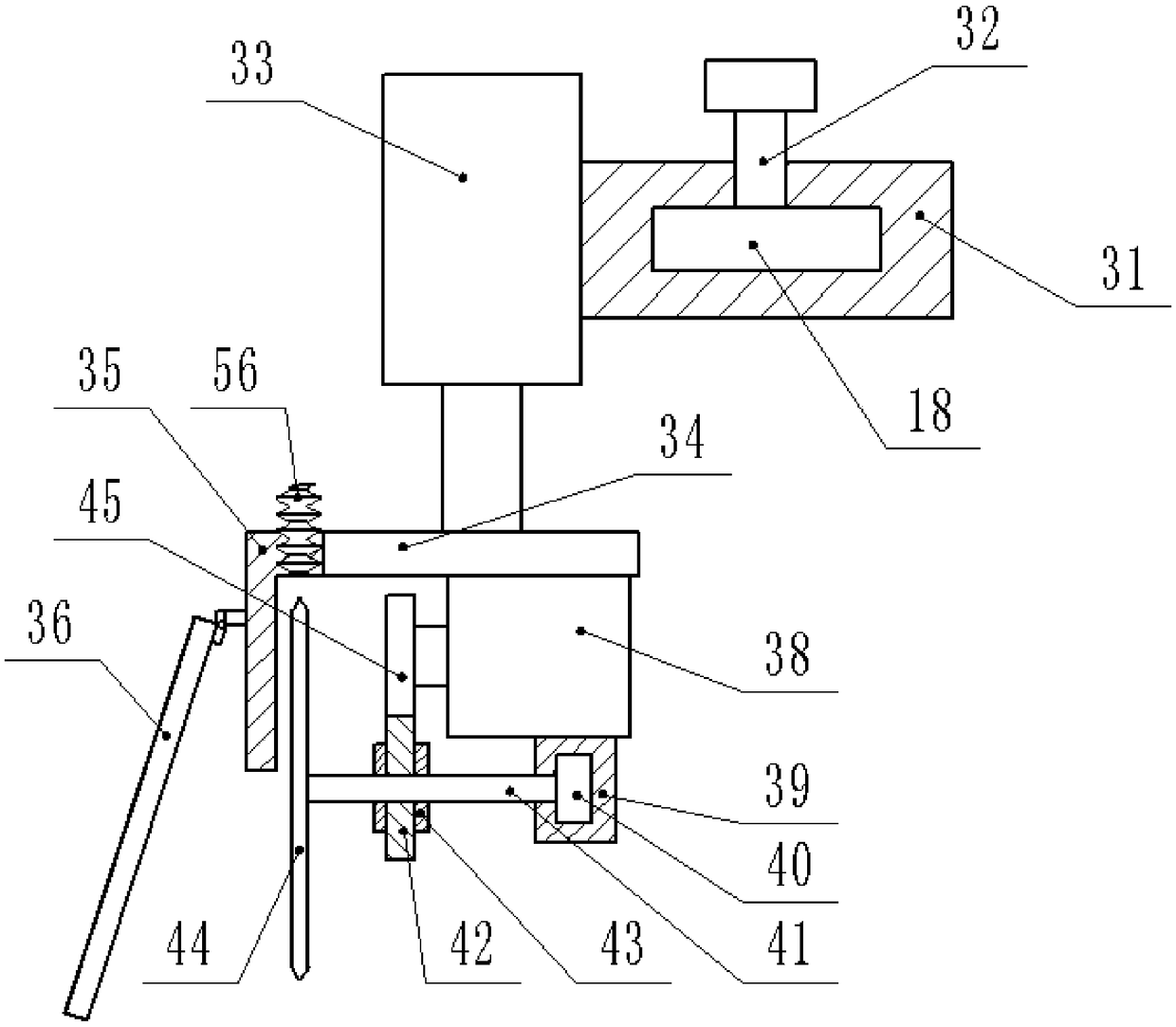

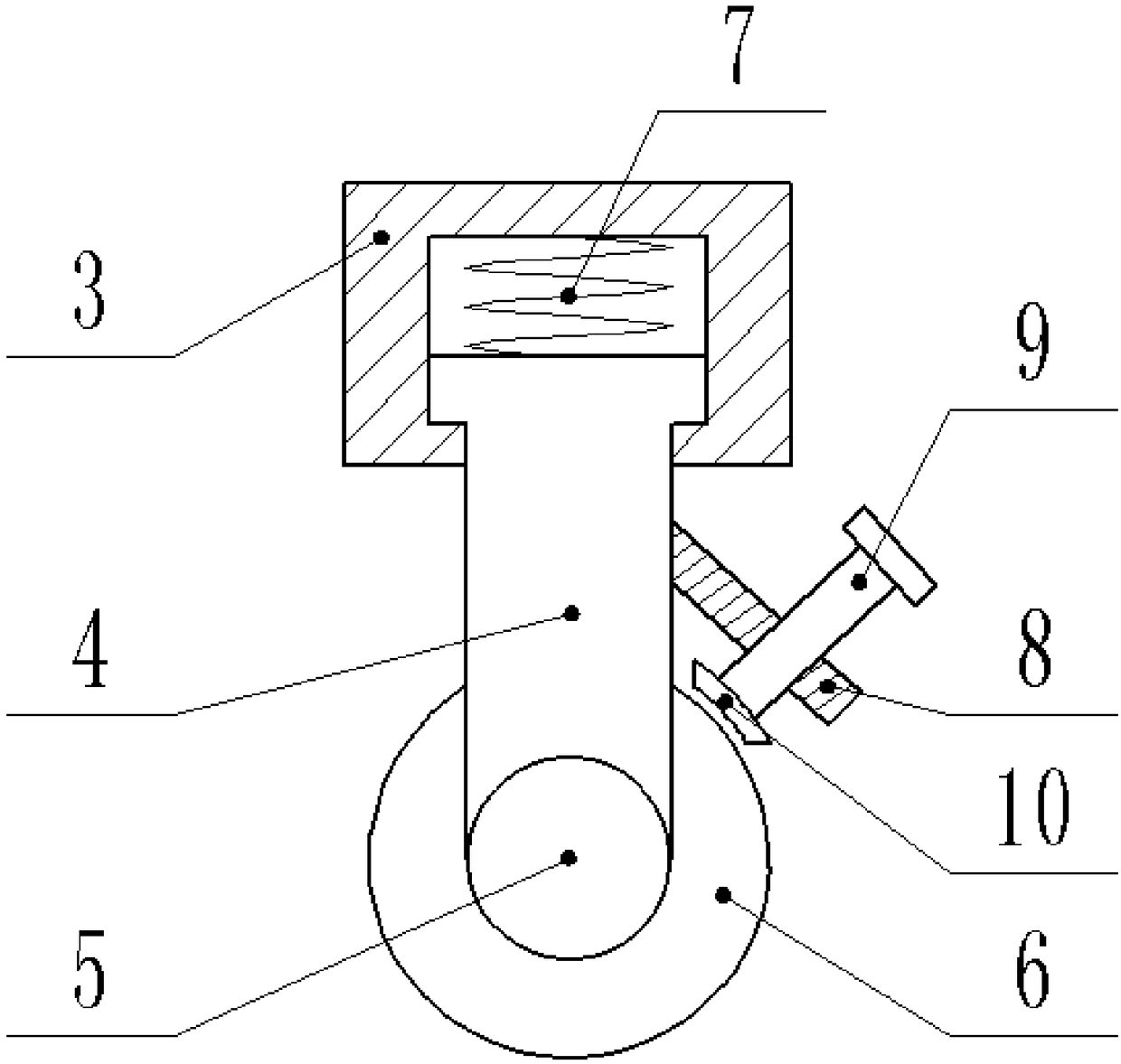

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] Such as Figure 1-Figure 7 As shown, a new environment-friendly plate cutting device includes a workbench 1 and a bottom plate 2 next to it. The lower end of the bottom plate 2 is fixed with a plurality of sleeves 3, and the lower end of the sleeve 3 is inserted with a vertical rod 4. , the lower end of the vertical bar 4 is rotatably connected with a wheel shaft 5, the wheel shaft 5 is covered with a roller 6 and fixed thereto, a spring 7 is fixed between the upper end of the vertical bar 4 and the upper wall of the sleeve 3, and the vertical bar 4 The side end is fixed with a slant plate 8, the angle between the lower end of the slant plate 8 and the vertical bar 4 is 45-50 degrees, the bolt 9 passes through the slant plate 8 and is threadedly connected with it, and the lower end of the bolt 9 is fixed There is a brake pad 10 above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com